Cabinet with tamper detection system and method

a detection system and tamper detection technology, applied in the field of cabinets, can solve the problems of vibration-based systems that cannot detect tampering using certain types of tools, methods that require high processing power, and vibration sensors sensitive to environmental vibration sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

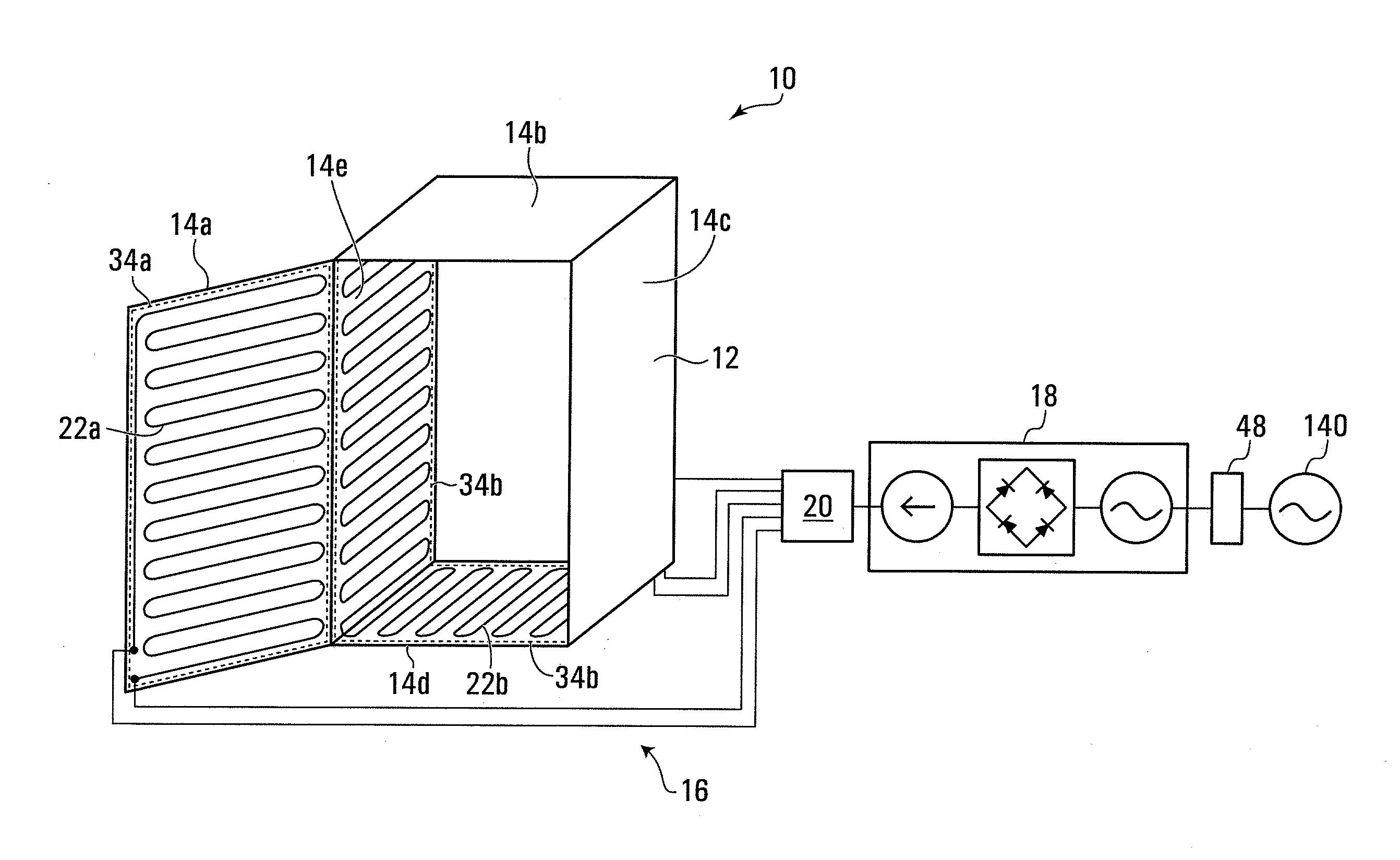

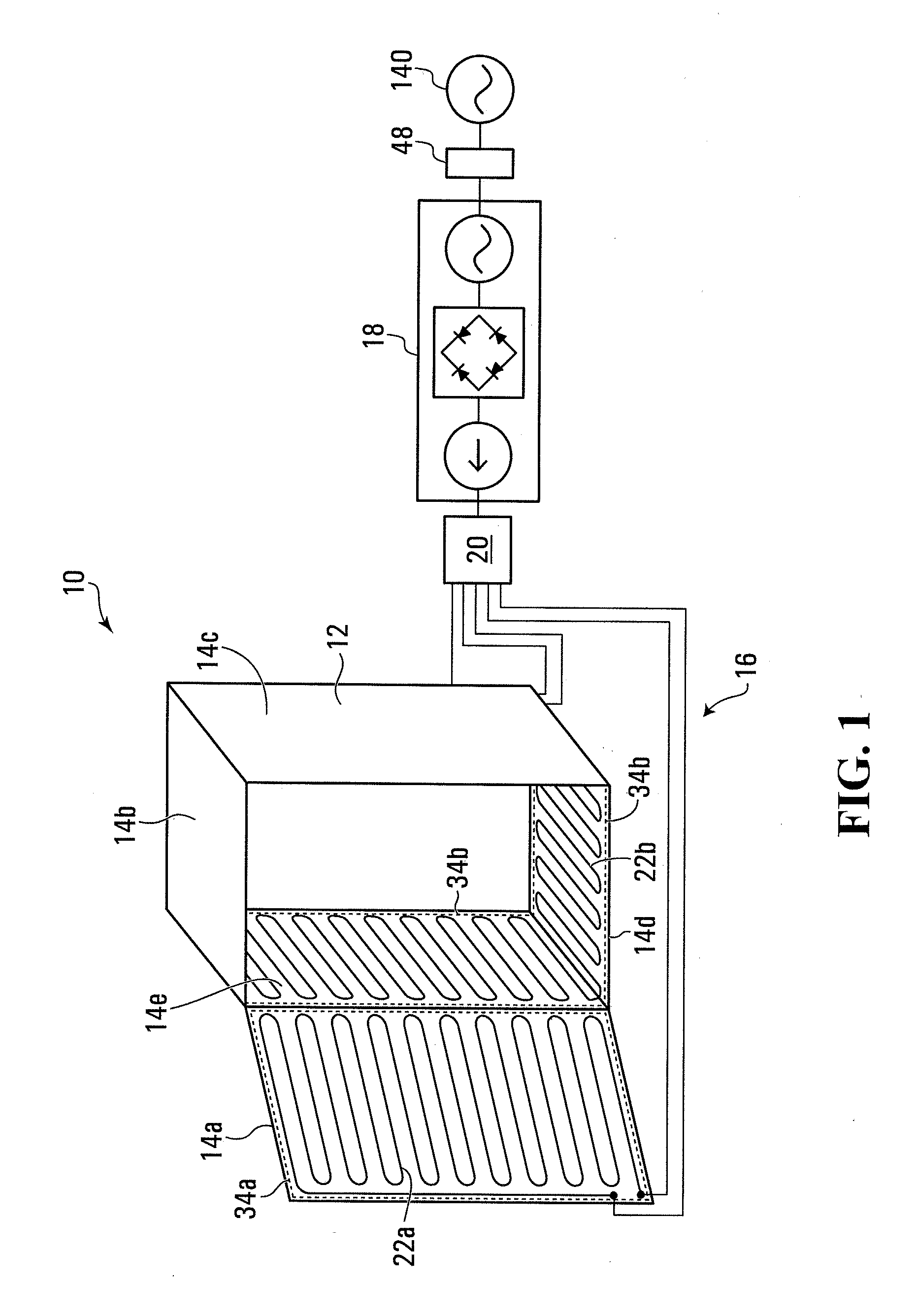

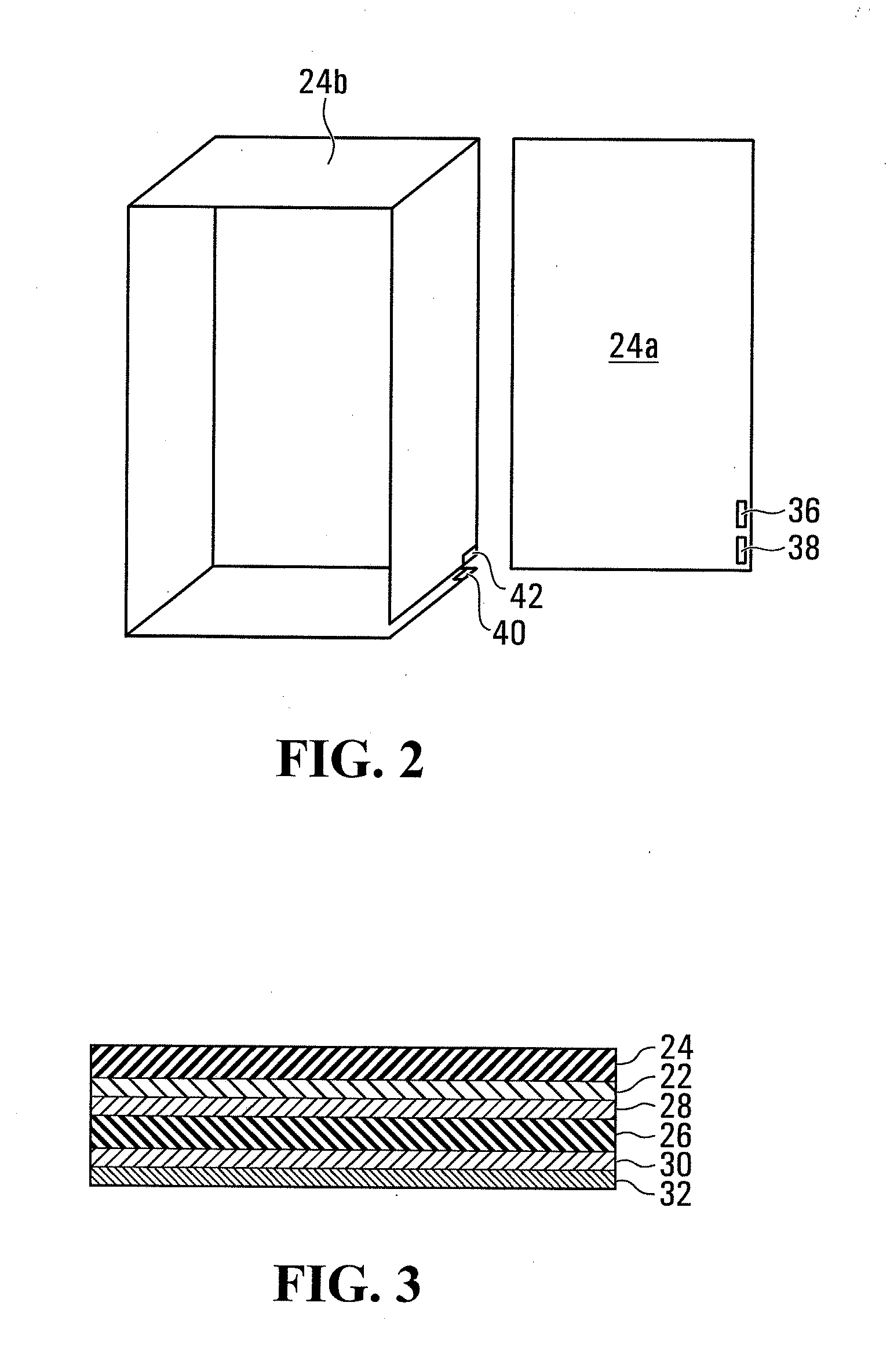

[0024]FIG. 1 depicts a tamper detection system 10, exemplary of an embodiment of the present invention. Tamper detection system 10 is provided to detect tampering with cabinet 12. Cabinet 12 is made up of a plurality of panels 14a, 14b, 14c, 14d and 14e (collectively, panels 14). Panels 14 are usually formed of metal or similar (usually conductive) material, for strength and electrical insulation purposes. Circuit 16 of tamper detection system 10 includes an electrical current source 18, sensor 20, and conductive traces 22a and 22b (collectively, conductive traces 22) on panels 14.

[0025]Conductive traces 22a, 22b span protection regions 34a, 34b respectively (collectively and individually protection region 34). A protection region 34, in this context is the region protected from tampering by system 10. As will be appreciated, the protection region 34 need not be co-extensive with all or any panel 14 of cabinet 12. Instead protection region 34 may simply span a vulnerable region of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com