Method of Connecting Structural Insulated Building Panels through Connecting Splines

a technology of insulated building panels and splines, which is applied in the direction of building components, building repairs, walls, etc., can solve the problems of reducing the thermal efficiency of the panel system, affecting the structural application, and affecting the structural performance of the building

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]All illustrations of the drawings are for the purpose of describing selected versions of the present invention and are not intended to limit the scope of the present invention.

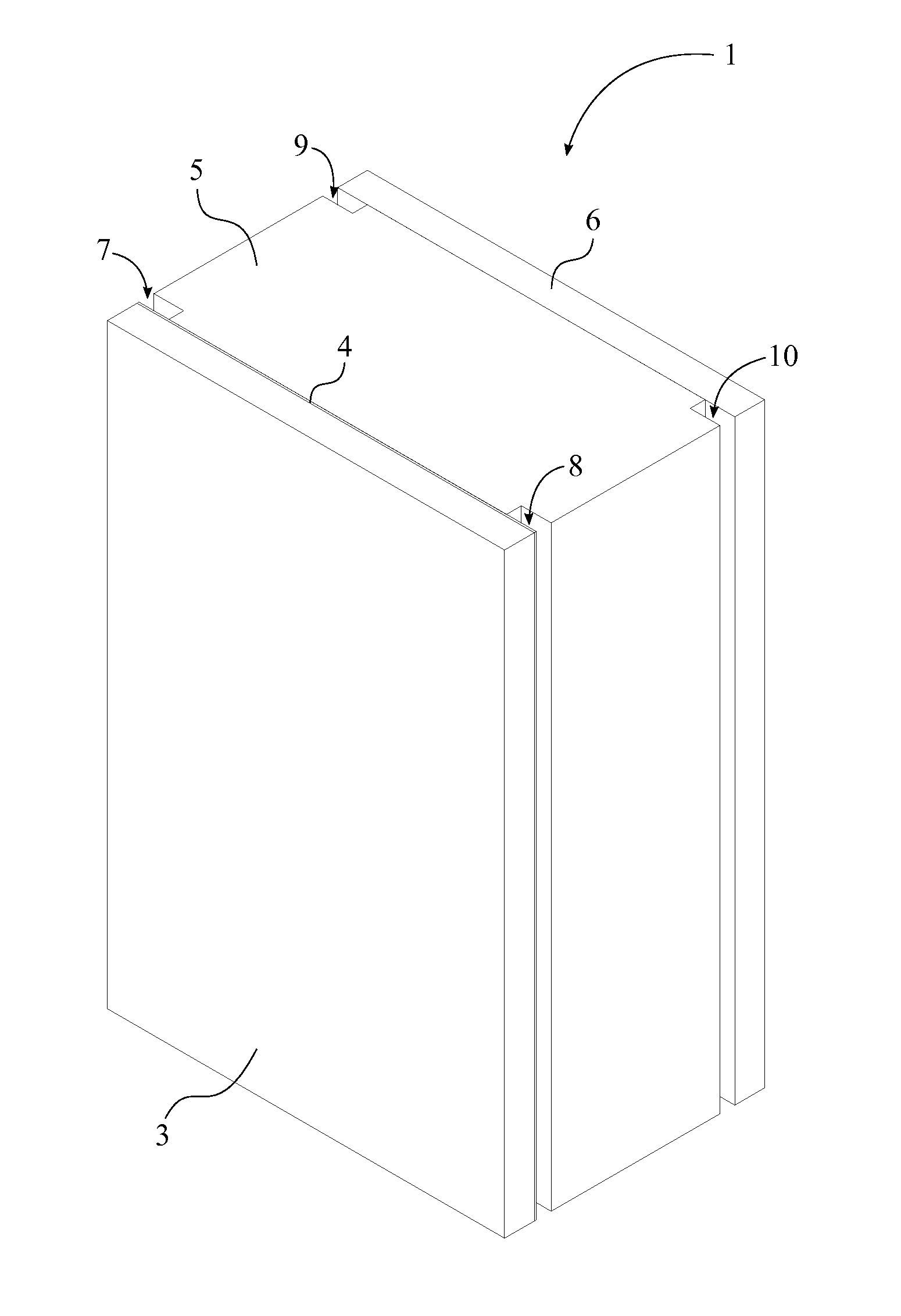

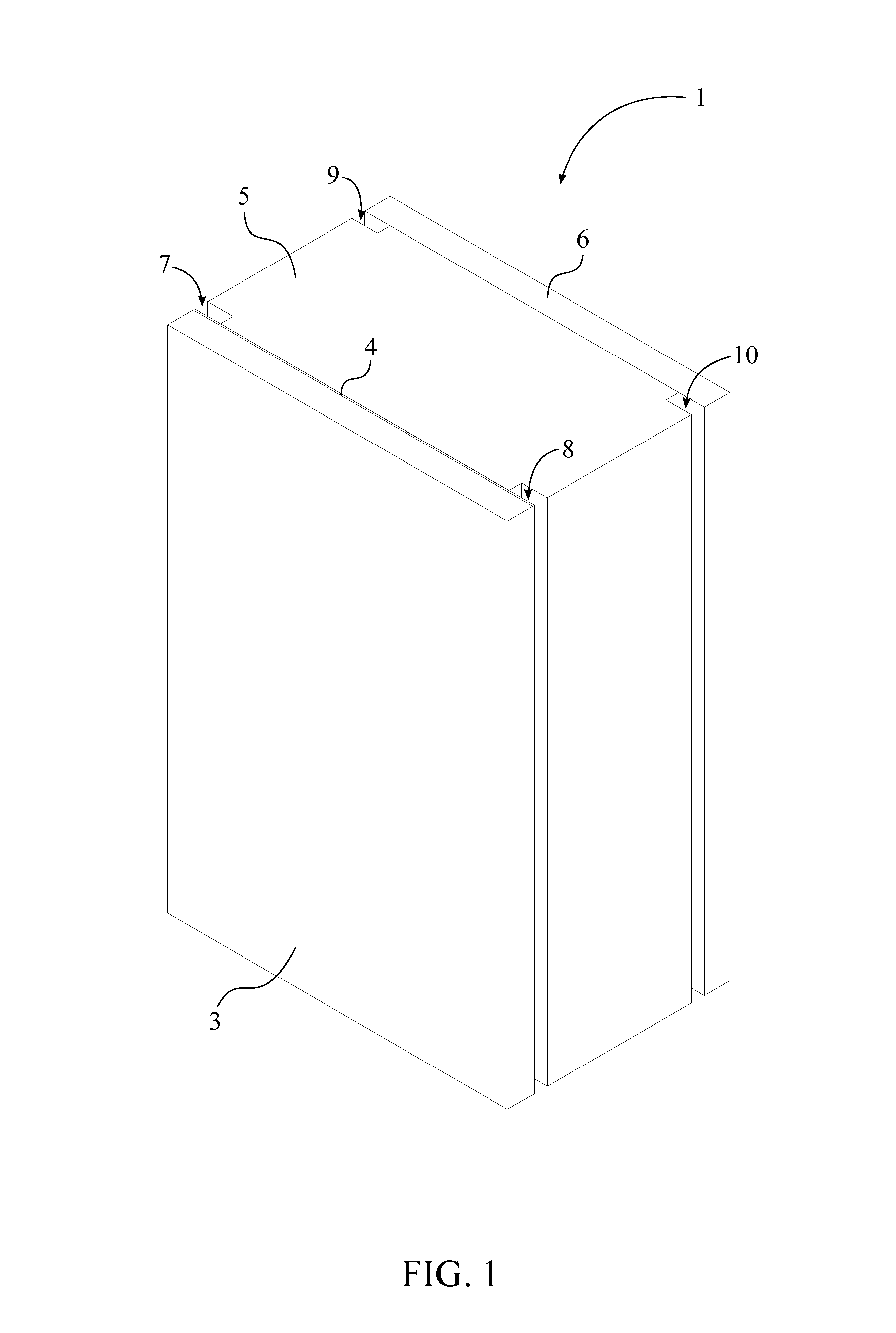

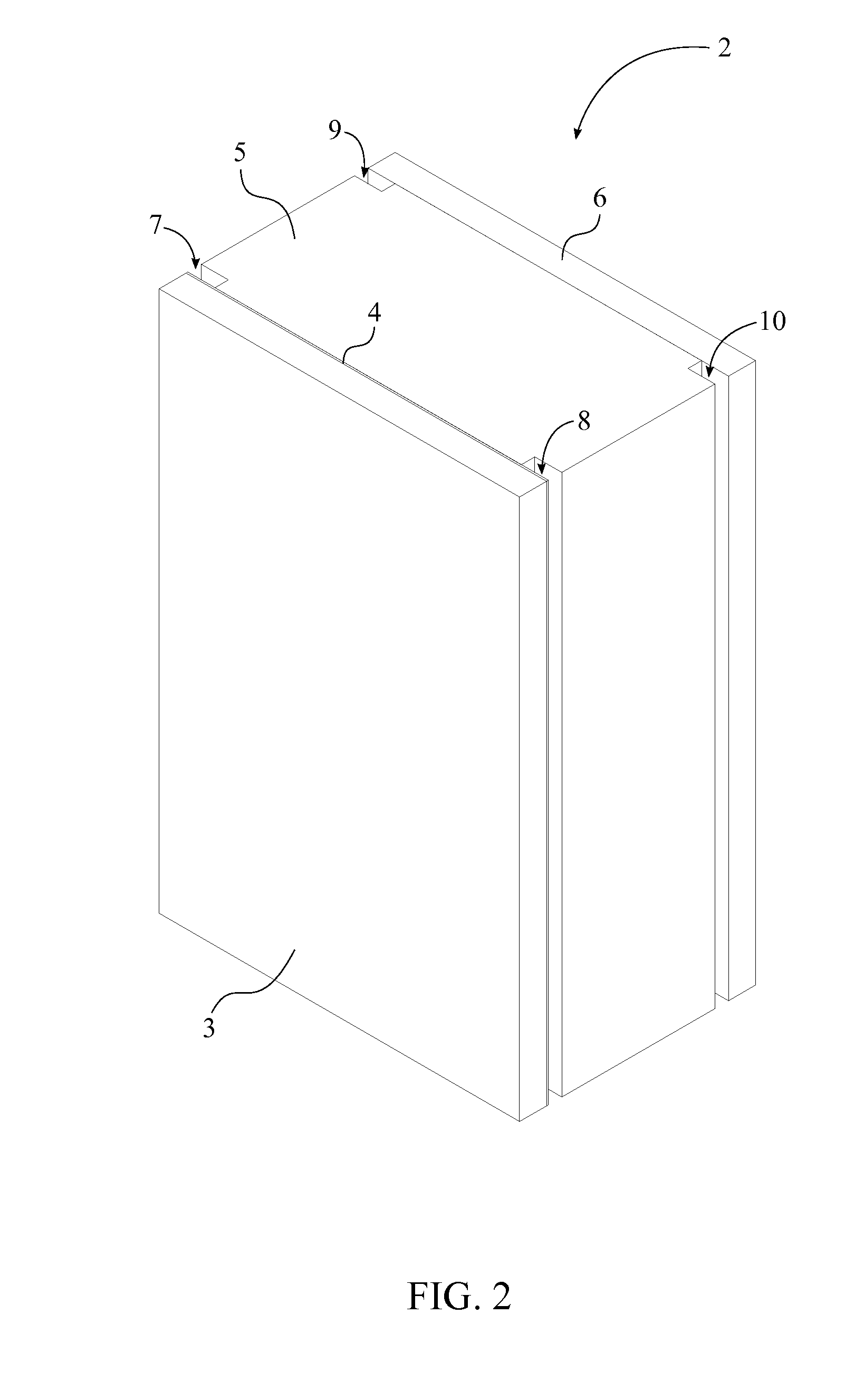

[0017]The present invention is a method of connecting the structural insulated building panel through connecting splines. The method of connecting the multiple structural insulated building panels are explained in relation to an arbitrary structural insulated panel 1, an adjoining structural insulated panel 2, a first spline 11, and a second spline 12.

[0018]In reference to FIG. 1 and FIG. 2, the arbitrary structural insulated panel 1 and the adjoining structural insulated panel 2 each comprise a first magnesium oxide (MgO) board 3, a phenolic resin sheet 4, an expanded polystyrene layer 5, and a second magnesium oxide (MgO) board 6. The phenolic resin sheet 4 is adjacently laminated with the expanded polystyrene layer 5 as the phenolic resin sheet 4 improves the fire resistance within the structural insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com