System and method for remote inspection of liquid filled structures

a liquid-filled structure and system-based technology, applied in the field of inspection of structures, can solve the problems of difficult inspection, maintenance and repair, slippery surfaces in the ballast tank, and accumulation of mud on the bottom of the ballast tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

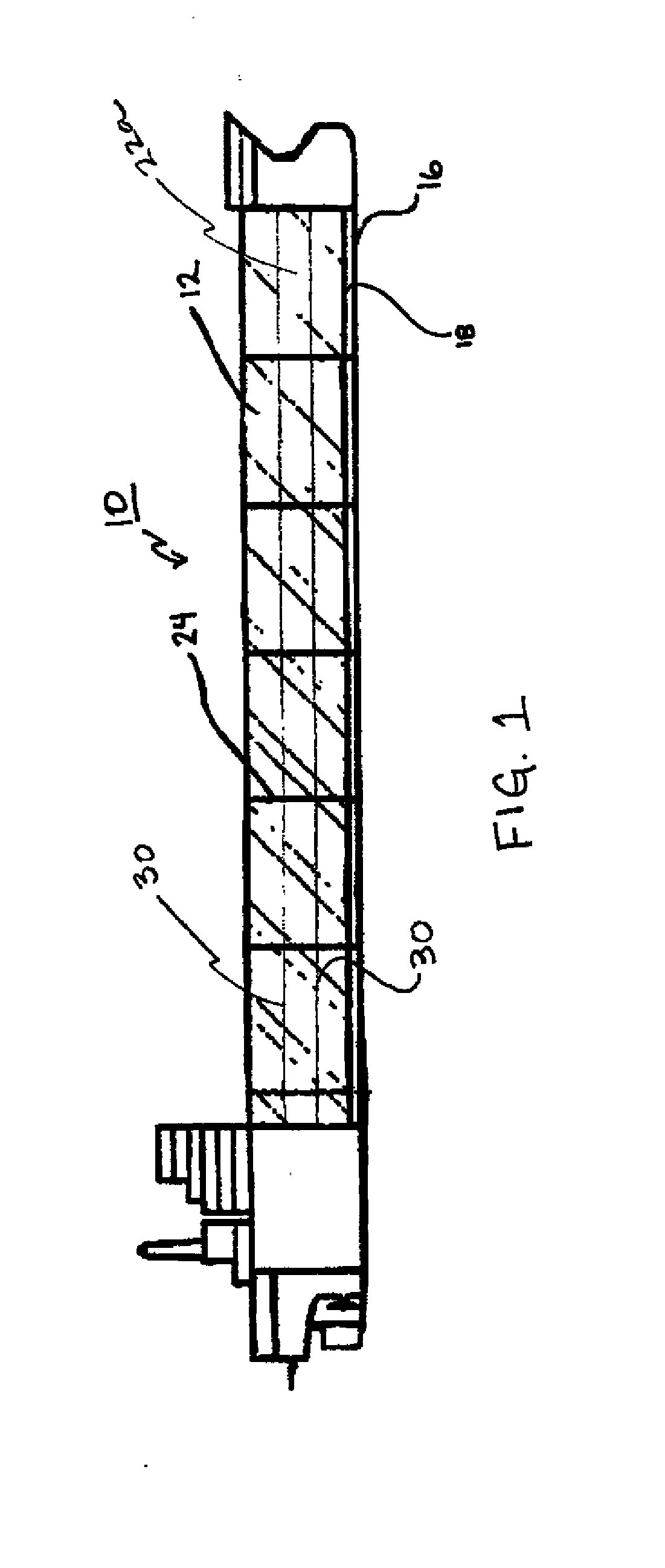

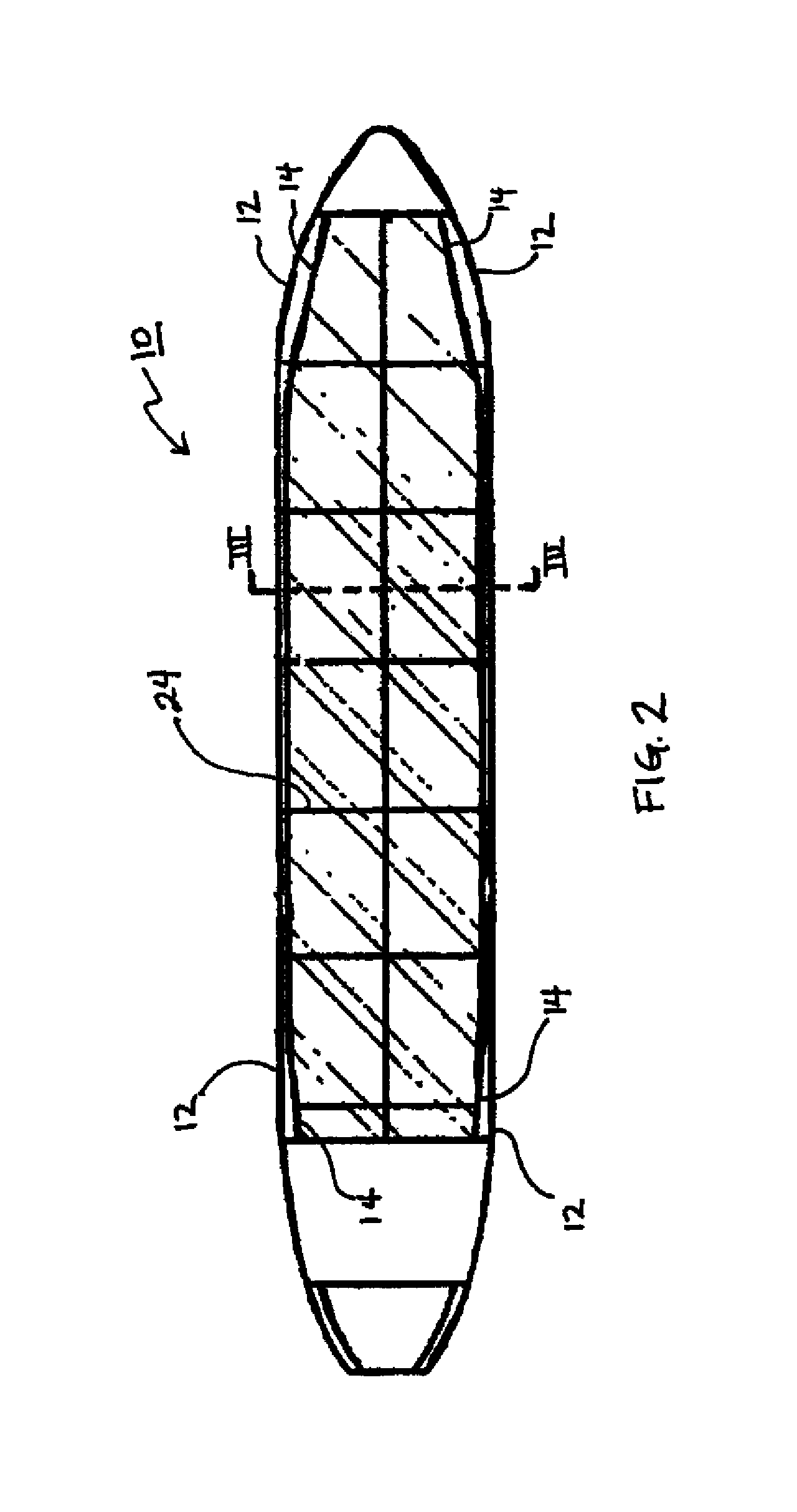

[0025]Reference will now be made in detail to embodiments of the system and methods for remote inspection of liquid filled structures with reference to the accompanying figures, in which like reference numerals indicate like elements.

[0026]It will be apparent to those skilled in the art that various modifications and variations can be made in the present invention without departing from the spirit or scope of the invention. Thus, it is intended that the present invention cover the modifications and variations of this invention provided they come within the scope of the appended claims and their equivalents.

[0027]The present invention will be further illustrated in the following Examples, which are given for illustration purposes only and are not intended to limit the invention in any way.

