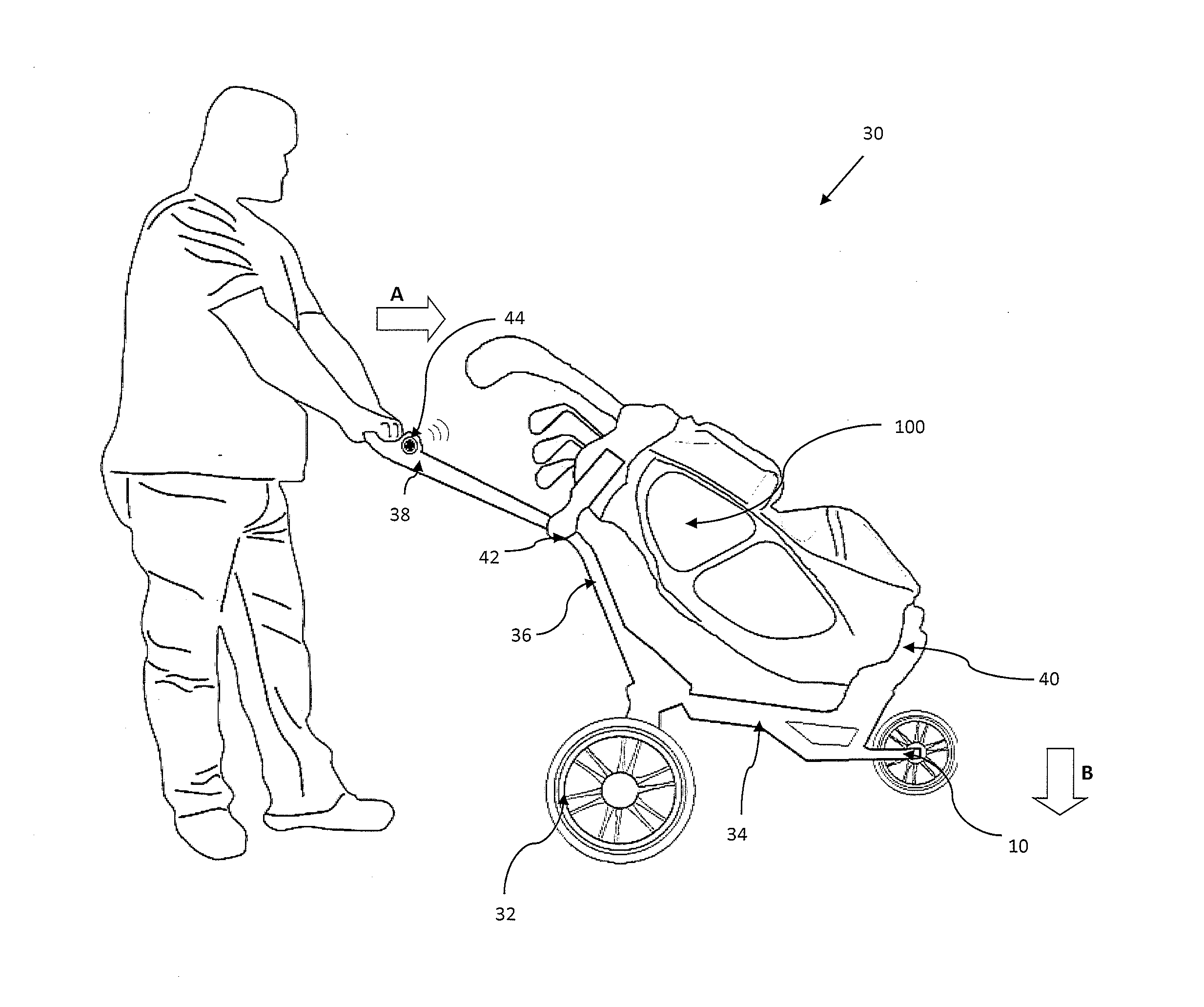

Wheel assembly for a golf trolley

a golf trolley and golf technology, applied in the direction of hand carts, sports apparatus, position/direction control, etc., can solve the problem of battery life depletion, and achieve the effect of convenient folding and useful battery li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

