Plastic Flanged Containers and Food Product Pack Comprising Such Containers

a technology of plastic flanges and food products, which is applied in the field of containers, can solve the problems of inability to easily reduce the weight of plastic containers, the container is more difficult to break apart, and the contents cannot be easily escaped, so as to achieve the effect of reducing the length of the container, reducing the risk of contamination, and constant thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]In the various figures, the same references are used to designate identical or similar elements.

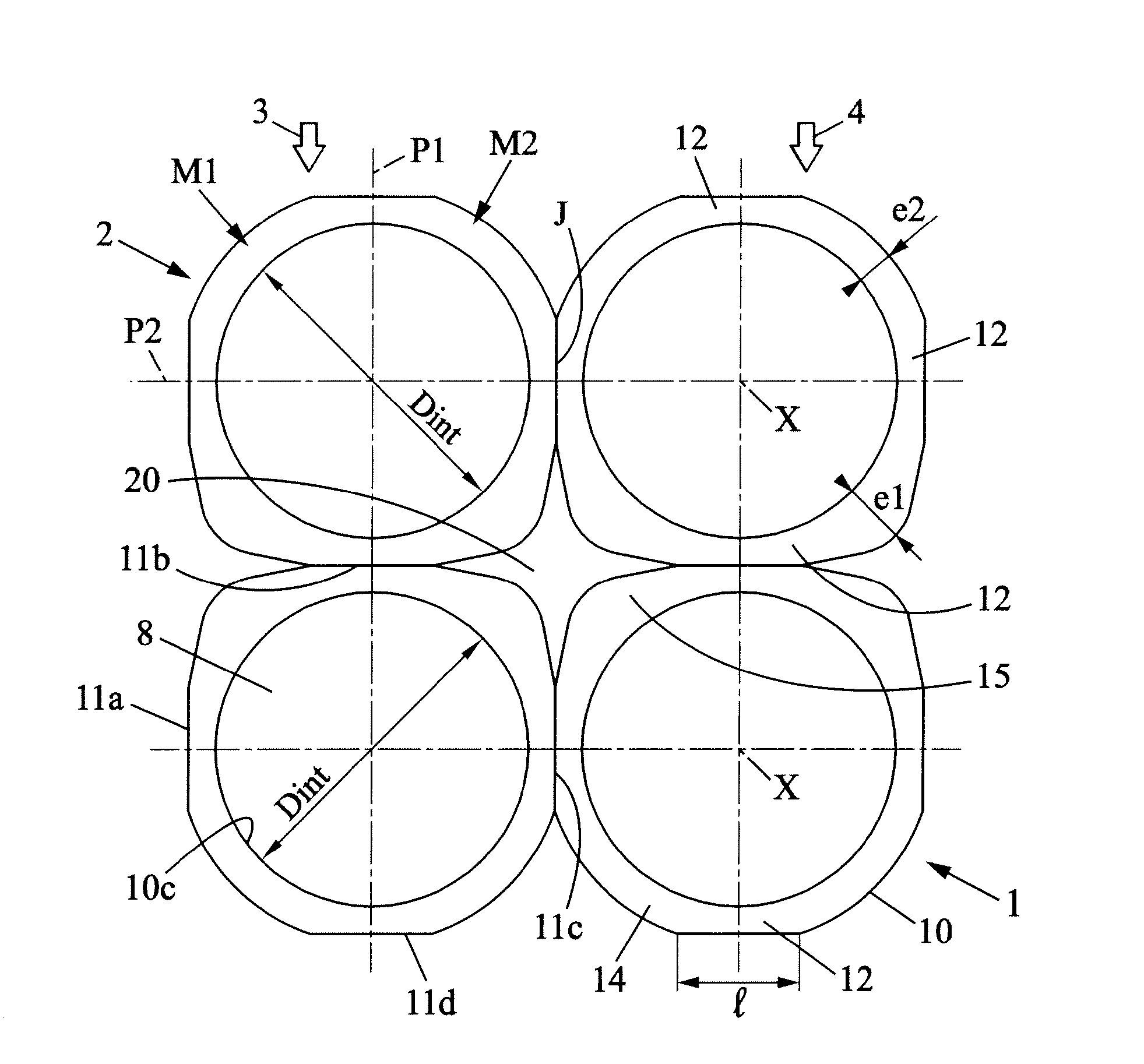

[0048]FIG. 1 shows a food pack 1 comprising for instance four individual containers 2. Of course the number of containers 2 may vary and a number of 2, 6, 8, 10 or 12 containers 2 may be provided, in a non-limitative example. The containers 2 are arranged in at least one row, and preferably at least in two rows 3, 4 when the pack 1 comprises four or more containers 2.

