Plate heat exchanger

a technology of heat exchanger and plate, which is applied in the direction of lighting and heating apparatus, washing machines, fastening devices, etc., can solve the problems reducing and long time, and achieves the effect of increasing the operational time of the plate heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

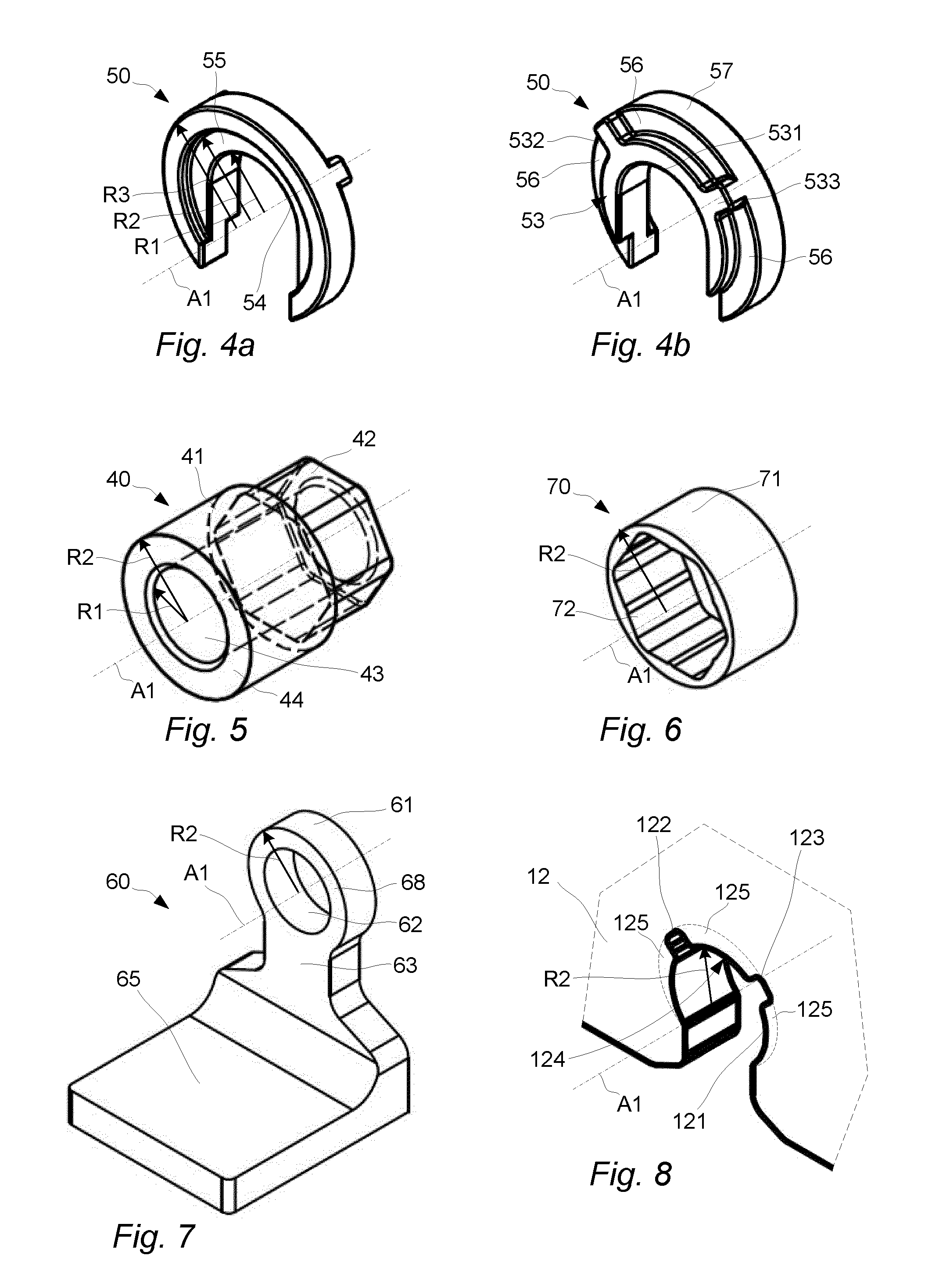

[0083]With reference to FIG. 13a a tightening member 412 is illustrated. In this embodiment the grip section of the tightening member 412 comprises a set of grooves 416 at an end of the tightening member 412. The tightening member 412 has also a guide section 422 with an outer periphery that is defined by the second radius R2.

third embodiment

[0084]With reference to FIG. 13b a tightening member 413 is illustrated. This embodiment corresponds to the embodiment of FIG. 13a with the difference that a grip section 417 is somewhat larger and is arranged as grooves at opposite sides of the tightening member 417. The tightening member 413 has a guide section 423 with an outer periphery that is defined by the second radius R2.

fourth embodiment

[0085]With reference to FIG. 13c a tightening member 414 is illustrated where a grip section 418 is arranged as elongated slots at a peripheral surface of the tightening member 414. The tightening member 414 has a guide section 424 with an outer periphery that is defined by the second radius R2. The guide section 424 is arranged intermediate the slots that form the grip section 418.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com