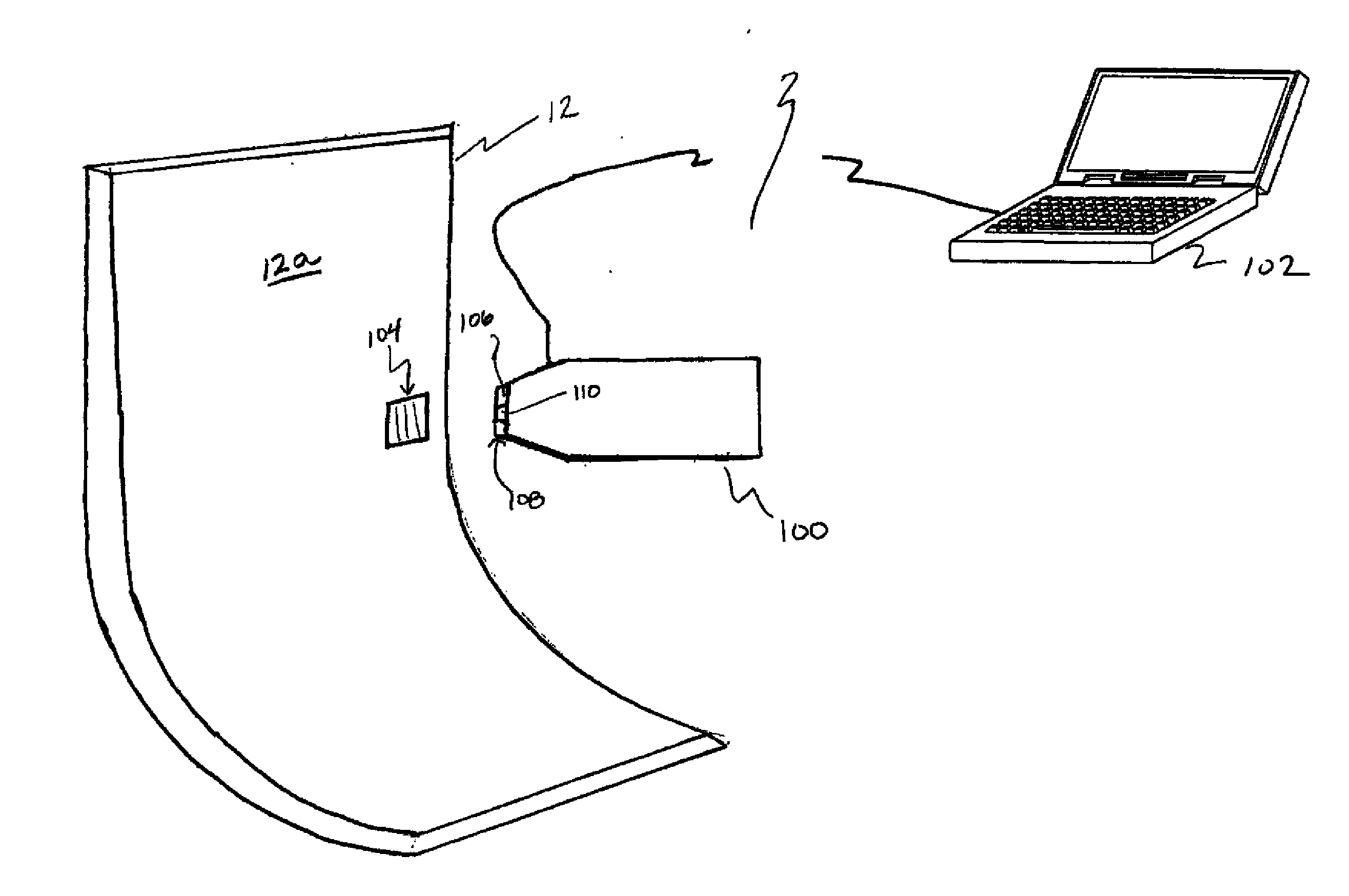

[0028]As illustrated in FIG. 5, the system of the present invention includes a remotely operated vehicle (“ROV”) 100. The ROV 100 includes at least one camera 106 capable of capturing video images w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com