Dyed textiles and method of producing the same

a technology of dyeing textiles and dyeing methods, applied in dyeing processes, weaving, sulfur dyes, etc., can solve the problem that coloring techniques cannot give natural and brilliant colors to denim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]As used herein and in the claims, “comprising” means including the following elements but not excluding others.

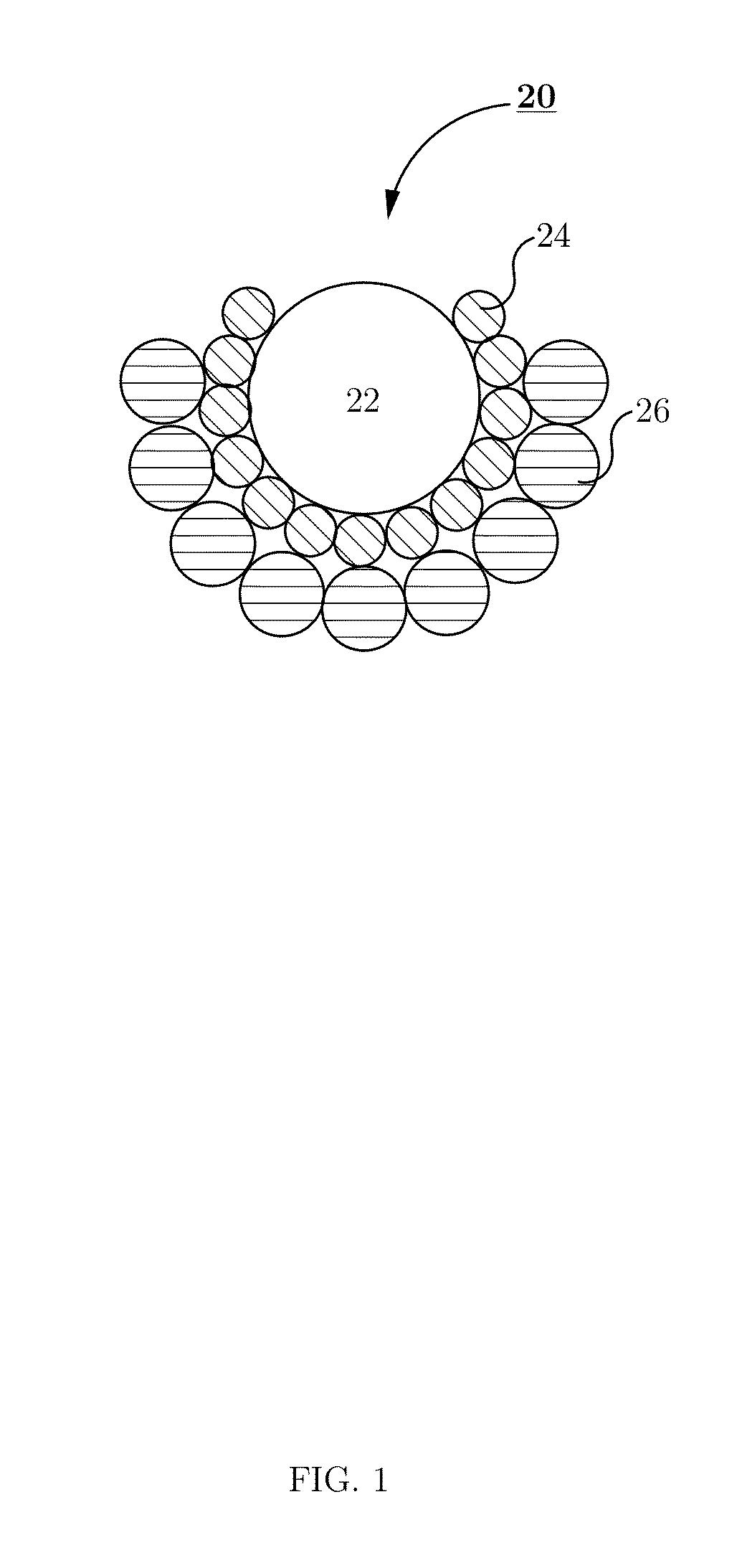

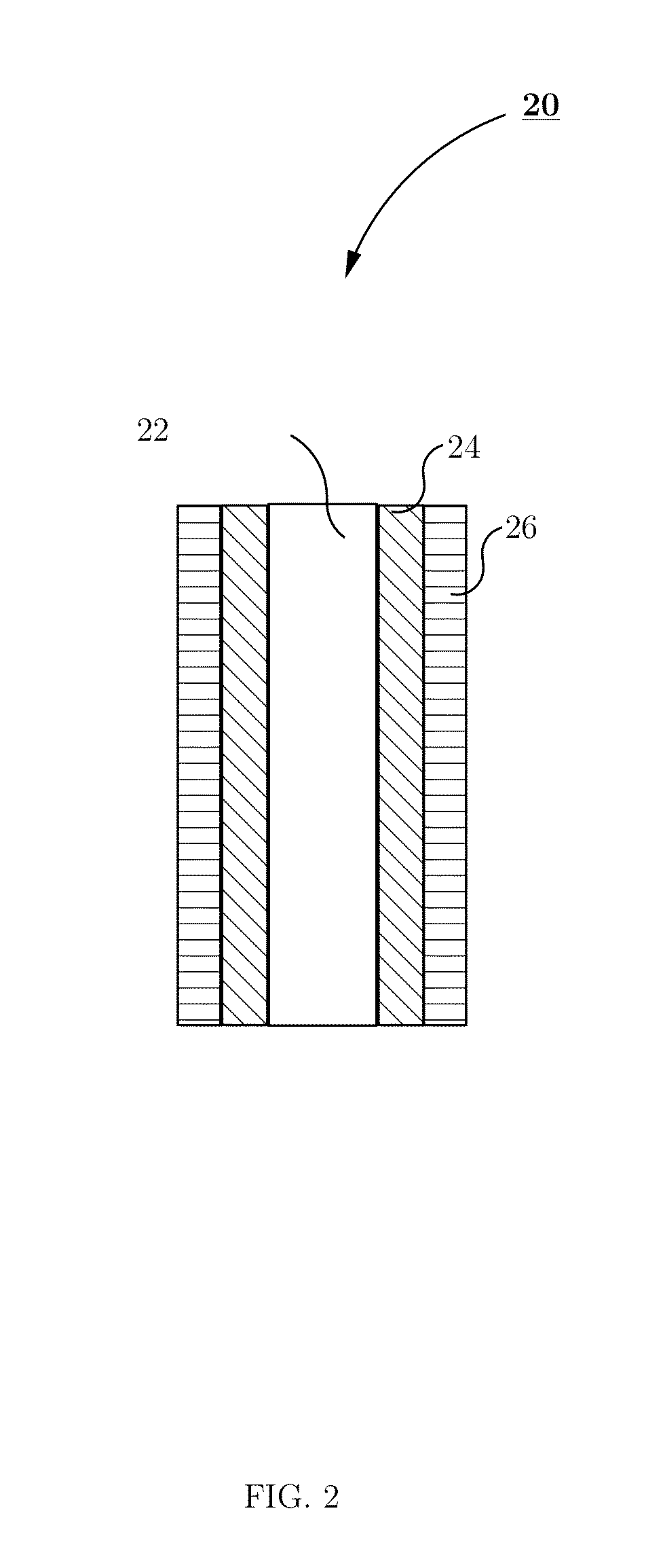

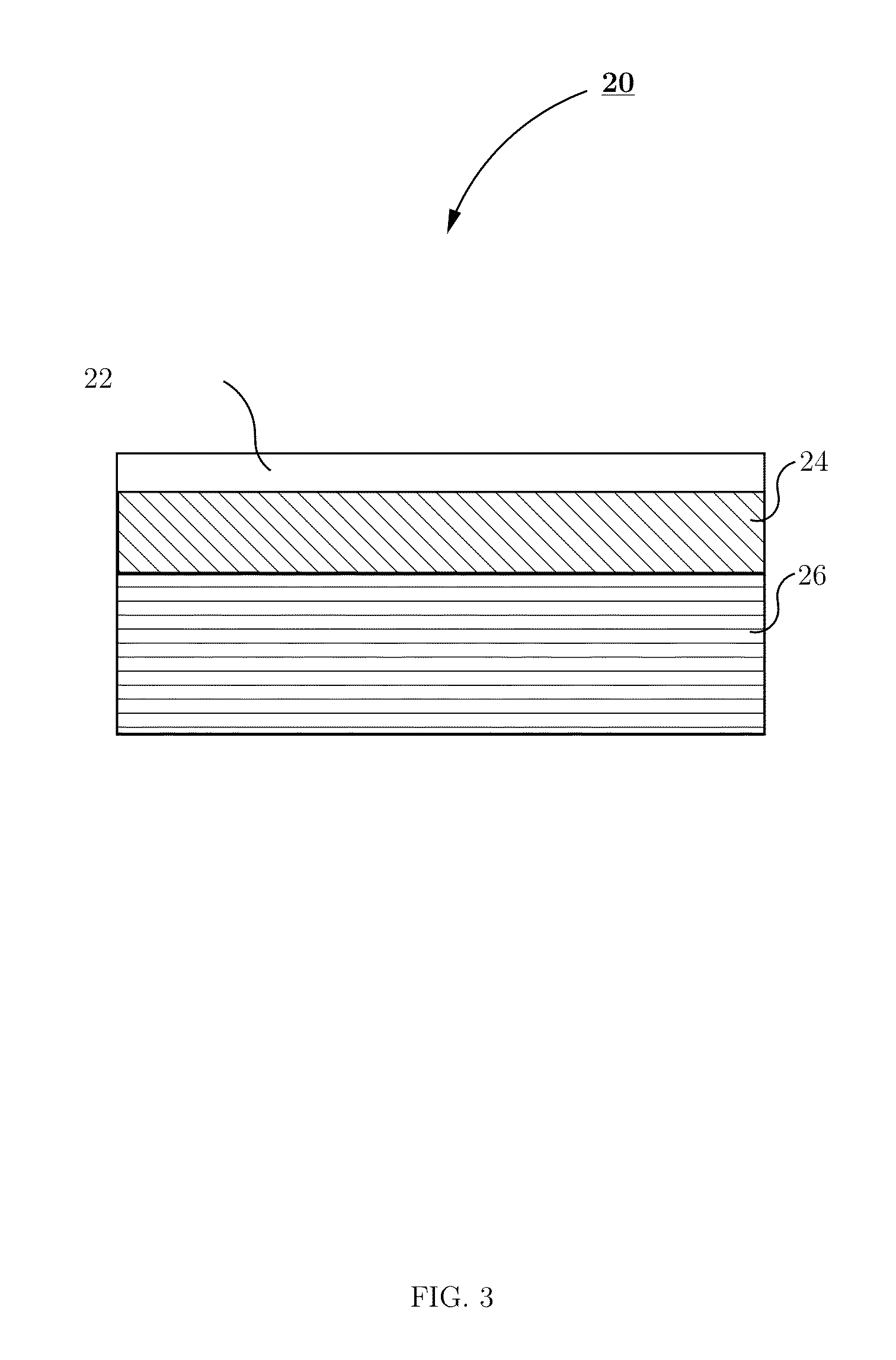

[0032]Now referring to FIG. 1, FIG. 2 and FIG. 3, the present invention, in one aspect is, a denim comprising a plurality of wrap threads 20 and a plurality of weft threads. Each of the wrap threads 20 further comprises a first yarn 22 and a dye coating that is disposed on the first yarn 22, in which the dye coating comprises a plurality of different dyes. At least one of the plurality of dyes in the dye coating (i.e. first dye 24) at least partially reveals and only partially covers another different dye immediately there-below (i.e. second dye 26); and the bottom most dye (i.e. second dye 26) only partially covers the first yarn 22, such that the dyes (i.e. both first dye 24 and second dye 26) are not disposed on at least a portion of the first yarn 22, thereby showing the wrap thread with a plurality of colors. Each weft thread only consists of a second yarn withou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| colors | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| plurality of colors | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com