Hydraulic pump for excavator and excavator comprising the same

a technology of hydraulic pump and excavating shaft, which is applied in the direction of pump components, positive displacement liquid engines, machines/engines, etc., can solve the problems of reducing the wear of the housing itself and prolonging the service life of the hydraulic pump, so as to reduce the vibration of the driving shaft, prolong the service life, and reduce the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Illustrative embodiments of the invention will be described with reference to the drawings. It should be noted that same reference numbers throughout the drawings denote functionally and / or structurally identical elements or devices.

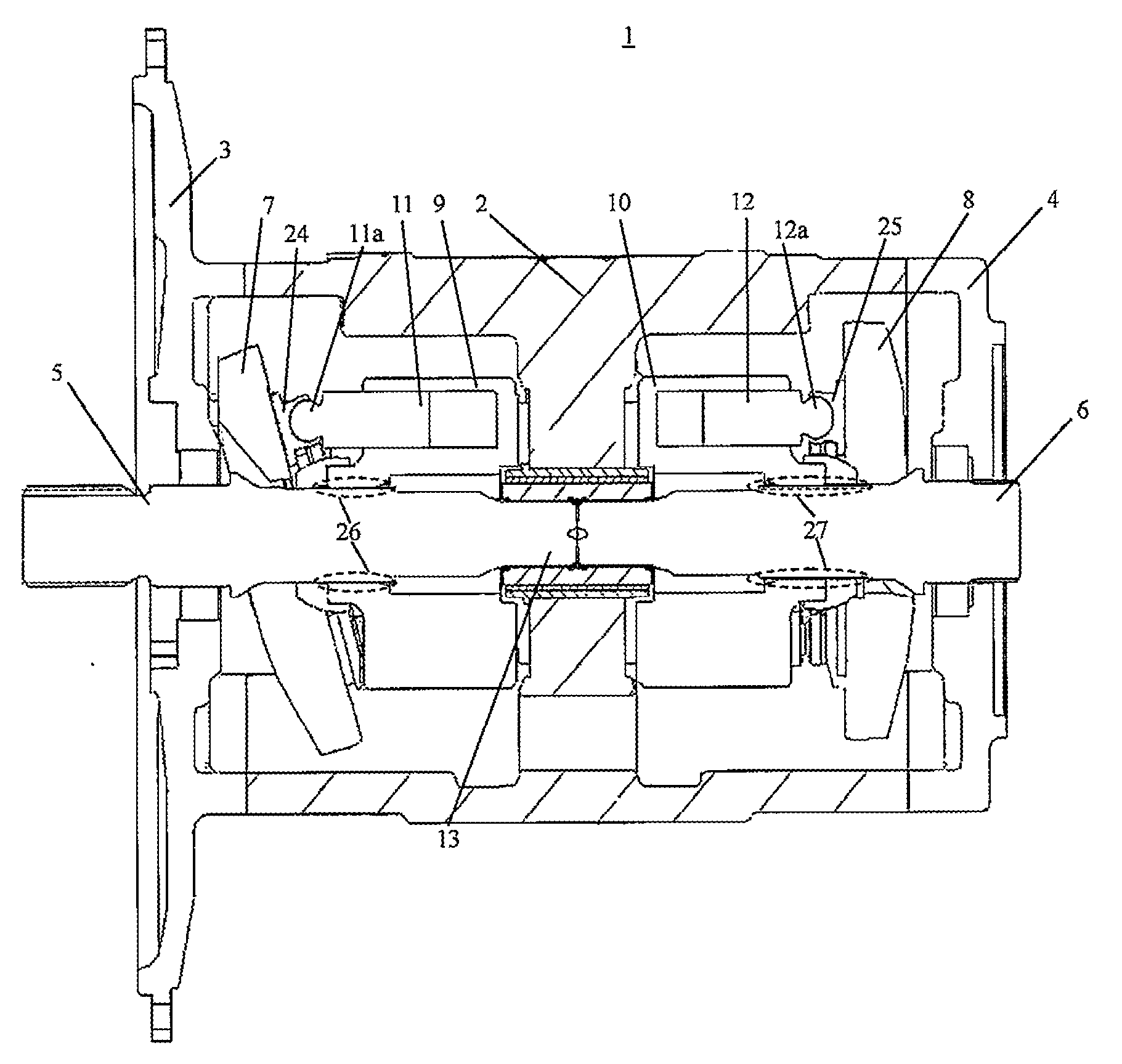

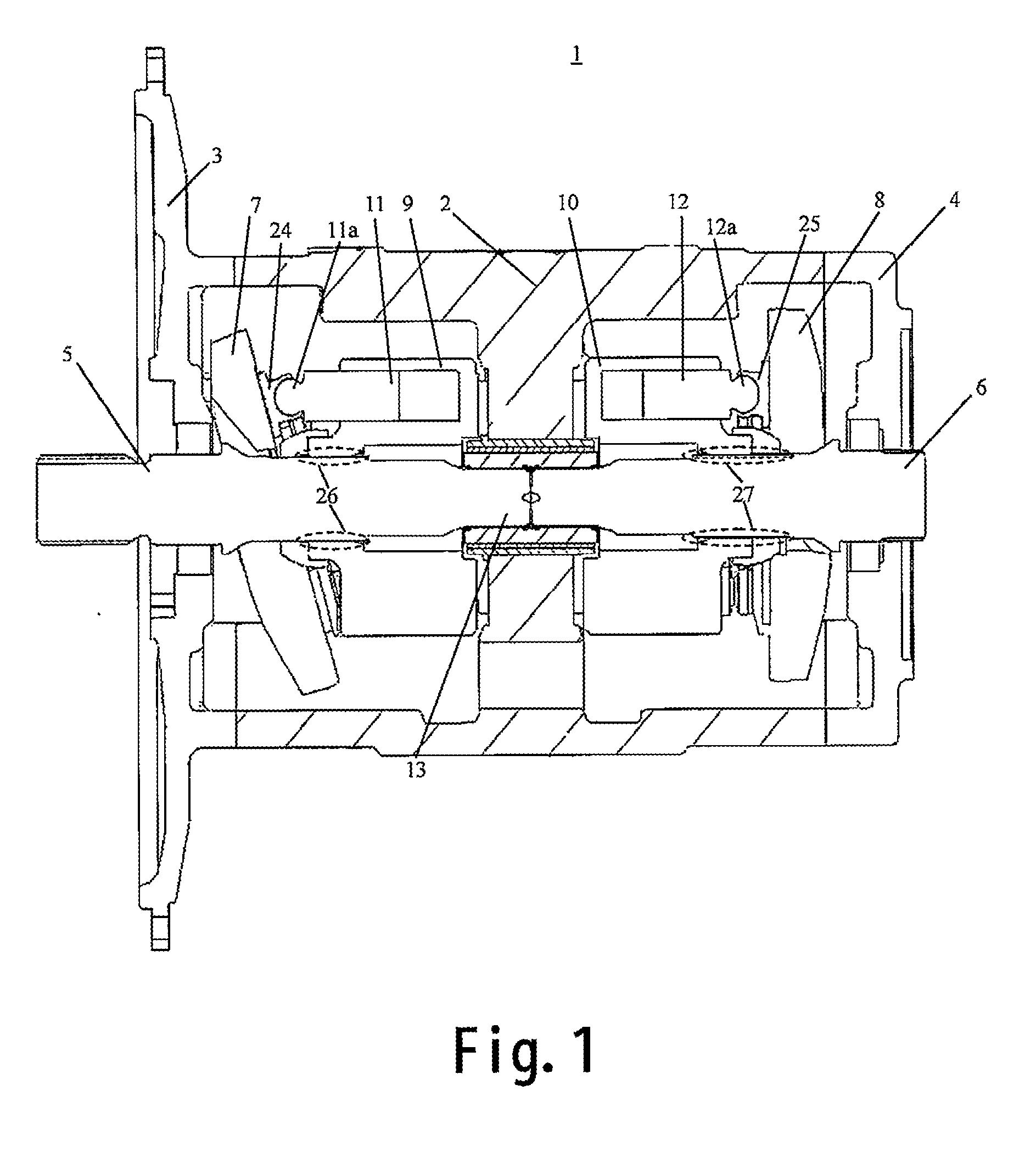

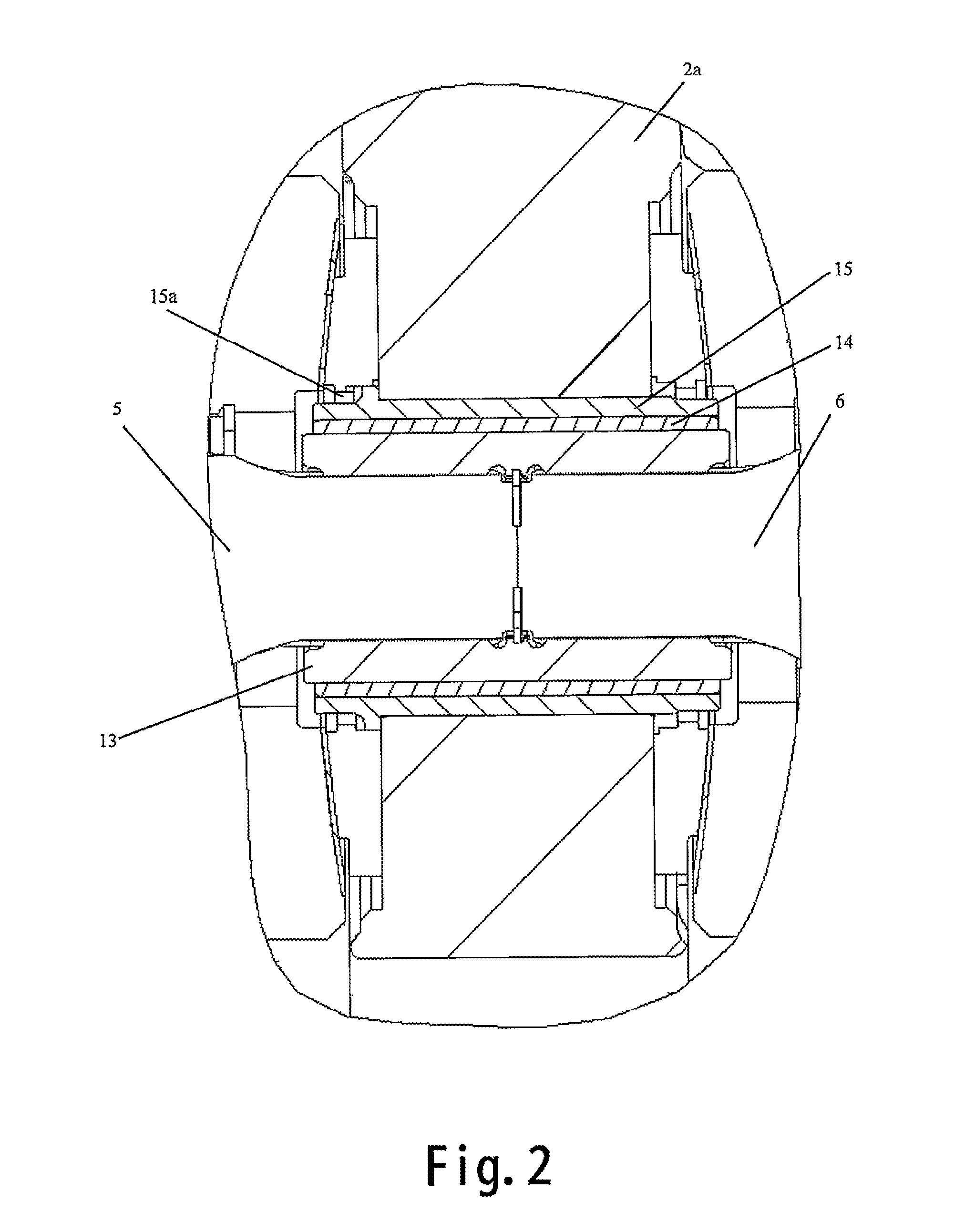

[0024]FIG. 1 shows an axial cross-sectional view of a hydraulic pump 1 according to one embodiment of the invention. The hydraulic pump according to the invention can be used in a mechanical device working in bad conditions, for example in an excavator.

[0025]As shown in FIG. 1, the hydraulic pump 1 comprises a housing 2 and end caps 3 and 4 mounted on opposite ends of the housing 2. Two spindles 5 and 6, two rotary hydraulic cylinders 9 and 10, and two swash plates 7 and 8 for driving the rotary hydraulic cylinders are provided in the housing 2. The swash plates 7 and 8 are configured for adjusting working strokes of the rotary hydraulic cylinders 9 and 10 respectively.

[0026]The two spindles 5 and 6 are disposed coaxially and are connected with eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com