Directly laminated plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

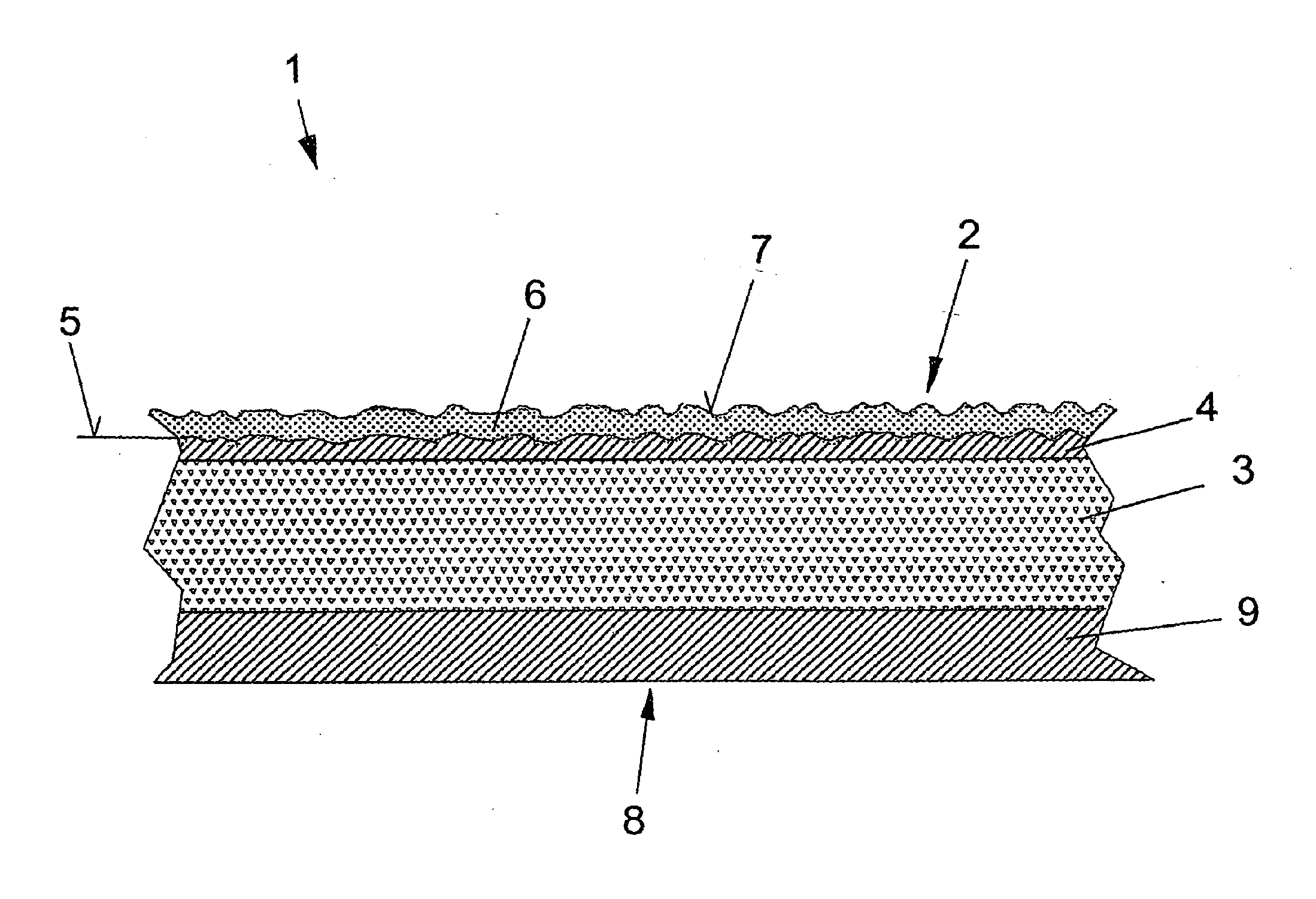

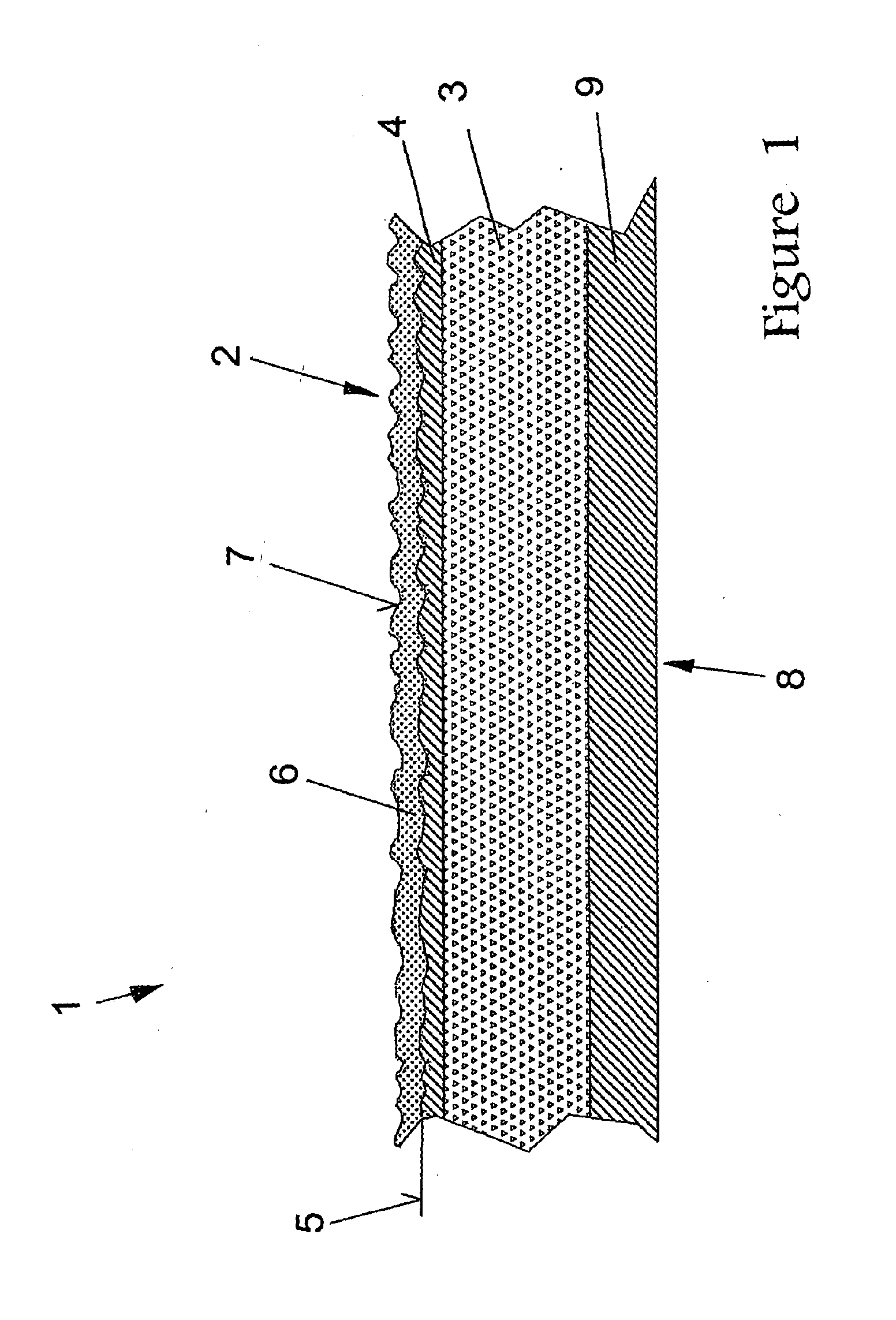

[0035]Board 1 shown in FIG. 1 is a board 1 according to the prior art. Decorative layer 4 is applied to top side 2 of core 3 made of HDF material (high-density fibreboard). Decorative layer 4 has a graphic representation 5 of an imitated material. Decorative layer 4 is provided with cover layer 6 comprising an overlay impregnated with resin. Surface structure 7, which simulates the surface of the imitated material, is embossed on the overlay. The objective is for graphic representation 5 of decorative layer 4 to be positioned exactly on top of embossed surface structure 7 of cover layer 6. In this way, the optical impression of graphic representation 5 is intended to match the tactile impression of embossed surface structure 7.

[0036]According to the prior art, decorative layer 4 is made of printed paper, which is also impregnated with resin prior to hot-pressing. The decorative paper lies directly on core 3 of the board. On underside 8 of the board, which faces away from decorative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com