Colored optical fiber, optical fiber ribbon, and optical fiber cable

a color fiber and ribbon technology, applied in the field of colored optical fibers, can solve the problems of difficult to achieve both anti-microbend property and hot-water resistance, and the anti-microbend property tends to deteriorate, so as to achieve good anti-microbend property and reduce the probability of transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0043]Hereinafter, Examples of the present invention will be described for the colored optical fiber 1 of the aforementioned embodiment. However, the present invention is not limited to the following Examples.

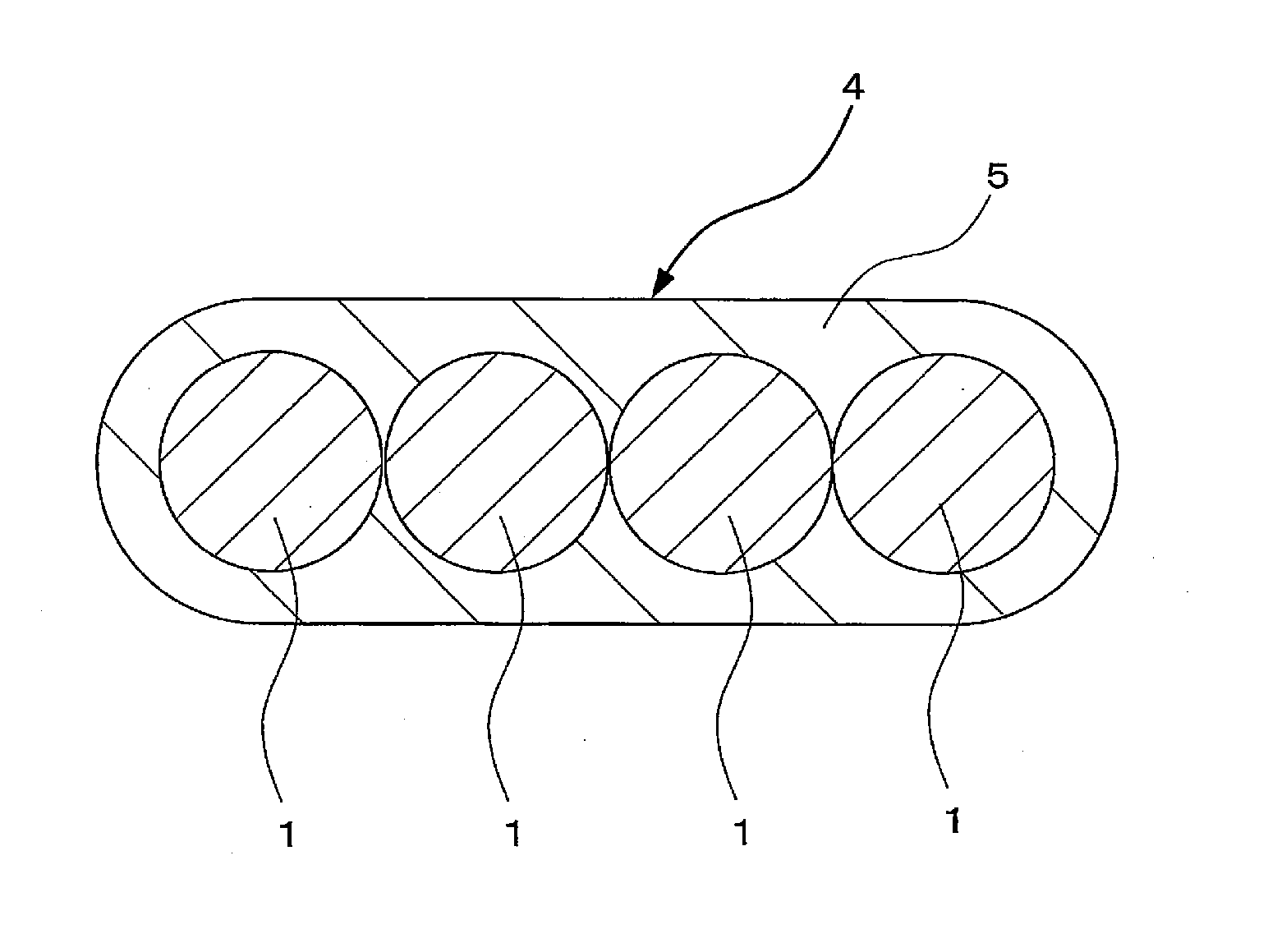

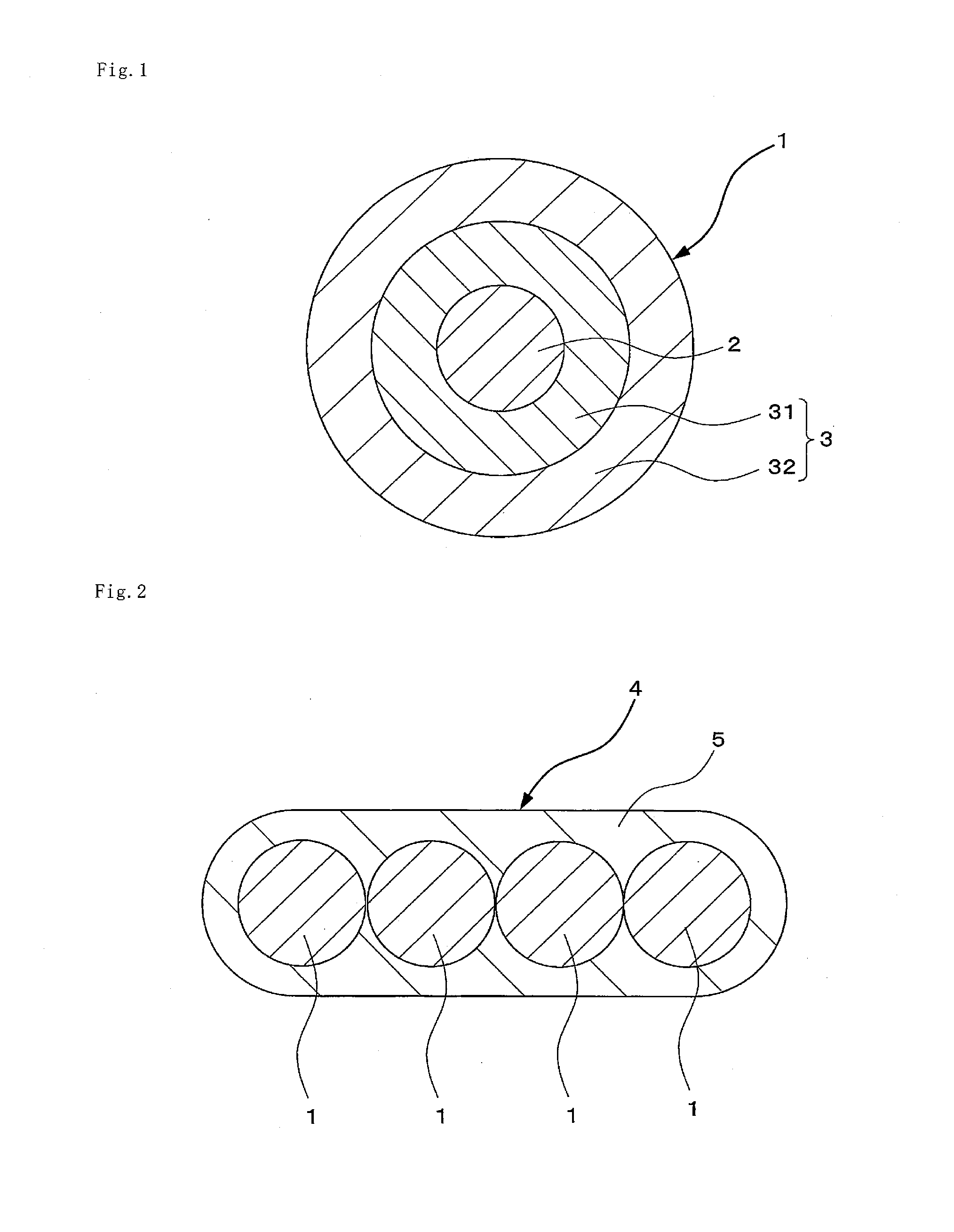

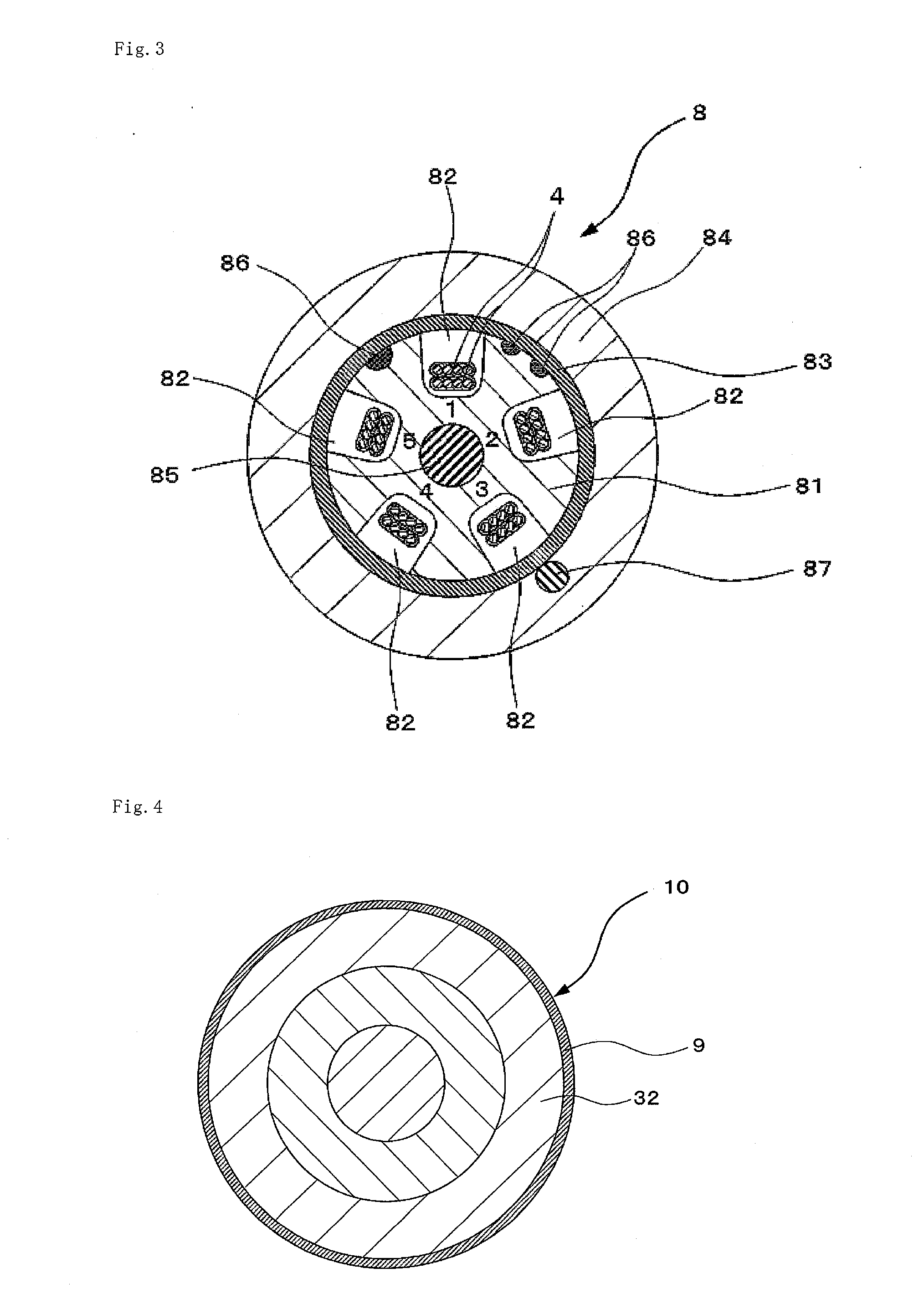

[0044]For the production of a sample colored optical fiber, as the glass optical fiber 2, a quartz glass optical fiber with an outer diameter (diameter) of φ125 μm was used, and a primary coating layer 31 was formed on its outer periphery, after which a colored secondary coating layer 32 was formed on the outer periphery thereof, to obtain a double-layered colored optical fiber 1 shown in FIG. 1 (Examples 1 to 4, Comparative Example 1). The outer diameter of the primary coating layer 31 was 185 μm and the outer diameter of the secondary coating layer 32 was 245 μm.

[0045]Further, an optical fiber was prepared by the same method except for using a non-colored secondary coating layer, and a colored layer 9 was formed on its outer periphery, to obtain the triple-layered colored opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| equilibrium elastic moduli | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com