Motor-driven compressor

a motor-driven compressor and compressor technology, applied in the direction of electric generator control, dynamo-electric converter control, dynamo-electric gear control, etc., can solve the problems of increasing the frequency increasing the noise of switching elements, and increasing the number of switching of switching elements, so as to reduce the heat generation of switching elements and minimize noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

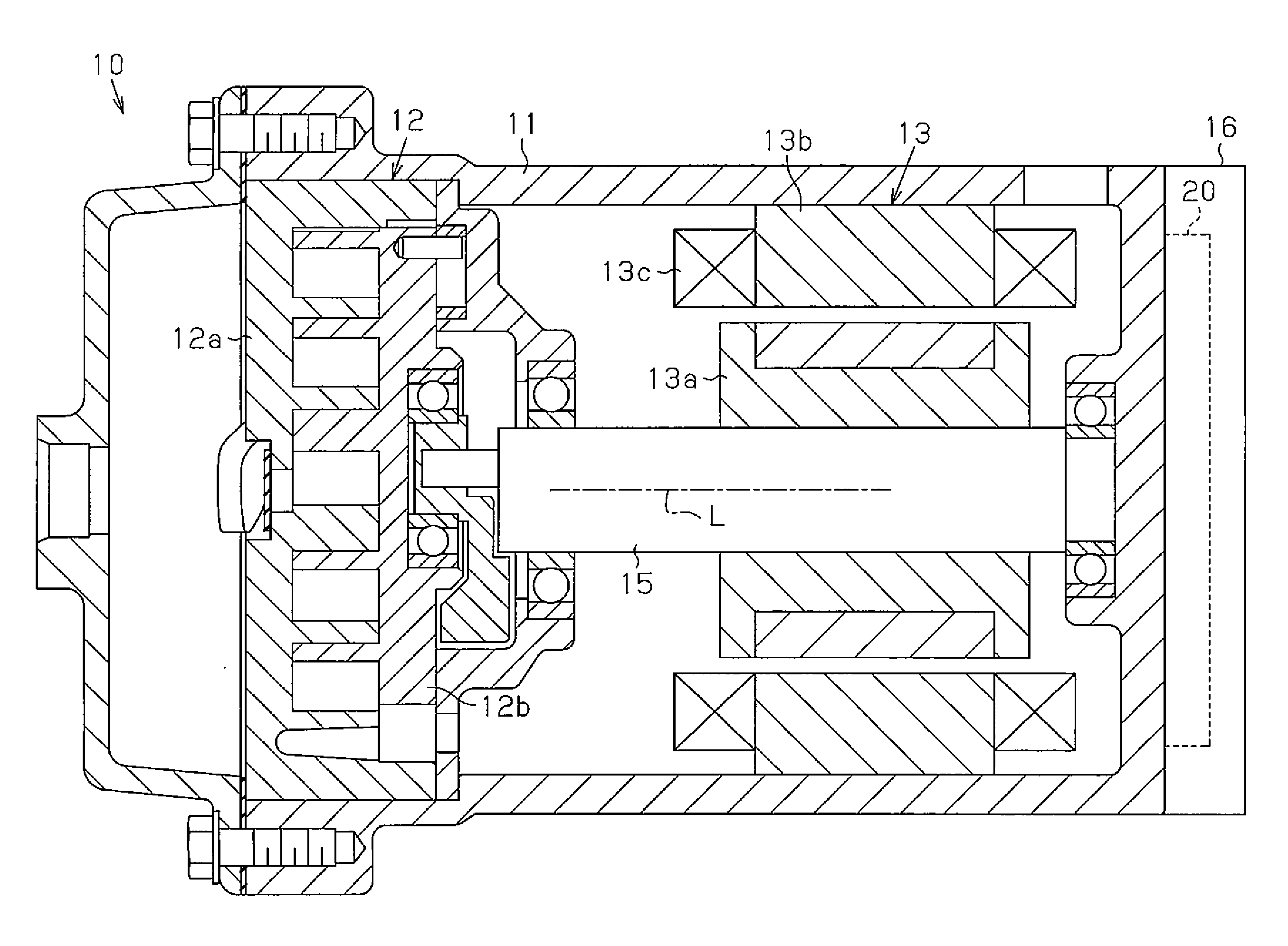

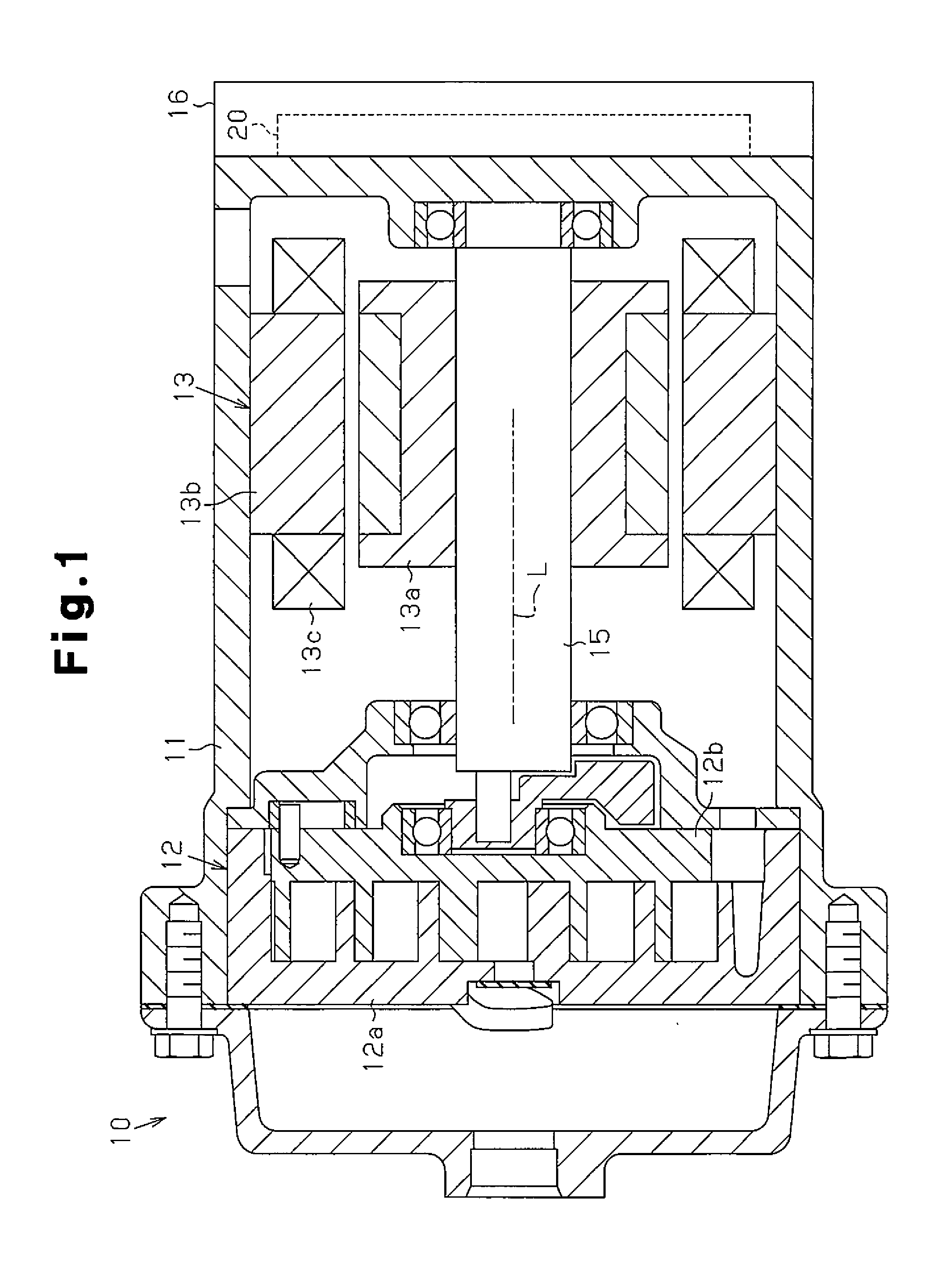

