Scalable automated cooking system having small footprint and reduced labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

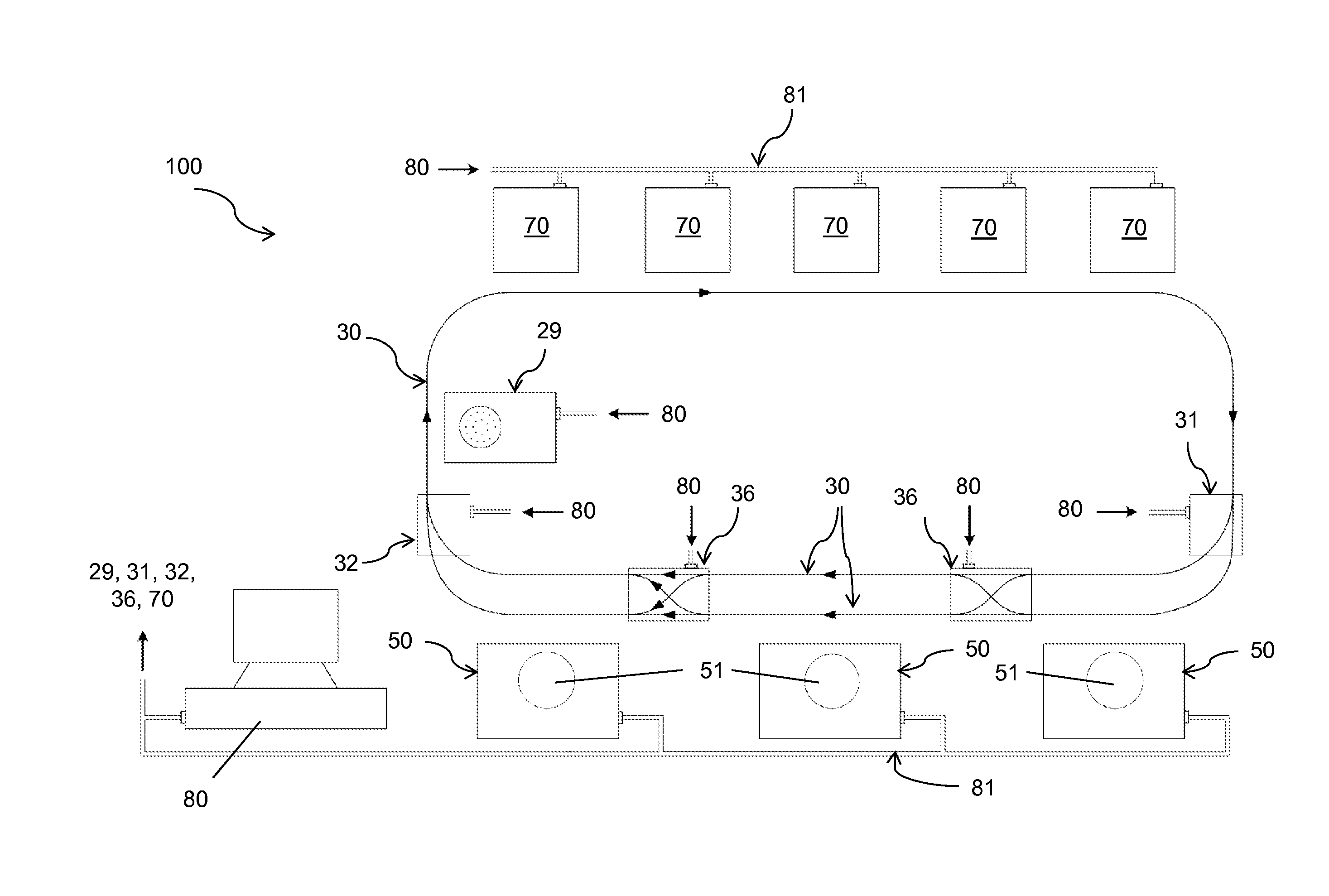

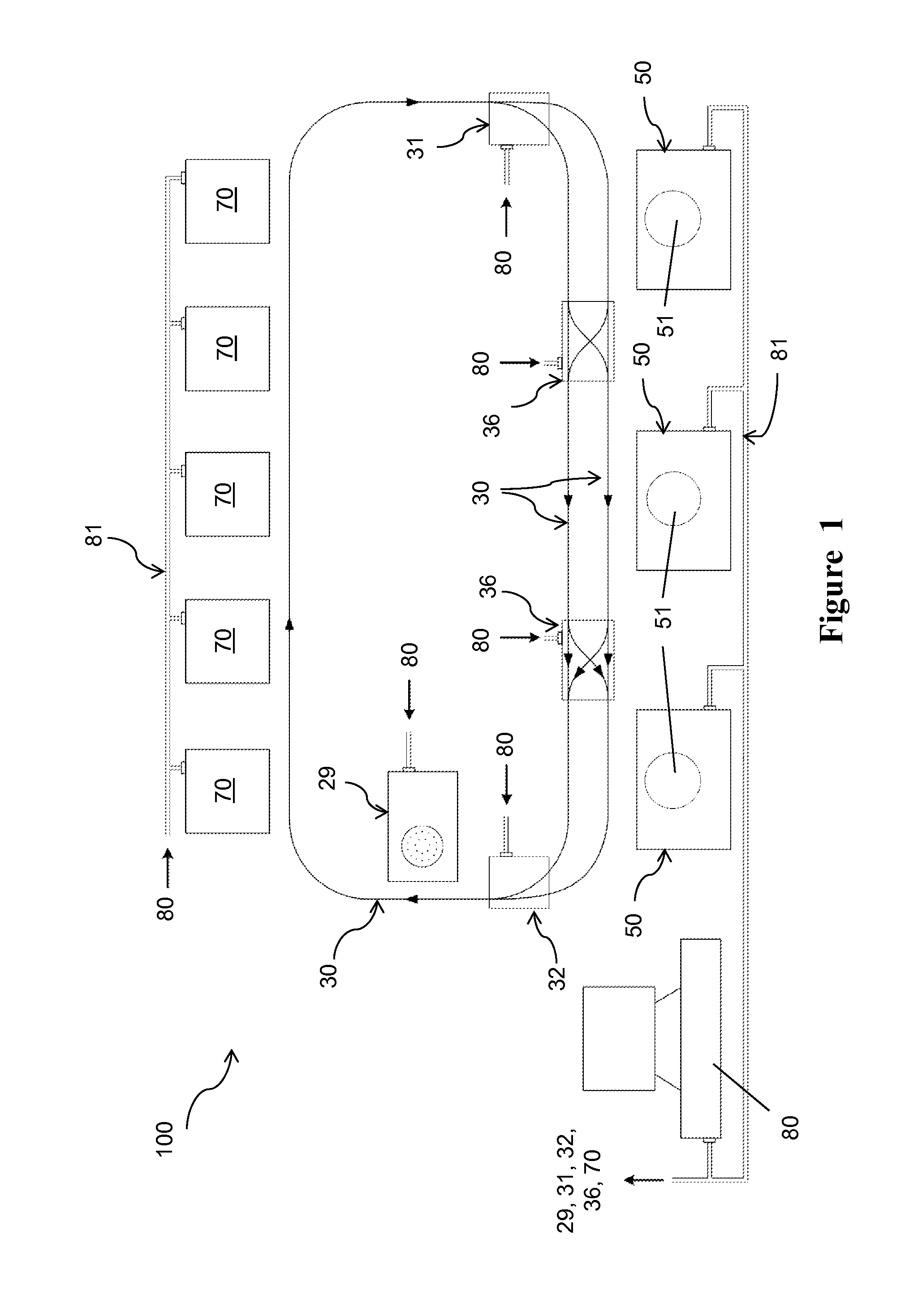

[0032]In some embodiments, referring to FIG. 1, an automated cooking system 100 includes cooking stations 50, storage stations 70, a cleaning station 29. A network of rail tracks 30 links the storage stations 70, the cooking stations 50 and the cleaning station 29. The rail tracks 30 includes split track switch (i.e., one-to-two track switch) 31, a merging track switch (i.e., two-to-one track switch) 32, and two-to-two track switches 36. A multiple of mini vehicles (not shown in FIG. 1) can move on the rail tracks 30. Each mini vehicle carries one or more transport containers configured to hold food ingredients. Each cooking station 50 includes at least one cooking apparatus with a cooking container 51, and a cart unloading apparatus to transfer food ingredients from transport containers to the cooking container (not shown in FIG. 1).

[0033]In the present disclosure, the term “cooking apparatus” refers to the subsystem in the cooking system that is responsible for heating, stirring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com