Flame gas burner diffuser for cooking equipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

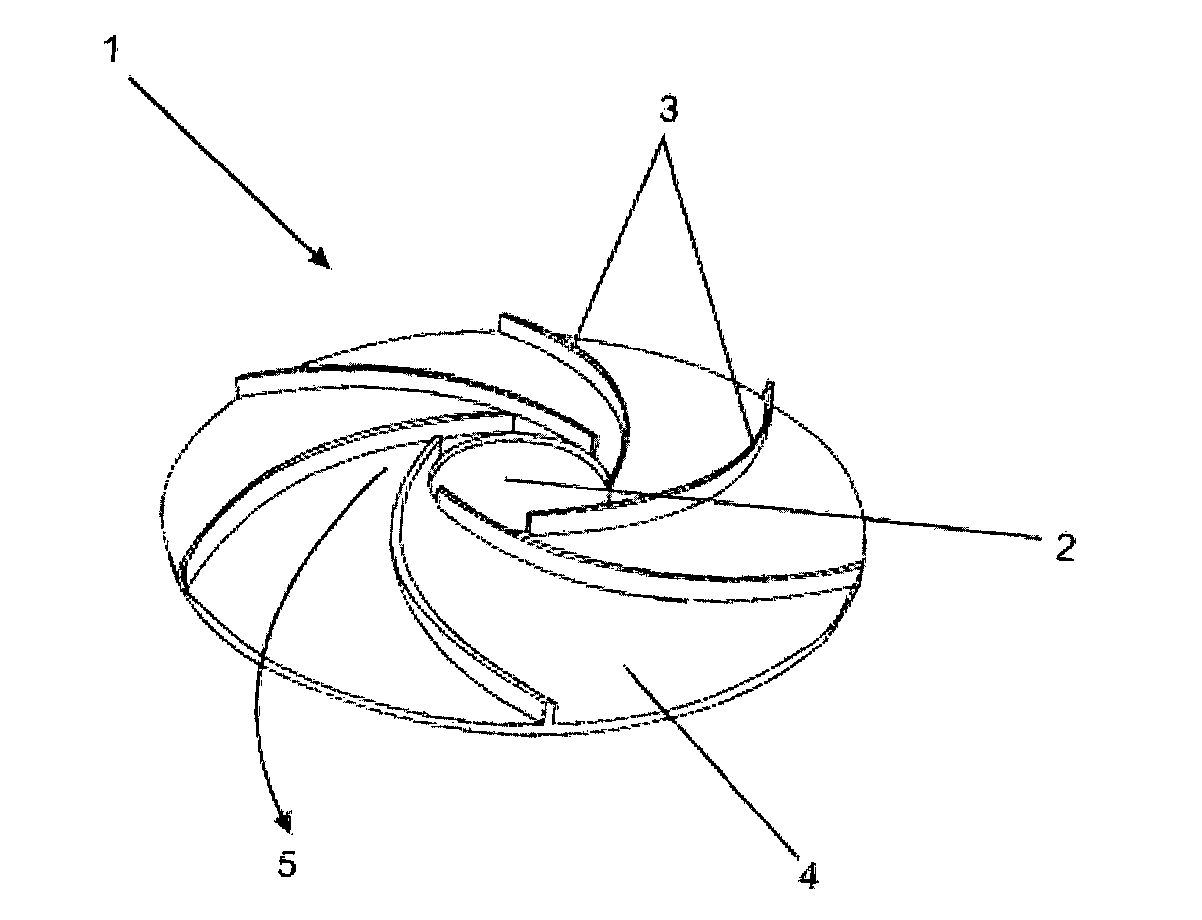

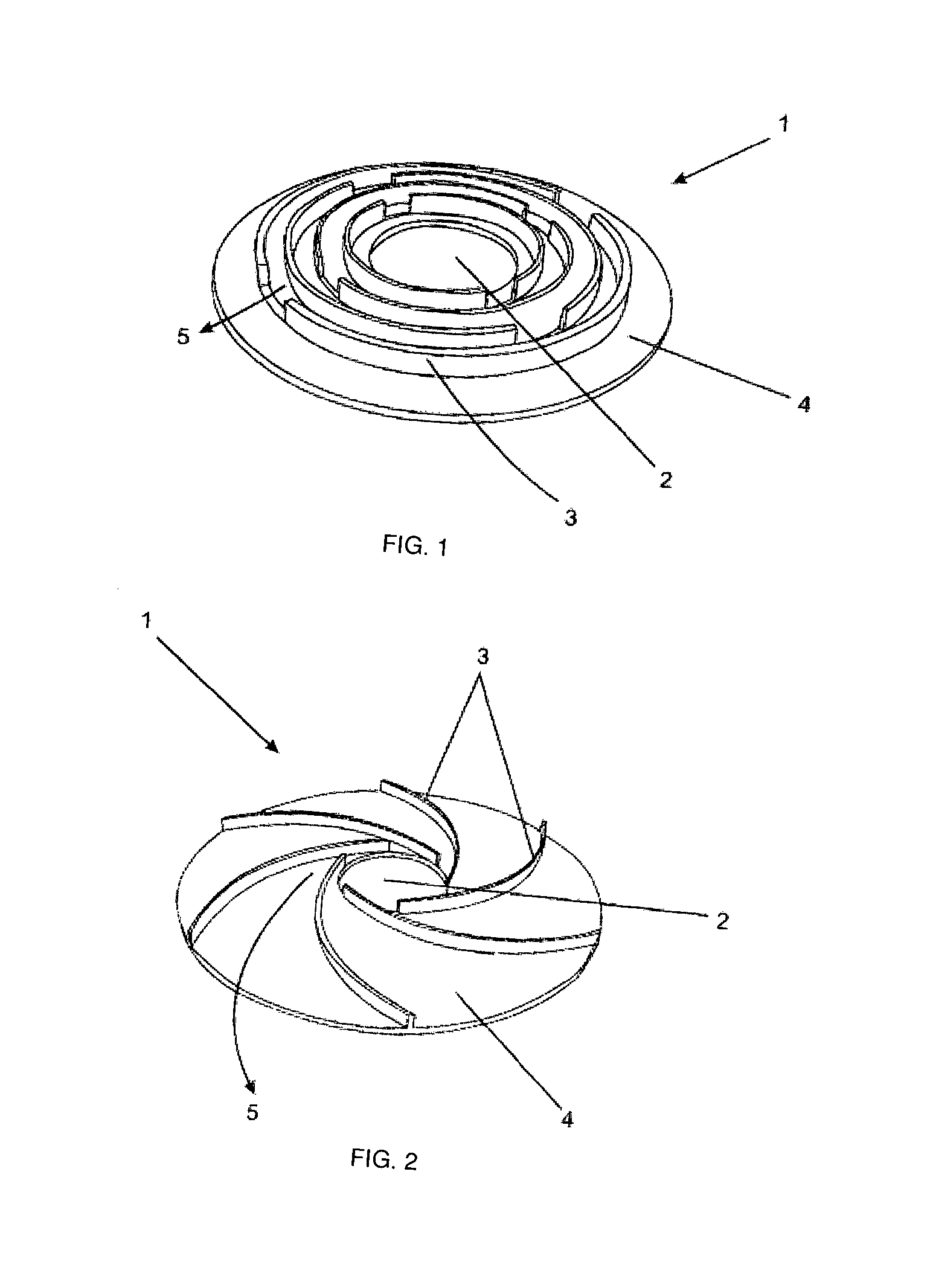

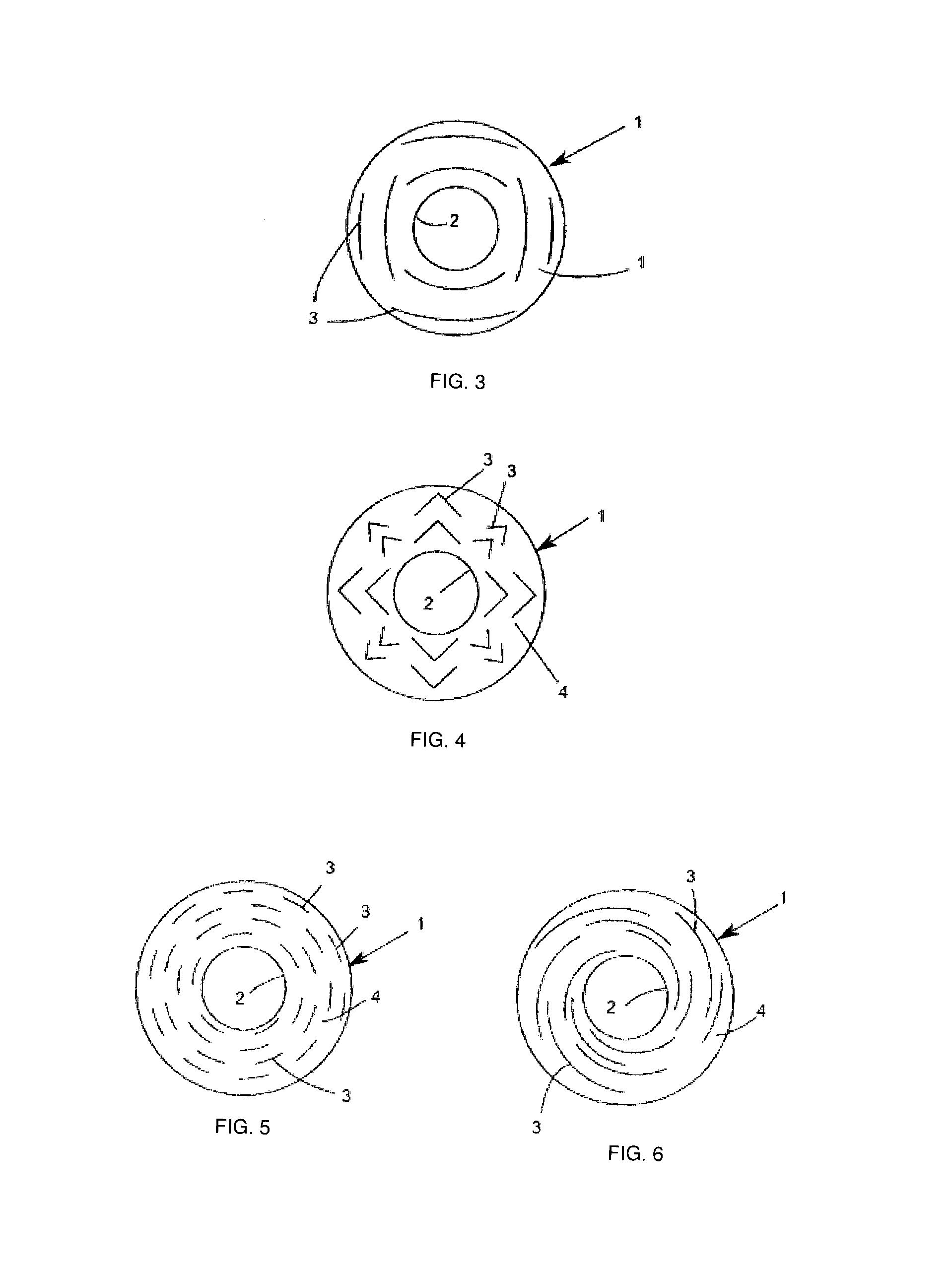

[0016]According to the above-mentioned schematic figures, the flame gas diffuser, in accordance with the present invention, comprises a cup 1 provided with a central opening 2 at which the cooking equipment burner is disposed, wherein on the surface 4 of said cup 1 barriers 3 are disposed, wherein said barriers are duly arranged and positioned in order to promote an extended passage pathways and channels for allowing the hot gas flow generated by the burner to pass.

[0017]As can be seen from the attached figures, it is possible to carry out a number of variations in the configurations concerning disposition and arrangement of said barriers 3. More particularly, FIGS. 1 to 4 illustrate mere examples of configurations, in which said barriers 3 are in a form capable of retaining or interrupting, at least partially, the continuous gas flow generated by the burner flame. In other words, said barriers 3 are intended to disturb or whirl the gas flow beneath the cooking utensil bottom, causi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com