Electron beam apparatus and lens array

a technology of electron beam and lens array, which is applied in the direction of beam deviation/focusing by electric/magnetic means, instruments, mass spectrometers, etc., can solve the problems of difficult control of the curvature of field of the objective lens, the inability to easily change the diameter of the opening of the lens array, and the limited optical condition under which the curvature of field can be corrected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

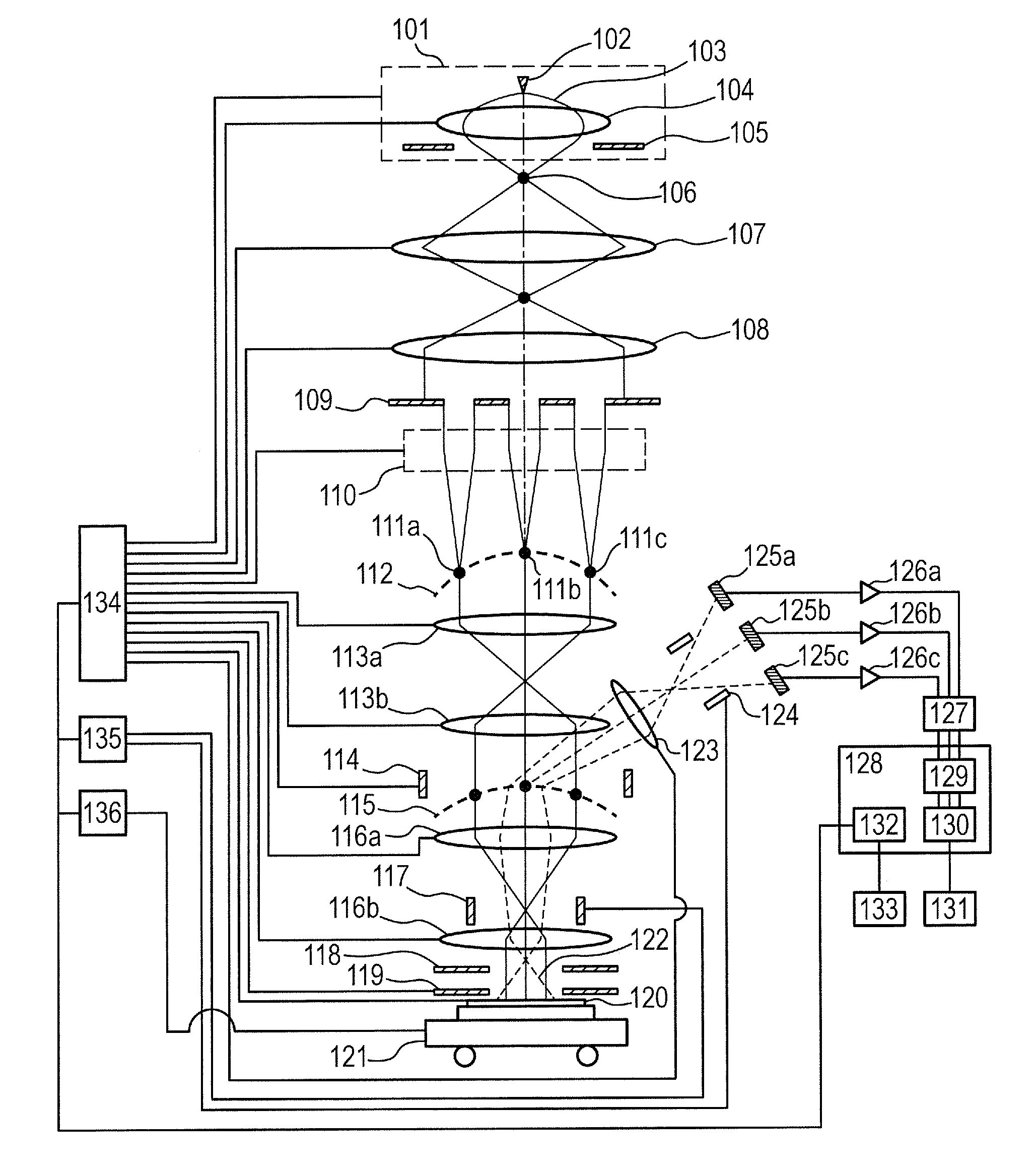

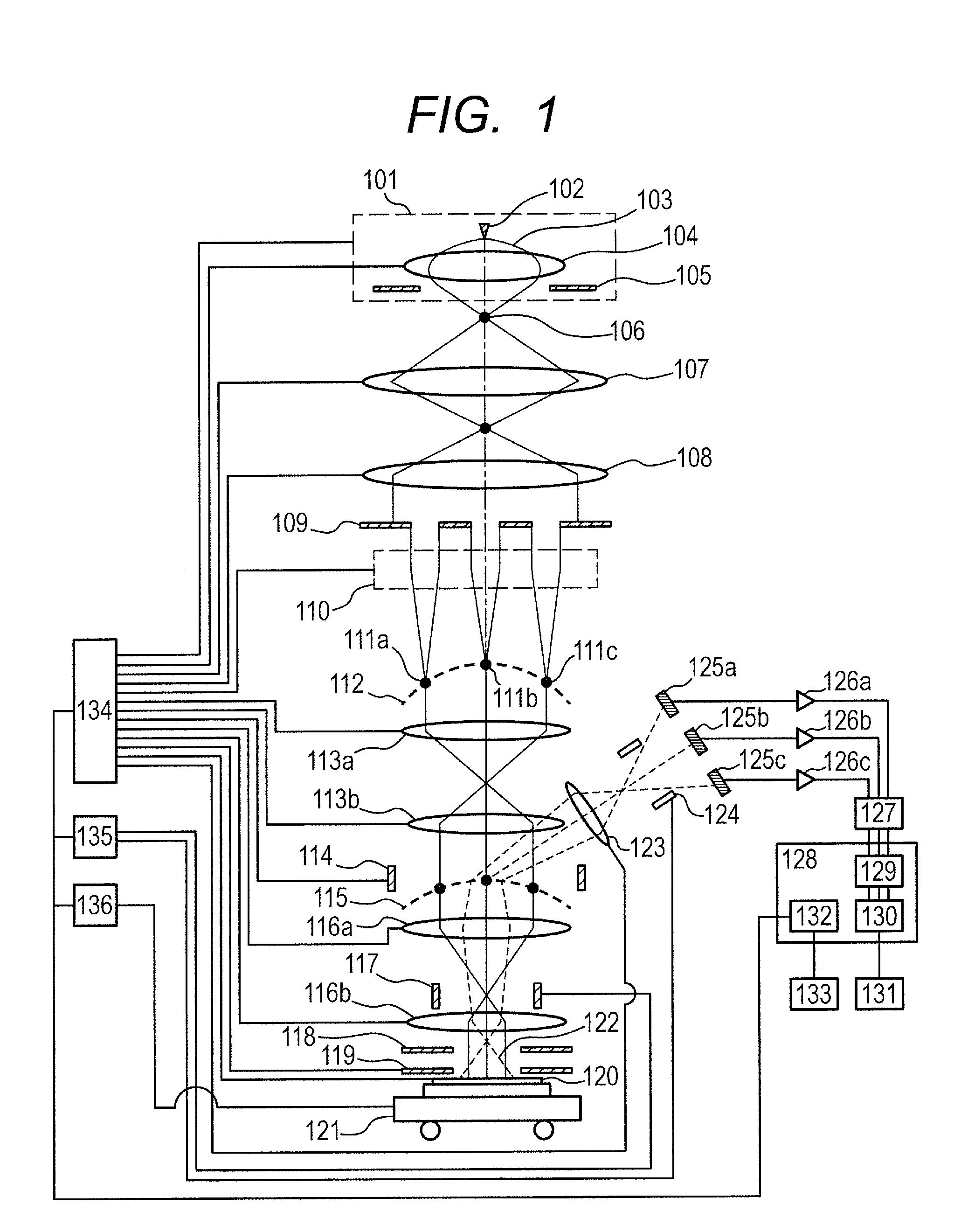

first embodiment

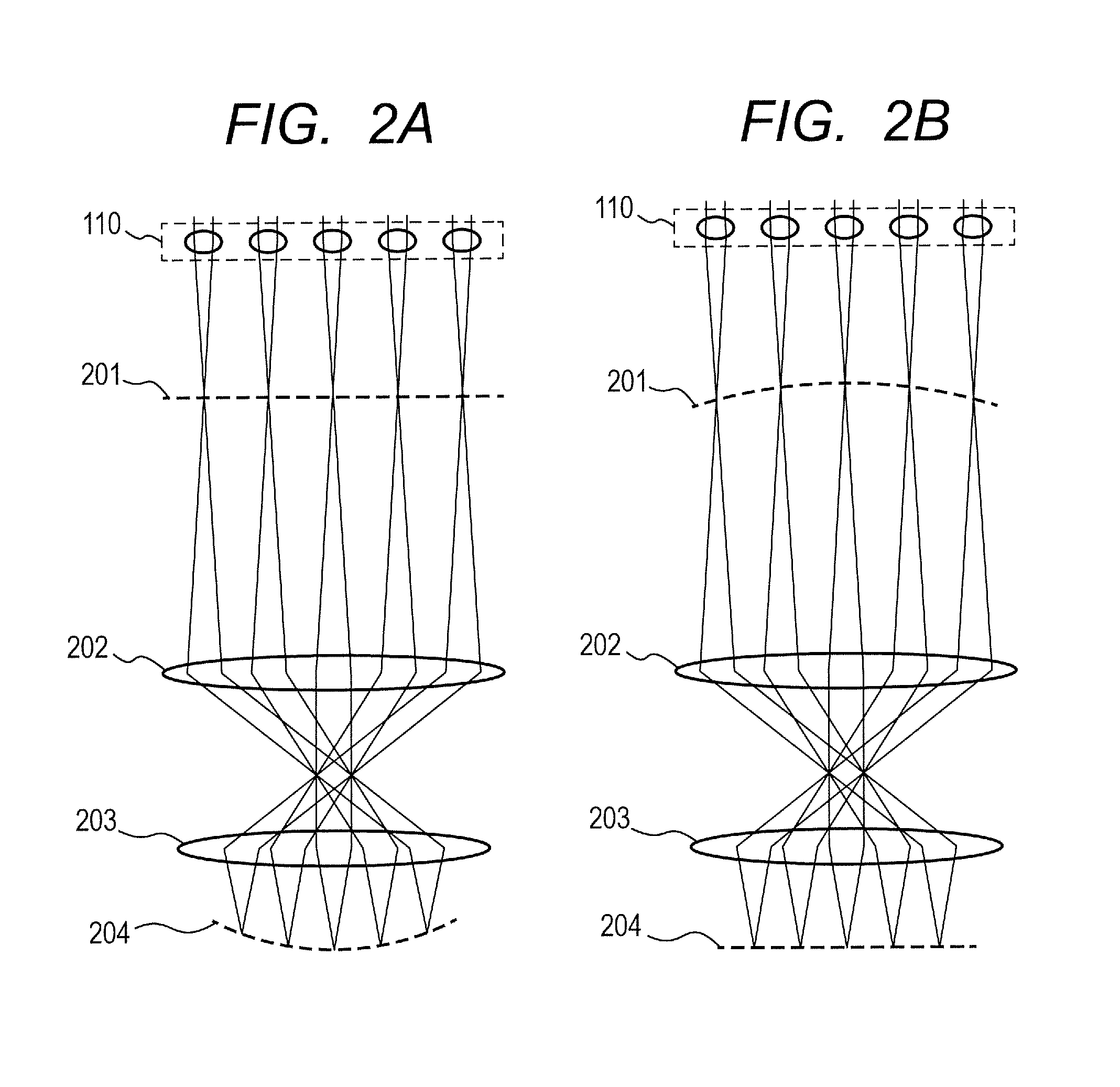

[0048]In a microscope for application to a semiconductor process, such as, for example, an electron beam inspection apparatus, an electron beam measuring apparatus, and so forth, the variety of controls as to an optical condition, according to a specimen, are required. Under such circumstances, a lens array according to the related art is unable to independently control an image forming position using a lens close to a center axis, and a curvature of a lens array image surface (a lens array image-forming surface or a crossover image surface), so that it has become difficult to have a desirable optical condition