Electric pump

a technology of electric pumps and electric motors, applied in the direction of piston pumps, positive displacement liquid engines, liquid fuel engines, etc., can solve the problems of risk of significant deterioration in heat discharging performance and adverse effects of various electronic components mounted, and achieve the effect of reducing the number of components and reducing the weight of electric pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

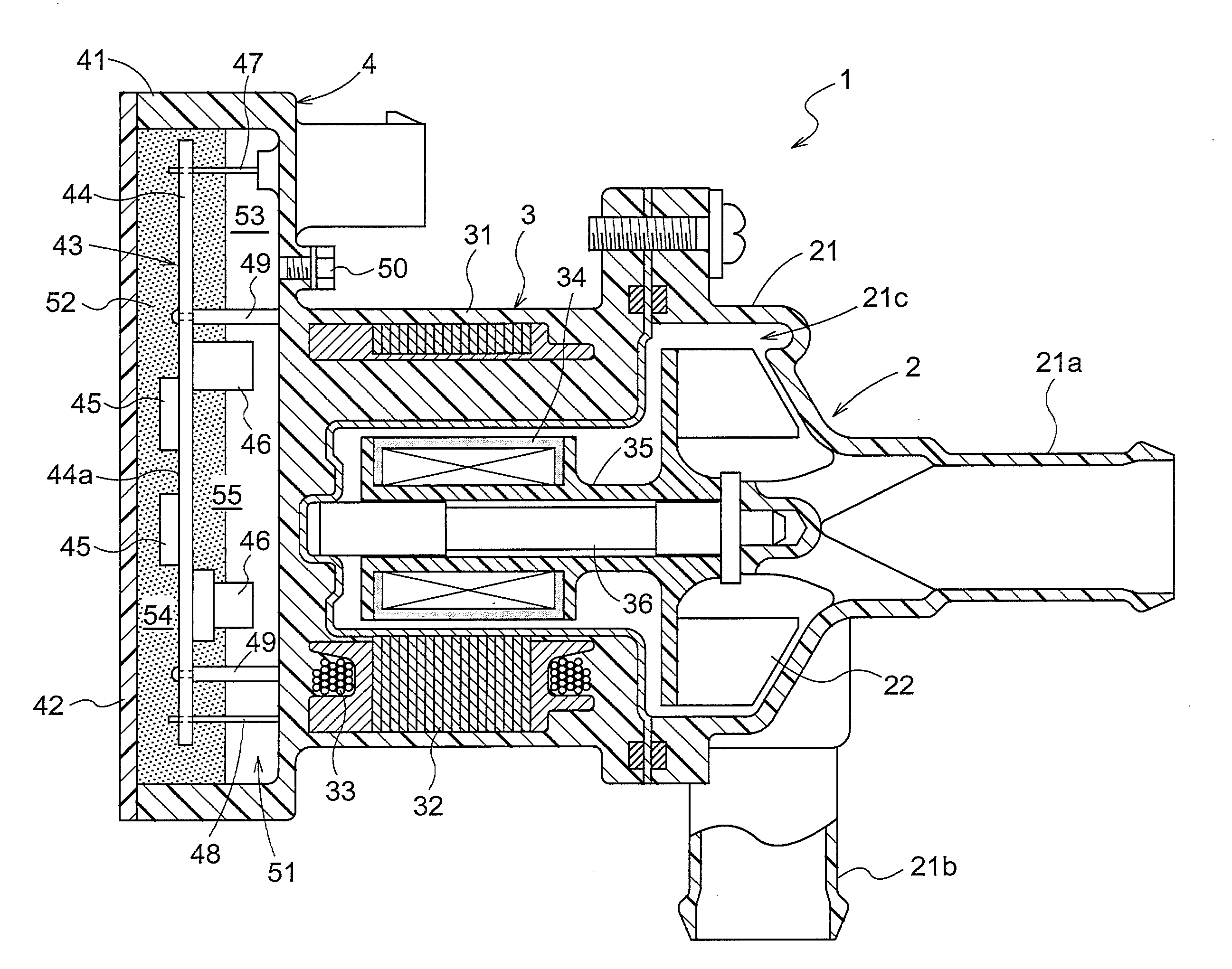

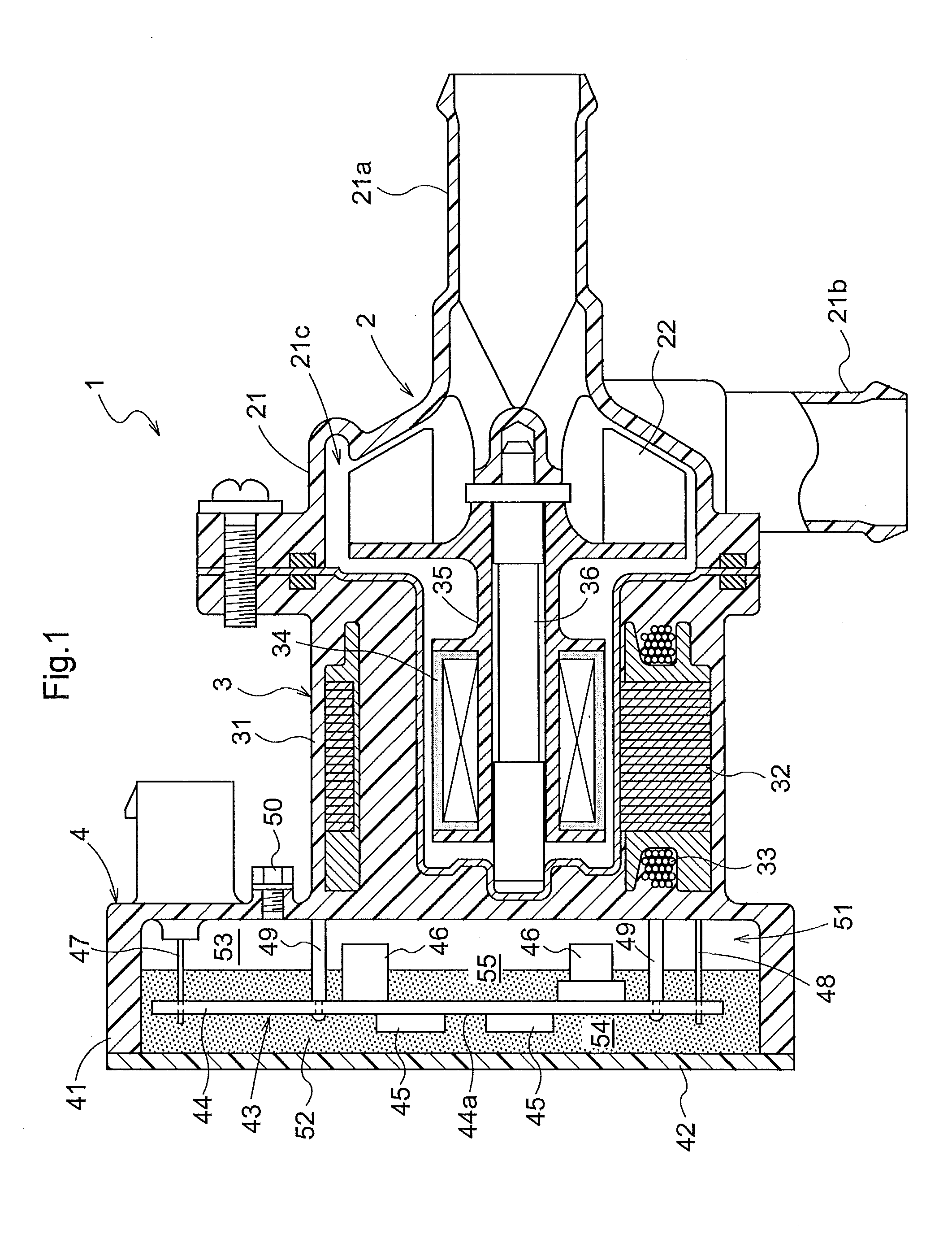

