Steam turbine comprising a thrust balance piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

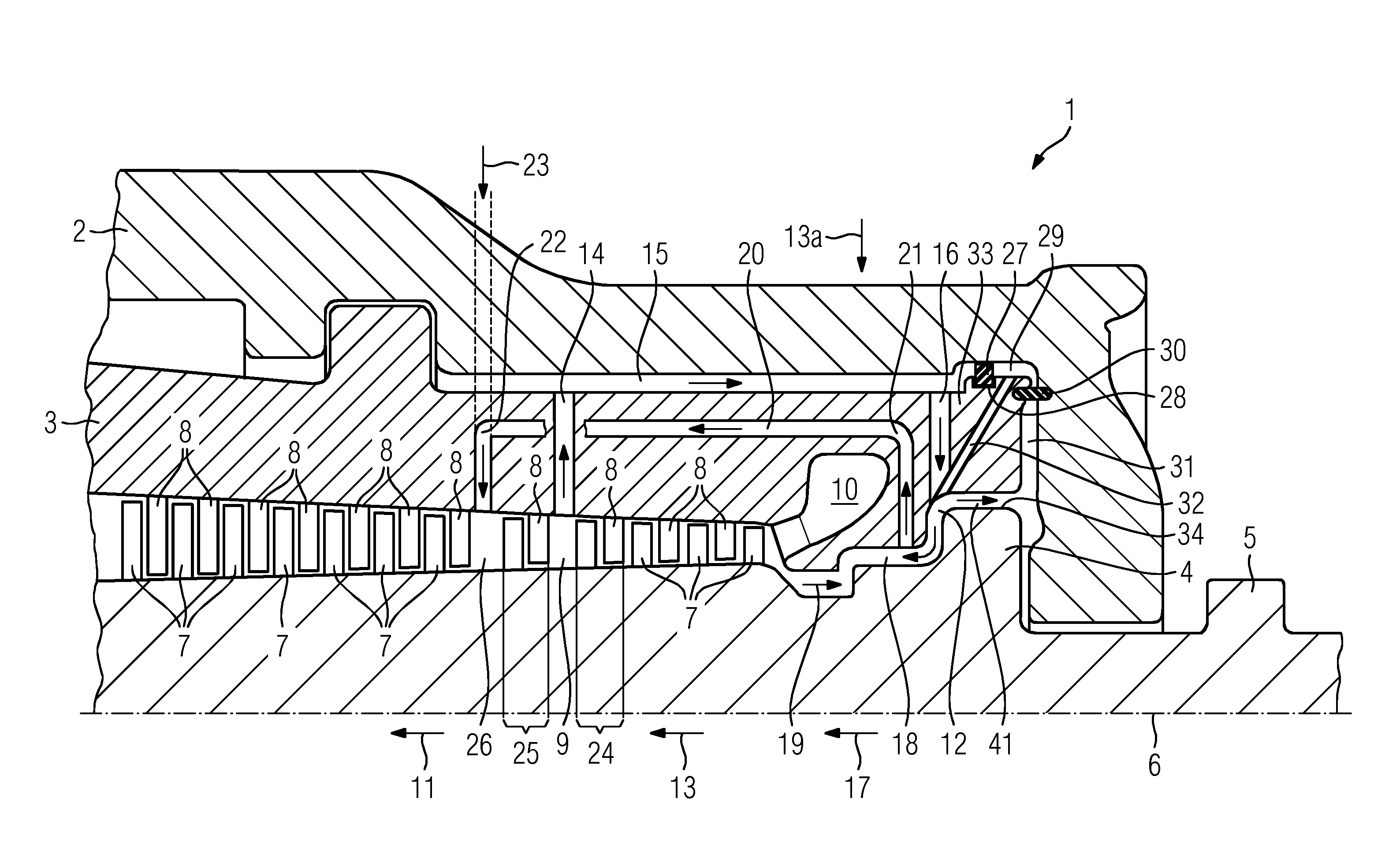

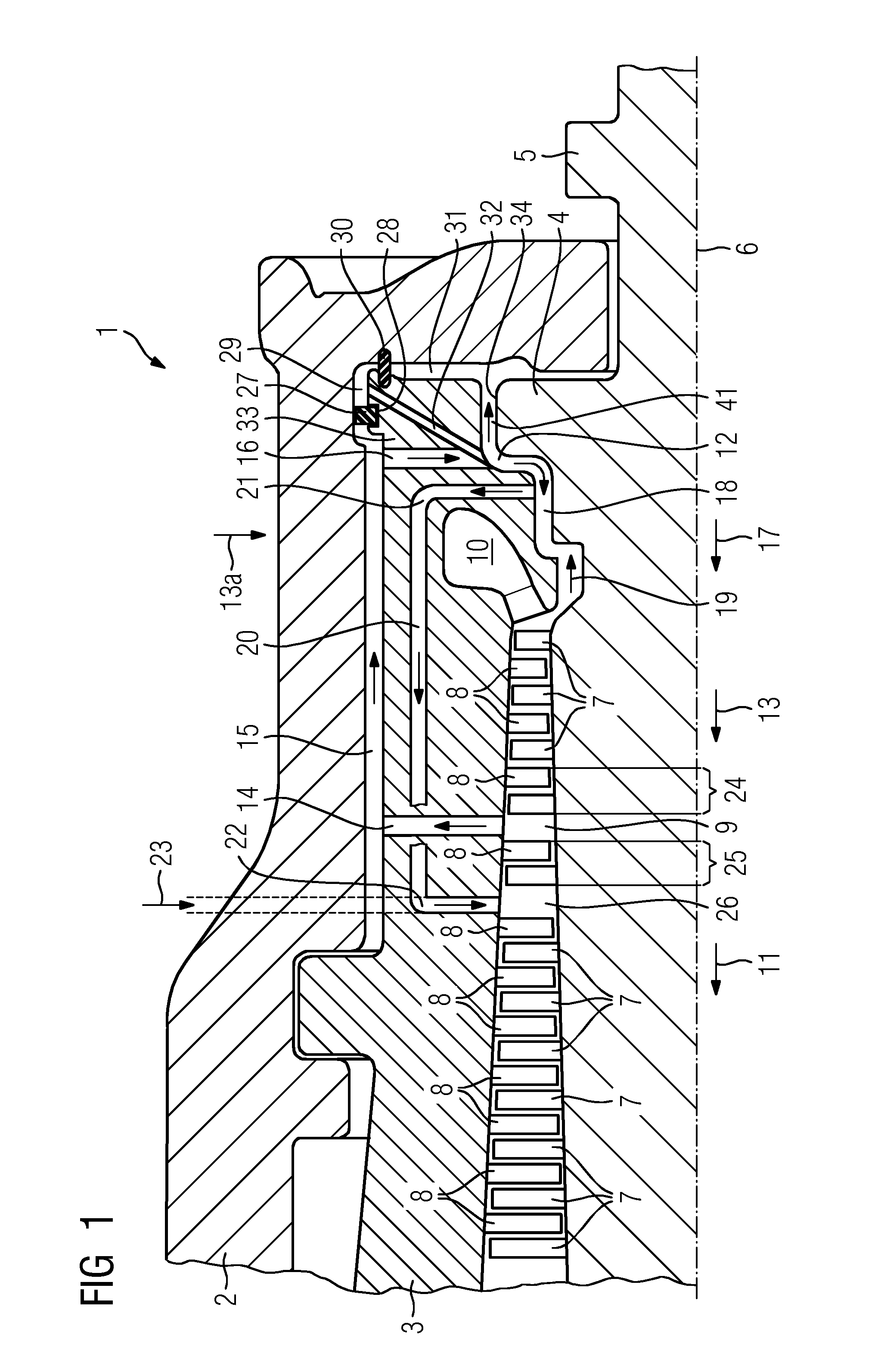

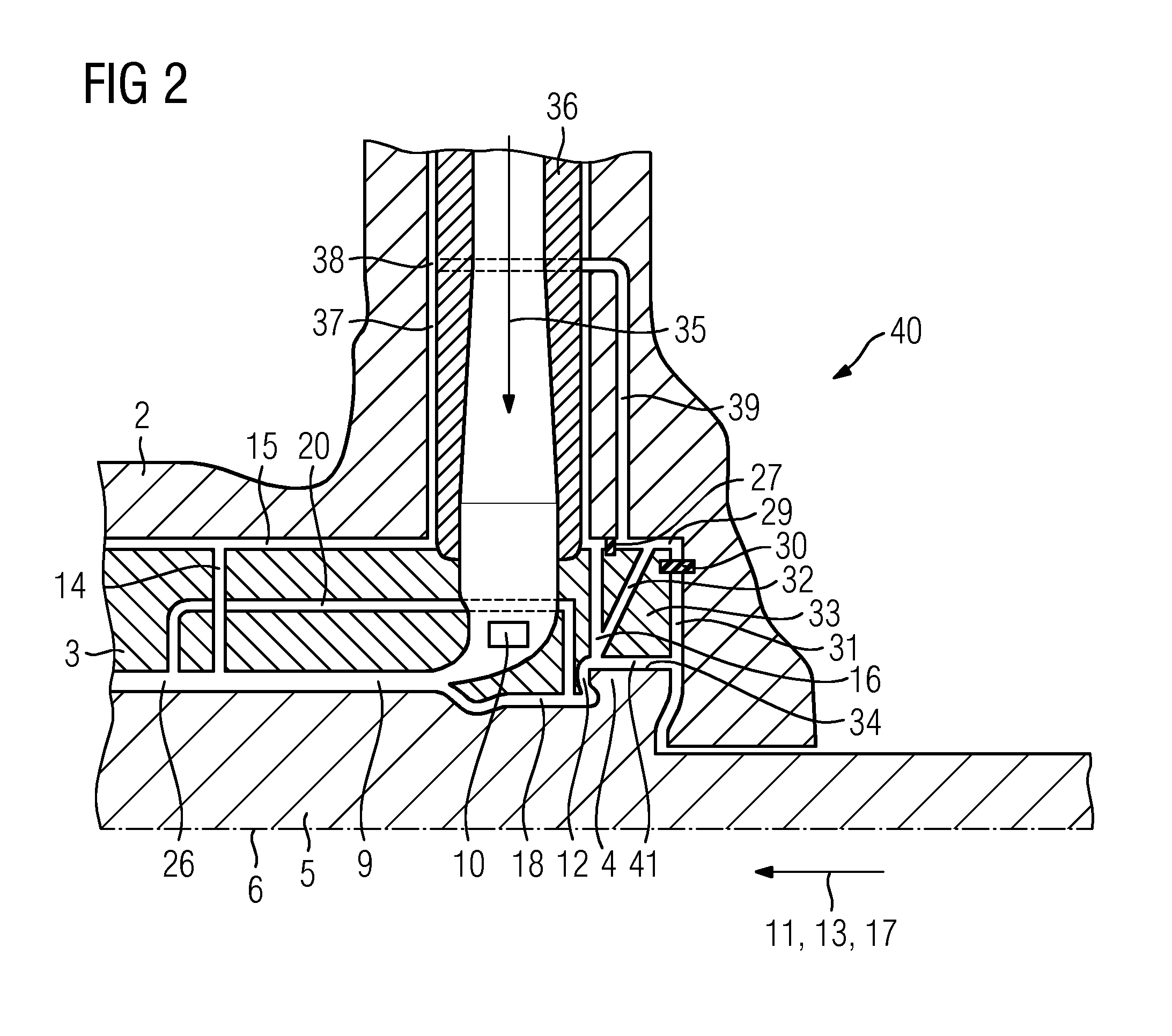

[0021]FIG. 1 shows a cross section through a steam turbine 1. The steam turbine 1 has an outer housing 2 and an inner housing 3. The inner housing 3 and the outer housing 2 have a fresh steam feed channel which is described in greater detail in FIG. 2. A rotor 5 which has a thrust compensating piston 4 is arranged in a rotationally mounted manner within the inner housing 3. The rotor is usually configured so as to be rotationally symmetrical about a rotational axis 6. The rotor 5 comprises a plurality of rotor blades 7. The inner housing 3 has a plurality of guide blades 8. A flow channel 9 is formed between the inner housing 3 and the rotor 5. The flow channel 9 comprises a plurality of blade stages which are formed in each case from a row of rotor blades 7 and a row of guide blades 8.

[0022]Fresh steam flows via the fresh steam feed channel into an inflow opening 10 and flows from there in a flow direction 11 through the flow channel 9 which extends substantially parallel to the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com