Marble composite board finger joint machining system and working method thereof

A working method and processing system technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of easy arching and cracking, poor connection quality of marble composite panels, etc., to ensure the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

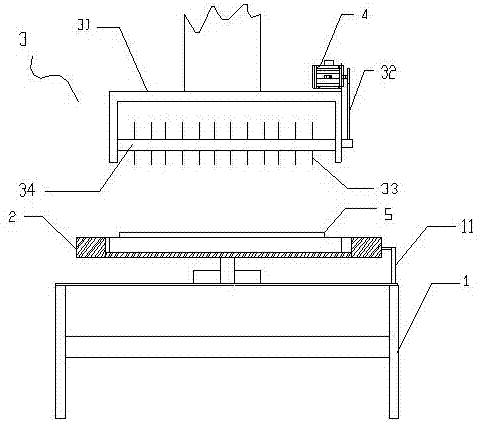

[0027] Such as figure 1 A marble composite board finger joint processing system and its working method shown include a base 1 , a processing platform 2 , a cutting device 3 and a driving motor 4 .

[0028] The processing platform 2 is a disc-shaped structure, and the center of the processing platform 2 is connected to the upper end surface of the base 1 through support. The processing platform 2 can rotate around the base 1. The scale value is engraved on the processing platform 2; the upper surface of the base 1 The end surface is provided with a positioning bolt 11 to position and fix the processing platform 2; the base 1 can move along the horizontal direction through the guide rail.

[0029] The cutting device 3 can move along the vertical direction, and the cutting de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com