Counterweighted pump jack with reversible motors

a counterweighted, motorized technology, applied in the direction of positive displacement liquid engine, fluid removal, borehole/well accessories, etc., can solve the problems of large, heavy, expensive construction, and large walking beam style of pumping unit, and achieve the effect of suitable strength and reliability, and reliably carrying large tensile loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

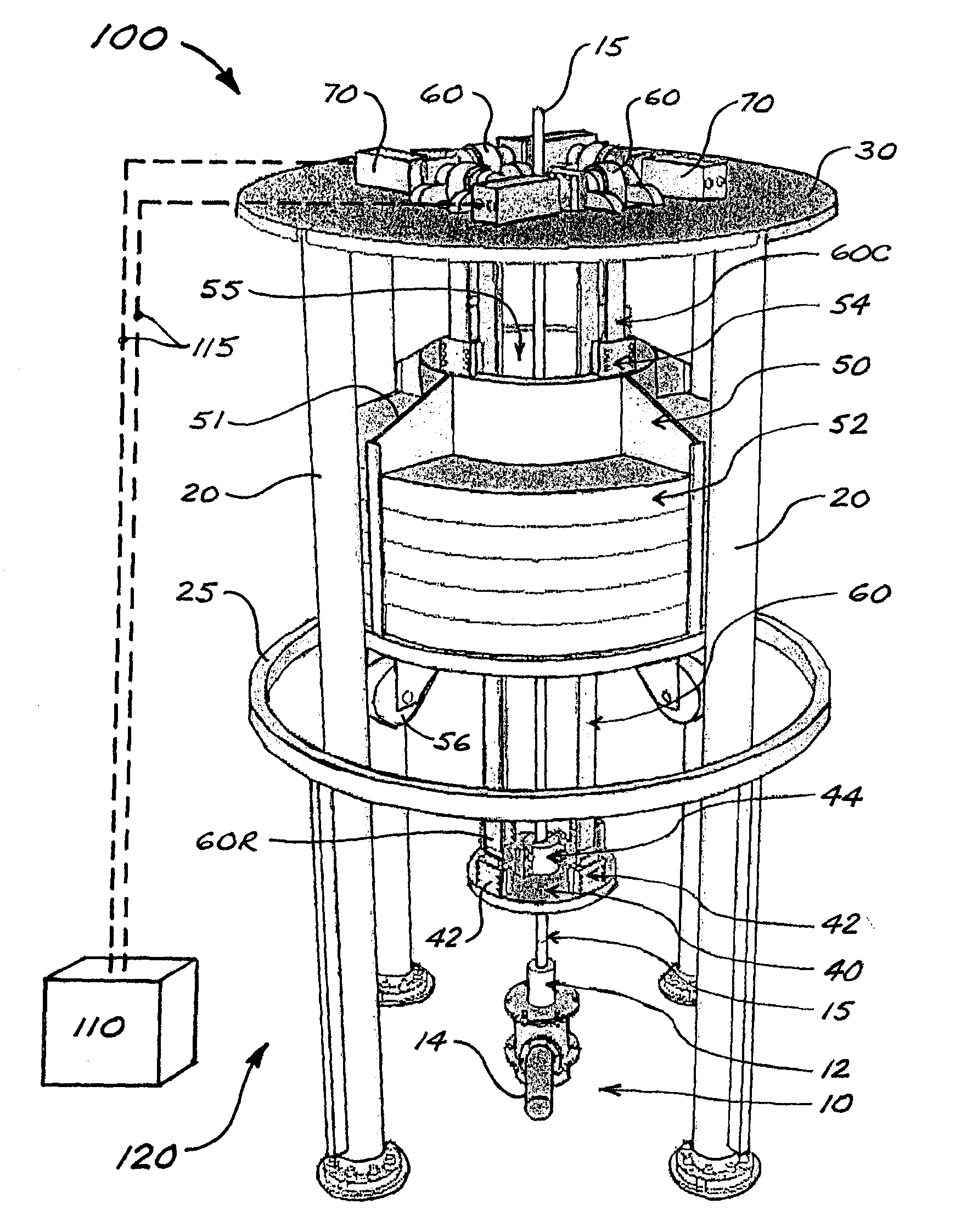

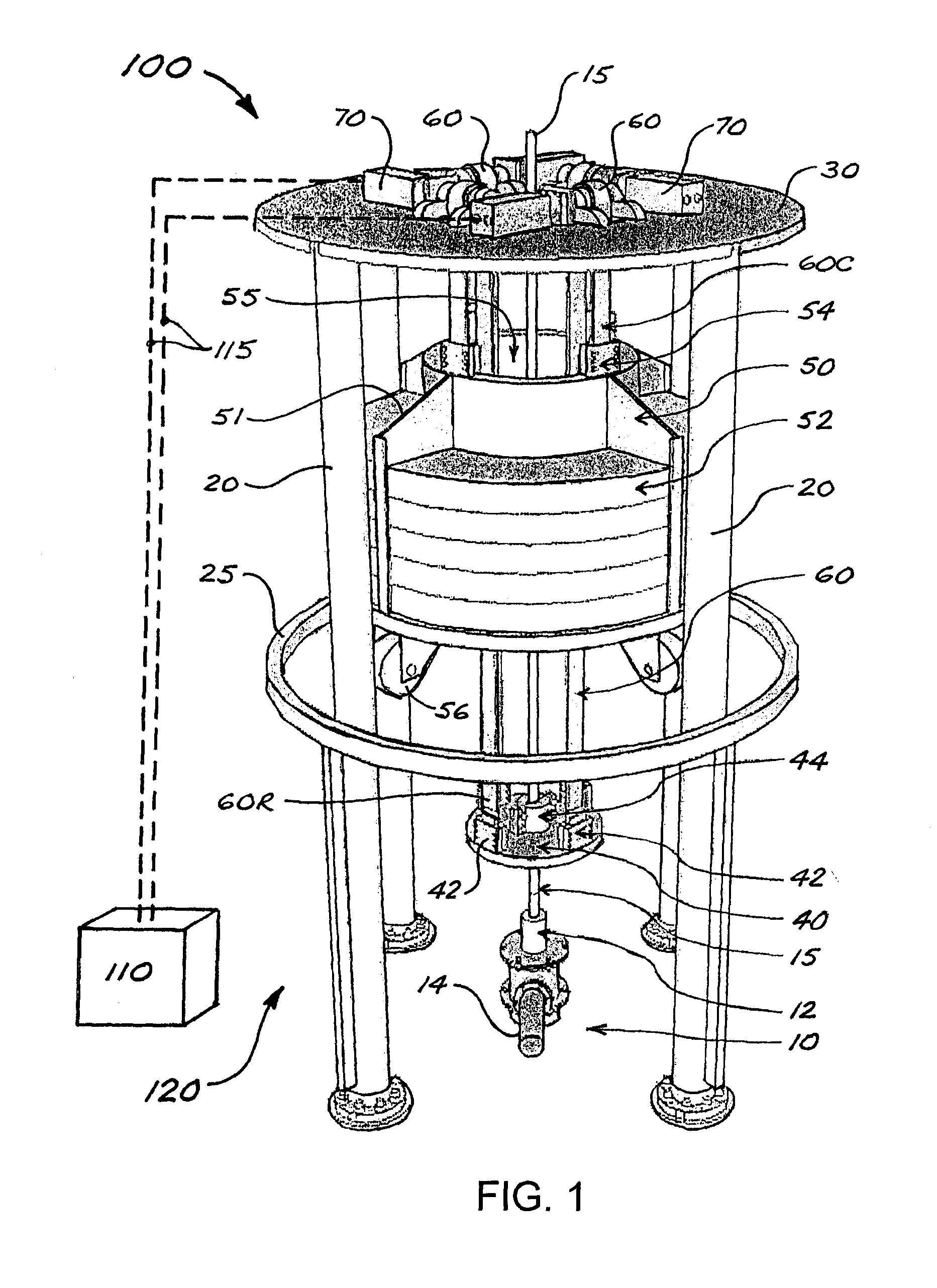

