Method and devices for securing bidirectional suture loops using coaxial mechanical fasteners

a technology of mechanical fasteners and bidirectional sutures, which is applied in the field of methods and devices for securing bidirectional sutures using coaxial mechanical fasteners, can solve the problems of complicated and challenging tie-dock technique, and the approach is generally limited, so as to reduce the risk of damaging adjacent structures and minimize the profile of the fastener

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

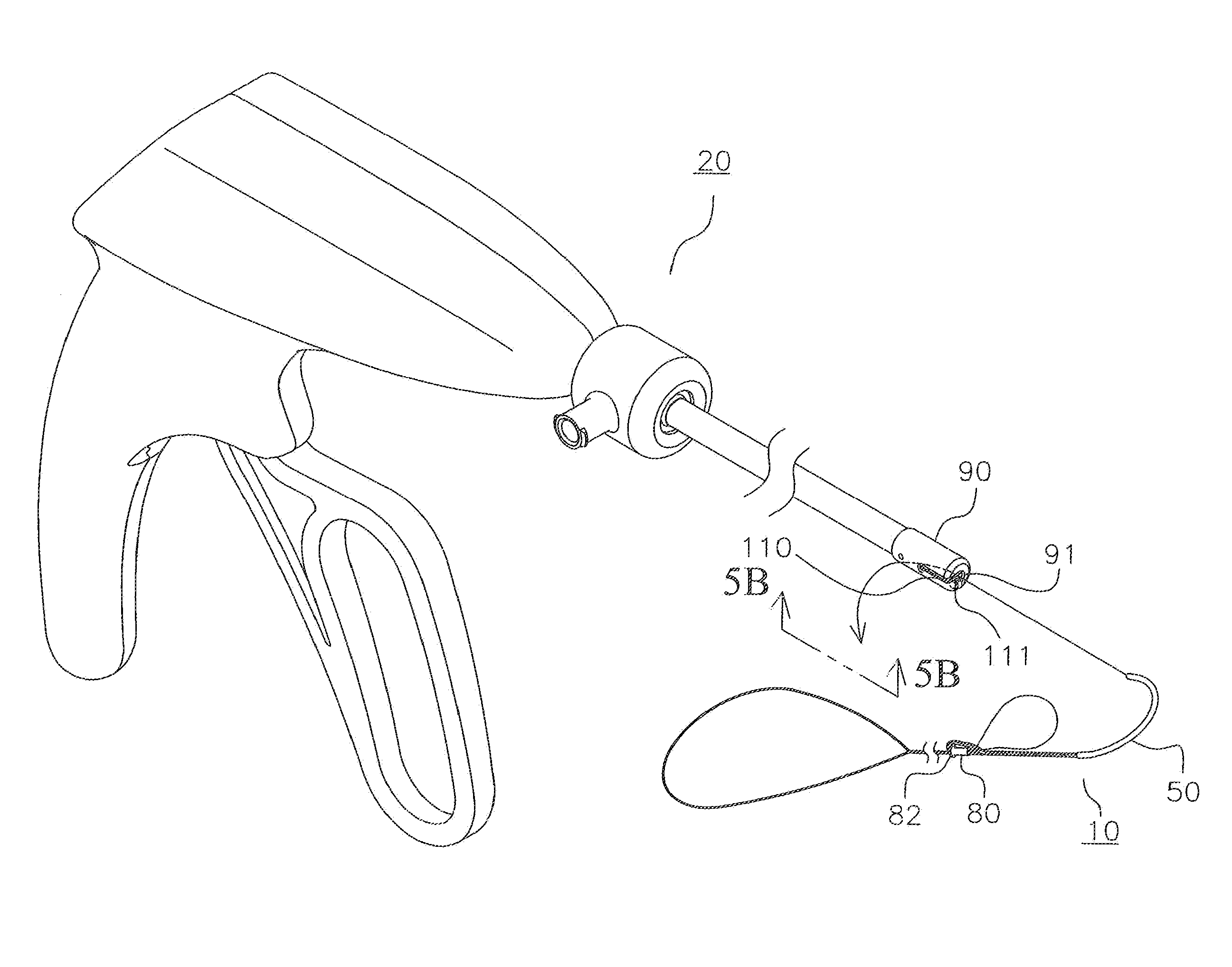

