Boring bit and method of manufacture

a technology of boring bits and manufacturing methods, applied in the field of boring bits, can solve the problems of not providing a good temporary connection, carbide teeth are not typically formed in situ, and the fluid does not provide any significant assistance in the steering of the head, so as to achieve the effect of loosening the temporary connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

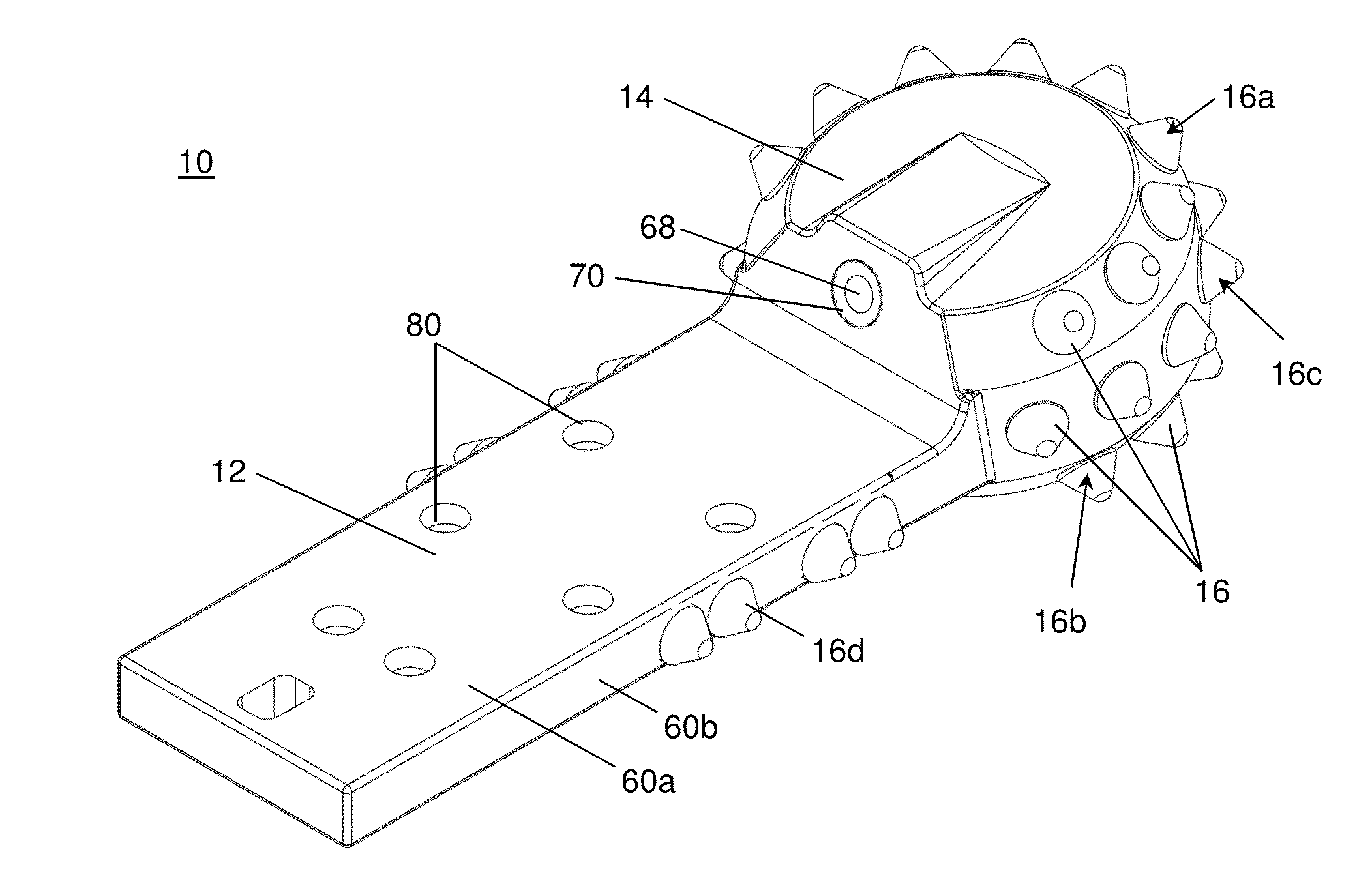

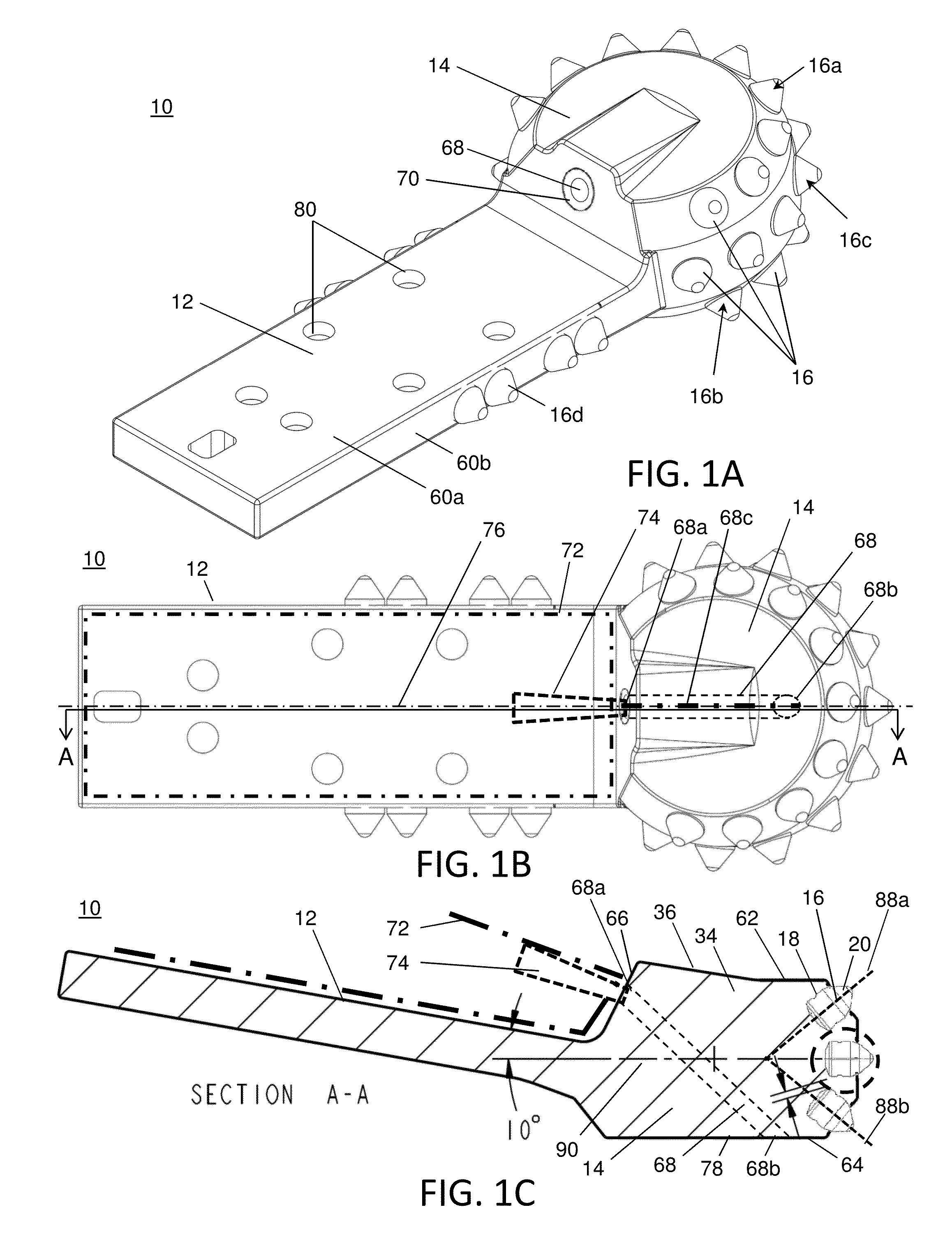

