Metallic Wick Assembly

a technology of wick and metal wick, which is applied in the direction of combustion process, burner, combustion type, etc., can solve the problems of inconvenient and wasteful, easy loosening of cotton wick at the terminal end, and users' only being able to replenish fuel or replace a new wick, so as to reduce manufacturing costs, easy and fast assembly, and the effect of reducing the number of wicks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

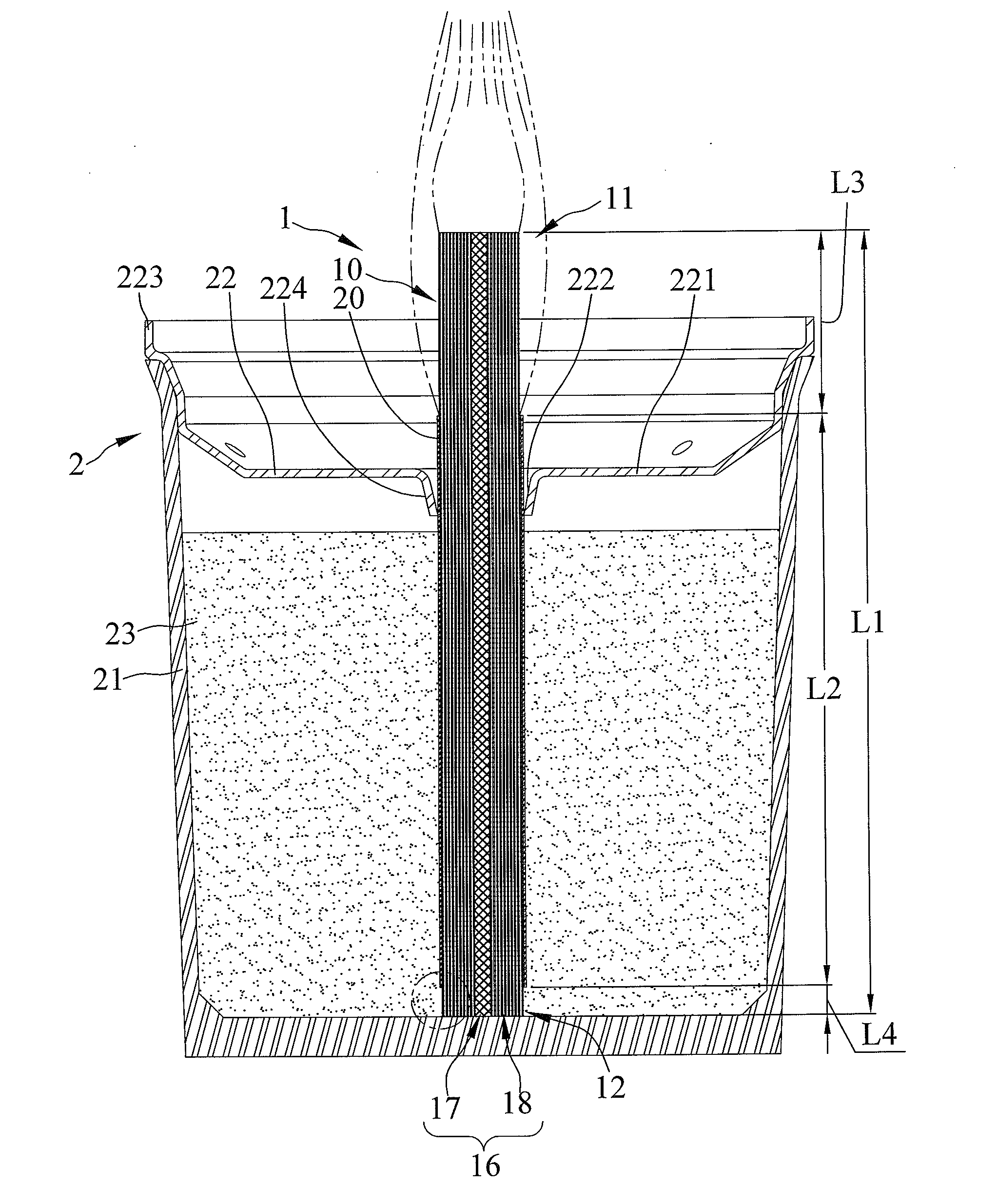

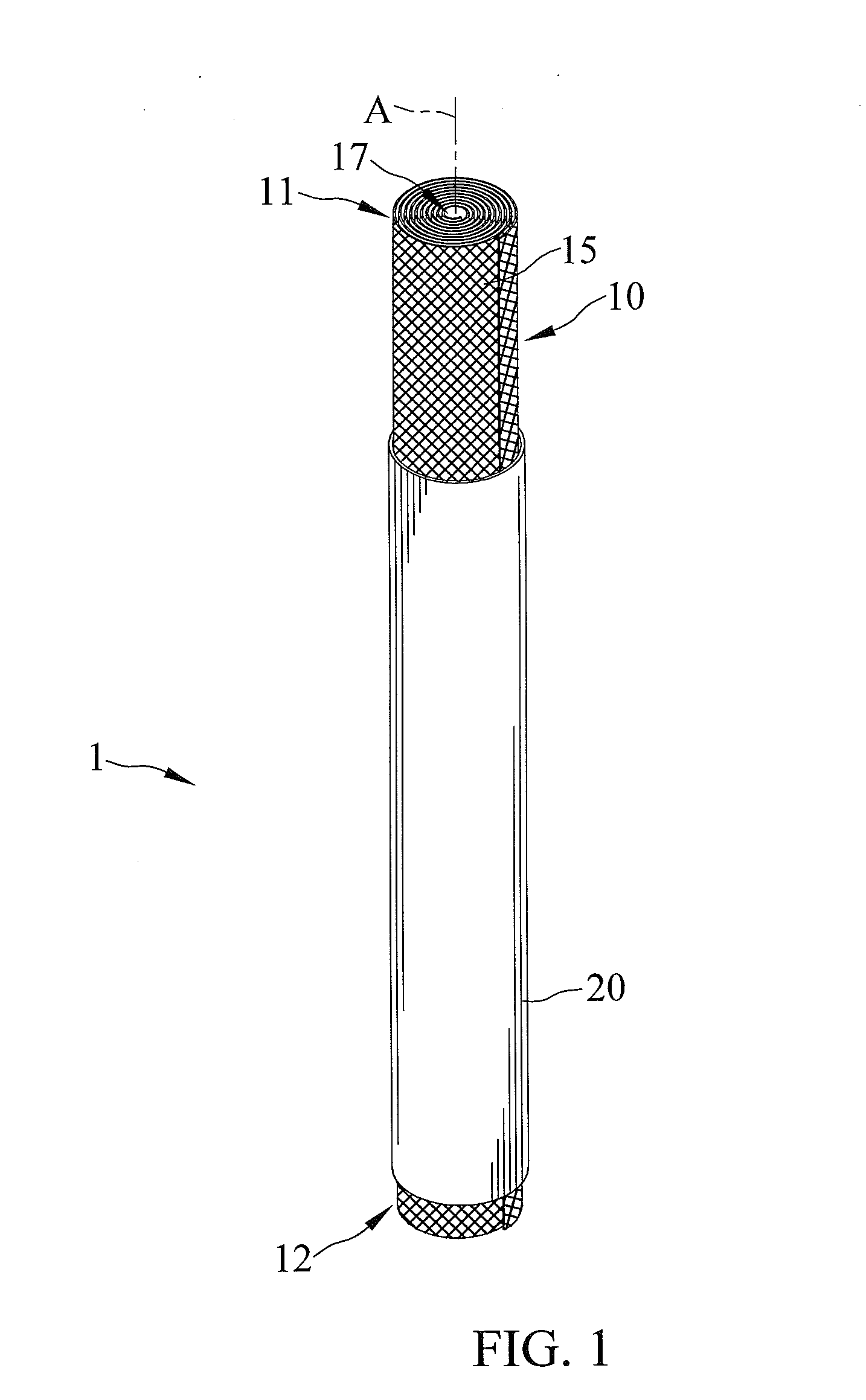

