Integrated dive suit

a dive suit and integrated technology, applied in the field of dive suits, can solve the problems of heavy, bulky, uncomfortable to wear, difficult to handle tanks,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

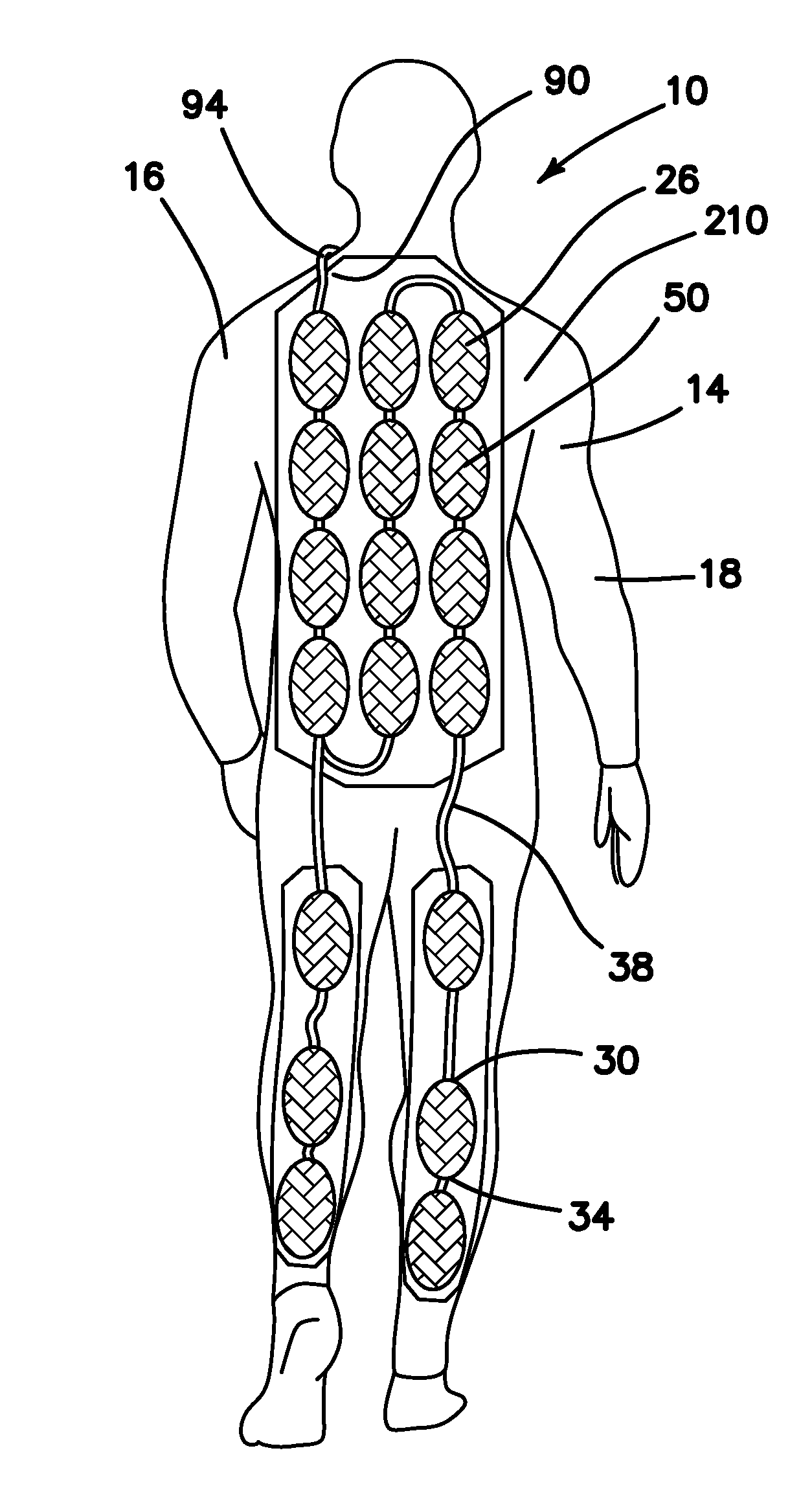

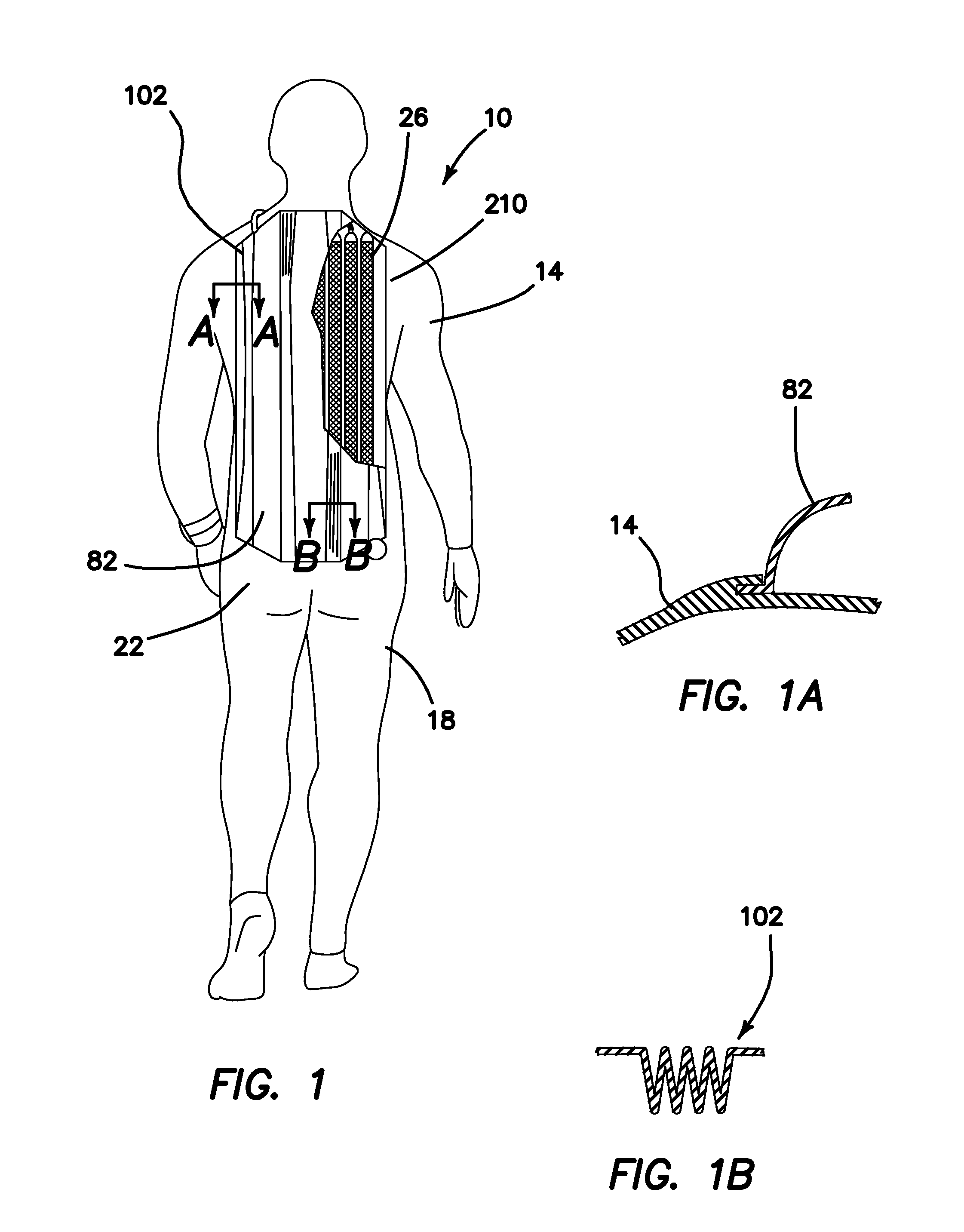

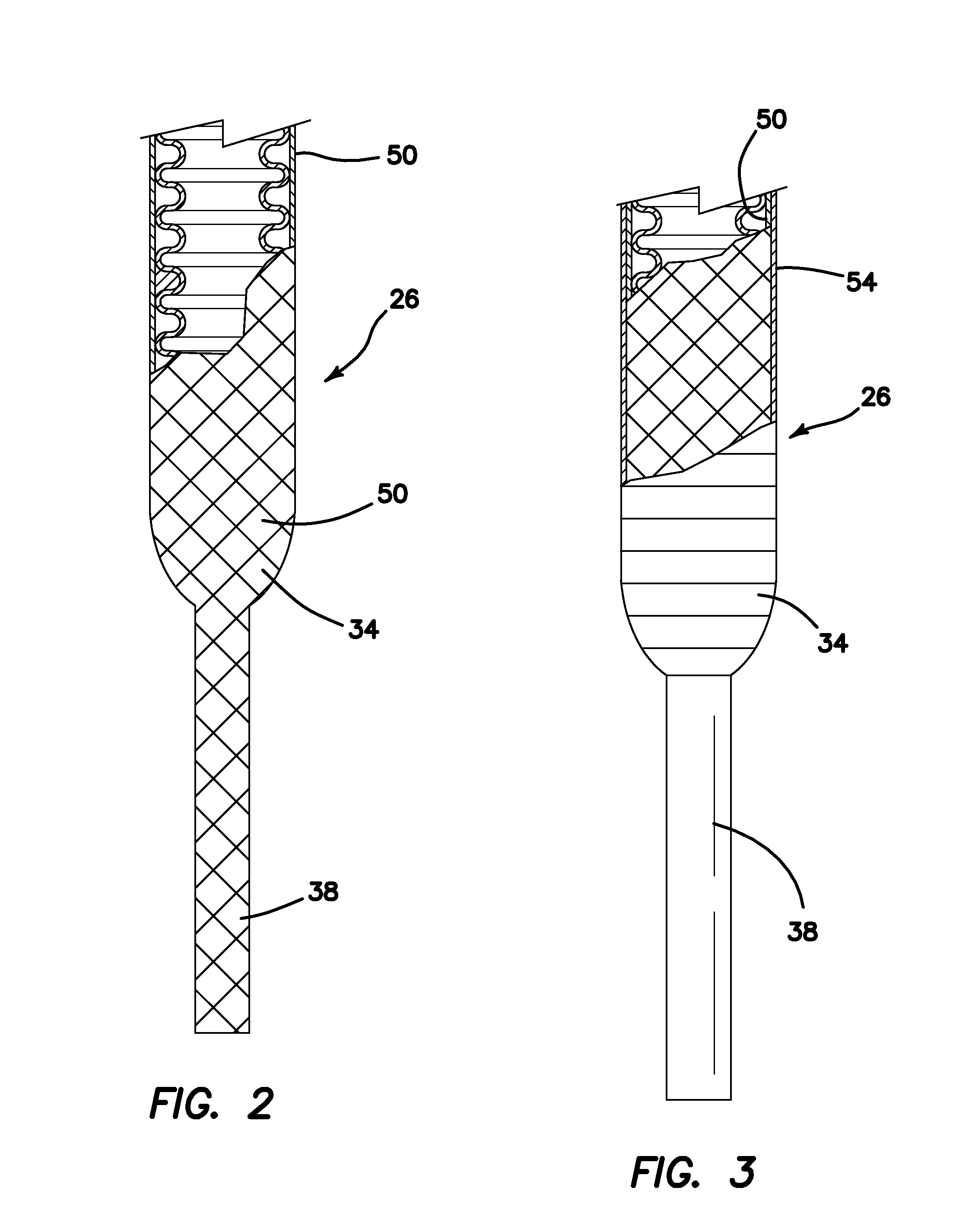

[0094](1) FIGS. 1, 8 and 9 illustrate an integrated dive suit 10 providing the desired features that may be constructed from the following components. A dive suit 14 is provided. The dive suit 14 is formed of flexible material 18 and shaped to fit about a diver's body 22. At least one flexible polymeric pressure vessels 26 is provided. The vessel 26 has a first end 30 and a second end 34. Each of the first 30 and second 34 ends has an attached section of flexible conduit 38. Each of the sections of flexible conduit 38 is attached to either of a sealing fitting 42, an inlet fitting 44, a coupling fitting 48, another section of flexible conduit 38 attached to another vessel 26 or a manifold 46. As illustrated in FIG. 2, the at least one pressure vessel 26 and the sections of flexible conduit 38 are encased in high strength fiber material 50. As illustrated in FIG. 3, the at least one pressure vessel 26 is wrapped with a high strength ballistic ribbon material 54. As illustrated in FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com