Directional Drilling Tool

a drilling tool and directional technology, applied in the field of oil and gas exploration, can solve the problems of affecting the drilling operation, and involving a significant amount of non-drilling time (ndt) in any drilling operation, and achieve the effect of a wide range of angle adjustmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

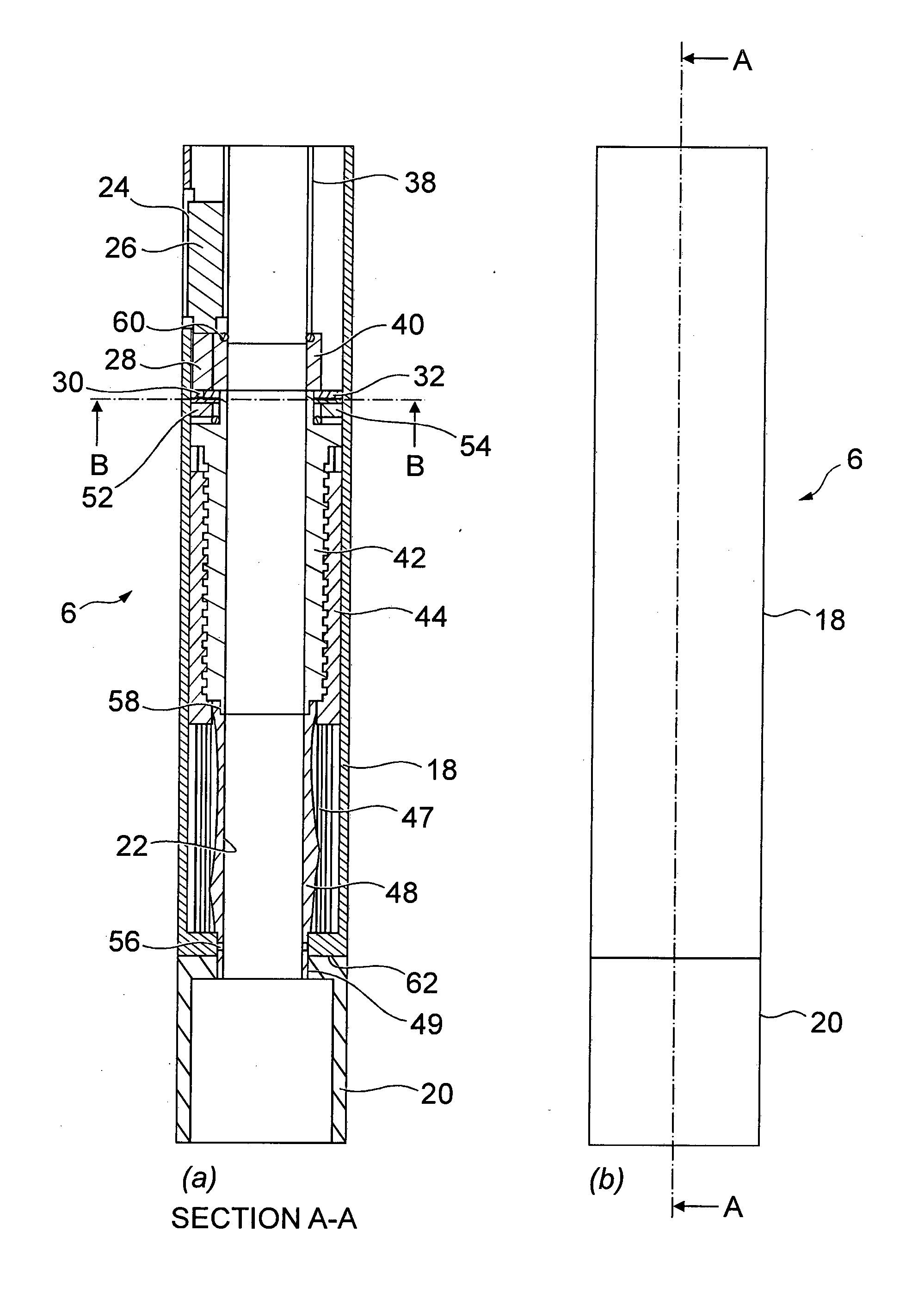

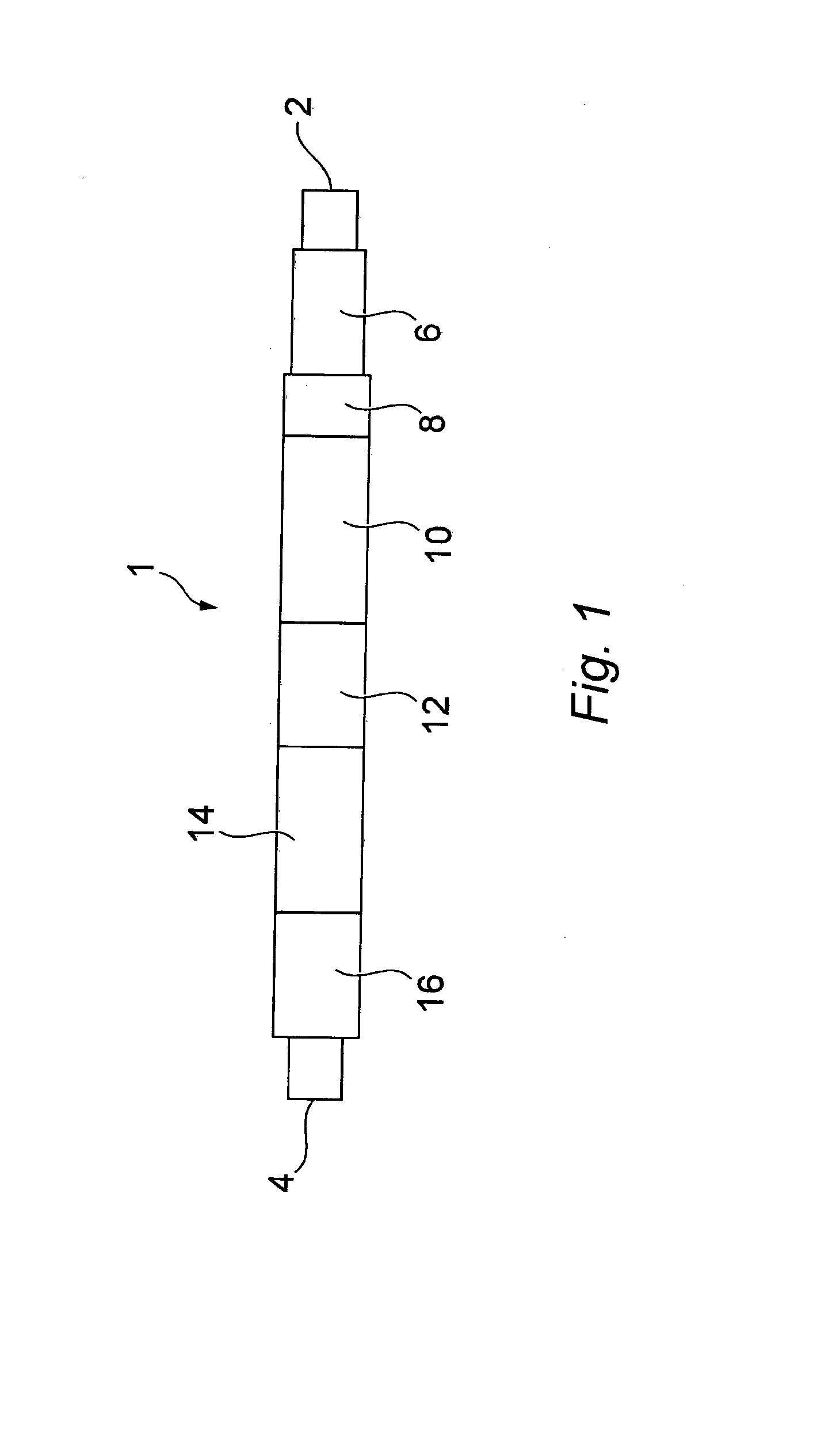

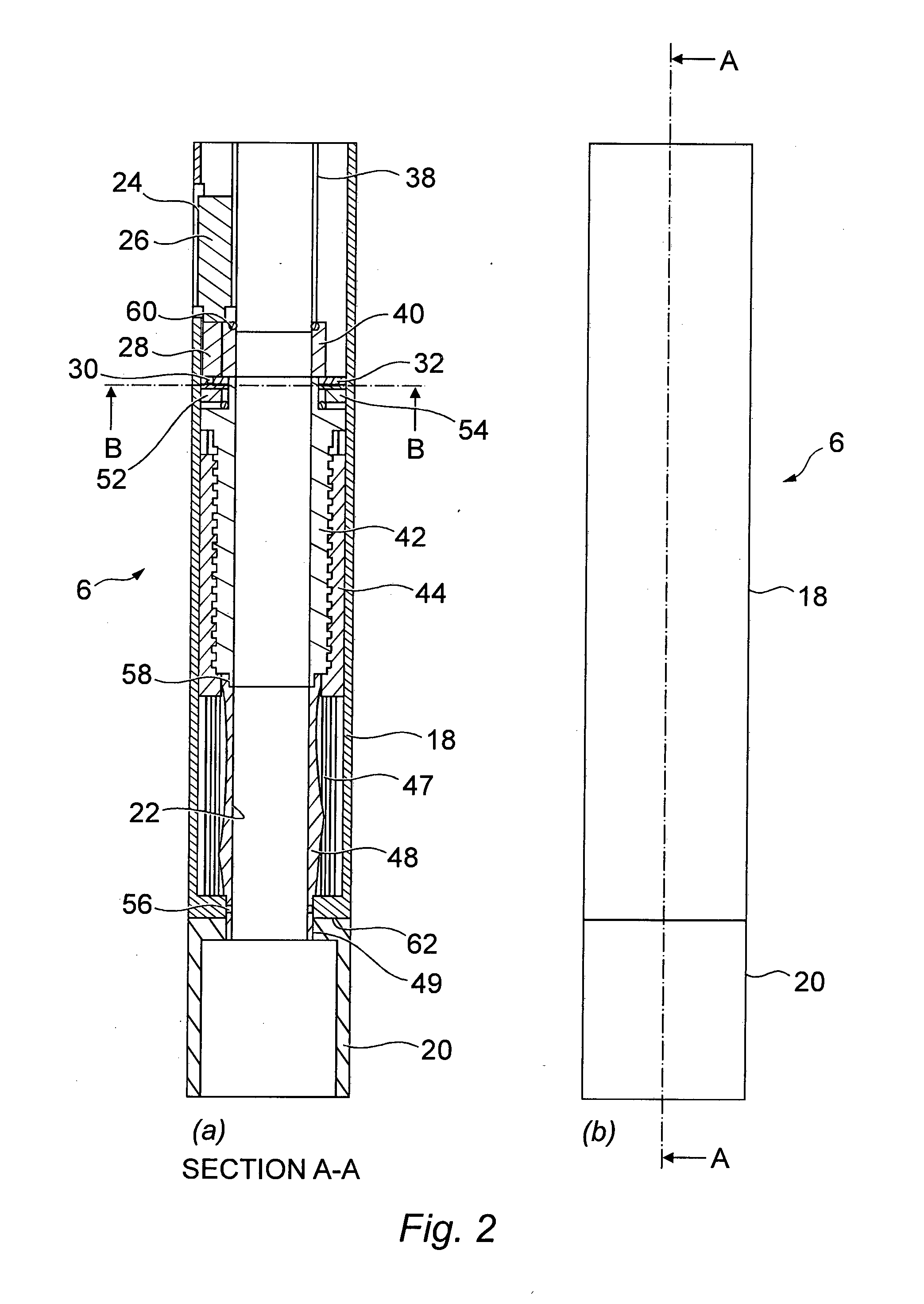

[0058]FIG. 1 schematically shows a directional drilling tool according to the present invention. The drilling tool, generally designated 1, comprises a first or upper end 2 connectable to a drill string (not shown) and a second or lower end 4 connectable to a drill bit (not shown in FIG. 1). The tool 1 further comprises a motorised swivel 6 having a first swivel member non-rotatably attached to the first end 2 and a second swivel member attached to the remainder of the tool 1. As will be explained in more detail below, the first and second swivel members may be selectively rotated relative to one another so as to rotate the tool 1 relative to the drill string.

[0059]Below the swivel 6, the tool 1 further comprises a dump valve section 8 and a power section 10, both of which are of a type known in the art. Below the power section 10 is an adjustable bend section, also known as a bent sub, 12 having a first bend member attached to the power section 10 and a second bend member attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com