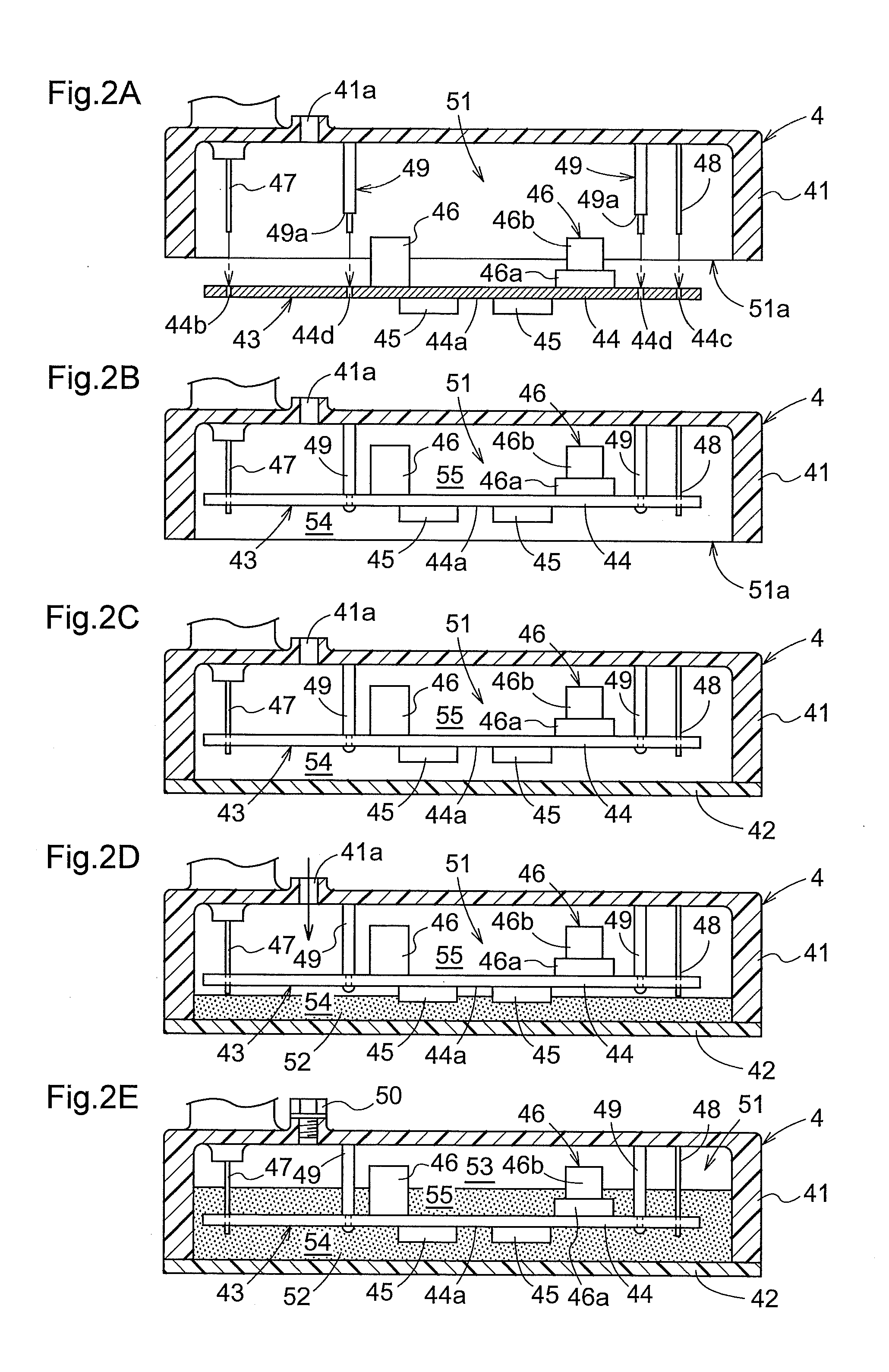

[0027]Next, embodiments of an electric pump relating to the present invention will be explained with reference to the accompanying drawings. As shown in FIG. 1, an electric pump 1 relating to this embodiment includes a pump unit 2, a motor unit 3 for driving the pump unit 2, and a driver chamber 4 having a driver 43 for controlling the motor unit 3.

[0028]A pump housing 21 accommodating the pump unit 2 is formed of resin; and a cylindrical inlet opening 21a and a cylindrical discharge opening 21b are formed in this housing 21. These inlet opening 21a and discharge opening opening 21b are communicated respectively to an impeller chamber 21c formed inside the pump housing 21. The impeller chamber 21c accommodates an impeller 22. In association with rotation of this impeller 22, an amount of fluid is introduced into the impeller chamber 21c via the inlet opening 21a and at the same time an amount of fluid is discharged from the impeller chamber 21c to the discharge opening 21b.

[0029]A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com