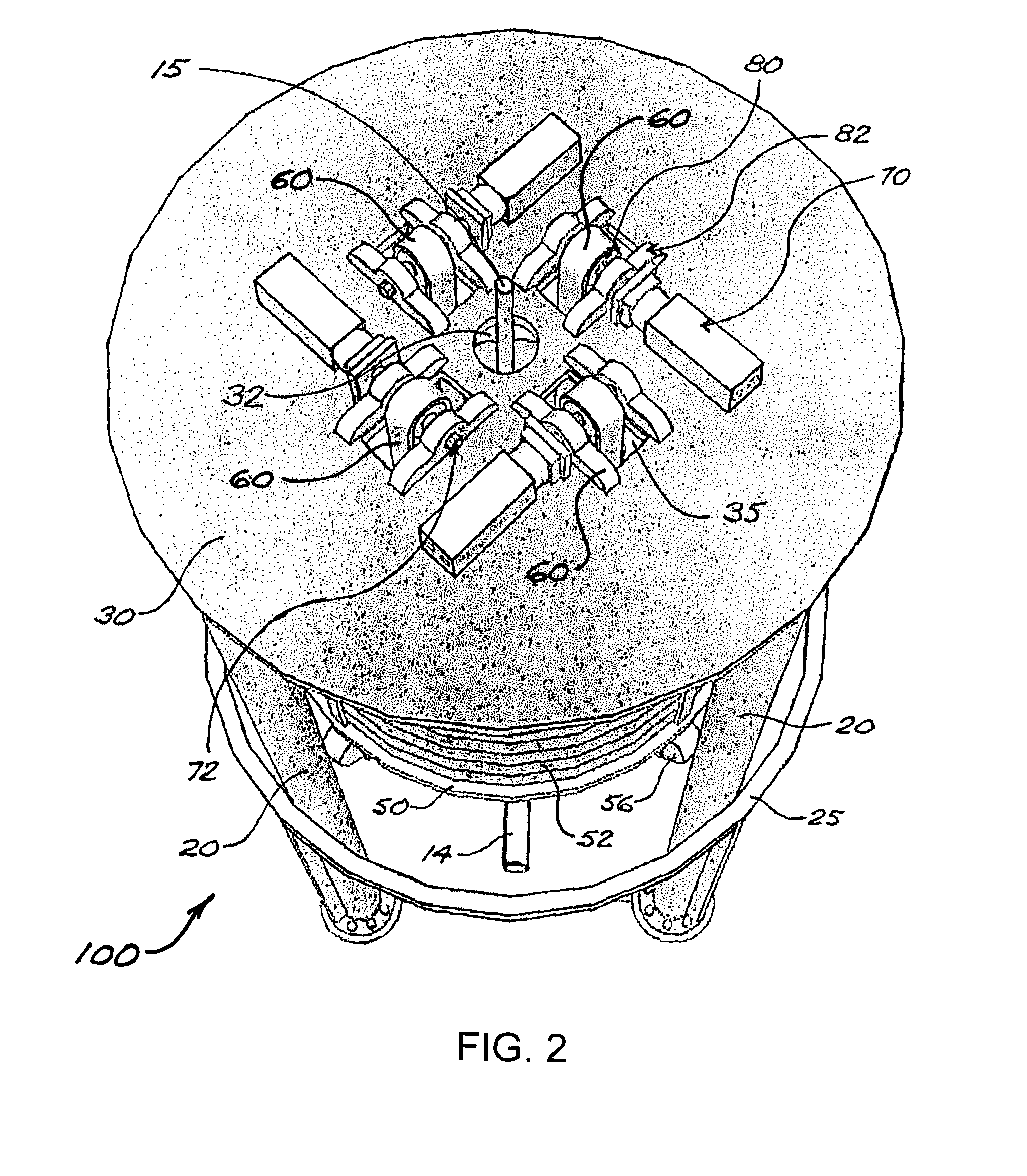

[0039]FIGS. 1-3 illustrate a first embodiment 100 of a well pumping unit in accordance with the present disclosure. Pumping unit 100 comprises a support structure 120 that may be positioned over a wellhead 10 associated with a wellbore. Wellhead 10 will typically include a stuffing box 12 through which and upward from which extends a polished rod 15 associated with a pump rod string connected to a downhole pump (not shown) disposed within a production tubing string installed in the wellbore. Wellhead 10 also includes a flow tee 14 for drawing off fluids produced from the well.

[0040]In FIGS. 1-3, support structure 120 is shown as comprising a plurality of vertical columns 20, with a perimeter support member 25 connecting columns 20 at about mid-height. This depiction is solely for conceptual illustrative purposes; the configuration of support structure 120 for a given application will be a matter of design choice, and embodiments of well pumping units in accordance with the present d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com