Metallic bondcoat or alloy with a high gamma/gamma' transition temperature and a component

a technology of transition temperature and metal bonding layer, applied in the direction of coatings, mechanical equipment, machines/engines, etc., can solve the problems of only and not being able to achieve requests. only, so as to achieve the effect of increasing the service temperature of the bonding layer, optimizing strength, and not being able to withstand oxidation and/or corrosion attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The figures and the description are only embodiments of the invention.

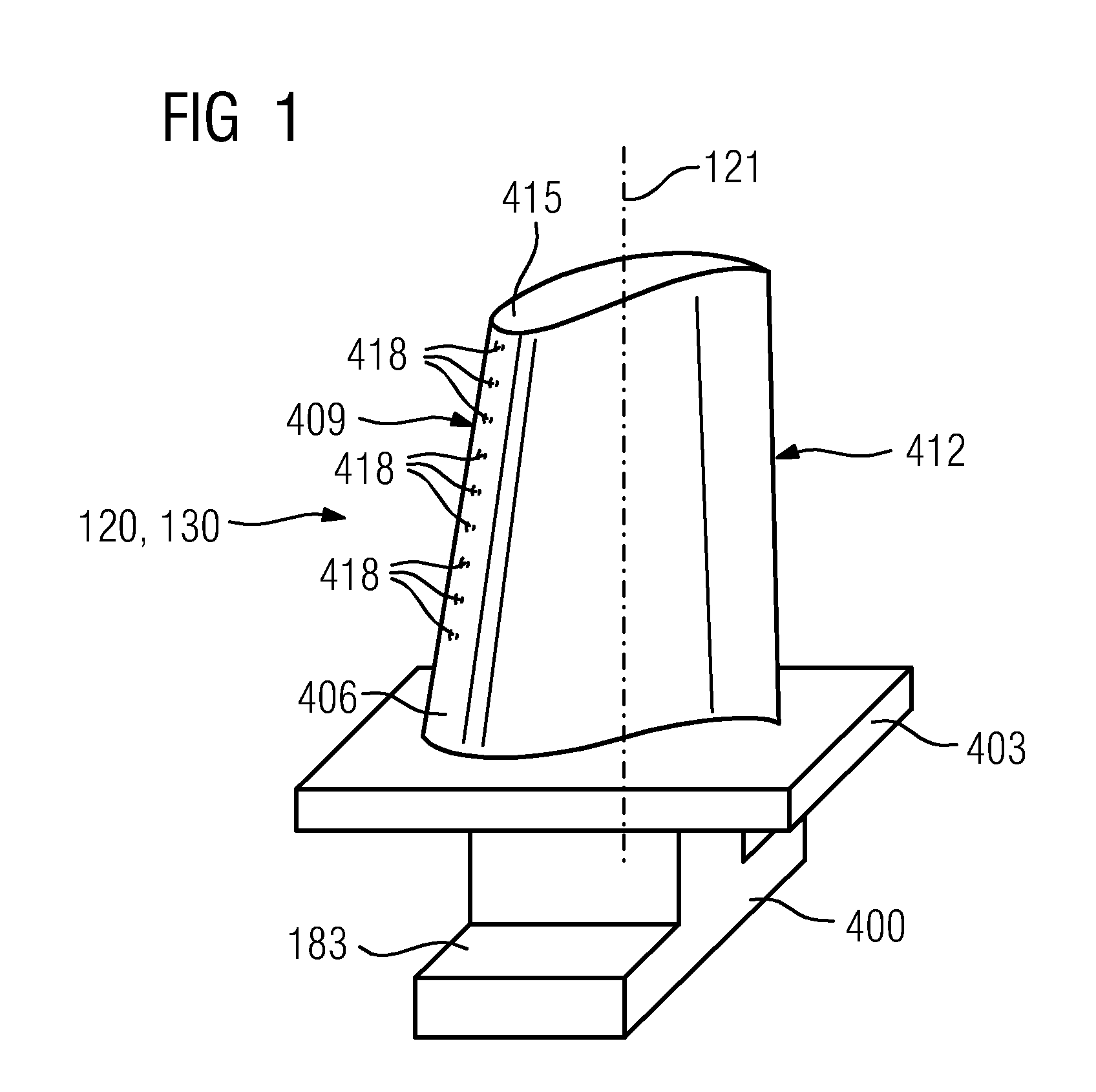

[0013]FIG. 1 shows a perspective view of a rotor blade 120 or guide vane 130 of a turbomachine, which extends along a longitudinal axis 121.

