Riser for Coil Tubing/Wire Line Injection

a coil tubing/wire line and riser technology, which is applied in the direction of special purpose vessels, vessel construction, borehole/well accessories, etc., can solve the problems of high cost and high day rate of coil tubing/wire line work-over procedures, and achieve the effect of reducing the cost of the procedure and avoiding the cost of the day ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

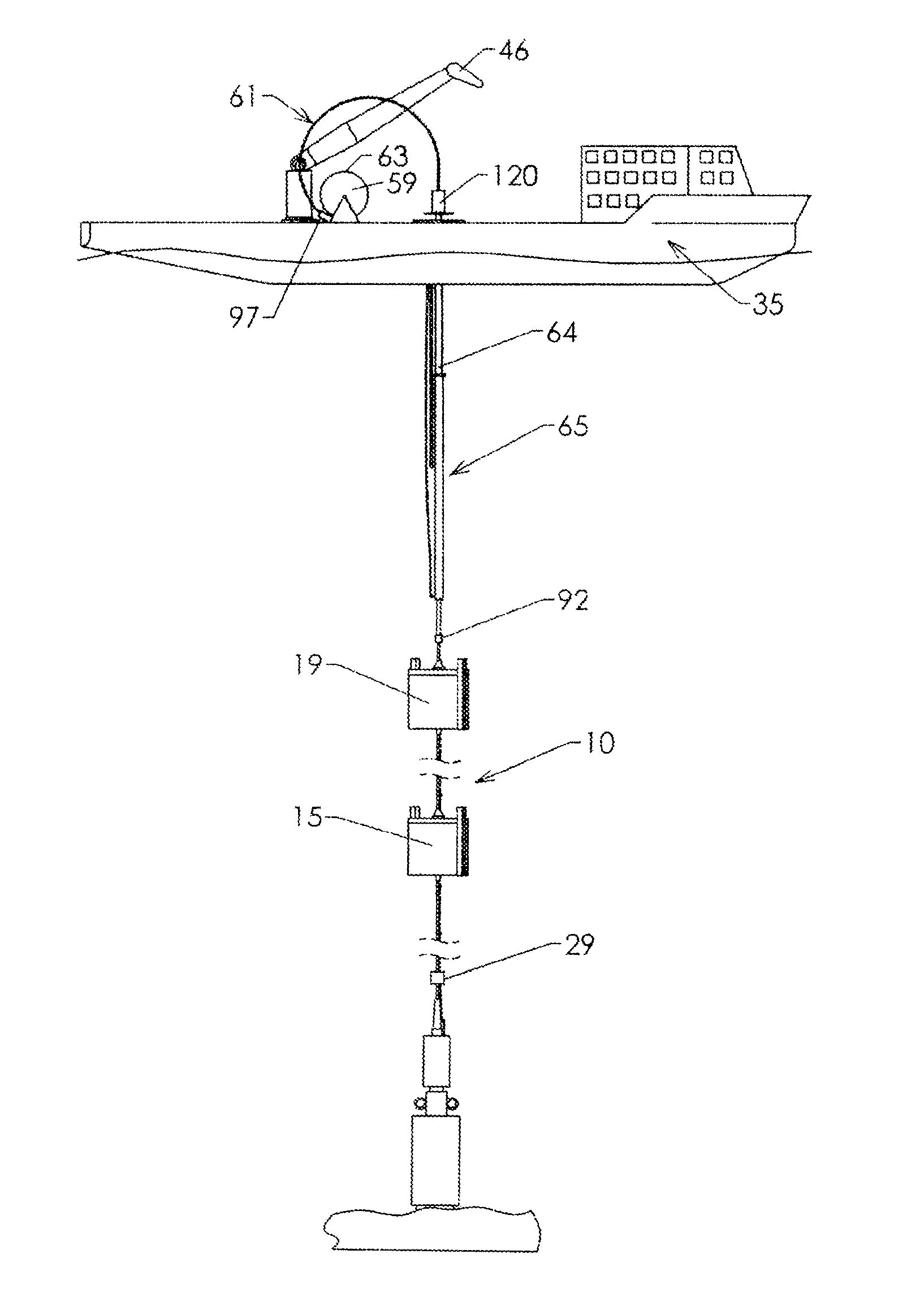

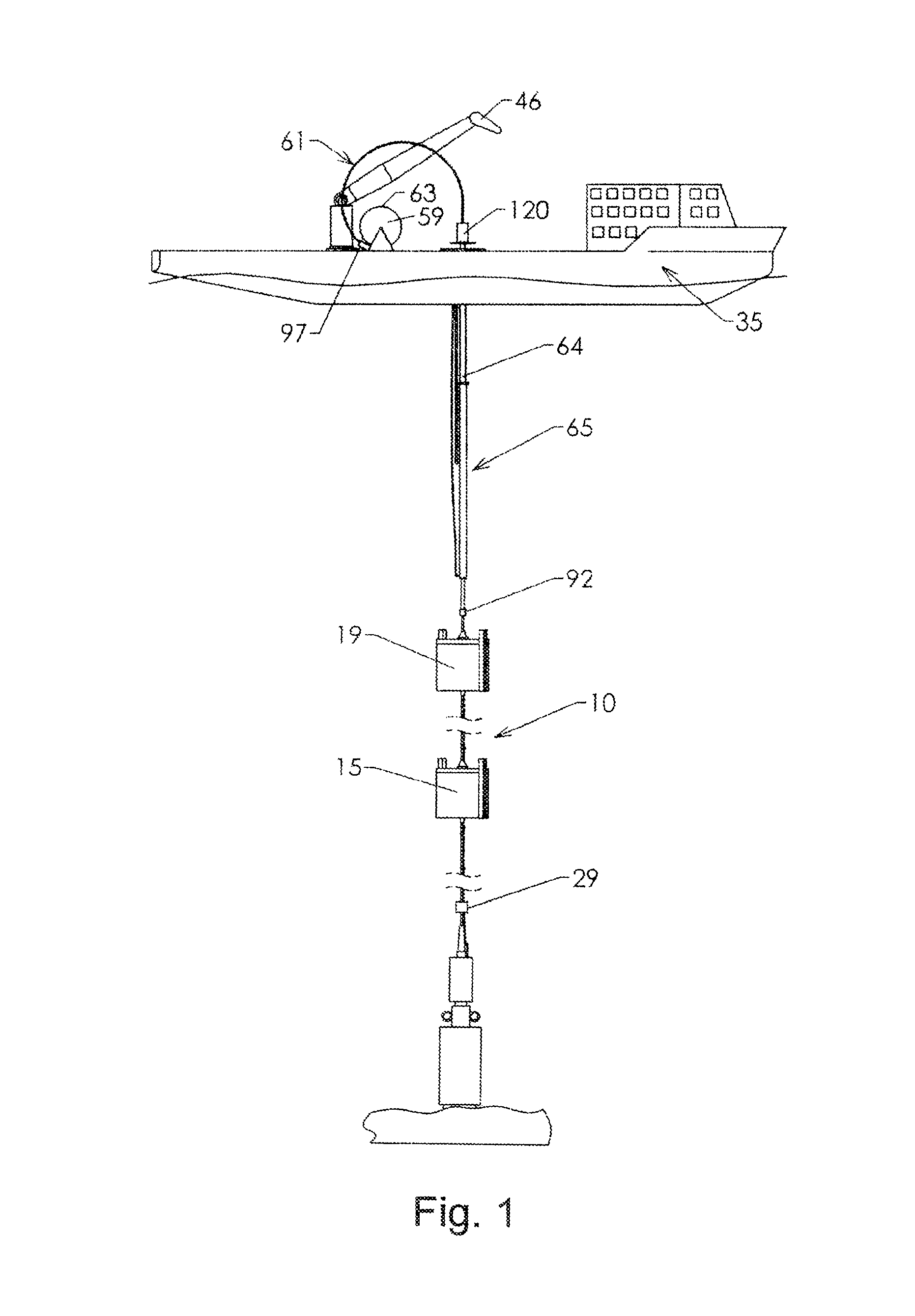