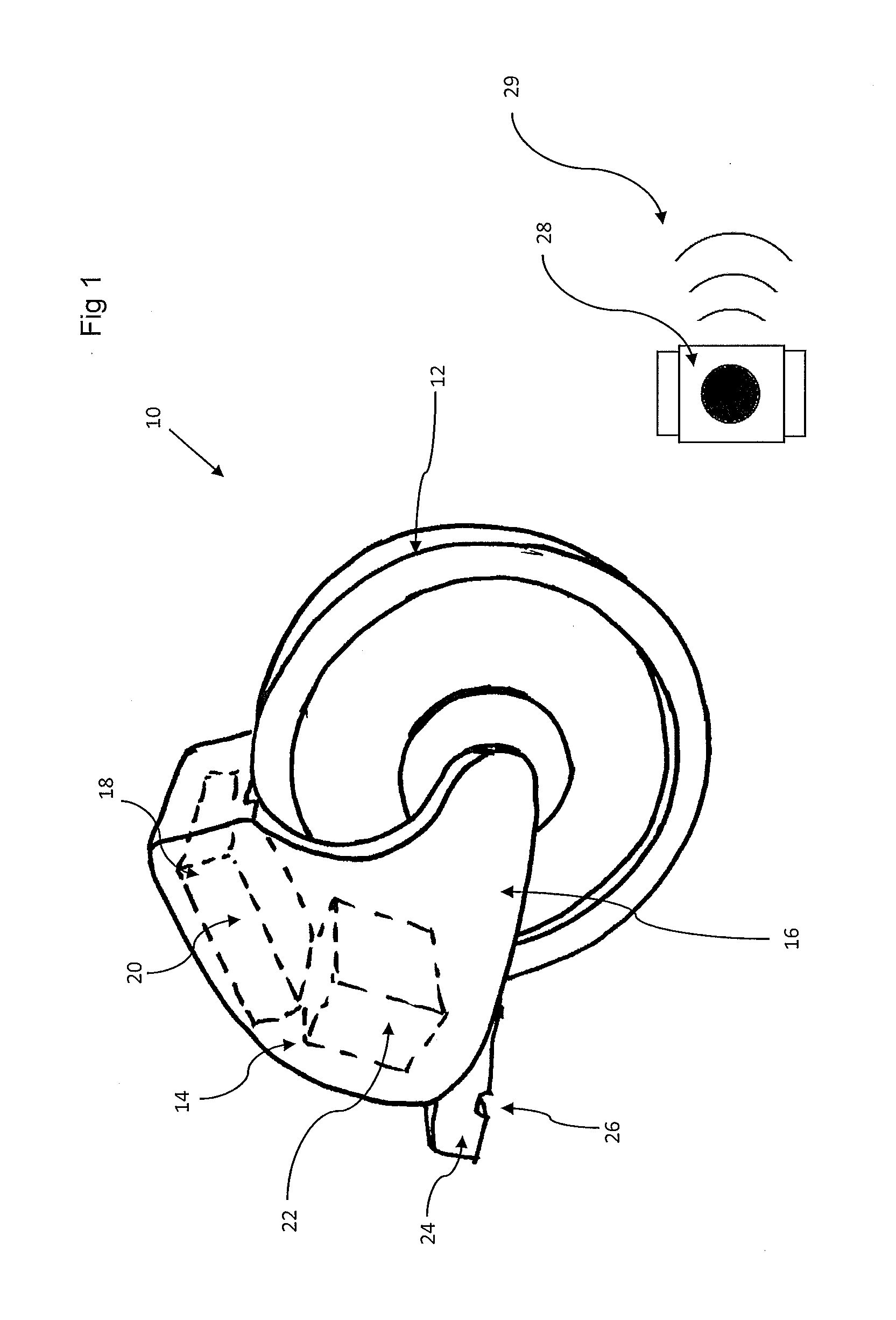

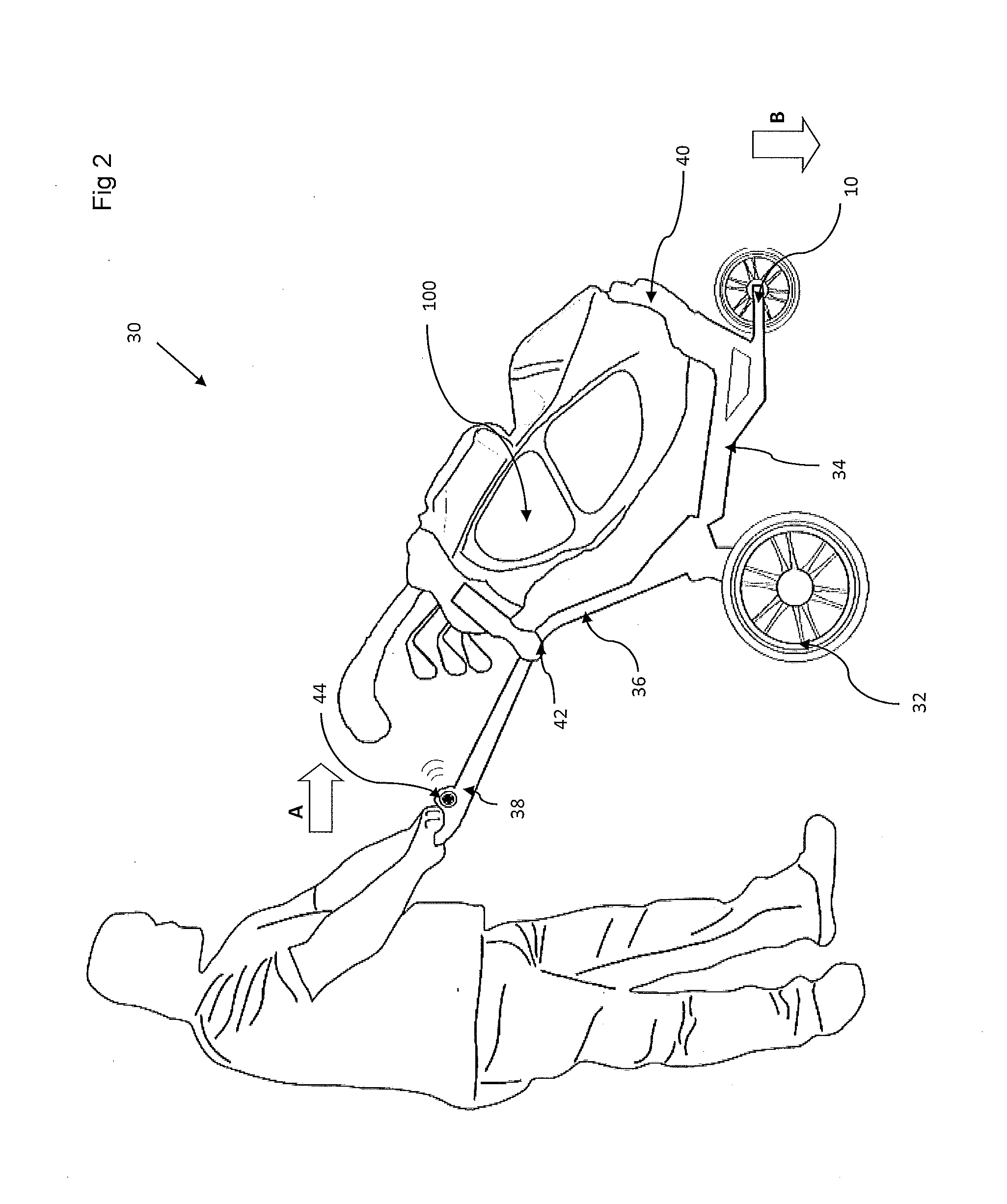

[0043]Referring firstly to FIG. 1, a wheel assembly for a golf trolley is indicated generally at 10. The wheel assembly includes a wheel 12 and a wheel mounting 14.

[0044]The wheel mounting 14 includes a pair of planar side members 16, extending from a housing 18. The wheel 12 is mounted on a bearing between the two side members 16, and the housing passes over and around the wheel 12. A battery 20 and a control unit 22 are disposed within the housing 18, and a motor is provided to drive the wheel 12. The battery 12 may be a Lithium-Ion battery, which provides an excellent power to weight ratio. It is found that a Lithium-Ion battery weighing around 300 g is suitable to provide enough power for power assistance around a typical 18-hole golf course.

[0045]A connecting member 24 extends from the rear of the wheel mounting 14, and is in the form of a box section. The connecting member 24 includes a recess 26 in one surface, for receiving a bolt of a locking device.

[0046]The control unit 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com