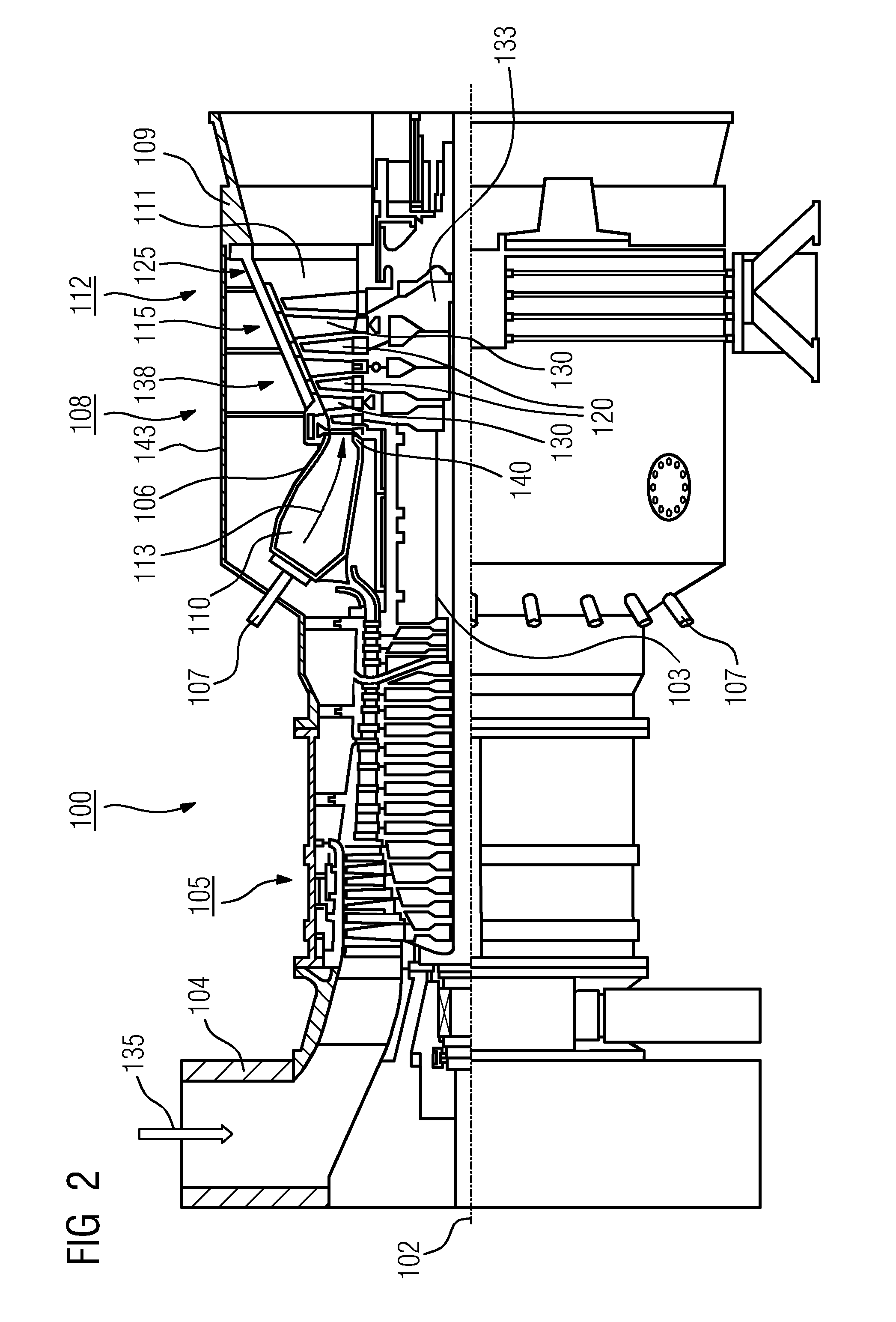

[0014]The turbomachine may be a gas turbine of an aircraft or of a power plant for generating electricity, a steam turbine or a compressor.

[0015]The blade or vane 120, 130 has, in succession along the longitudinal axis 121, a securing region 400, an adjoining blade or vane platform 403 and a main blade or vane part 406 as well as a blade or vane tip 415.

[0016]As a guide vane 130, the vane 130 may have a further platform (not shown) at its vane tip 415.

[0017]A blade or vane root 183, which is used to secure the rotor blades 120, 130 to a shaft or disk (not shown), is formed in the securing region 400.

[0018]The blade or vane root 183 is designed, for example, in hammerhead form. Other configurations, such as a fir-tree or dovetail root, are possible.

[0019]The blade or vane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| metallic | aaaaa | aaaaa |

| γ'/γ | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com