Backlight unit and manufacturing method thereof, and liquid crystal display device having the same

a backlight unit and liquid crystal display technology, applied in the direction of instruments, lighting and heating apparatus, optical elements, etc., can solve the problems of productivity decline, inconvenient use of optical resin layers, etc., and achieve the effect of excellent color reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

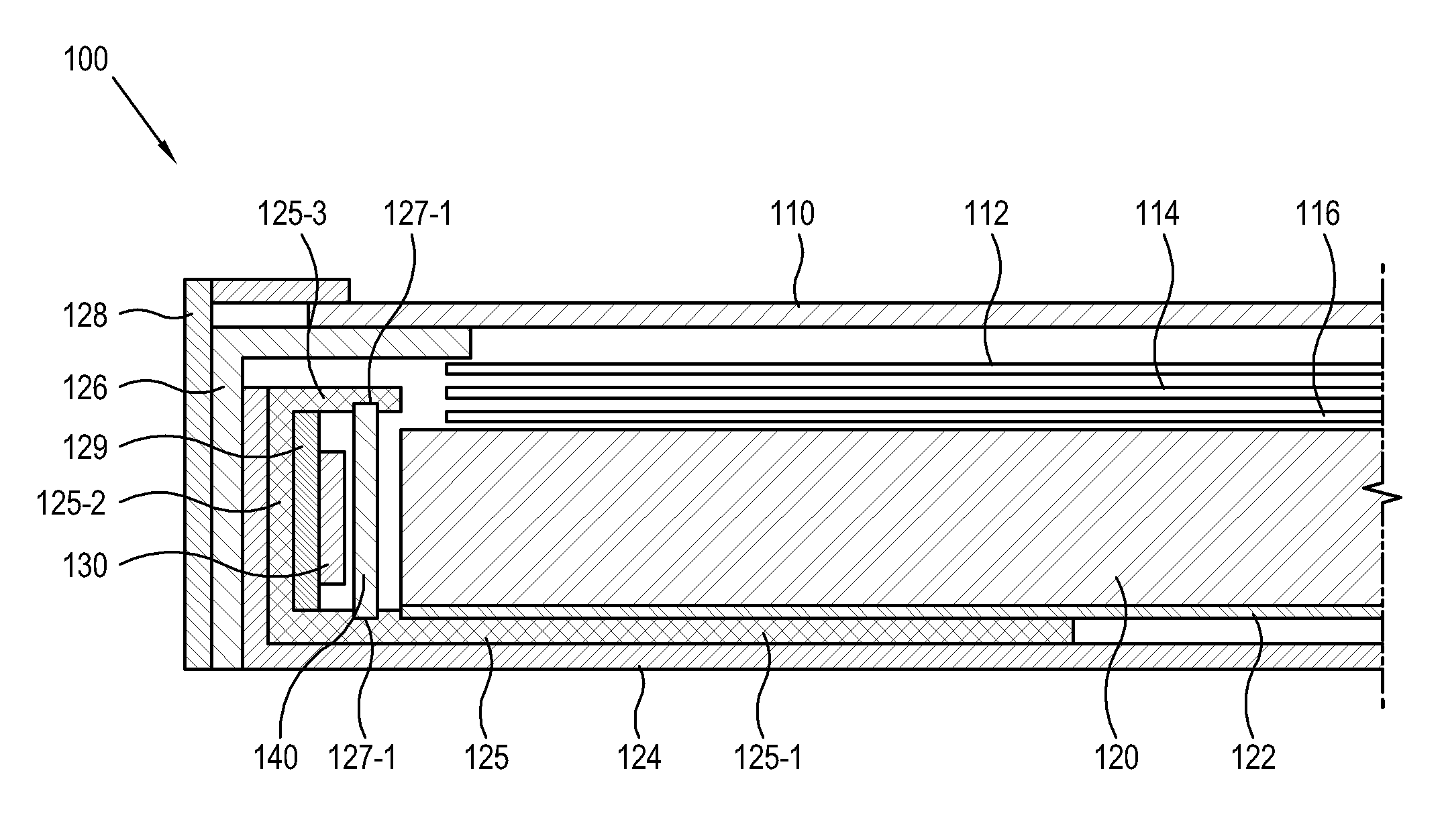

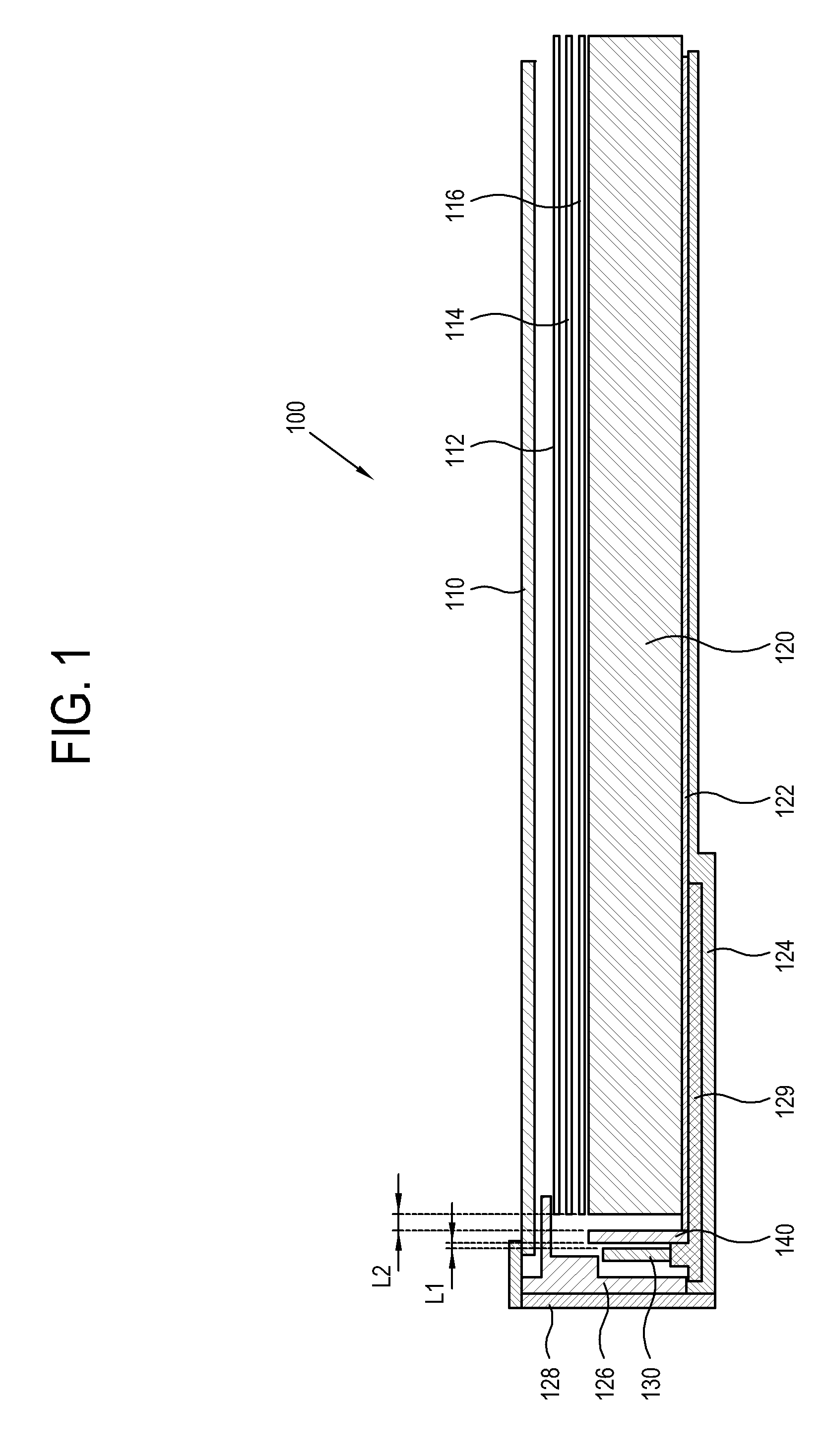

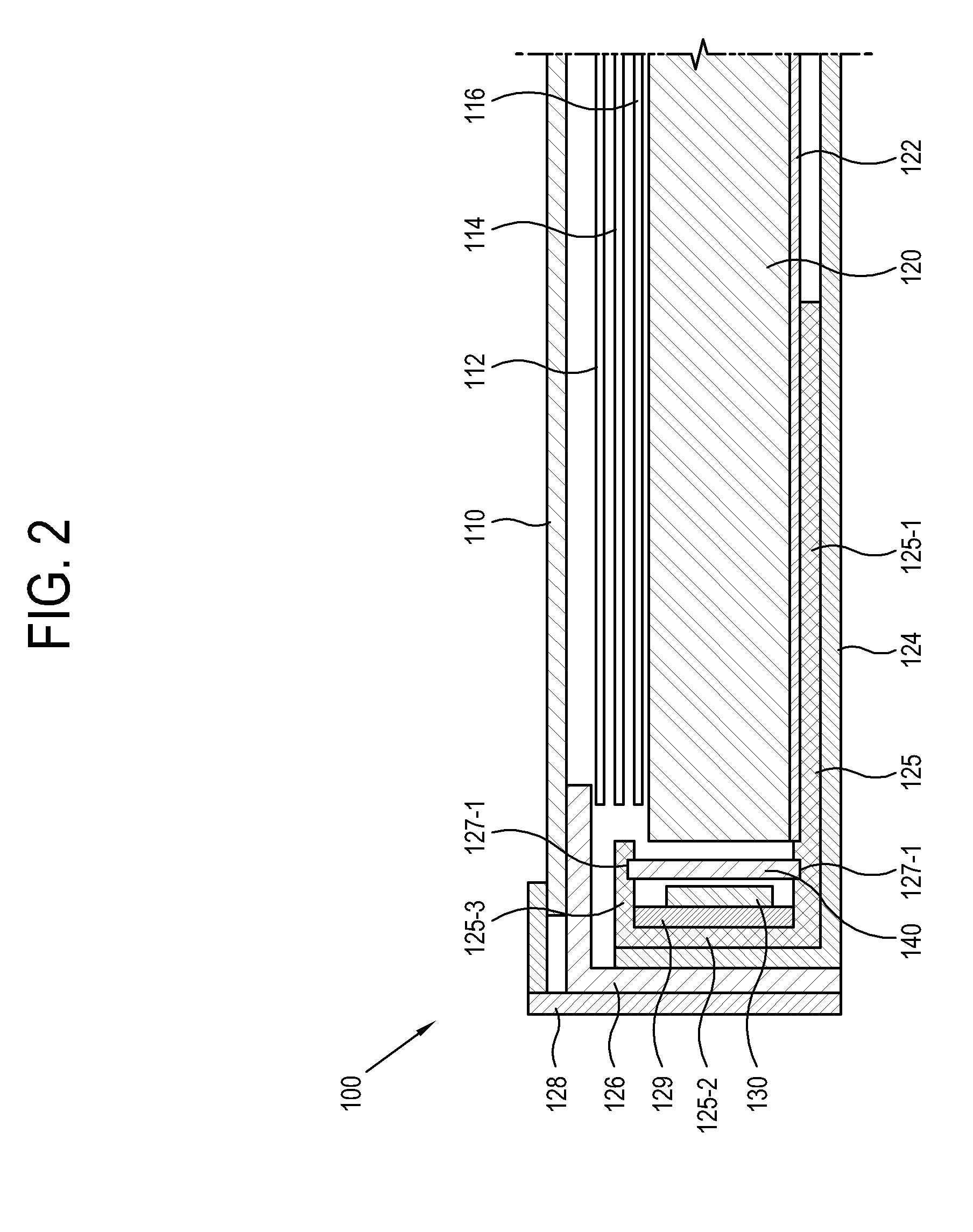

[0062]Below, exemplary embodiments will be described in detail with reference to accompanying drawings. For the convenience of description, elements having no direct relationship to the exemplary embodiments are omitted for clarity, and like reference numerals refer to like elements throughout. Here, the “rear” refers to a direction where a light guide plate 120 is placed in an LCD panel 110, and the “up,”“down,”“left” and “right” are defined with respect to the front of the LCD panel 110.

[0063]As shown in FIG. 1, an LCD device 100 includes an LCD panel 110 and a backlight unit. The backlight unit includes a dual brightness enhance film (DBEF) sheet 112, a prism sheet 114, a diffuser sheet 116, a light guide plate 120, a reflection sheet 122, an LED 130 and a QD bar 140 arranged in sequence on the rear of the LCD panel 110.

[0064]In the LCD panel 110, a nematic liquid crystal is interposed between two sheets of glass, and counter electrodes with a thin film transistor are arranged on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| elastic projection | aaaaa | aaaaa |

| color reproduction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com