Electric steam mop

a steam mop and electric technology, applied in the field of cleaning tools, can solve the problems of affecting the cleaning effect of the wet floor, the difficulty of dewatering the full-wetted mop, and the occurrence of water droplets, etc., and achieve the effect of convenient operation and simple structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

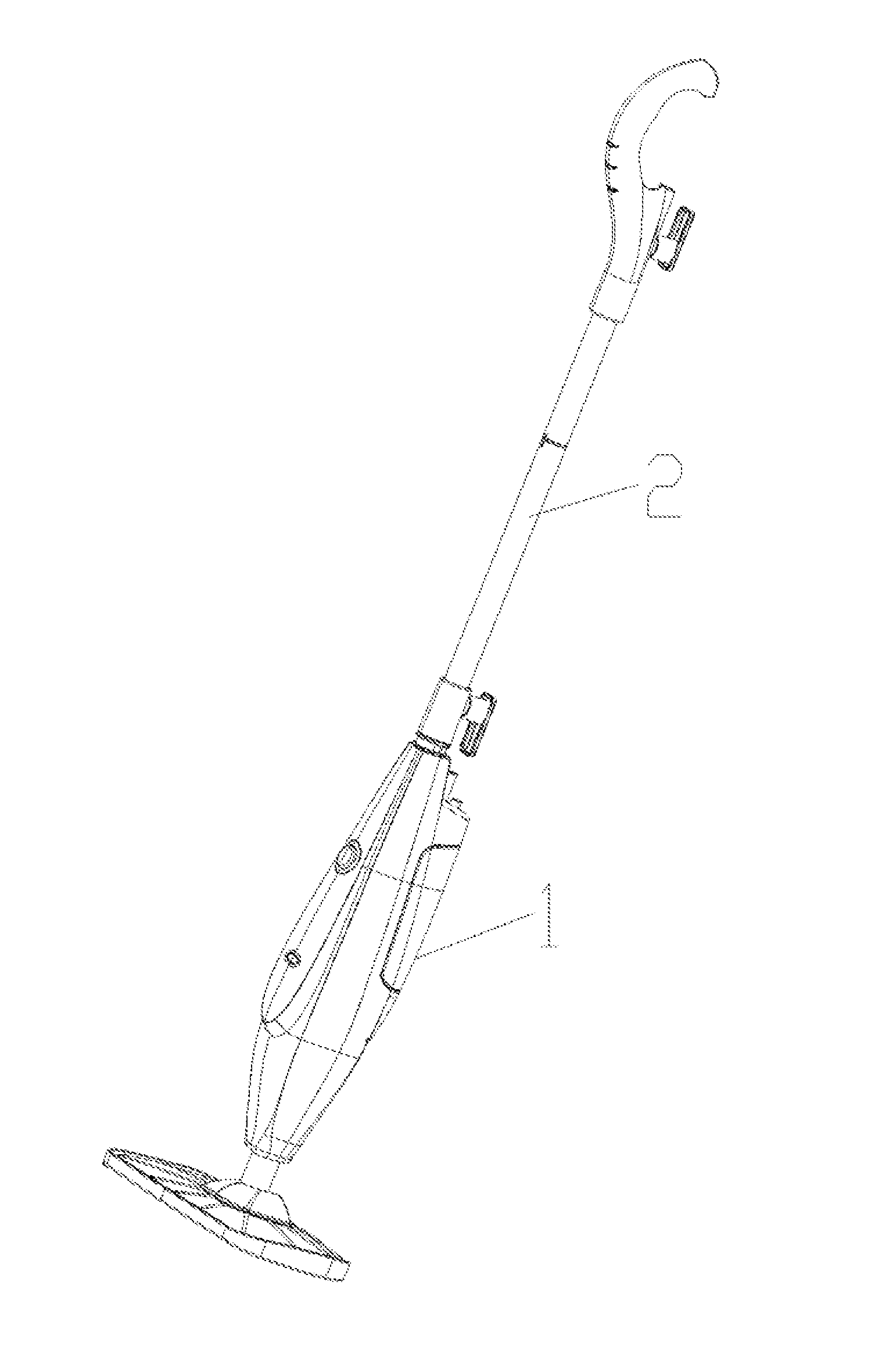

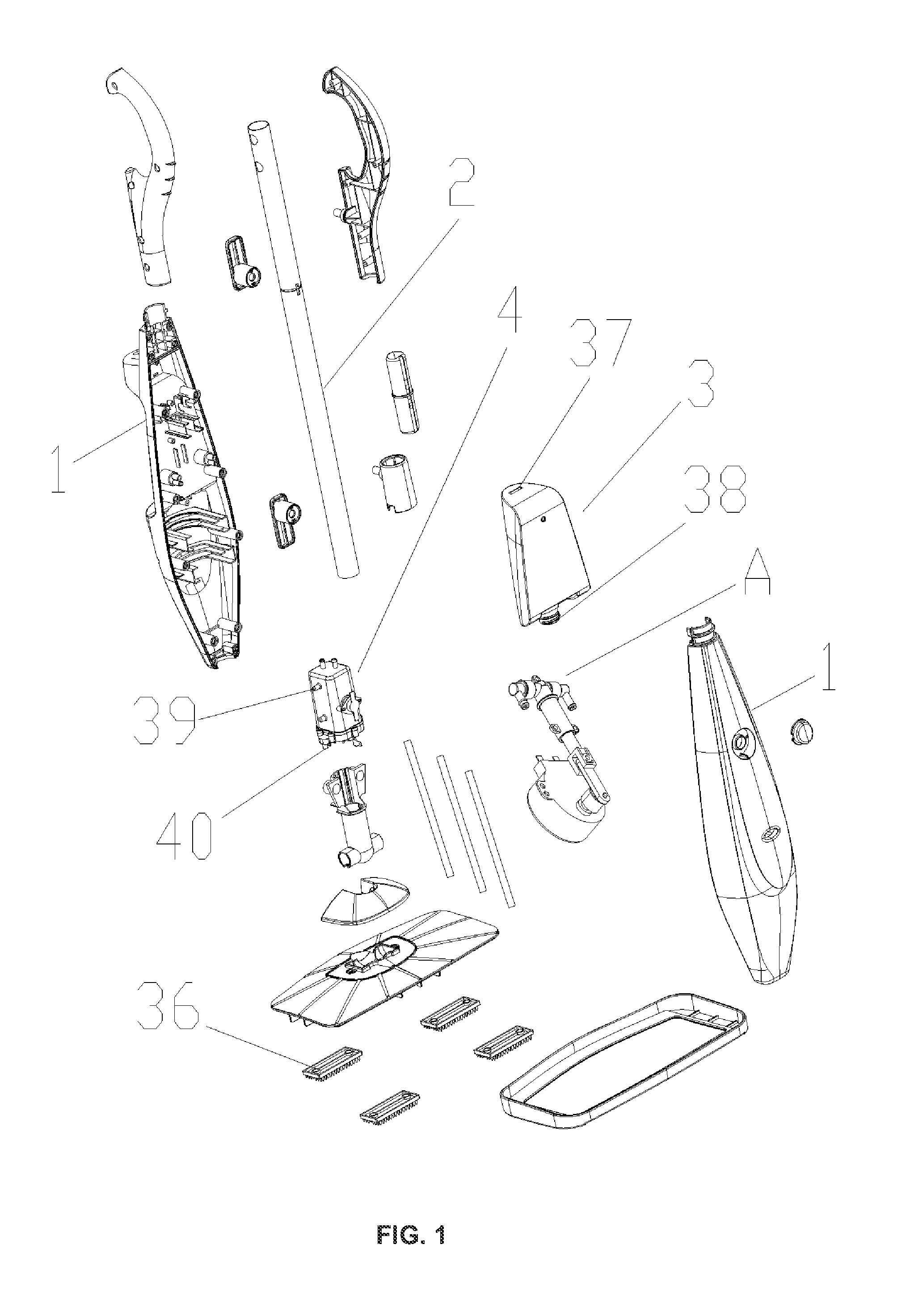

[0047]As shown in FIGS. 1, 2, 7 and 8, an electric steam mop, comprising:

[0048]a shell 1, which is placed to a surface to be cleaned, and has a decontamination surface which is faced downwards and opposite to the surface to be cleaned, wherein the decontamination surface has a steam outlet 36;

[0049]a handheld part 2, which is connected to the shell 1 for handholding;

[0050]a water tank 3, which is provided with a water inlet 37 and a water outlet 38;