compatible with the correction of the curvature of field aberration. In the first embodiment of the invention, with an eye on this point, it is intended to implement an electron beam apparatus capable of independently controlling the image forming position by the lens close to the center axis, and the curvature of the lens array image surface. As one of specific unit (will be...

second embodiment

[0096]FIGS. 8A to 8C each are a schematic representation showing an example of the configuration of a lens array in an electron beam apparatus according to a second embodiment of the invention. The lens array shown in FIG. 8A is comprised of two units of lens arrays, including a first lens array 801, and a second lens array 805. The first lens array 801 is comprised of 3 plates of electrodes, including a first electrode 802, a second electrode 803, and a third electrode 804, provided in this order from the upstream side (a side of the lens array, adjacent to an electron gun). The respective electrodes have 25 pieces of openings formed therein. The respective openings are circular in shape, and the respective openings in each of the electrodes are disposed such that a beam axis of each of 25 lengths of beams, indicated by a solid line in the figure, penetrates through the center of the opening. A common voltage (in this case, the ground voltage) is connected to the first electrode 80...

third embodiment

[0101]FIG. 9A is a schematic representation showing an example of the configuration of a lens array in an electron beam apparatus according to a third embodiment of the invention. The lens array shown in FIG. 9A is comprised of 5 plates of electrodes, including a first electrode 901, a second electrode 902, a third electrode 903, a fourth electrode 904, and a fifth electrode 905, provided in this order from the upstream side (a side of the lens array, adjacent to an electron gun). The lens array of FIG. 9A is made up so as to be vertically symmetrical about the third electrode 903, and an interval between the first electrode 901 and the second electrode 902 is equal to an interval between the fourth electrode 904 and the fifth electrode 905. Further, an interval between the second electrode 902 and the third electrode 903 is equal to an interval between the third electrode 903 and the fourth electrode 904. Multiple openings, each thereof being circular in shape, are disposed in each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| curvature | aaaaa | aaaaa |

| voltages | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com