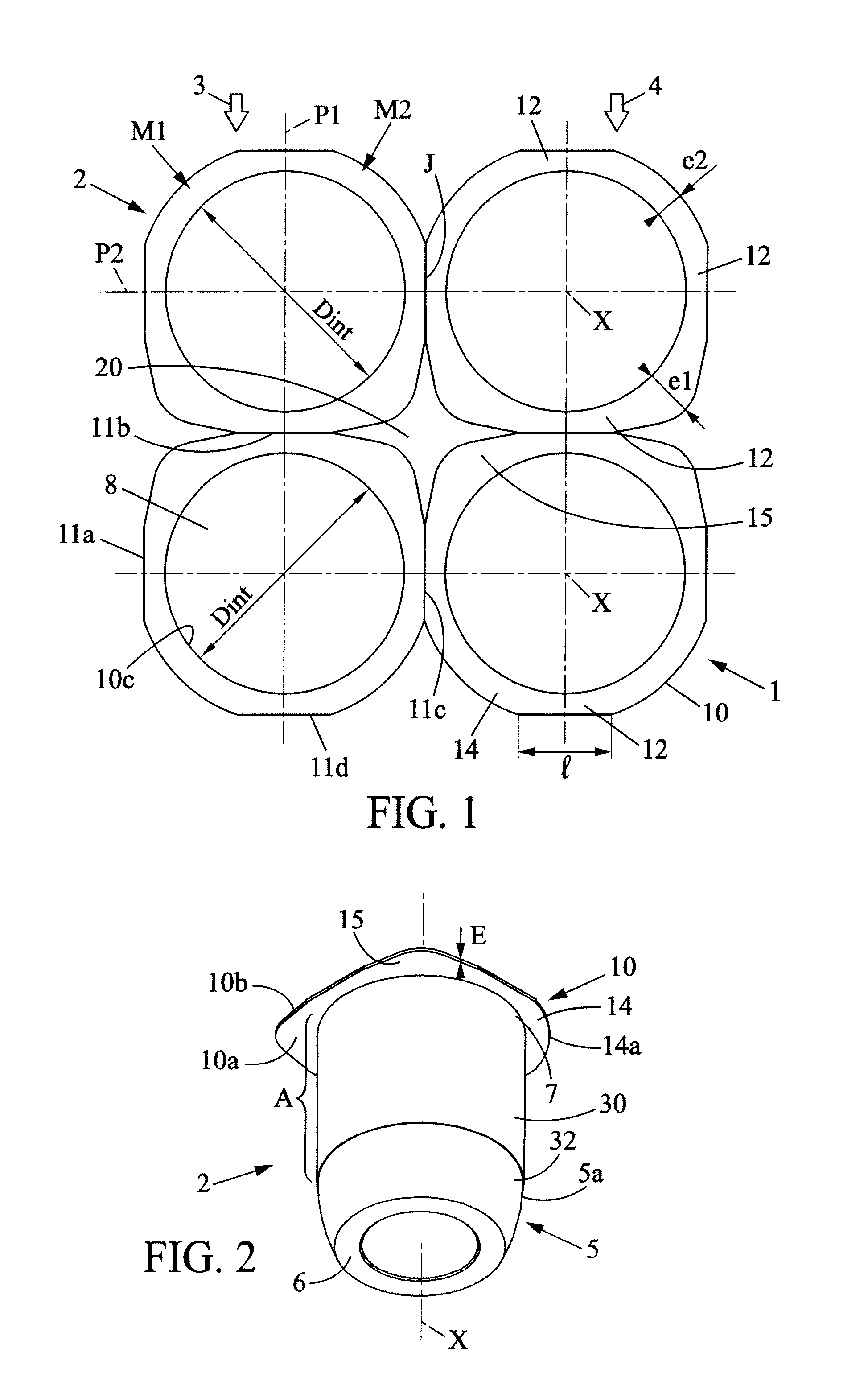

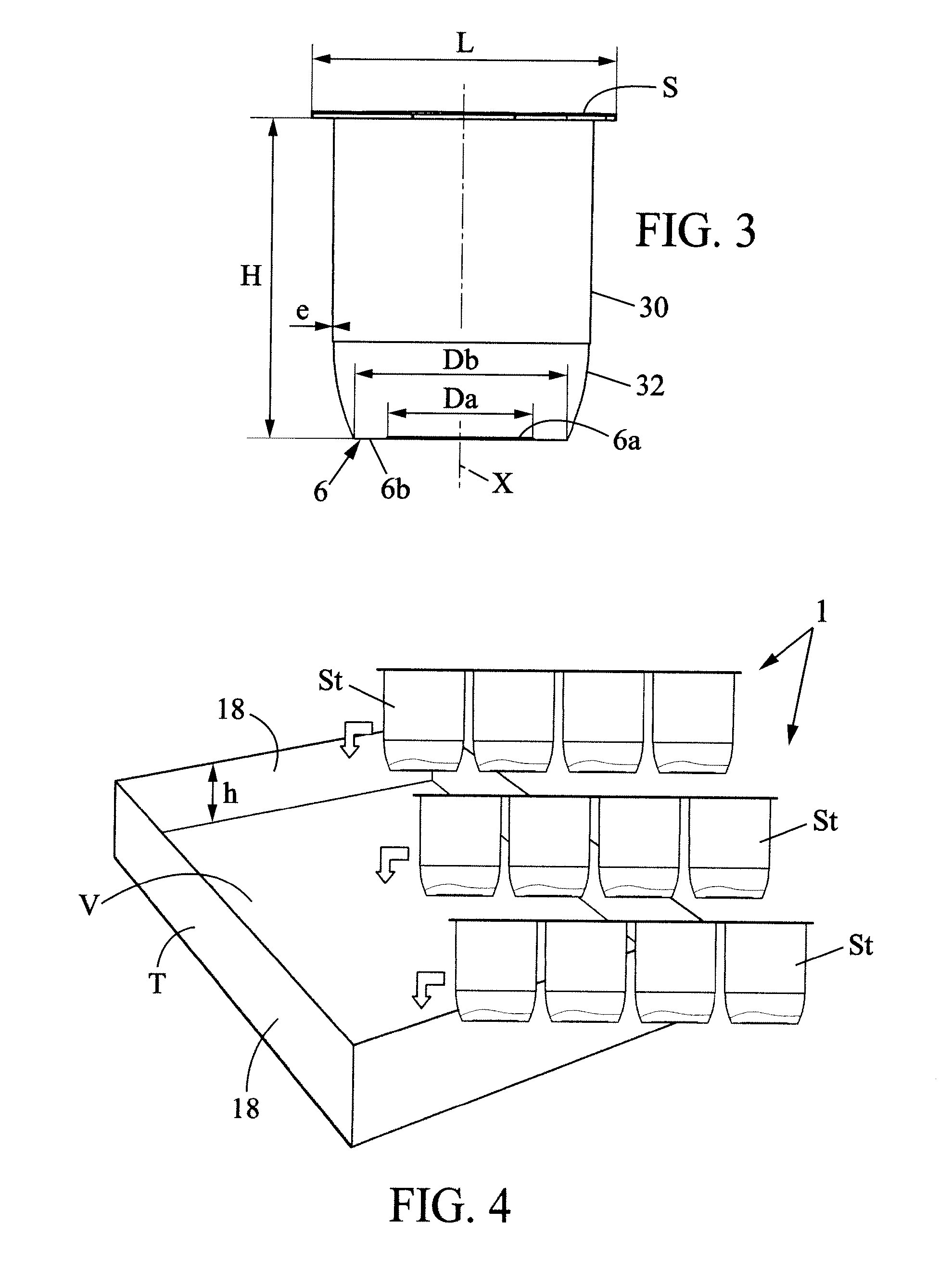

[0049]Referring to FIGS. 1, 2 and 3, the containers 2 are preferably polystyrene containers, each comprising a hollow body 5 having a side wall extending along a longitudinal axis X from a bottom 6 as far as an open top 7. The side wall 5a of the body 5 is tubular and is adapted to be covered by a cylindrical decorative strip St, sticker or banderol in the upper area A adjacent to the upper body opening, called hereafter circular opening 8. It is understood that the longitudinal axis X is here a central axis for the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com