Heat-Transfer Device

a technology of heat-transfer device and nano-particle, which is applied in the direction of lighting and heating apparatus, tubular elements, stationary conduit assemblies, etc., can solve the problem of difficulty in obtaining the heat-transfer enhancement effect of nano-particle porous layer sufficiently, and achieve the effect of heat-transfer enhancement effect of micro-porous layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

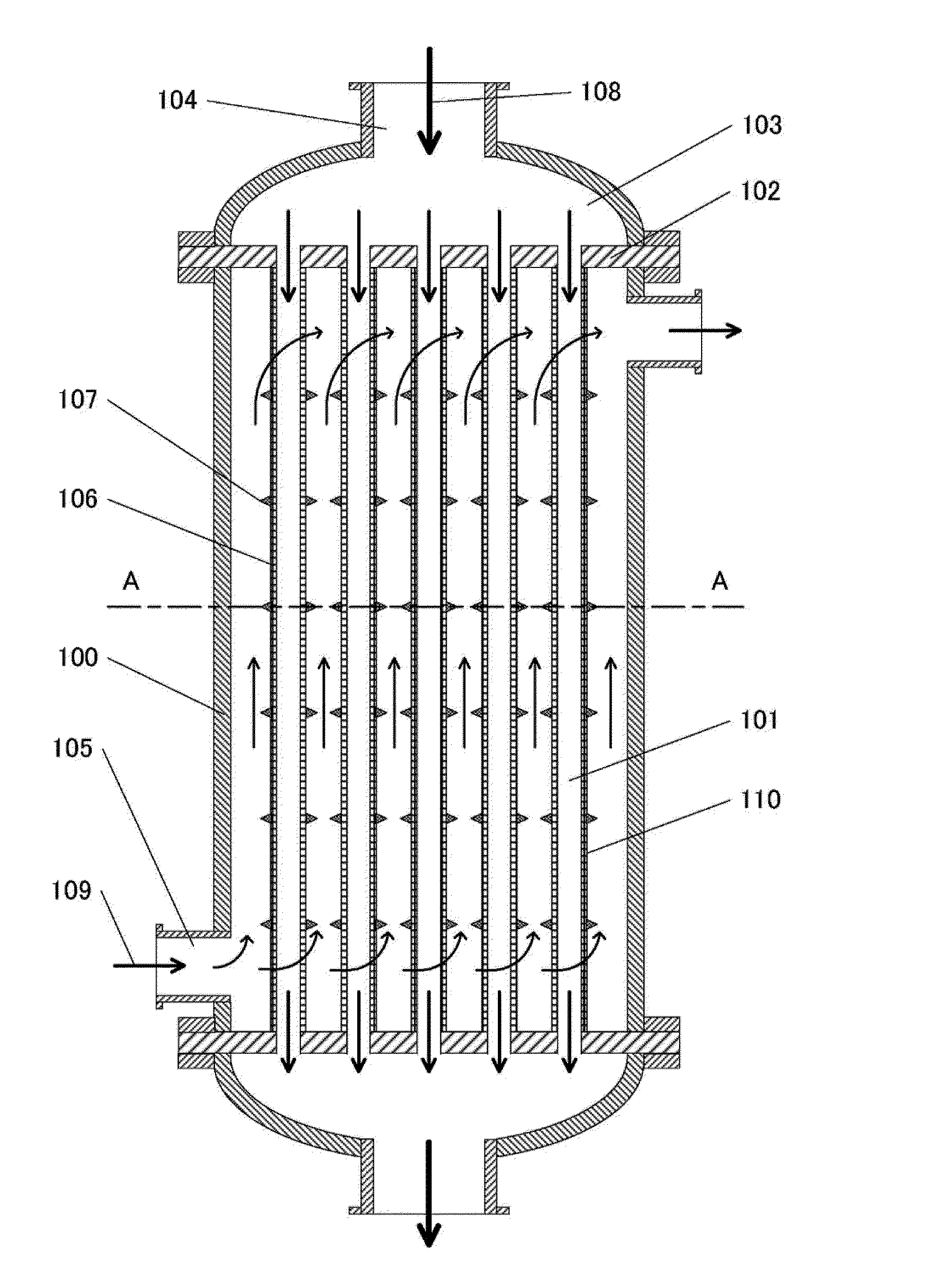

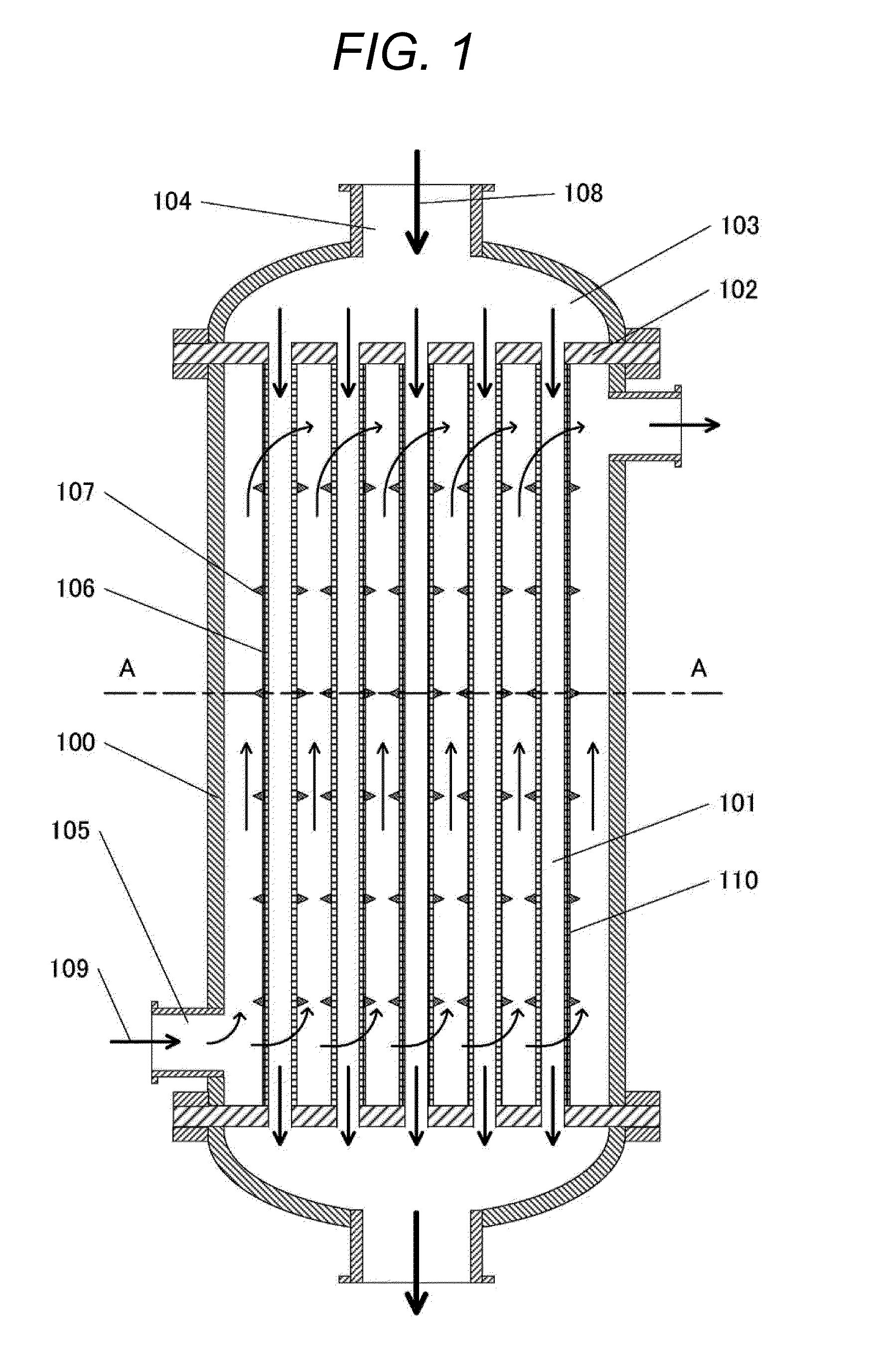

[0019]A first embodiment of the invention is a shell and tube heat exchanger with the heat-transfer device applied. This embodiment is capable of improving heat-transfer performance even under conditions of low flow velocities of a fluid used for heat exchange, in comparison with a conventional shell and tube heat exchanger.