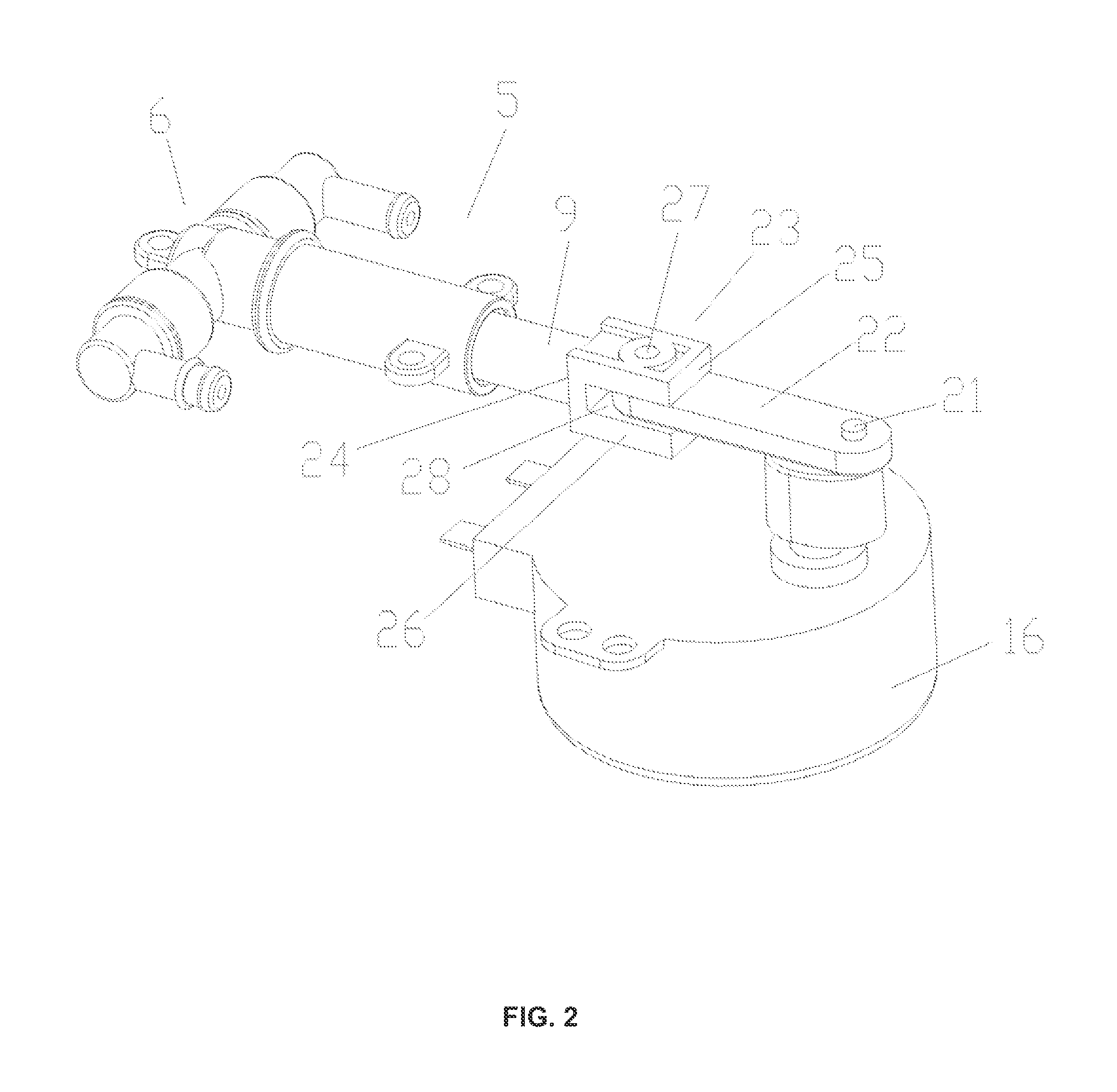

[0051]a steam formation device 4, which has a water inlet 39 and a steam outlet 40, wherein the steam outlet 40 is communicated with the steam outlet of the decontamination surface of the shell 36, a steam formation cavity (not shown in these figures) is provided between the water inlet 39 and the steam outlet 40 for communicating with the both, and the steam formation cavity (not shown in these figures) can be heated electrically by a heating wire provided therein to create steam;

[0052]a water pump 5, which is provided between the water ...

embodiment 2

[0058]As shown in FIGS. 3, 4, 7 and 8, an electric steam mop, comprising:

[0059]a shell 1, which is placed to the surface to be cleaned, and has a decontamination surface which is faced downwards and opposite to the surface to be cleaned, wherein the decontamination surface has a steam outlet 36;

[0060]a handheld part 2, which is connected to the shell 1 for handholding;

[0061]a water tank 3, which is provided, with a water inlet 37 and a water outlet 38;

[0062]a steam formation device 4, which has a water inlet 39 and a steam outlet 40, wherein the steam outlet 40 is communicated with the steam outlet 36 of the decontamination surface of the shell, a steam formation cavity (not shown in these figures) is provided between the water inlet 39 and the steam outlet 40 for communicating with the both, and the steam formation cavity (not shown in these figures) can be heated electrically by a heating wire provided therein to create steam;

[0063]a water pump 5, which is provided between the wat...

embodiment 3

[0068]As shown in FIGS. 5, 6, 7 and 8, an electric steam mop, comprising:

[0069]a shell 1, which is placed to a surface to be cleaned, and has a decontamination surface which is faced downwards and opposite to the surface to be cleaned, wherein the decontamination surface has a steam outlet 36;

[0070]a handheld part 2, which is connected to the shell 1 for handholding;

[0071]a water tank 3, which is provided with a water inlet 37 and a water outlet 38;

[0072]a steam formation device 4, which has a water inlet 39 and a steam outlet 40, wherein the steam outlet 40 is communicated with the steam outlet 36 of the decontamination surface of the shell, a steam formation cavity (not shown in theses figures) is provided between the water inlet 39 and the steam outlet 40 for communicating with the both, and the steam formation cavity (not shown in these figures) can be heated electrically by a heating wire provided therein to create steam;

[0073]a water pump 5, which is provided between the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com