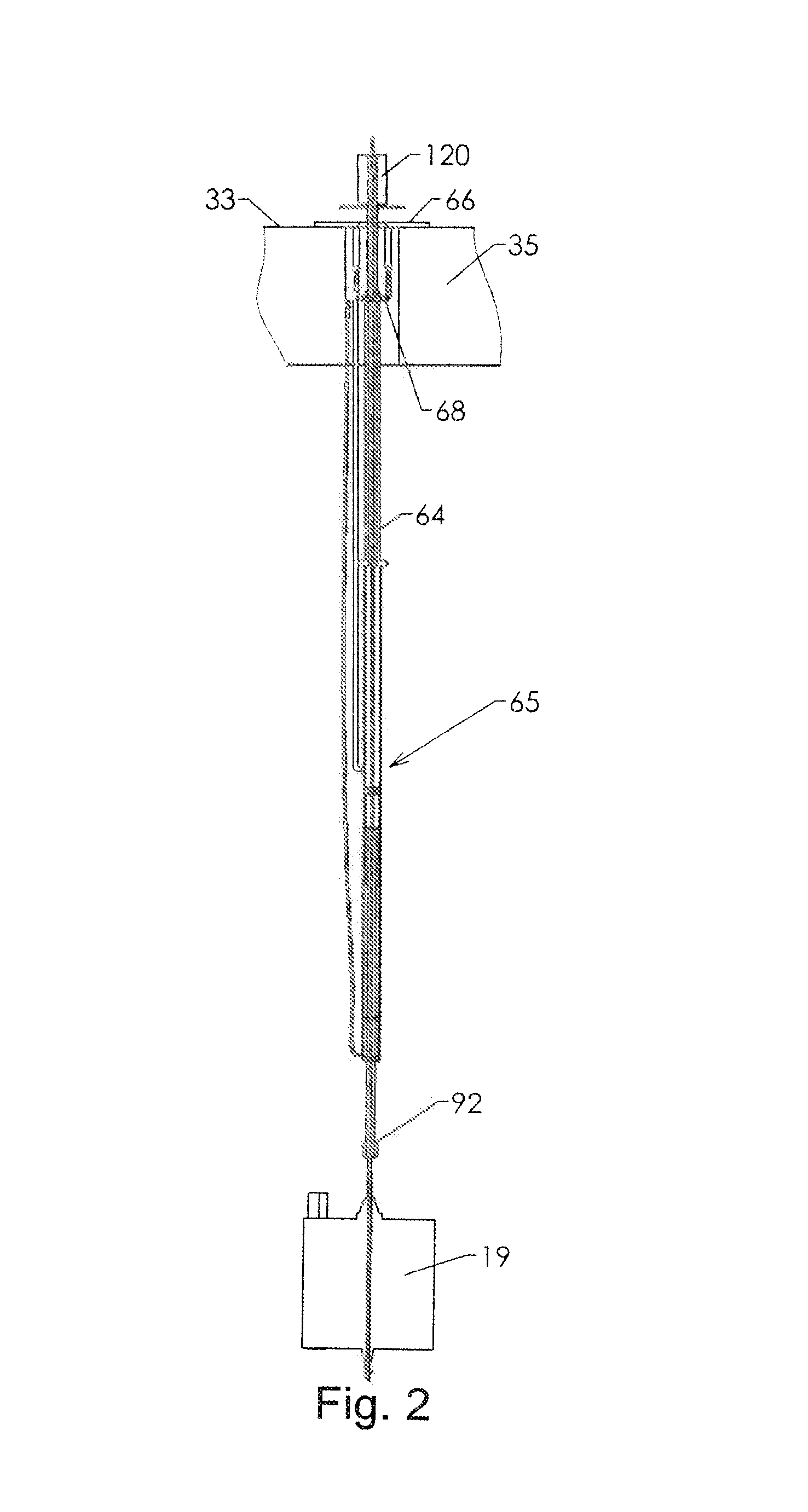

[0011]Referring to FIG. 1, reference is made to Ser. No. 12 / 714,919 and the drawing therein for a more detail description, a novel Riser Vessel Interface System (RVI) 60 facilitates using the SSR for downhole intervention and workover through the SSR 10 using relatively small vessels. The nature of an SSR is such that it may be relatively sensitive to the magnitude of externally applied tension and to variations in externally applied tension. It is the nature of small vessels that their motions in response to waves and swells are greater than those of larger vessels and substantially greater than the motions of platforms or floating production facilities. The interface between an SSR and a small vessel therefore requires a greater range of motion and less tension variation than is provided by the previous art. The coiled tubing injector must be supported by the vessel, and the weight of deployed tubing normally hangs from the injector.

[0012]Referring to FIG. 1, intervention vessel 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com