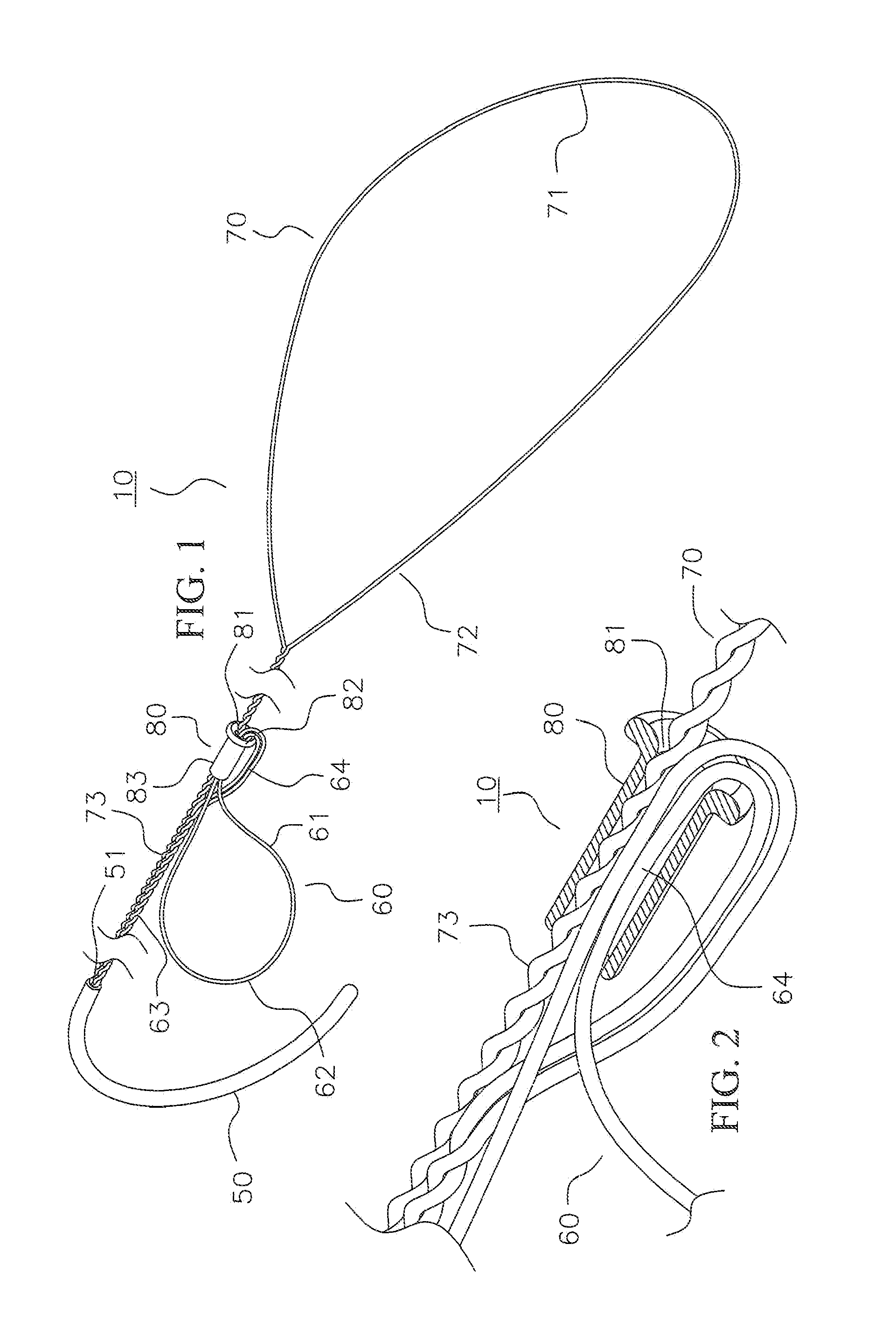

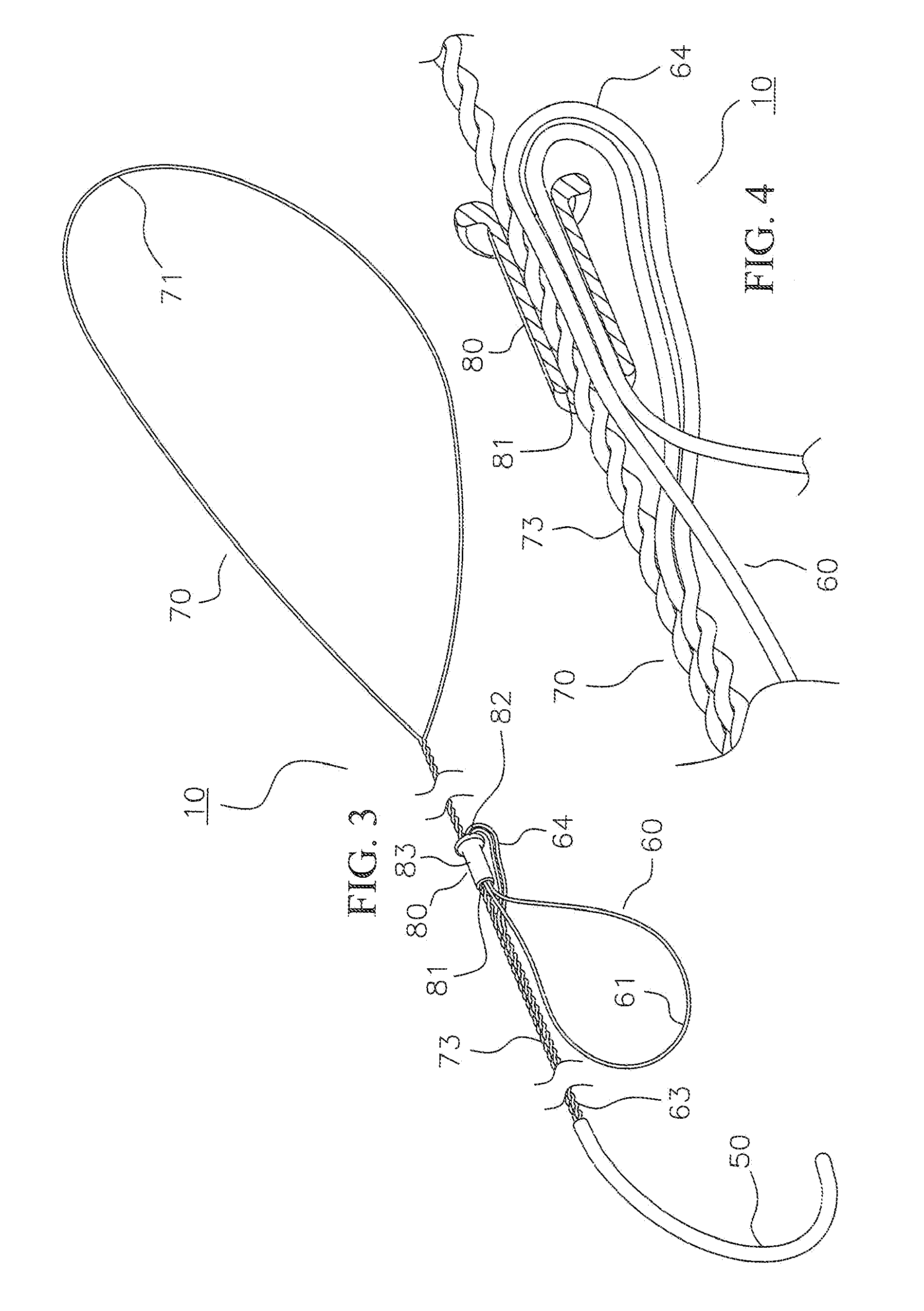

[0084]Referring to FIGS. 1 through 4, a bidirectional snare device 10 is shown. FIG. 1 is a distally oriented perspective view of the bidirectional snare device 10. The bidirectional snare device 10 consists of a curved handle 50 which fixedly holds a short wire snare 60 and a long wire snare 70 within a receiving bore 51. The curved handle 50 is typically comprised of a medical-grade stainless steel and formed in such a manner to allow for manipulation by the user. The short wire snare 60 and long wire snare 70 are also made from medical-grade stainless steel, but in small diameter wire form. The short wire snare 60 and long wire snare 70 pass through a wire bore 81 of a malleable sleeve 80. The sleeve is typically manufactured form a nonreactive, biocompatible material such as titanium and is fashioned that the distal end has an enlarged flange 82 connected to a body 83 of a slightly smaller diameter. The long wire snare 70 is formed by bending a length of wire 72 into a loop 71 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com