Exhaust after treatment device mode regulation

a treatment device and exhaust mode technology, applied in the direction of exhaust treatment, electrical control, mechanical equipment, etc., can solve the problems of increasing the back pressure of the exhaust, oxidising the carbon based soot and burning it off, and heating the air intake requires additional fuel, so as to achieve the effect of regulating more precisely and efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

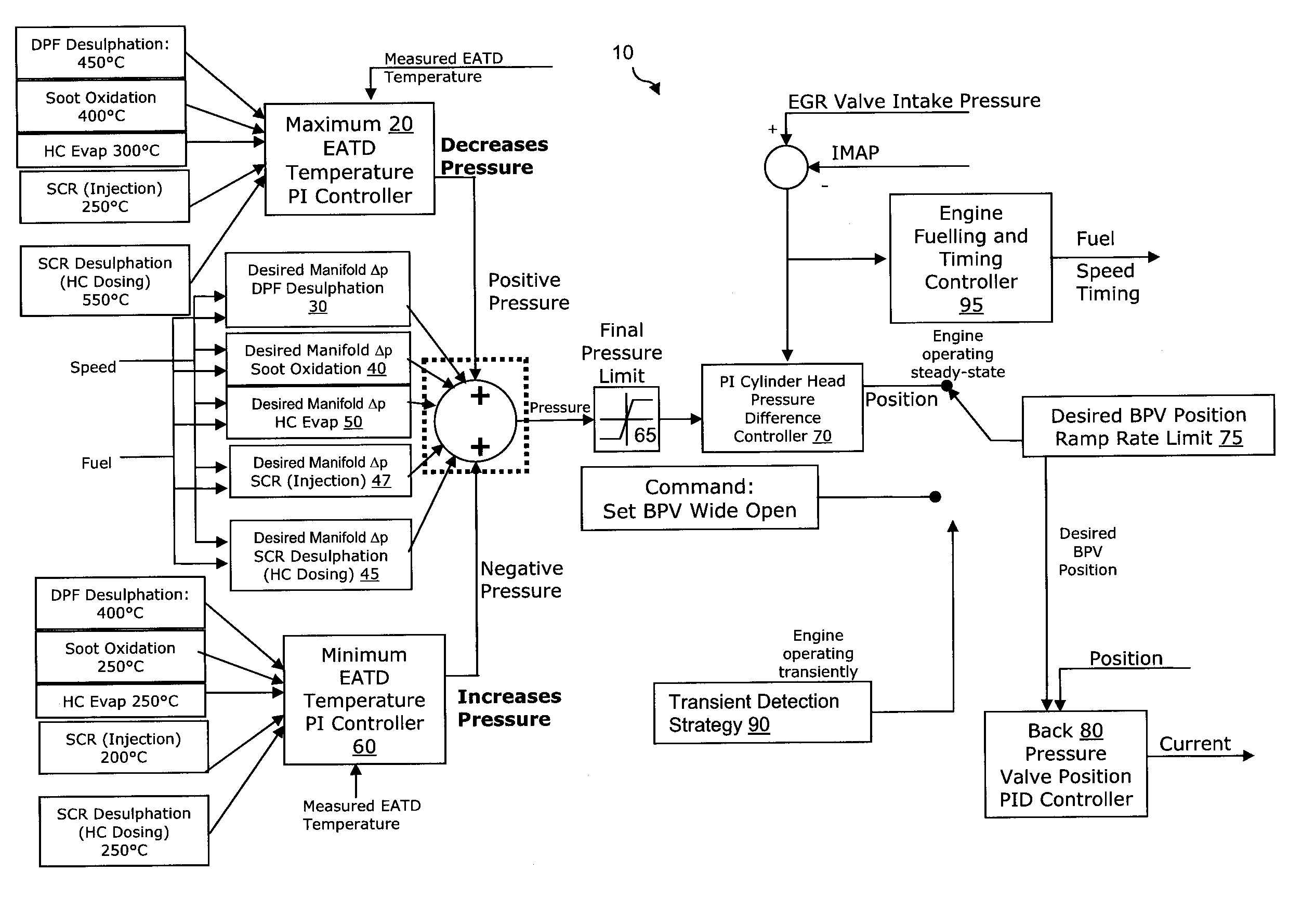

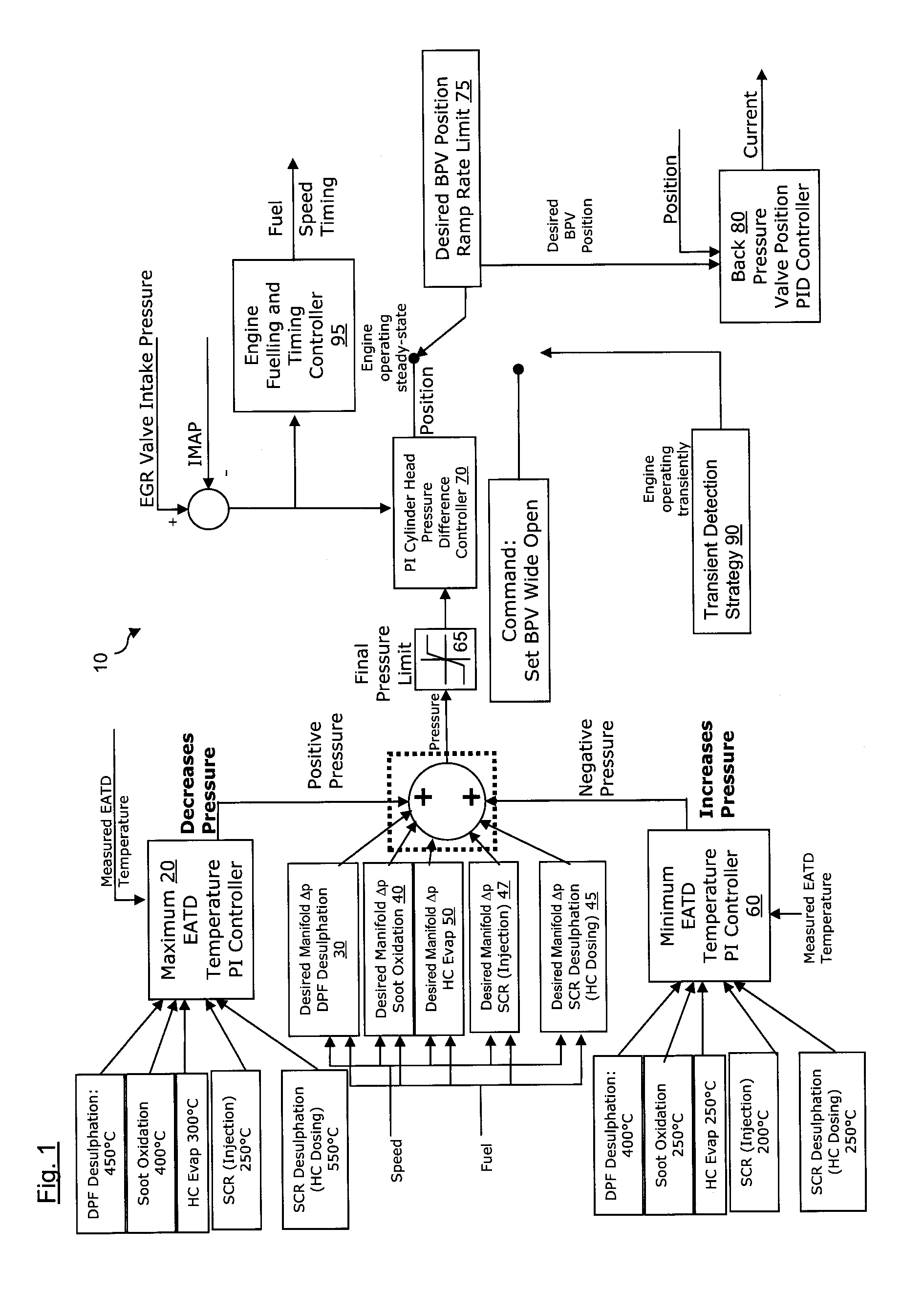

[0017]Exhaust after treatment devices (EATD) may have several modes of operation including warm-up modes, normal operation modes and regeneration modes. Various parameters may be used to determine when and how to change an EATD mode. For example, a soot sensor may detect when too much soot has built up on a diesel particulate filter (DPF), which is one type of EATD. A differential pressure sensor across the DPF may also be used to determine if the DPF has become clogged and requires regeneration. Regeneration of an EATD may occur during periods of high engine load, which consequently result in elevated exhaust temperatures. However, should the EATD require regeneration during extended idle periods or when the engine is not under load, as detected by monitoring engine speed and fuel delivery, for example, then this information may be used to arrive at a decision whether or not to assist in the regeneration process and so change the EATD mode from normal operation mode to one of perha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com