Latching Cargo Stake

a cargo stake and cargo technology, applied in the field of cargo stakes, can solve the problems of inconvenient attachment of stakes in the middle of the bed, and the loss of attachment hardware such as removable pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

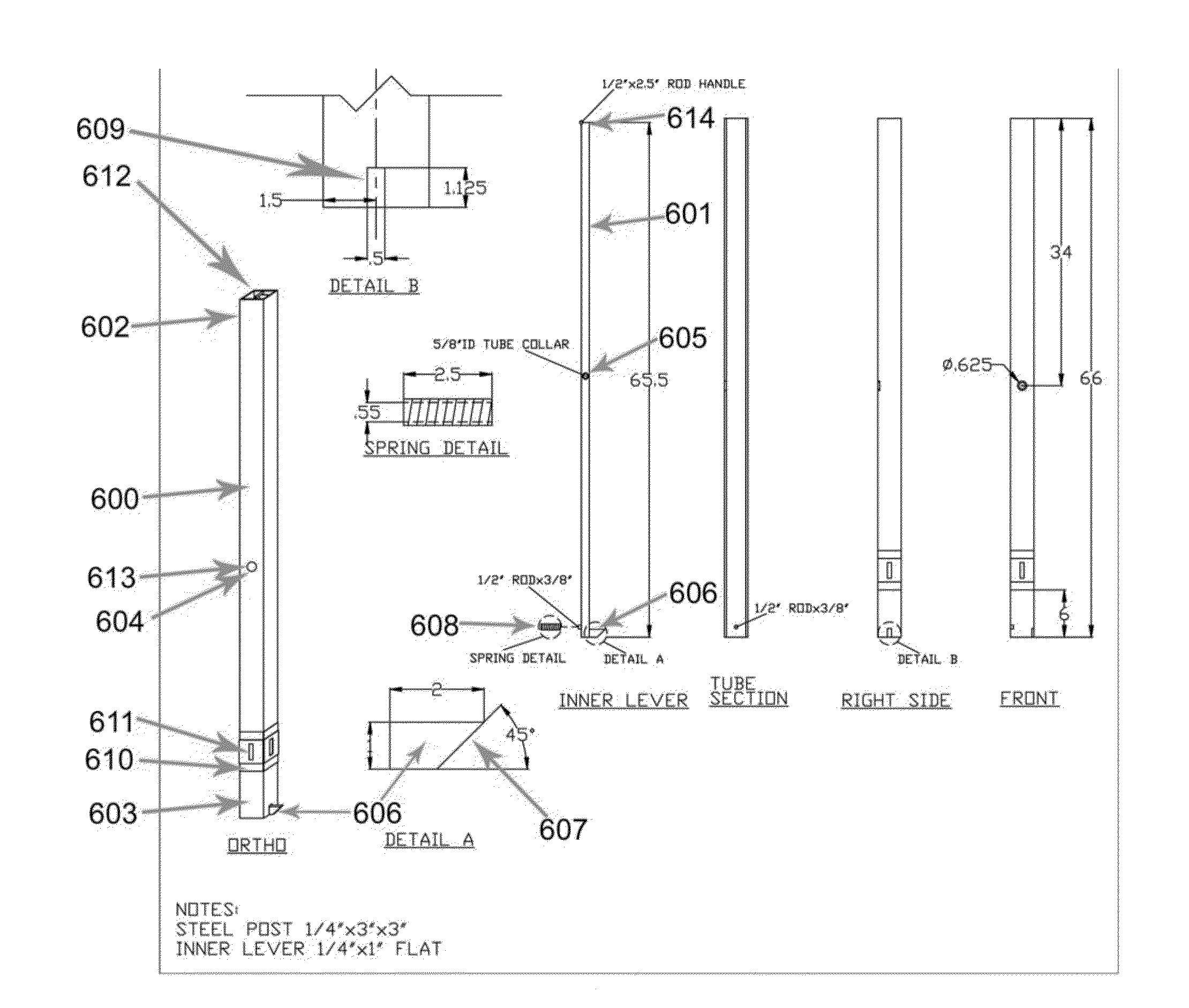

[0018]FIG. 6 is a mechanical drawing of a preferred embodiment of the present invention, where an integral latching mechanism is used to affix the cargo stake in an existing standard stake hole. Assembled cargo stake 601 contains latch lever 601 which runs internally from stake top 602 to stake bottom 603, pivoting at pivot point 613 comprising pivot hole 604 and ⅝″ ID tube collar 605. Latching member 606 is mounted at the bottom end of lever 601 and protrudes from stake 600 in the installed state, engaging (for instance) the bottom edge of the box steel tubing portion of a typical stake hole, or engaging a pin or bolt hole that might exist within an existing stake hole. Beveled surface 607 on latching member 606 contacts the edge of any standard 3″ stake hole into which stake 600 is inserted, and insertion force acts to compress spring 608 during installation, allowing latch tooth 607 to momentarily retract into slot 609.

[0019]Once stake 600 is inserted all the way into a stake hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com