Punching apparatus and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

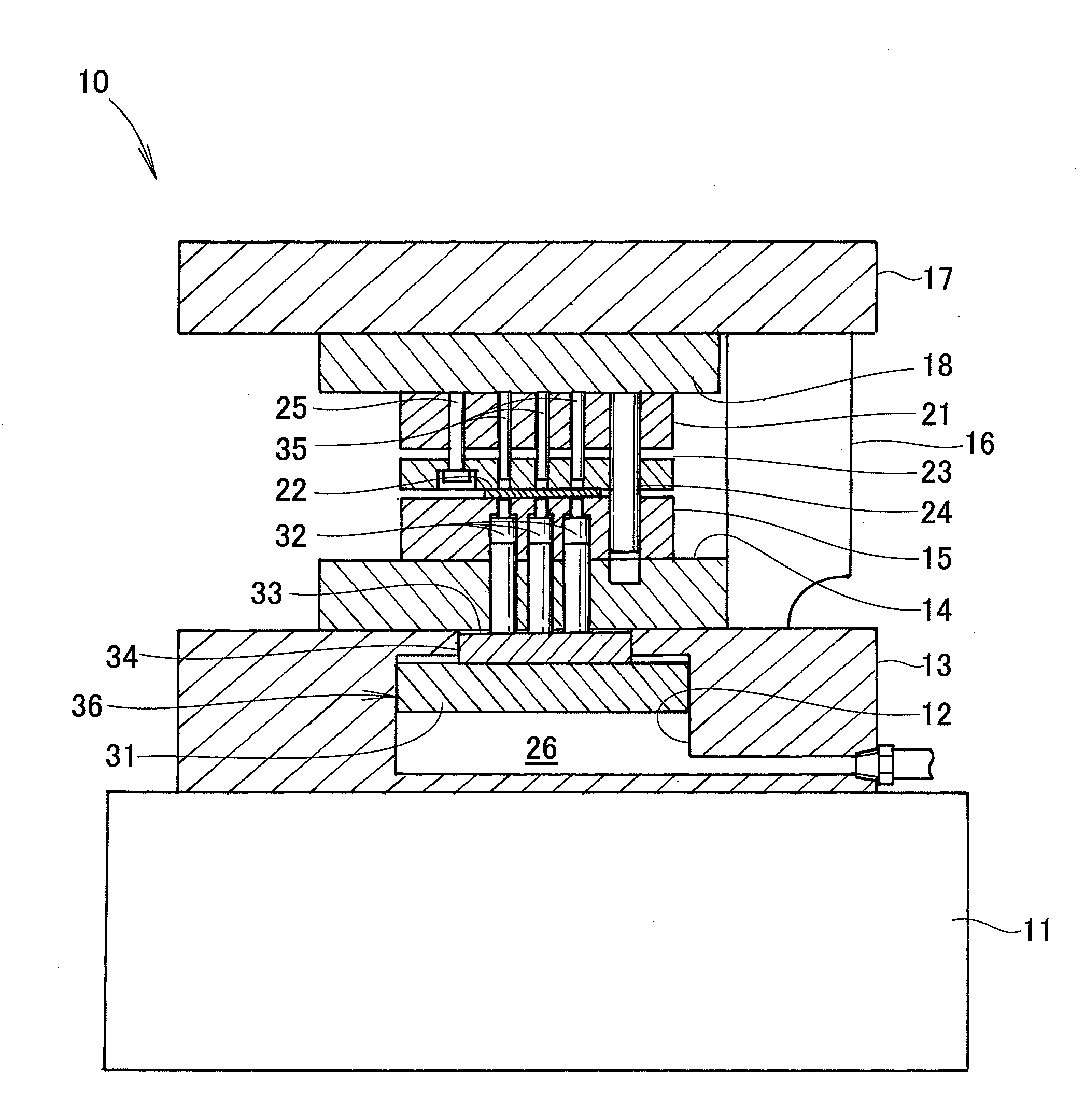

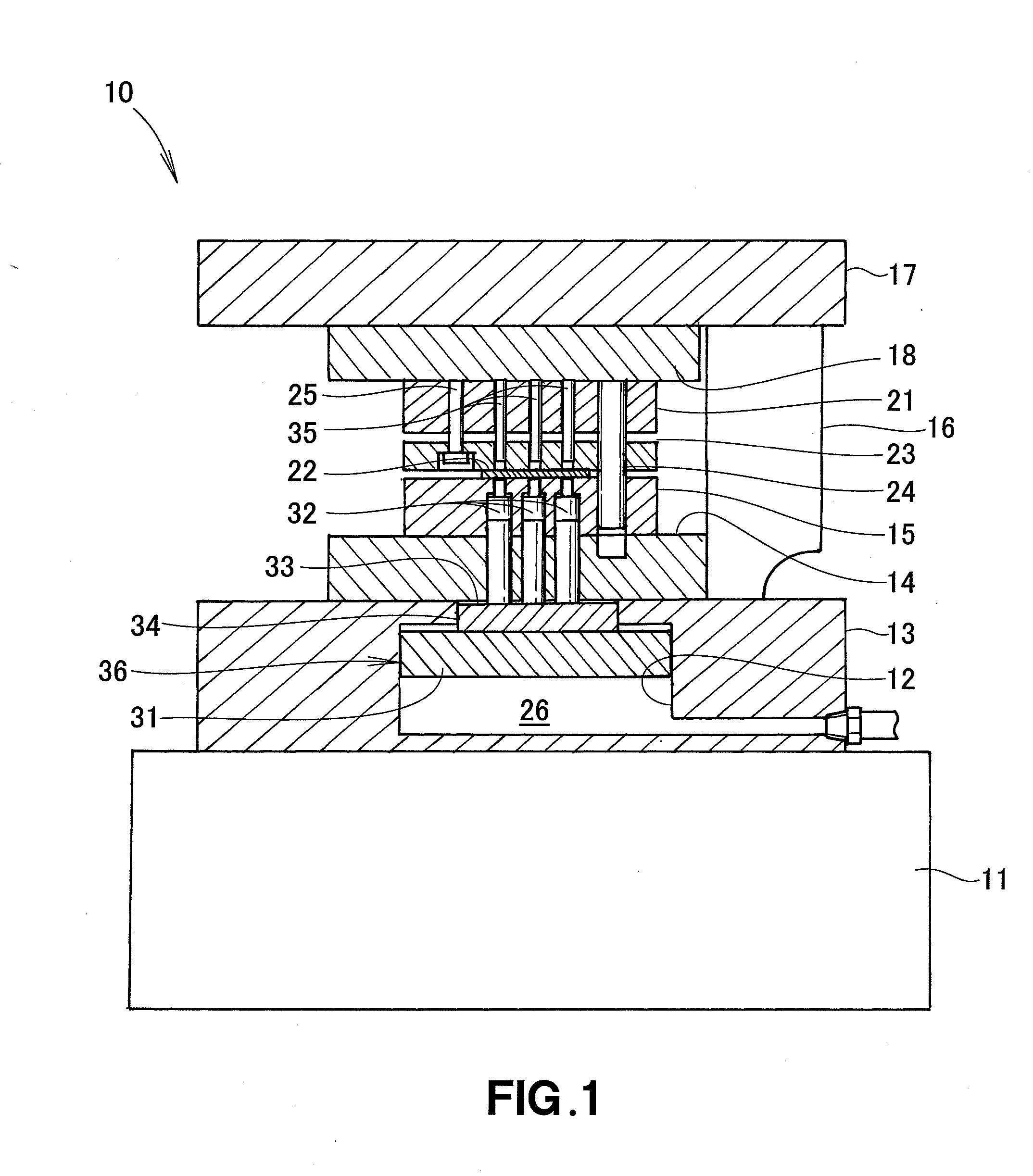

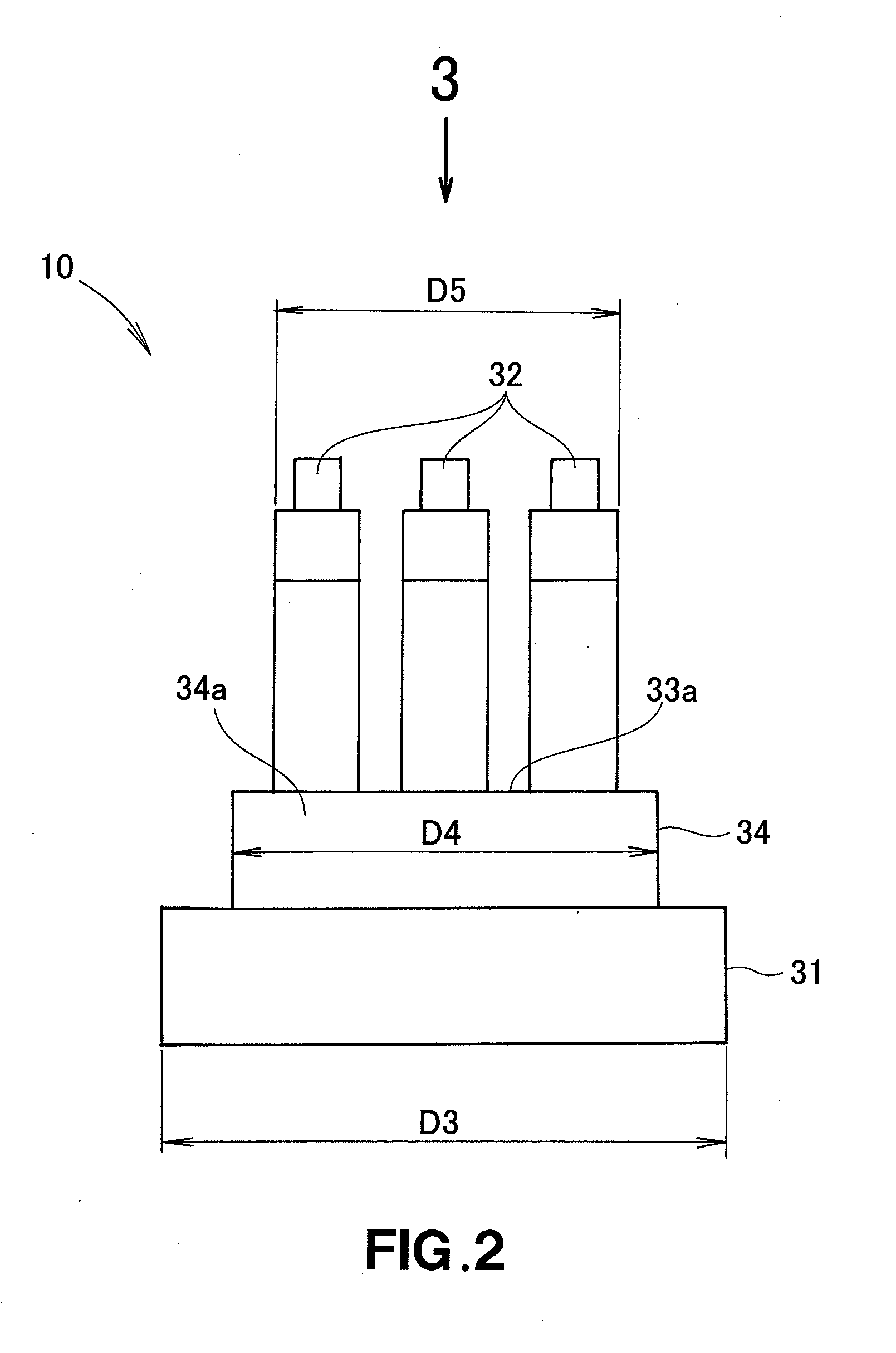

[0028]As shown in FIG. 1, a workpiece-punching apparatus 10 in one embodiment of the present invention includes a base or bolster 11, and a lower die set 13 provided on a top of the bolster 11 and defining a hydraulic cylinder 12 therein. The apparatus 10 also includes a die plate 15 disposed above the lower die set 13 with a packing plate 14 provided therebetween. The apparatus 10 further includes an upper die set 17 actuated by a driver 16 to move vertically in opposed relation to the lower die set 13. The apparatus 10 further includes a punch plate 21 disposed the upper die set 17 with a packing plate 18 provided therebetween. The apparatus 10 further includes a vertically moveable upper die pad 23 disposed below the punch plate 21 for clamping a workpiece or metal sheet 22 from thereabove.

[0029]Attached to the packing plate 18 is a guide post 24 for guiding the punch plate 21 and the upper die pad 23 to the die plate 15. A retainer 25 is attached to the packing plate 18 for limi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com