Epitaxial film forming method, sputtering apparatus, manufacturing method of semiconductor light-emitting element, semiconductor light-emitting element, and illumination device

a manufacturing method and film technology, applied in the direction of polycrystalline material growth, chemically reactive gas growth, crystal growth process, etc., can solve the problems of not revealing a control method, unable to obtain high-quality gan film, and unable to obtain favorable emission characteristics, etc., to achieve the effect of improving the light emission characteristics of light-emitting elements such as led and ld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

First Example

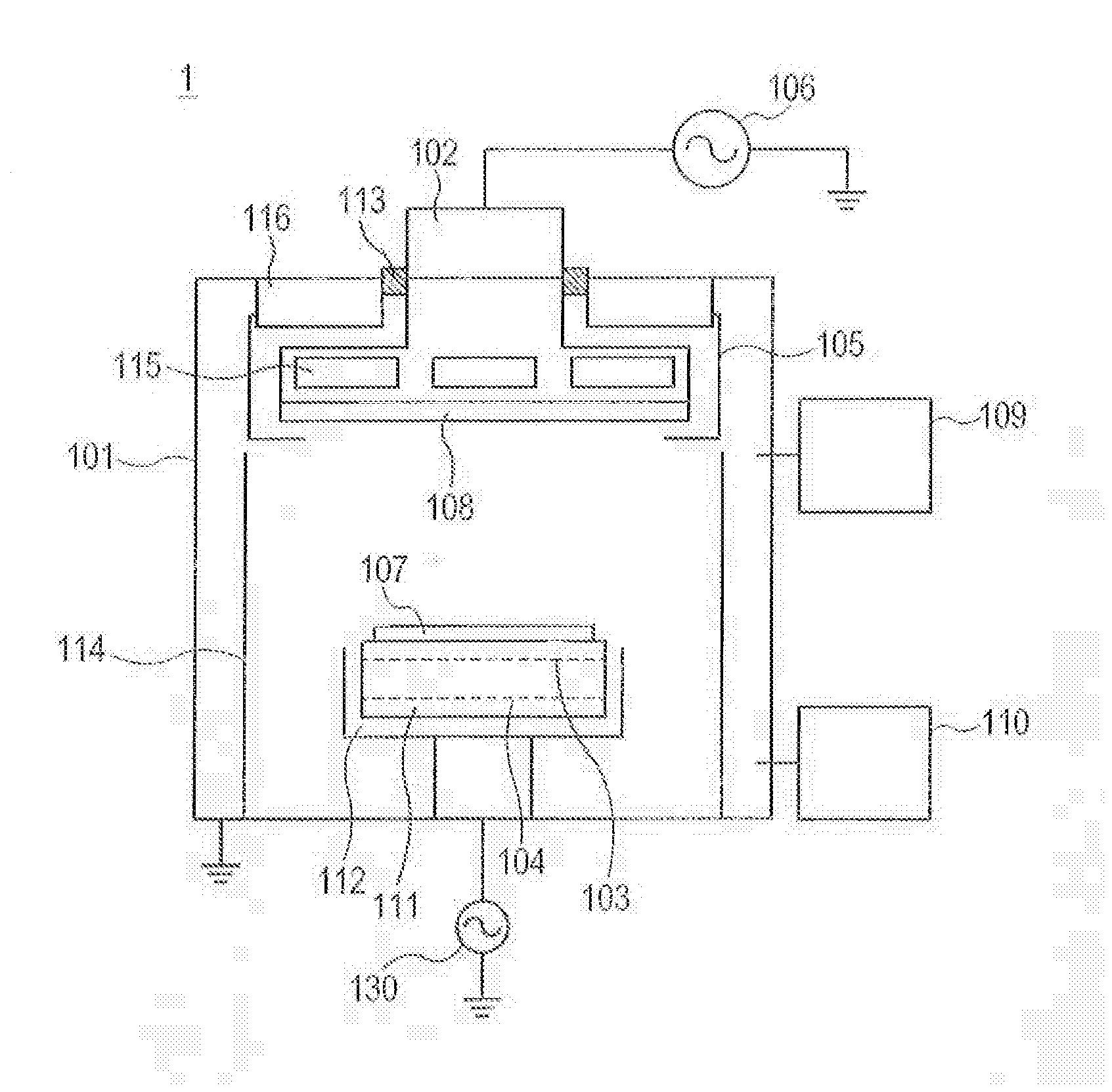

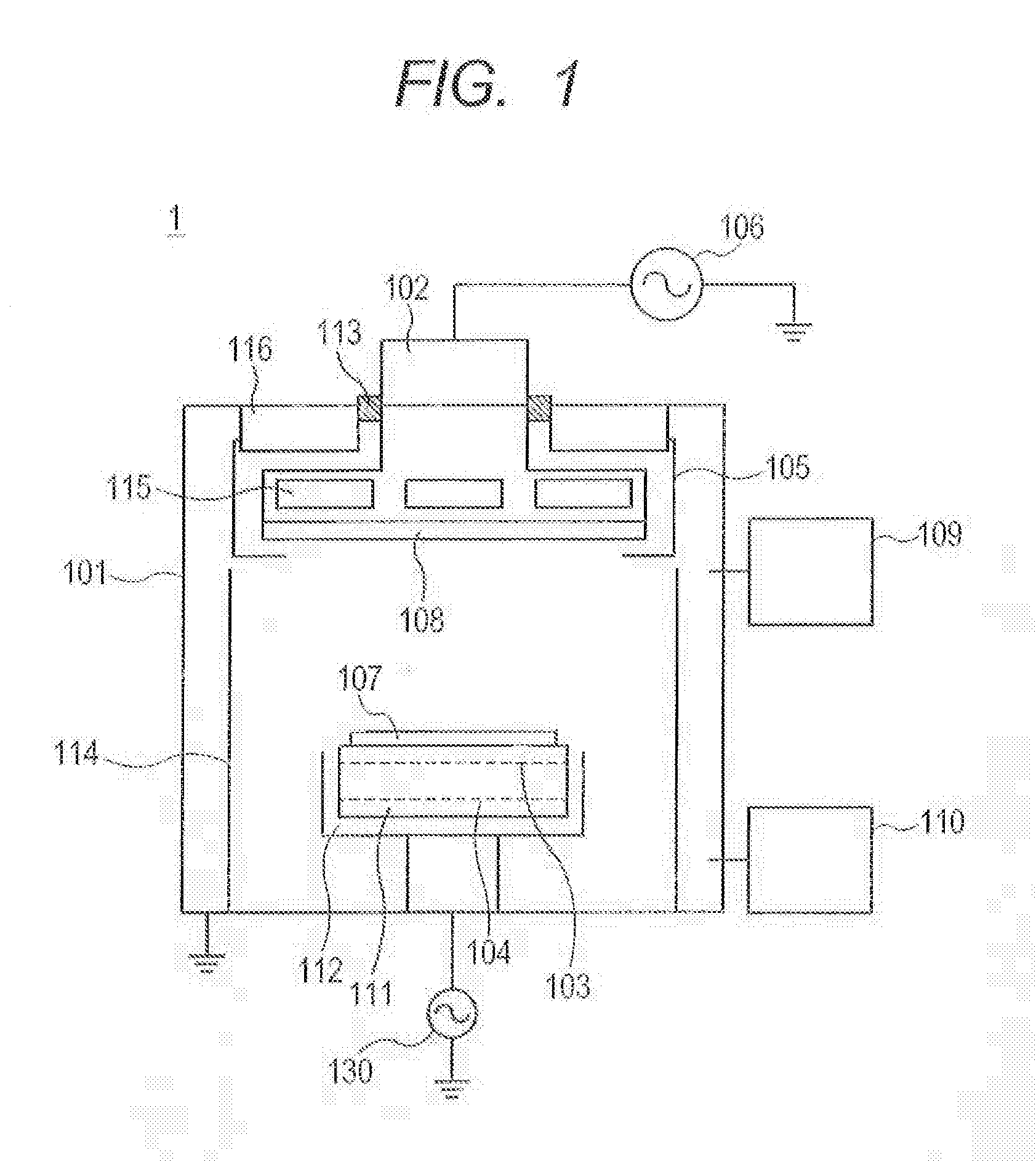

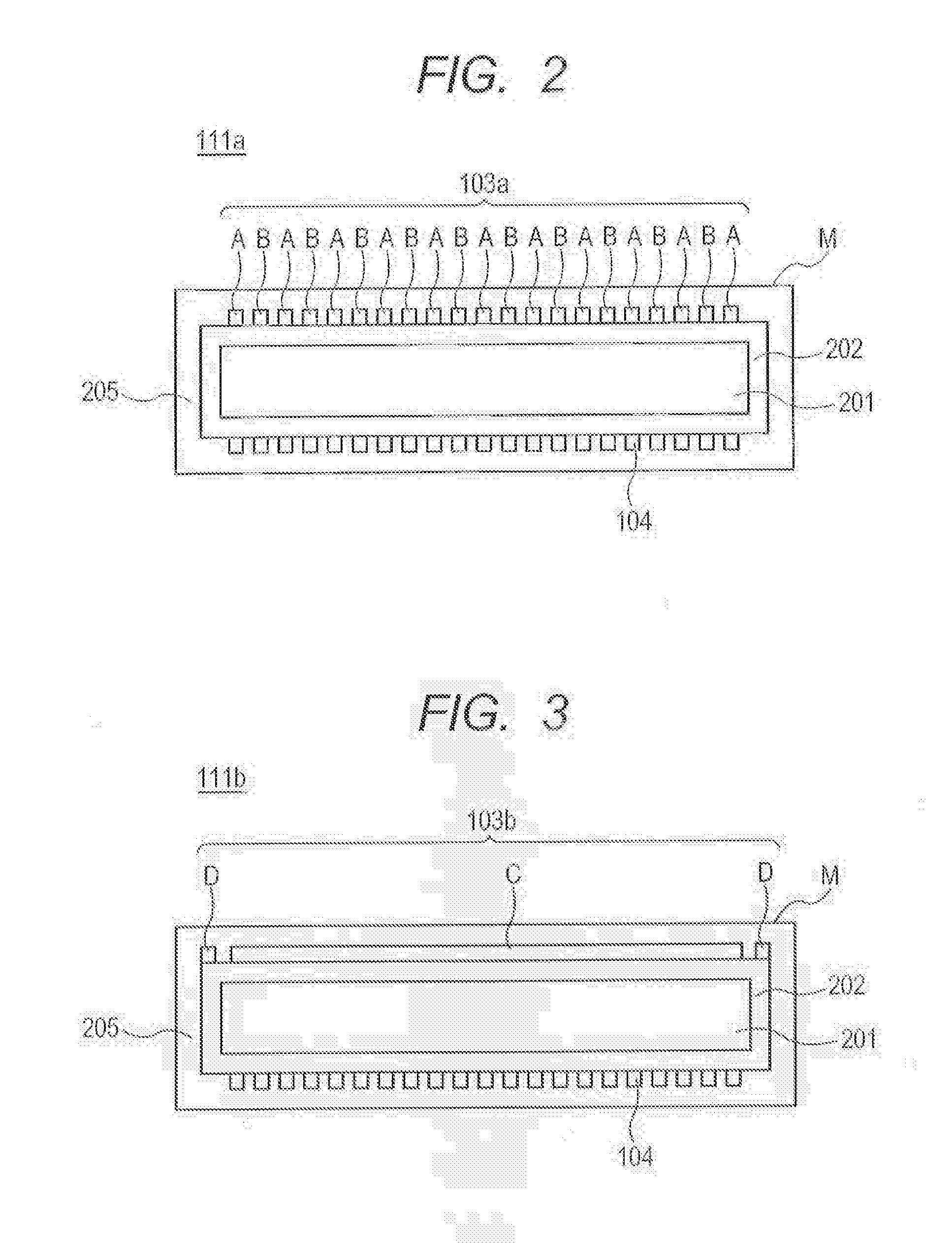

[0099]As a first example of the present invention, an example in which an AlN film as the buffer layer 602 (See FIG. 6) was formed on an α—Al2O3 (0001) substrate by using the film-forming method of a group III nitride semiconductor thin film according to an embodiment of the present invention will be described. More specifically, an example in which, in a state where the high-frequency bias power was applied to the bias electrode 103, the AlN film was formed on the α—Al2O3 (0001) substrate by using the sputtering method will be described. In the first example, the AlN film was formed by using the sputtering apparatus similar to that in FIG. 1. Moreover, the frequencies of the high-frequency power to be applied to the target electrode 102 and the high-frequency power to be applied to the bias electrode 103 are set to 13.56 MHz and 13.54 MHz, respectively.

[0100]In the first example, first, the α—Al2O3 (0001) substrate was conveyed to the vacuum vessel 101 maintained at 1×...

second example

[0110]Subsequently, as a second example of the present invention, an example in which the AlN film fabricated by using the film-forming method of the group III nitride semiconductor thin film according to the present invention was used as a buffer layer and an undoped GaN film as the group III nitride semiconductor intermediate layer 603 in FIG. 6 was formed on the buffer layer by using the MOCVD method will be described.

[0111]The AlN film was formed on the α—Al2O3 (0001) substrate by using the sputtering method with the same apparatus and conditions as those in the first example and then, a wafer (substrate) was introduced into the MOCVD device so as to form an undoped GaN film having a film thickness of 5 μm.

[0112]The surface of the obtained undoped GaN film was a mirror surface, and it was indicated in the XRD measurement in the 2θ / ω scan mode at a symmetric reflection position that the undoped GaN film had a c-axis orientation. Subsequently, the XRC measurement in the ω scan mod...

third example

[0115]As a third example of the present invention, an example will be described in which the AlN film fabricated by using the film-forming method of the group III nitride semiconductor thin film according to the present invention was used as a buffer layer, and on the buffer layer, by using the MOCVD method, the group III nitride semiconductor intermediate layer made of undoped GaN, the n-type group III nitride semiconductor layer made of Si doped GaN, the group III nitride semiconductor active layer having an MQW structure of InGaN and GaN, and the p-type group III nitride semiconductor layer made of Mg doped GaN were epitaxially grown sequentially and moreover, after the n-type electrode layer, the translucent electrode, the p-type electrode layer, and the protective film were formed, a wafer was separated by scribing and an LED element was fabricated.

[0116]By using the sputtering method, the AlN film as the buffer layer 602 was formed on the α—Al2O3 (0001) substrate under the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com