Lightweight Helicopter Skid Shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

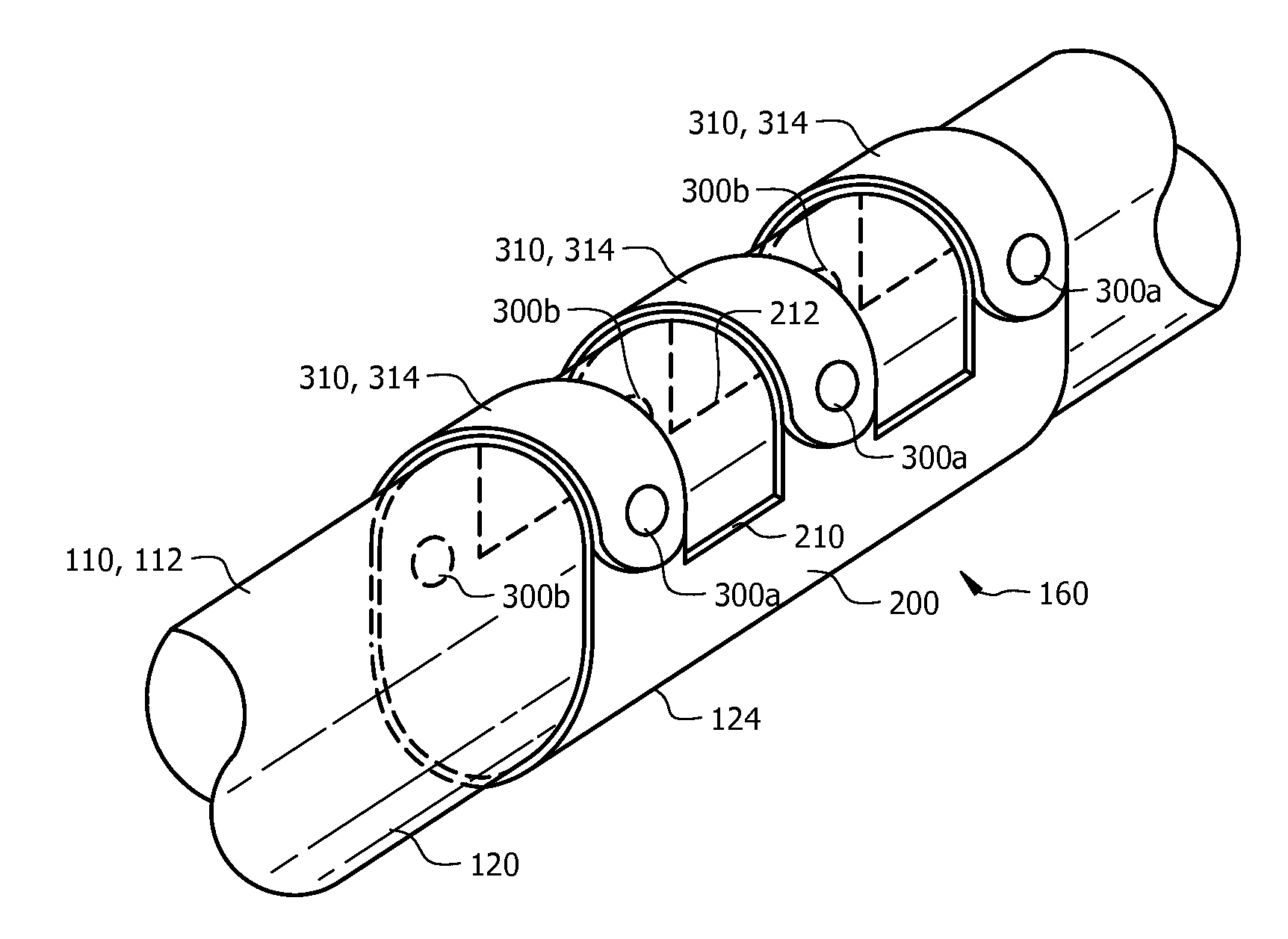

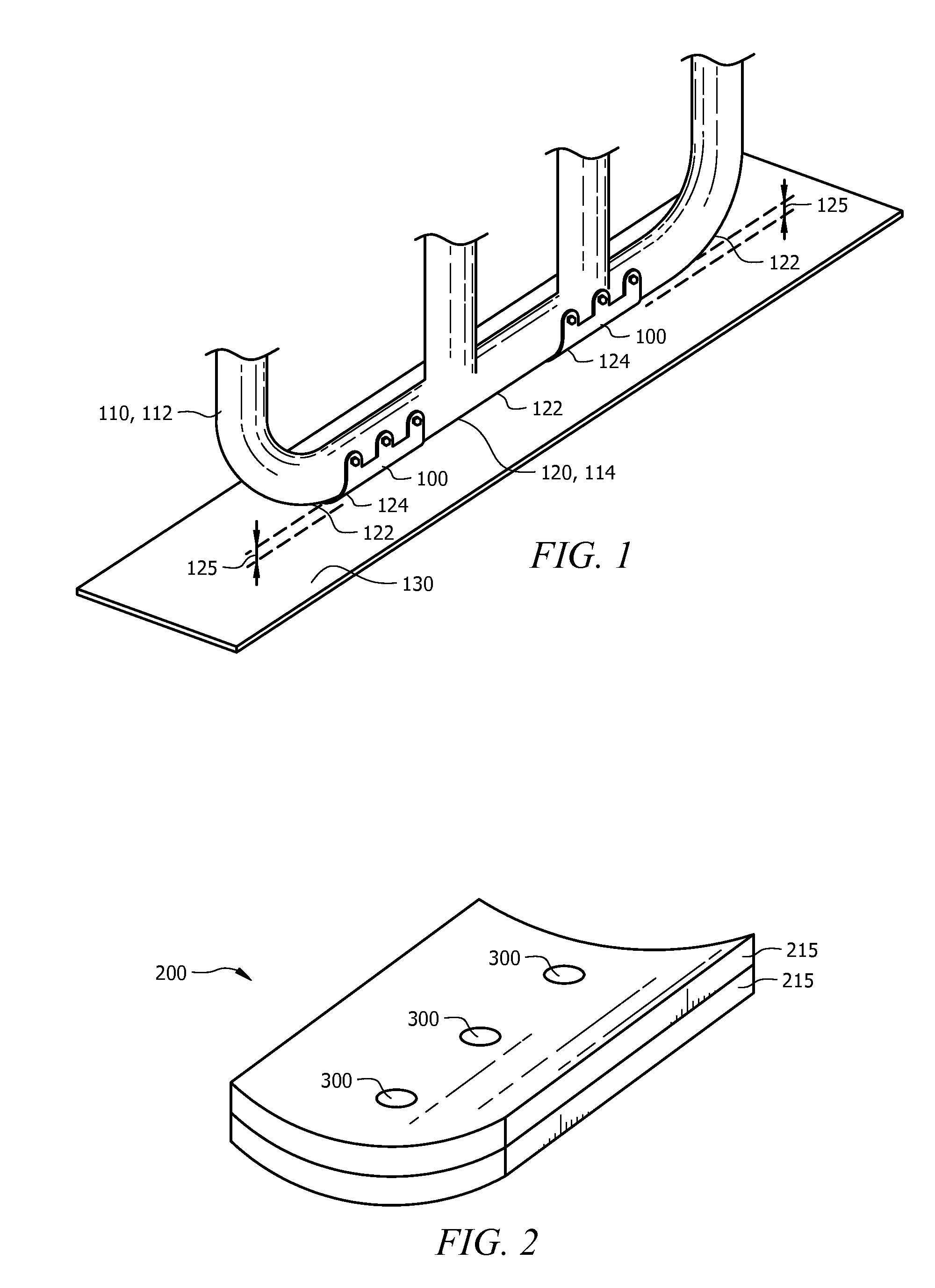

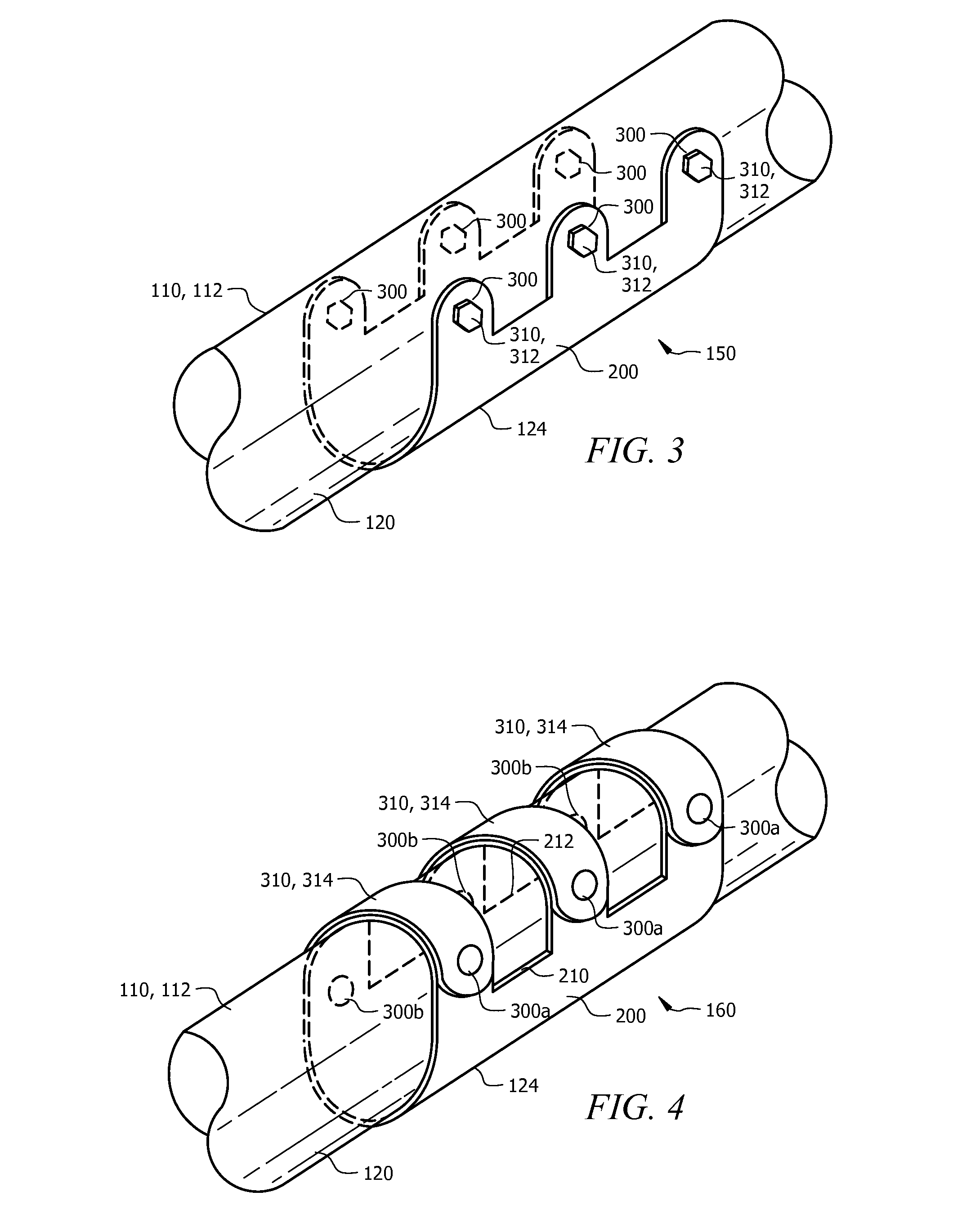

[0024]Embodiments of the present disclosure generally provide a lightweight skid shoe assembly for use in a variety of applications including, but not limited to, protecting helicopter skid landing gear and other structures from friction-related damage. The skid shoe assembly may be lighter than traditional skid shoe assemblies, thereby reducing a helicopter's empty weight and increasing its useful load. In various embodiments, lightweight skid shoe assembly may be easier to periodically replace than traditional skid shoe assemblies. In various embodiments, the skid shoe assembly may comprise a skid shoe body of wear-resistant materials, all or a portion of which having sacrificial wear properties, a shear-bearing coupling mechanism to alleviate shear forces acting on the skid shoe body, and / or a recess in a protected structure within which the skid shoe body is disposed.

[0025]FIGS. 1-6B illustrate representative embodiments of skid shoe assemblies 100, 150, 160, 170, 180 and parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com