Method for electrically conductively connecting a contact piece to an electrical conductor, and corresponding arrangement

a technology of electrical conductor and contact piece, which is applied in the direction of non-electric welding apparatus, manufacturing tools, and conductors, etc., can solve the problems of deficiency and problems when placing contact parts on the conductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

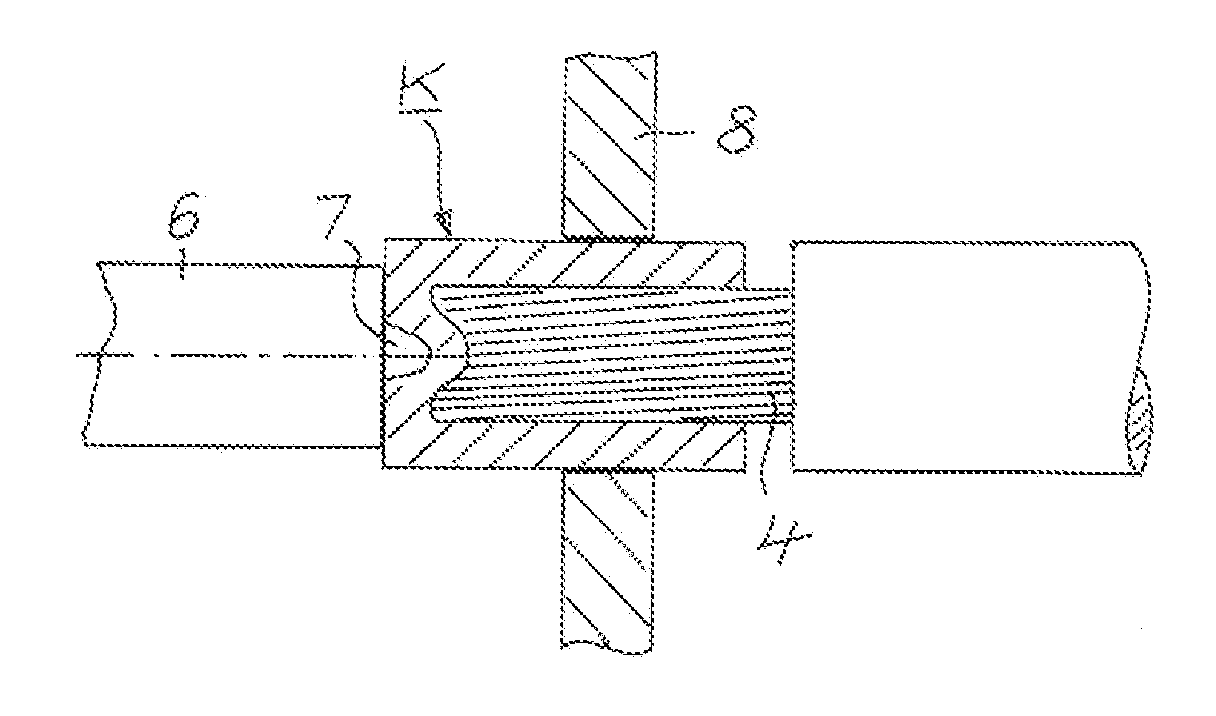

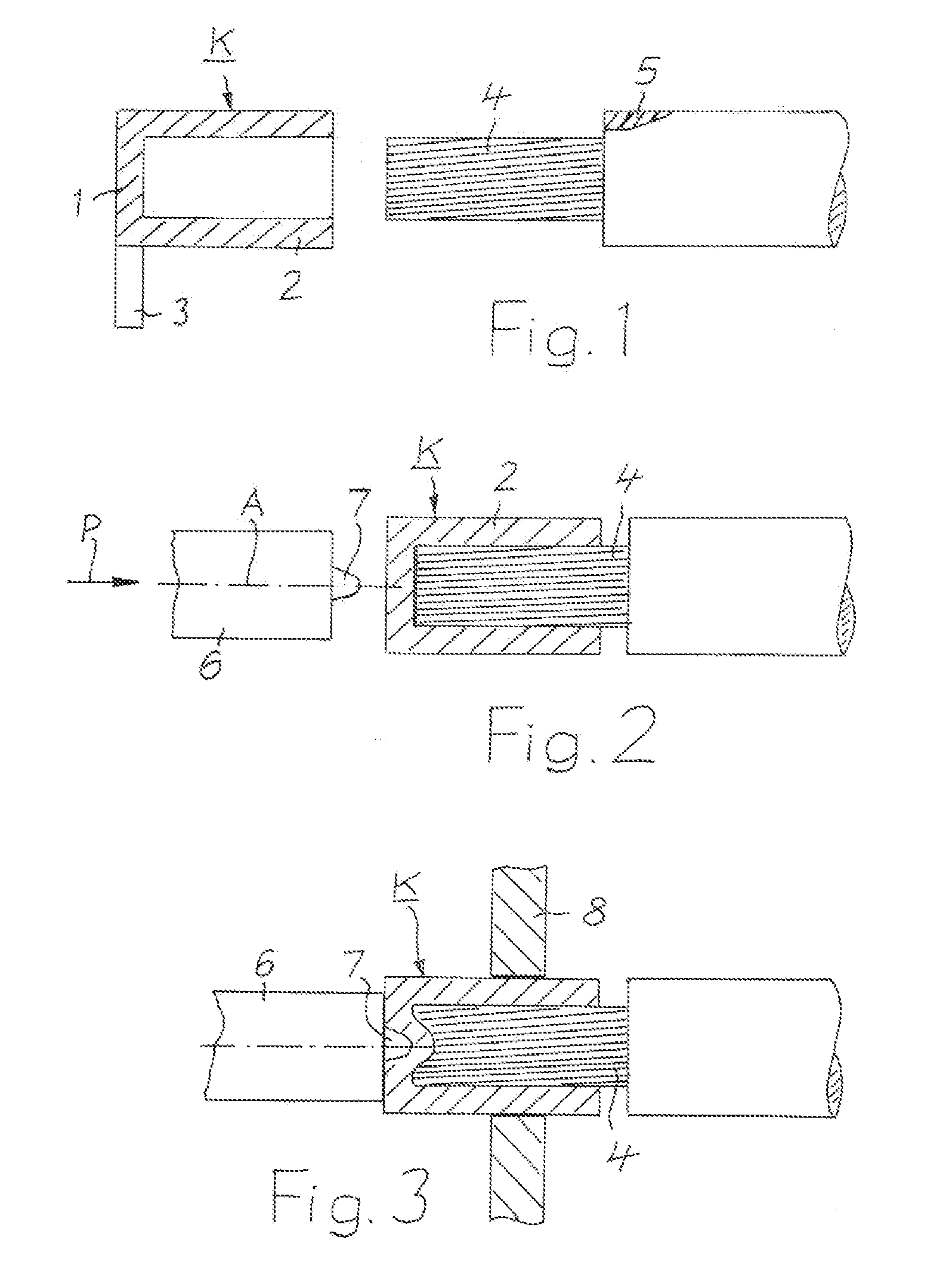