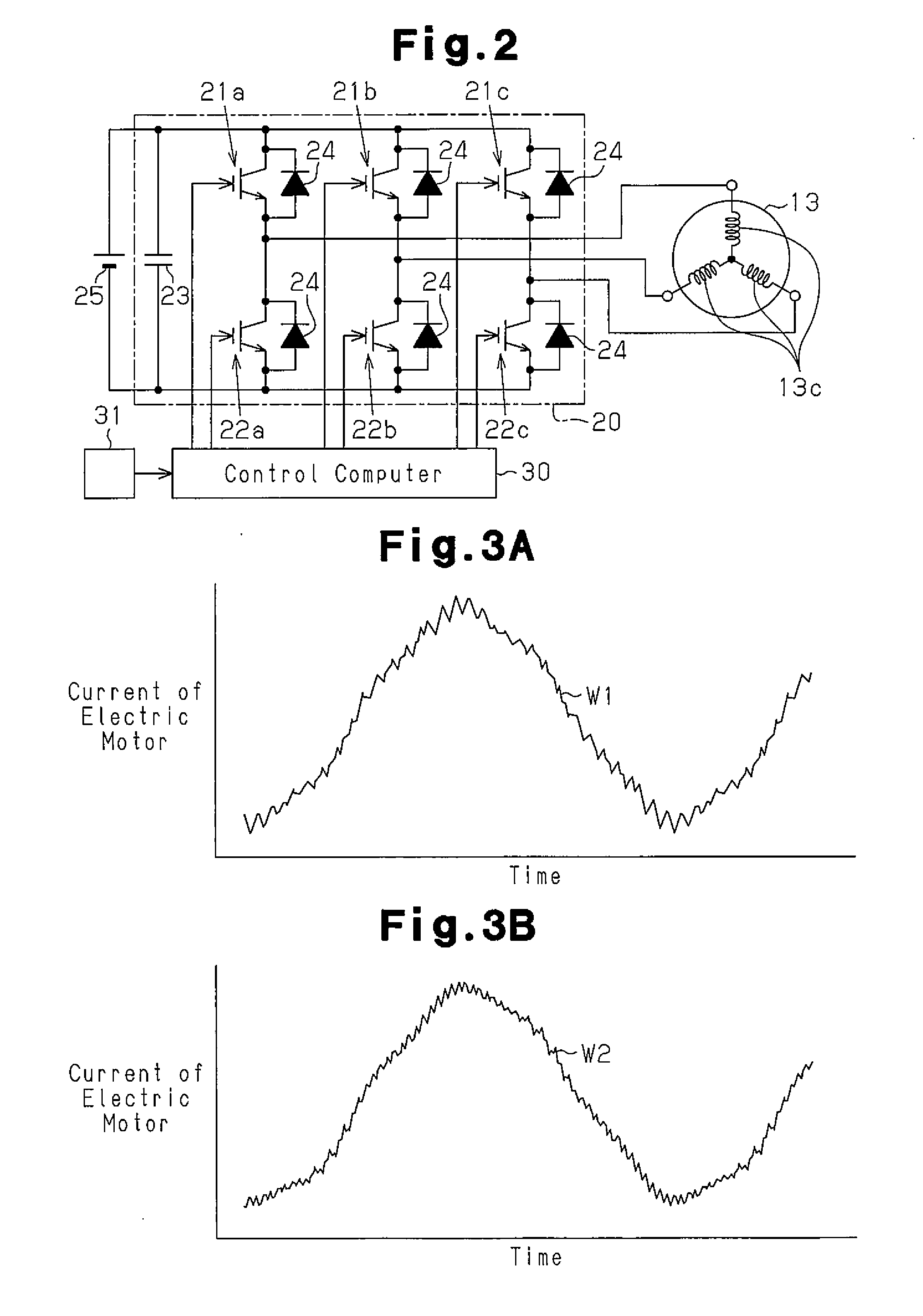

[0017]A motor-driven compressor 10 according to one embodiment will now be described with reference to FIGS. 1 to 6. The motor-driven compressor 10 of the present embodiment is mounted on a vehicle and employed for a vehicle air conditioner.

[0018]As shown in FIG. 1, the motor-driven compressor 10 has a housing 11, which accommodates a compression portion 12 and an electric motor 13. The compression portion 12 compresses and discharges refrigerant, and the electric motor 13 drives the compression portion 12. The compression portion 12 includes a fixed scroll 12a, which is fixed in the housing 11, and an orbiting scroll 12b, which is arranged to be opposed to the fixed scroll 12a. The electric motor 13 includes a rotor 13a and a stator 13b. The rotor 13a is fixed to a rotary shaft 15 to rotate integrally with the rotary shaft 15, and the stator 13b is fixed to the inner circumferential surface of the housing 11.

[0019]A cover 16 is attached to the bottom wall of the housing 11. The cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com