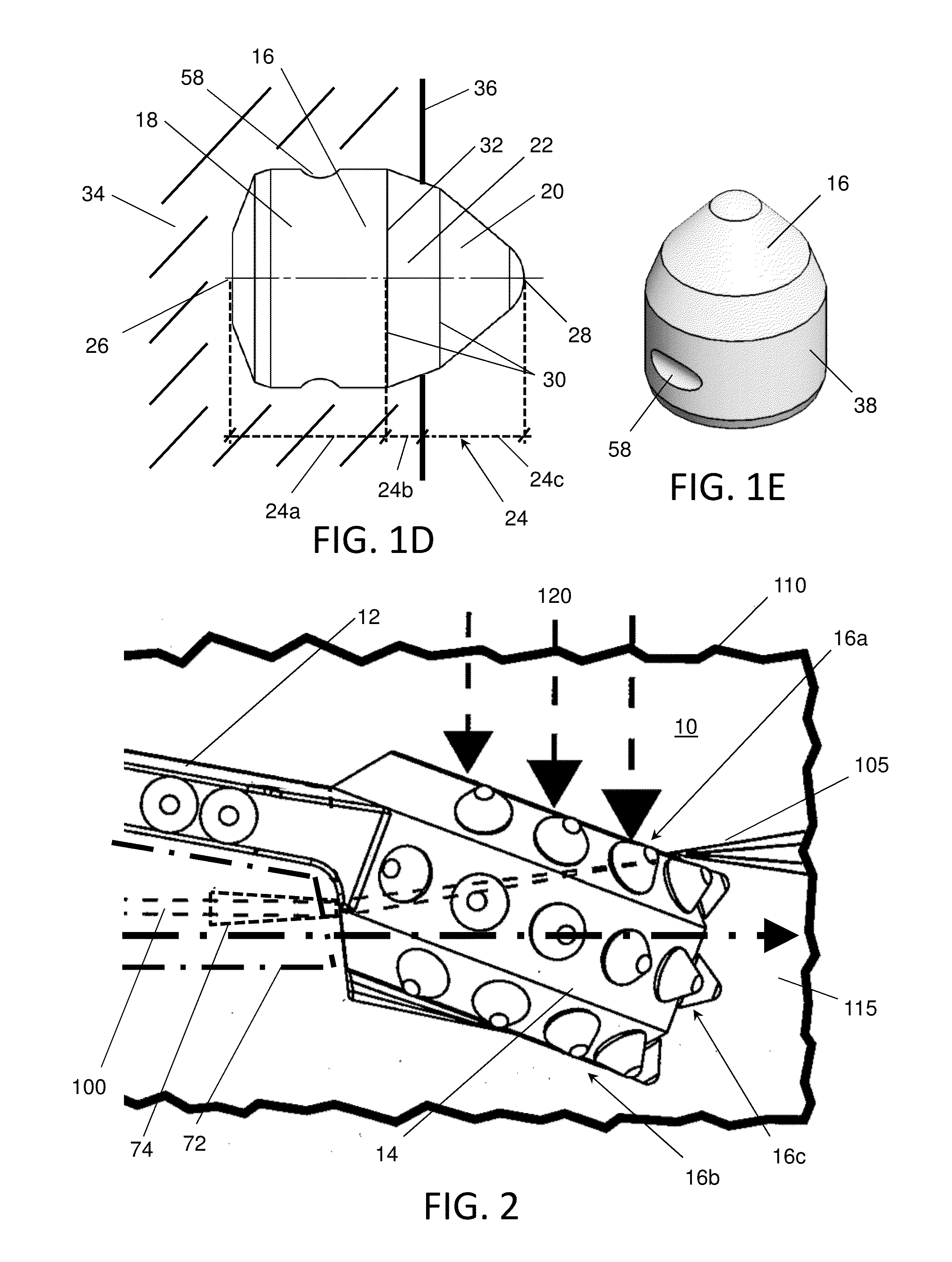

[0023]The following description of the inventive boring bit 10 for a horizontal directional drilling machine is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses. Generally, as shown in FIG. 1A, the boring bit 10 of the present invention has a body with a head portion 12 connected to a shank portion 14, and teeth 16 are radially distributed around the periphery of the head portion. Preferably, the head has an upper row of teeth 16a, a lower row of teeth 16b and a middle row of teeth 16c which are angled relative to each other. In particular, the upper and lower rows have diverging teeth axes 88a, 88b relative to a plane 90 through the center of the head, and the axes of the teeth in the middle row are aligned with the head's center plane. The head has a top surface 62 proximate to the upper row, a bottom surface 64 proximate to the lower row, and angled surface 66 between the shank 14 and the top surface 62. Also, as explained in f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com