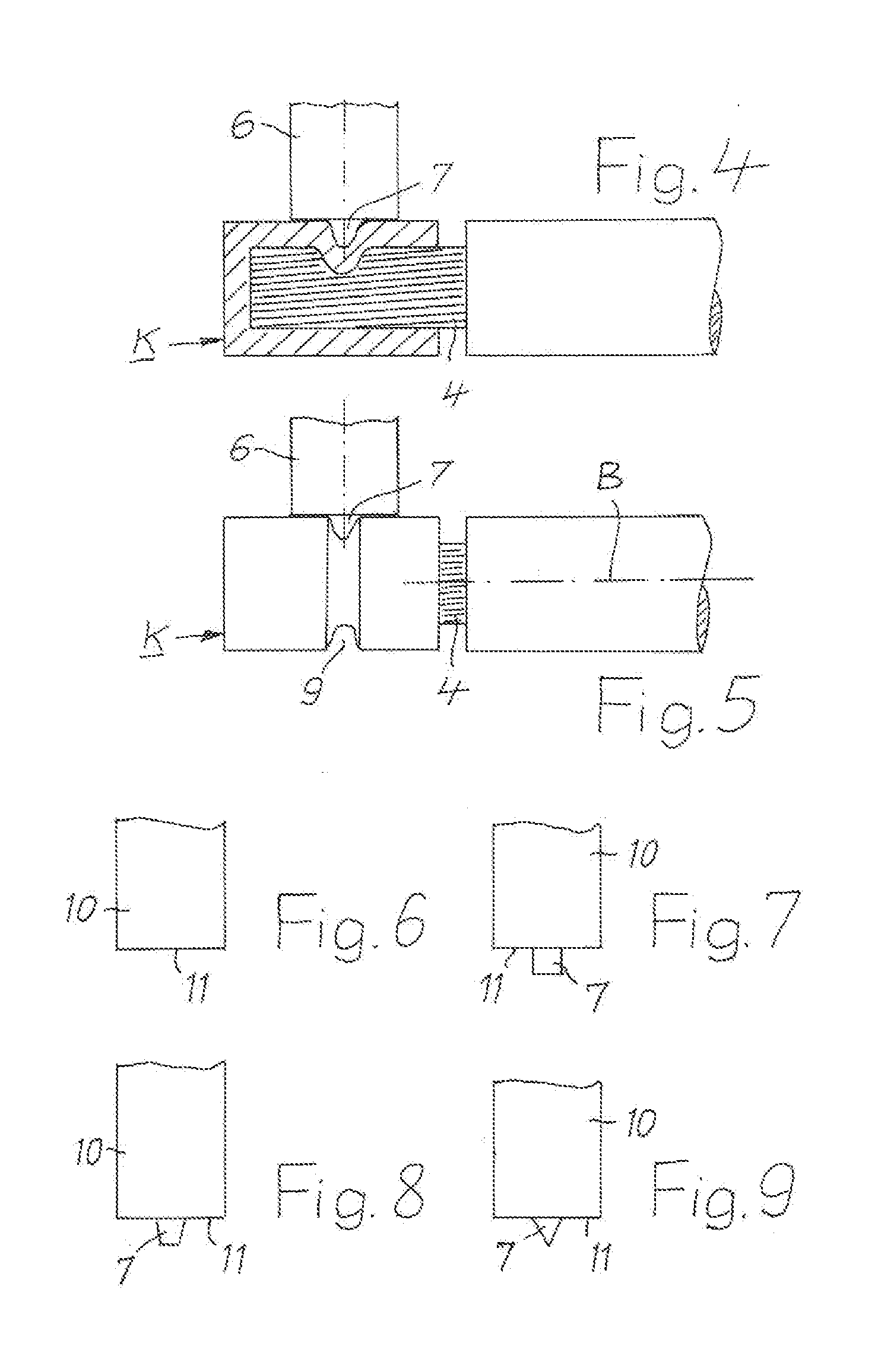

[0028]The method according to the invention is a welding method, wherein the increased temperature required for welding is produced by friction. The method can also be called “friction stir welding” and has the effect that the aluminum of the conductor integrally connects with the copper of the contact part at a temperature that is lower than the welding temperature, caused also by the pressure applied by the tool and the deformation work applied as a result. Consequently, the tool applied in this manner has correspondingly a friction surface by means of which it can be pressed against the contact part with sustained pressure, or is pressed into the wall of the contact part. The friction surface must be constructed in such a way that the wall of the contact part is not damaged during operation of the tool and in particular does not break through. A protrusion can protrude from the end face of the tool which serves as the friction surface, wherein the protrusion can be arranged symme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com