Workpiece holding frame

a workpiece and frame technology, applied in the field of workpiece holding frames, can solve the problems of limited movement of the print head, difficult positional alignment between the print pattern and the embroidery pattern, and high labor intensity, and achieve the effect of improving the structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

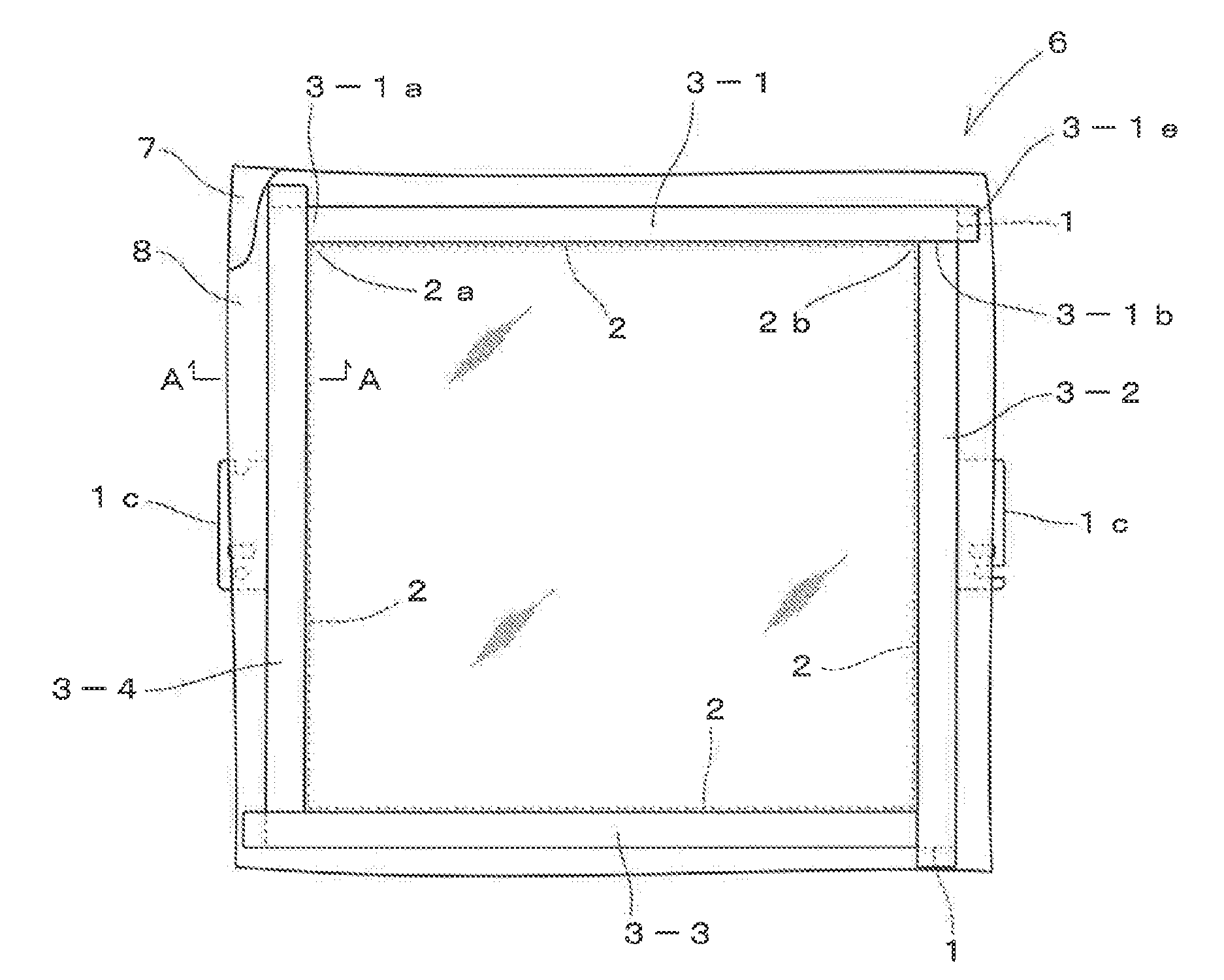

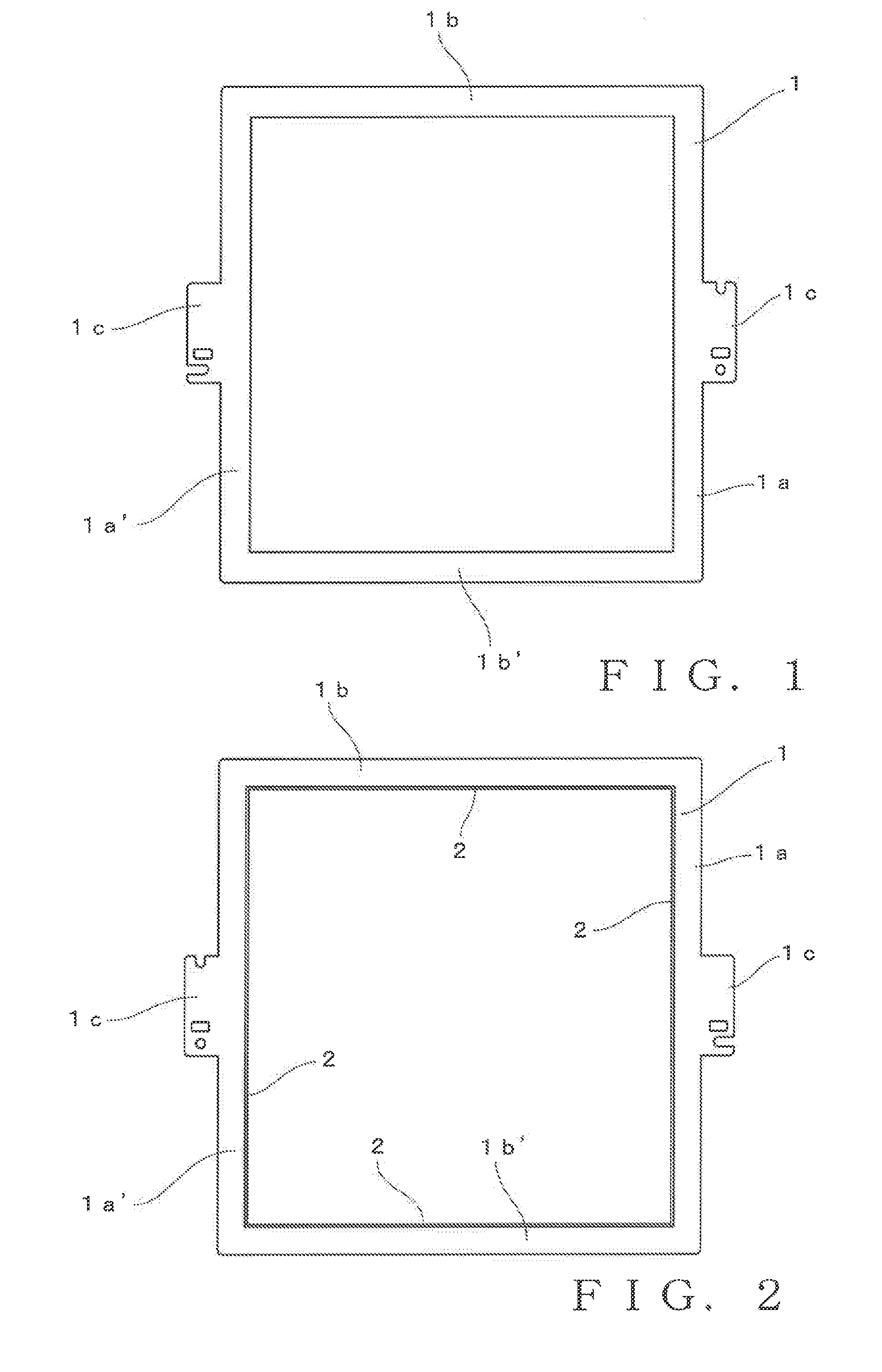

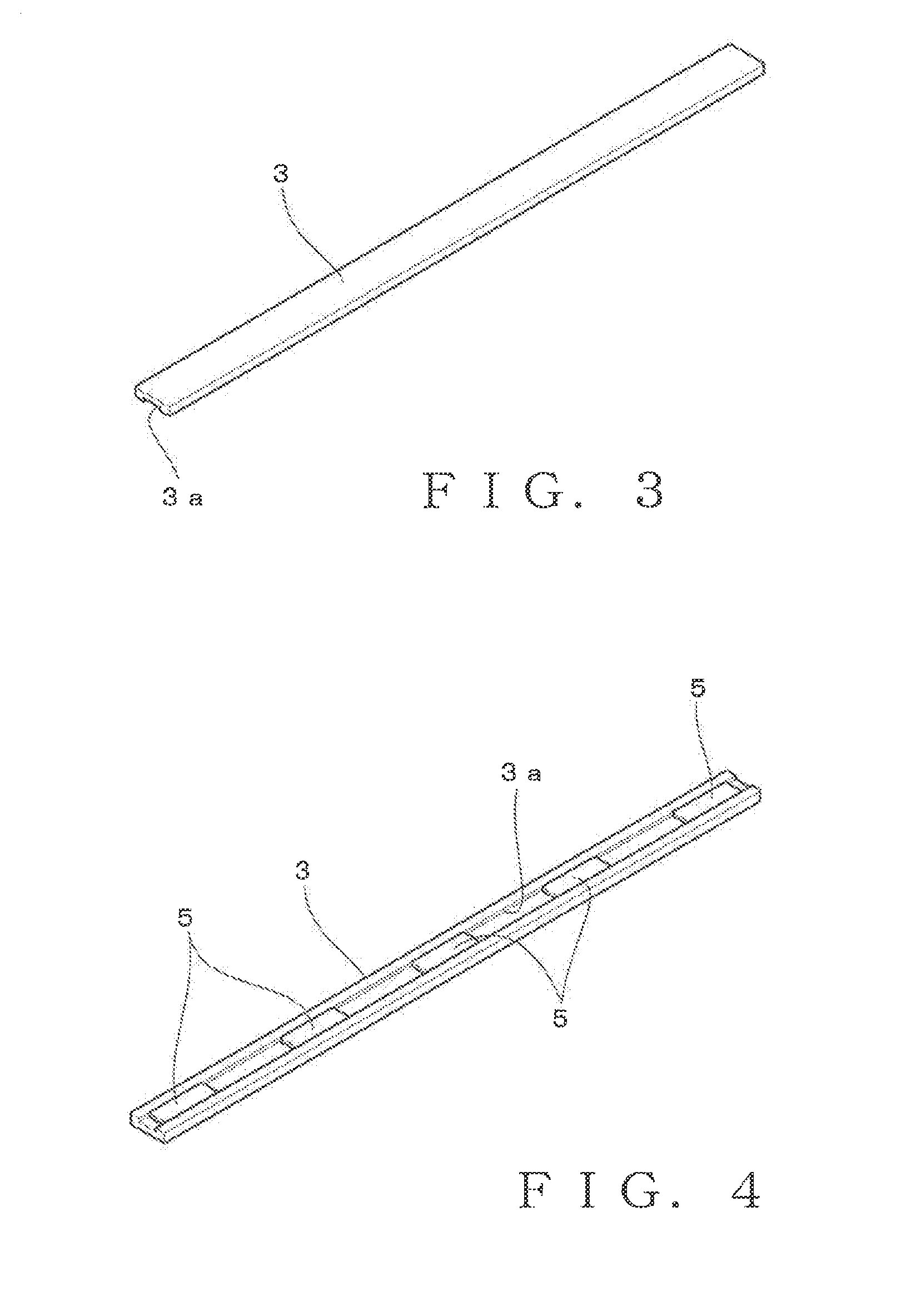

[0025]A holding frame 6 according to the present invention is configured by a combination of a holding frame main body 1 shown in FIGS. 1 and 2 and a holding piece 3 shown in FIGS. 3 and 4. The holding frame main body 1 is configured by a thin plate made of magnetic materials such as a steel plate, and is formed by joining, by means of welding or the like, respective frame sides 1a and 1a′ on right and left sides and respective frame sides 1b and 1b′ on upper and lower sides into a rectangular shape. On opposing inner edges of the respective frame sides 1a, 1a′, 1b and 1b′, a rib 2 bent toward a bottom side at a predetermined width from an end of the inner edge is formed for each frame side, as shown in FIGS. 2 and 5. A height of the rib 2 is, for example, 5 mm or less. Attaching arms 1c are formed respectively on outer sides of the right and left frame sides 1a, 1a′. The attaching arms 1c are provided for attaching the holding frame main body 1 to a frame driving portion (not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com