Thermal receptacle with phase change material containing insert

a technology of phase change material and thermoplastic, which is applied in the direction of domestic cooling apparatus, packaging goods type, lighting and heating apparatus, etc., can solve the problems of diluting hot beverages, burning to the mouth, and burning to the skin, and achieves the effect of high demand for hot beverages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

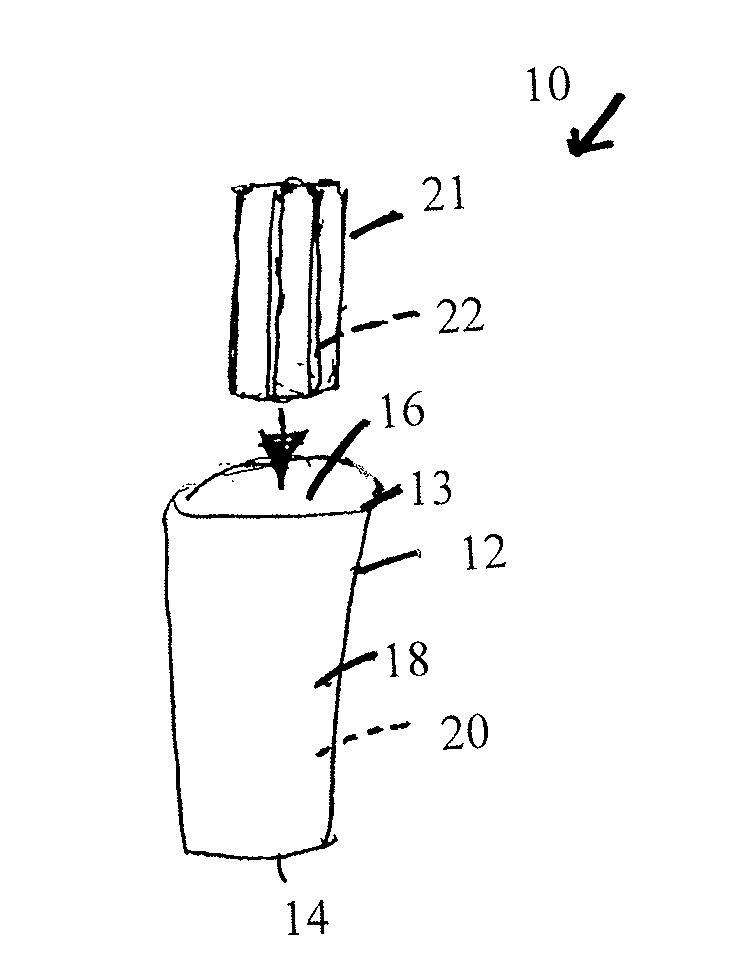

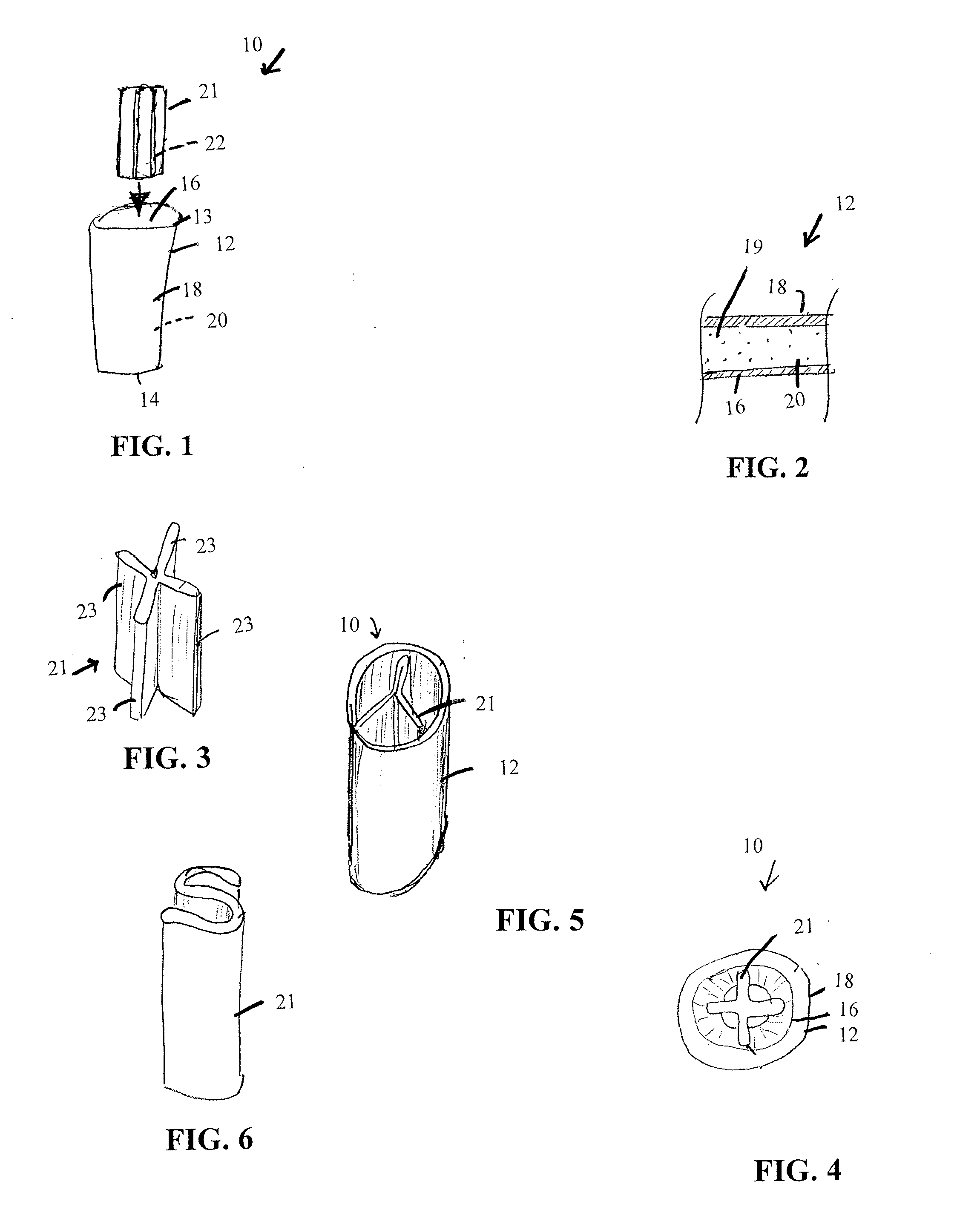

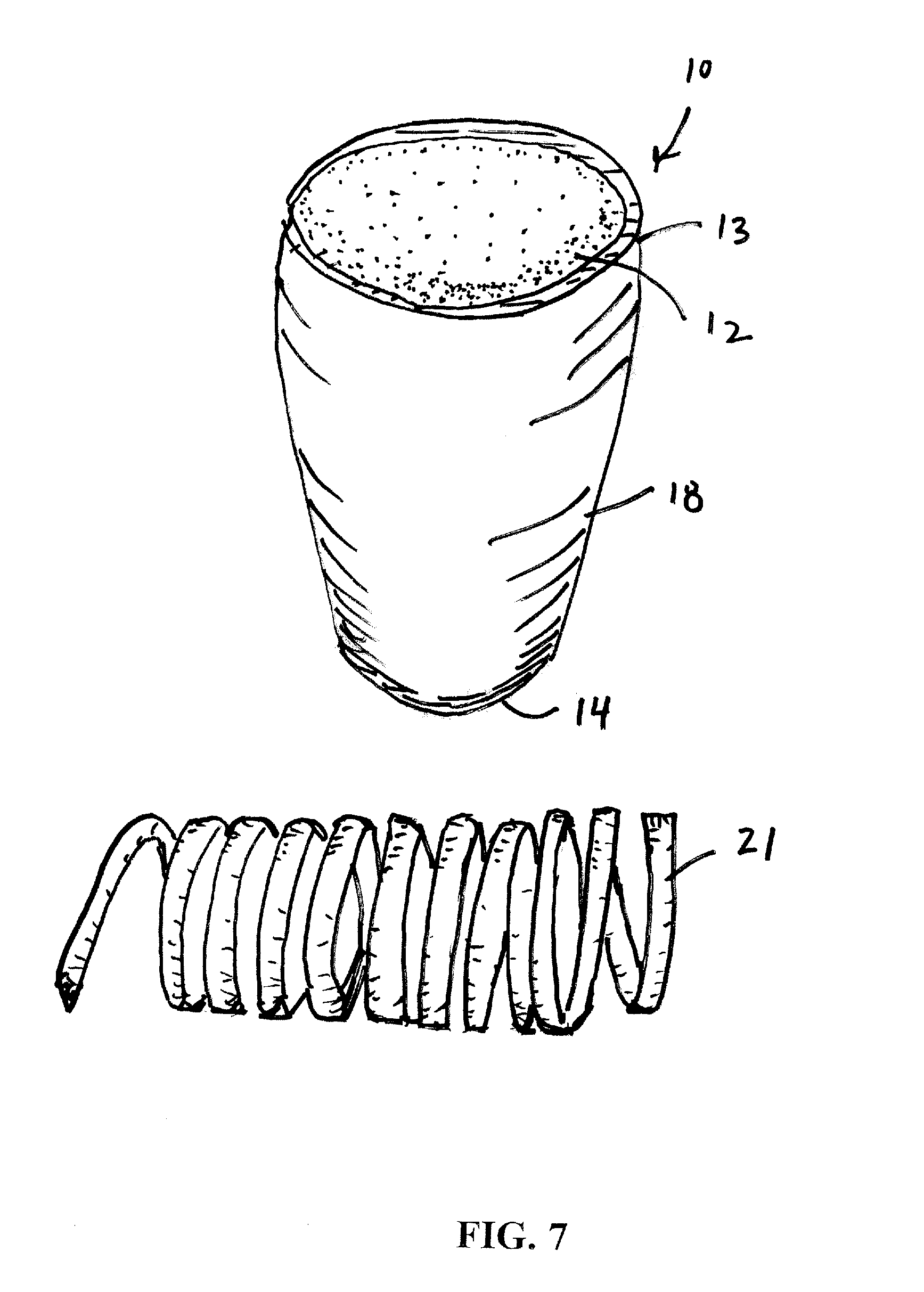

[0024]One embodiment of the present invention is a coffee cup. Such an embodiment can be used for coffee or any liquid that is desired to be brought into and maintained within a desired temperature range. The cup rapidly cools the coffee or liquid by employing phase change materials (PCMs) to help manage the temperature of the coffee. The phase change materials are placed within an insert adapted to be inserted into the cup. Additional phase change materials can be placed inside the cup walls, such as disclosed in U.S. Pat. No. 6,634,417, incorporated herein by reference.

[0025]Cup embodiments of the present invention include phase change material in an insert or inserts designed to be placed within the interior of the liquid cavity of the cup. The insert can be of several different designs but each design increases the amount of surface area that is between the coffee and the PCM (as compared to PCM in the walls of the cup alone) thereby increasing the thermal transfer between the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wall thickness | aaaaa | aaaaa |

| wall thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com