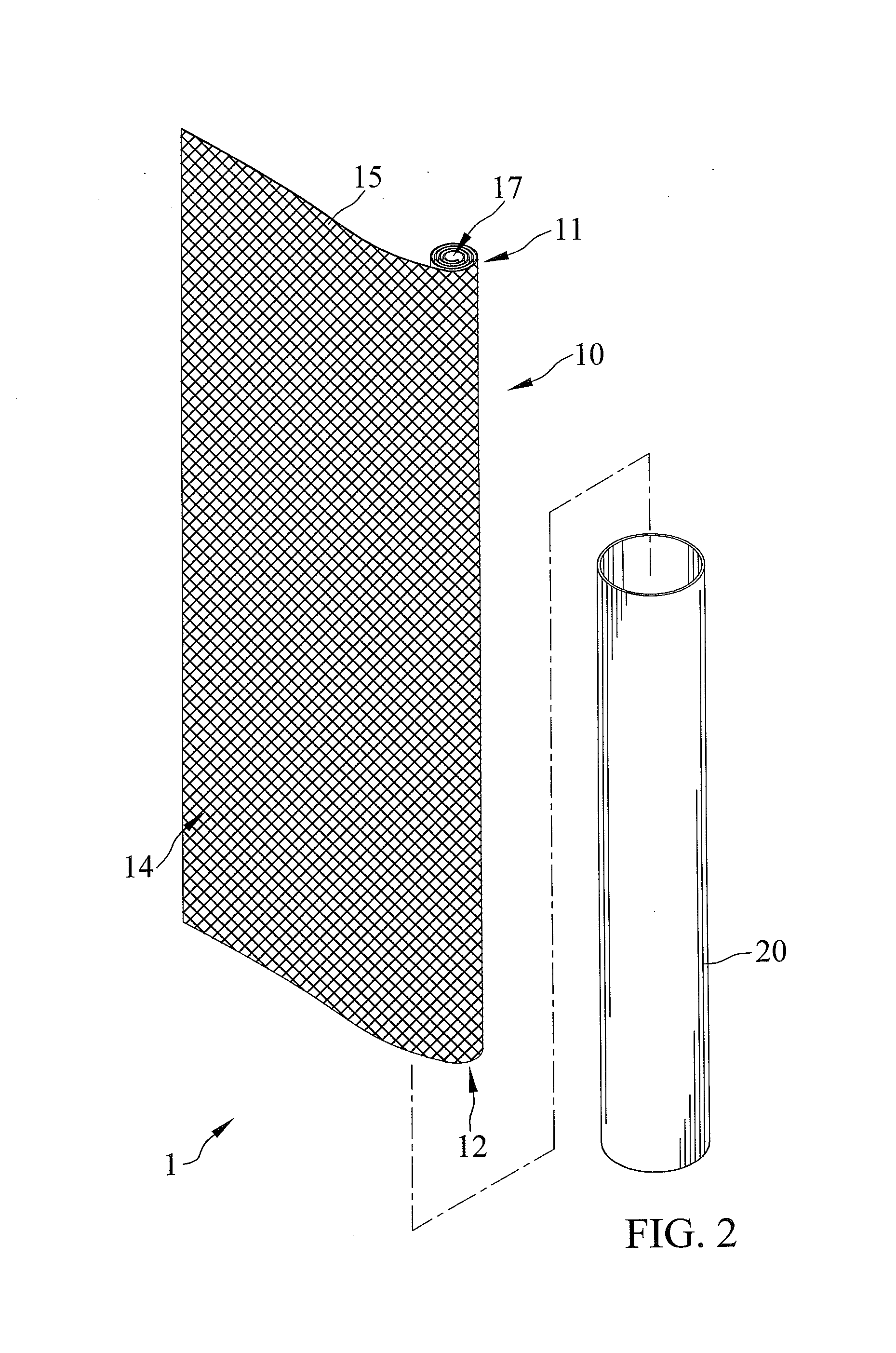

[0057]FIGS. 1 through 3 show a first embodiment of a metallic wick assembly according to the present invention shown in the drawings. The metallic wick assembly 1 generally includes a mesh member 10 and a sleeve member 20 mounted around the mesh member 10. The mesh member 10 is rolled into a tubular shape and having a plurality of circles spaced from each other along a longitudinal axis A to form an Archimedean spiral cross-section perpendicular to the longitudinal axis A. The mesh member 10 includes first and second ends 11 and 12 disposed opposite to each other along the longitudinal axis A, and first and second surfaces 13 and 14 respectively extended from the first end 11 to the second end 12 thereof and arranged opposite to each other. Furthermore, the mesh member 10 essentially includes a plurality of metallic wires interlacing and overlapping each other to form into a plurality of meshes 15 penetrating the first and second surfaces 13 and 14 between the first and second ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com