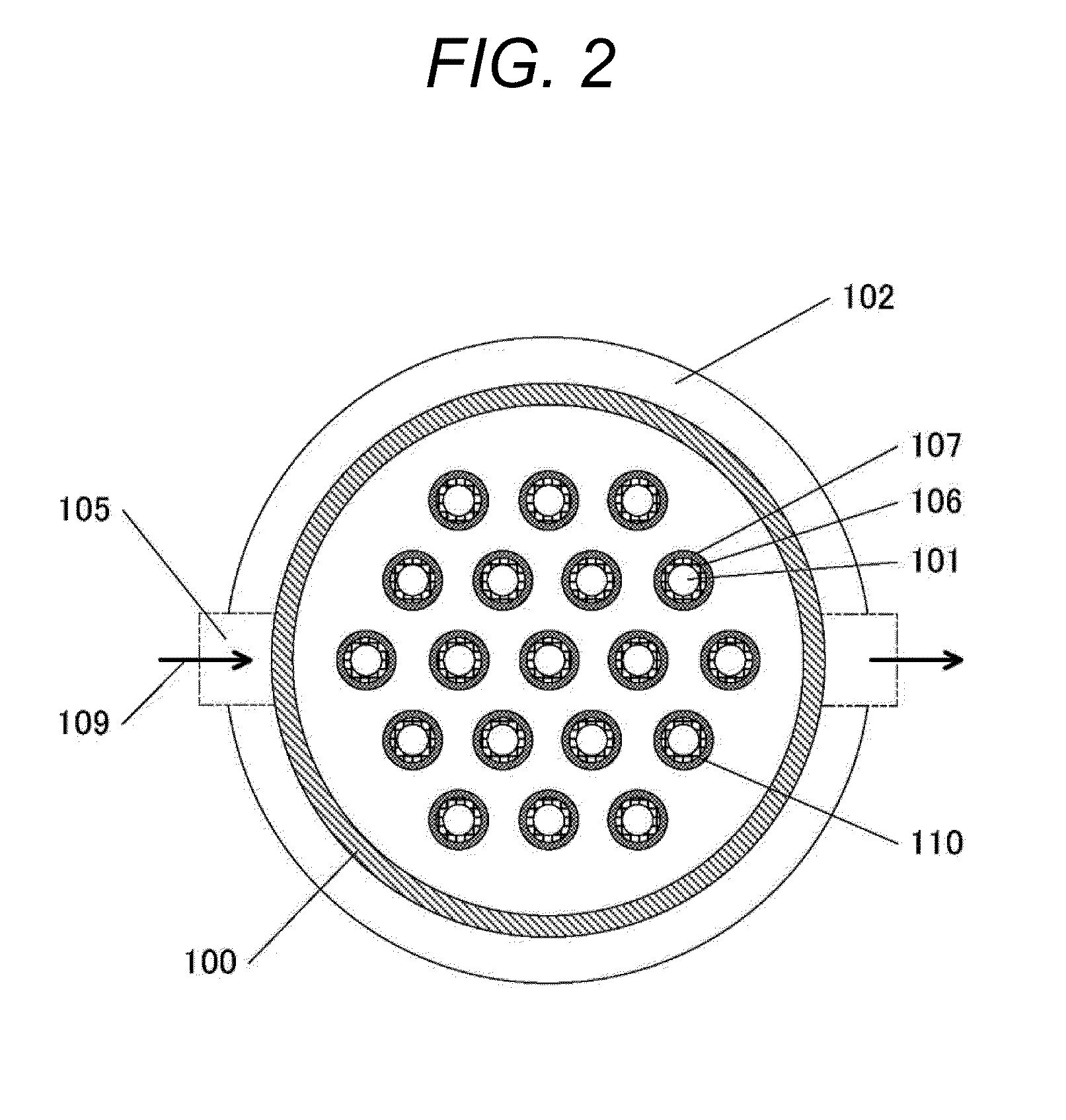

[0020]FIG. 1 is a structure diagram of the shell and tube heat exchanger according to the embodiment. A shell 100, which is circular or polygonal, is provided on both sides with tube plates 102 for supporting heat transfer tubes 101. The tube plates 102 each have a large number of holes arranged therein in a zigzag manner to allow the passage of the heat transfer tubes 101. The heat transfer tubes 101 pass through these tube holes to be fixed to the tube plates 102 at both sides. The heat transfer tubes 101 are made with a metal having high thermal conductivity, such as aluminum and copper. The heat transfer tubes 101 may be made with SUS. A vapor 108, which is a...

second embodiment

[0029]A second embodiment is a shell and tube heat exchanger with the heat-transfer device applied. This embodiment is capable of improving the heat-transfer performance even under conditions of low flow velocities of a fluid used for heat exchange, in comparison with a conventional shell and tube heat exchanger. The embodiment can also curb vibration of heat transfer tubes that accompanies the condensation of vapor.

[0030]FIG. 4 is a structure diagram of the shell and tube heat exchanger according to the second embodiment. FIG. 5 is a sectional view taken along line A-A of FIG. 4. The shell and tube heat exchanger in FIG. 4 will now be described, with an omission of parts indicated with the same reference numerals and having similar functions with those in the arrangement described in FIG. 1.

[0031]A micro porous layer 110 described in the first embodiment is formed on the outer surface of each heat transfer tube 101 to enhance heat transfer. A plurality of heat-transfer enhancing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com