Sheet conveying apparatus and image forming apparatus

a technology of conveying apparatus and sheet, which is applied in the direction of transportation and packaging, electrographic process, instruments, etc., can solve the problems of difficult to sufficiently correct shearing of the fibrous tissue, etc., and achieves the effect of reducing the difference, and improving the rippling of the sh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

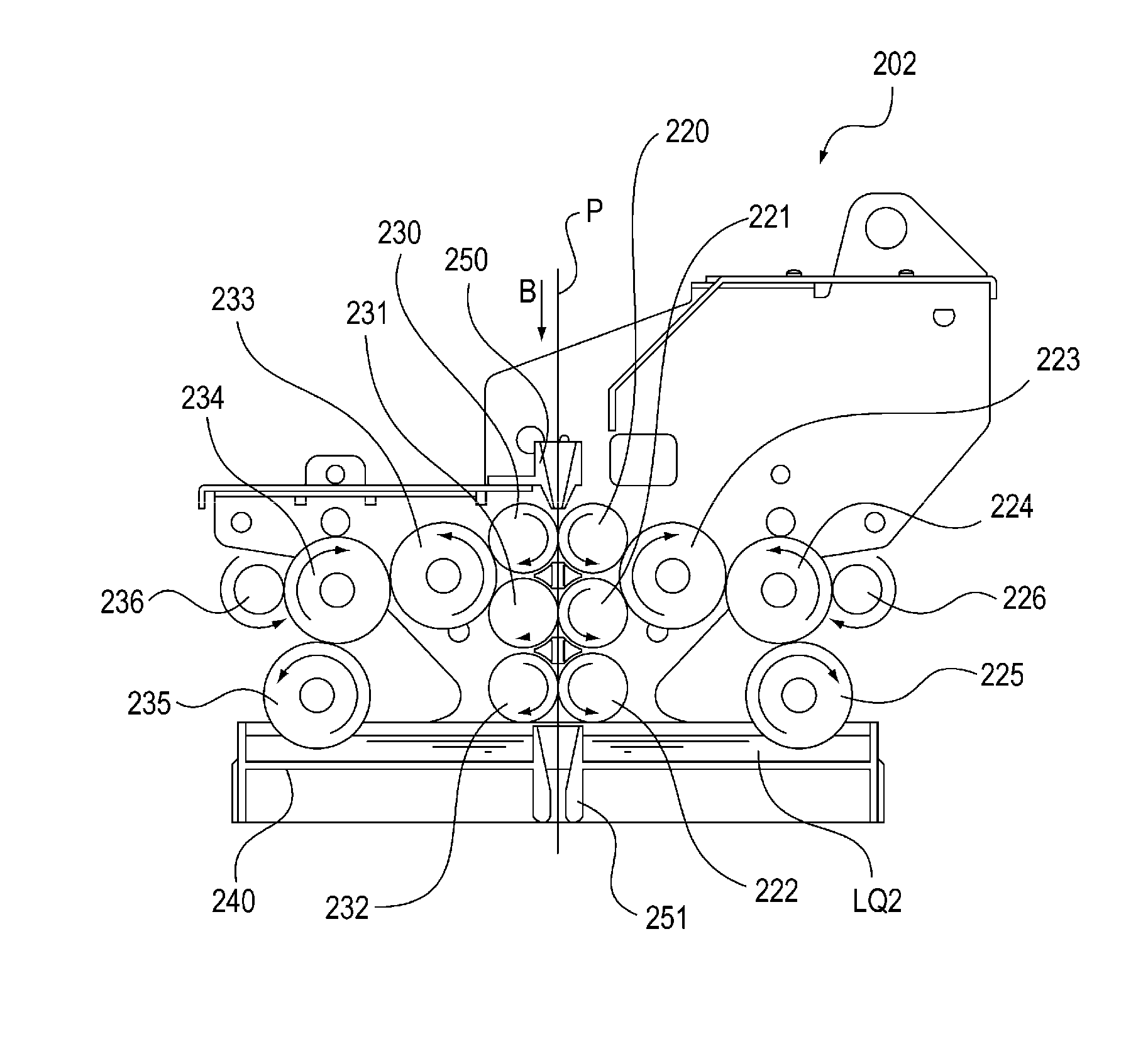

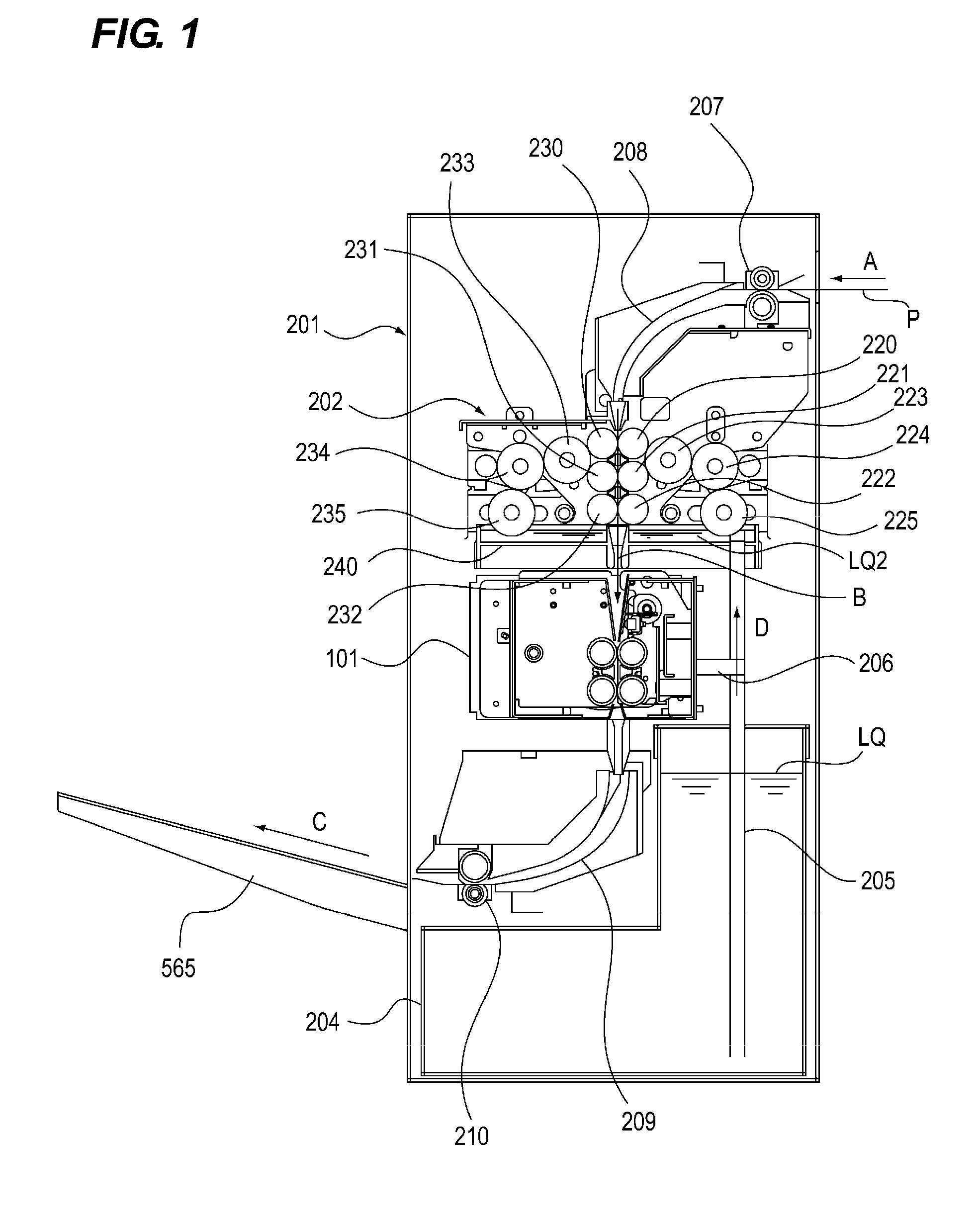

[0051]An image forming apparatus according to the embodiment will be described using FIGS. 1 to 14C.

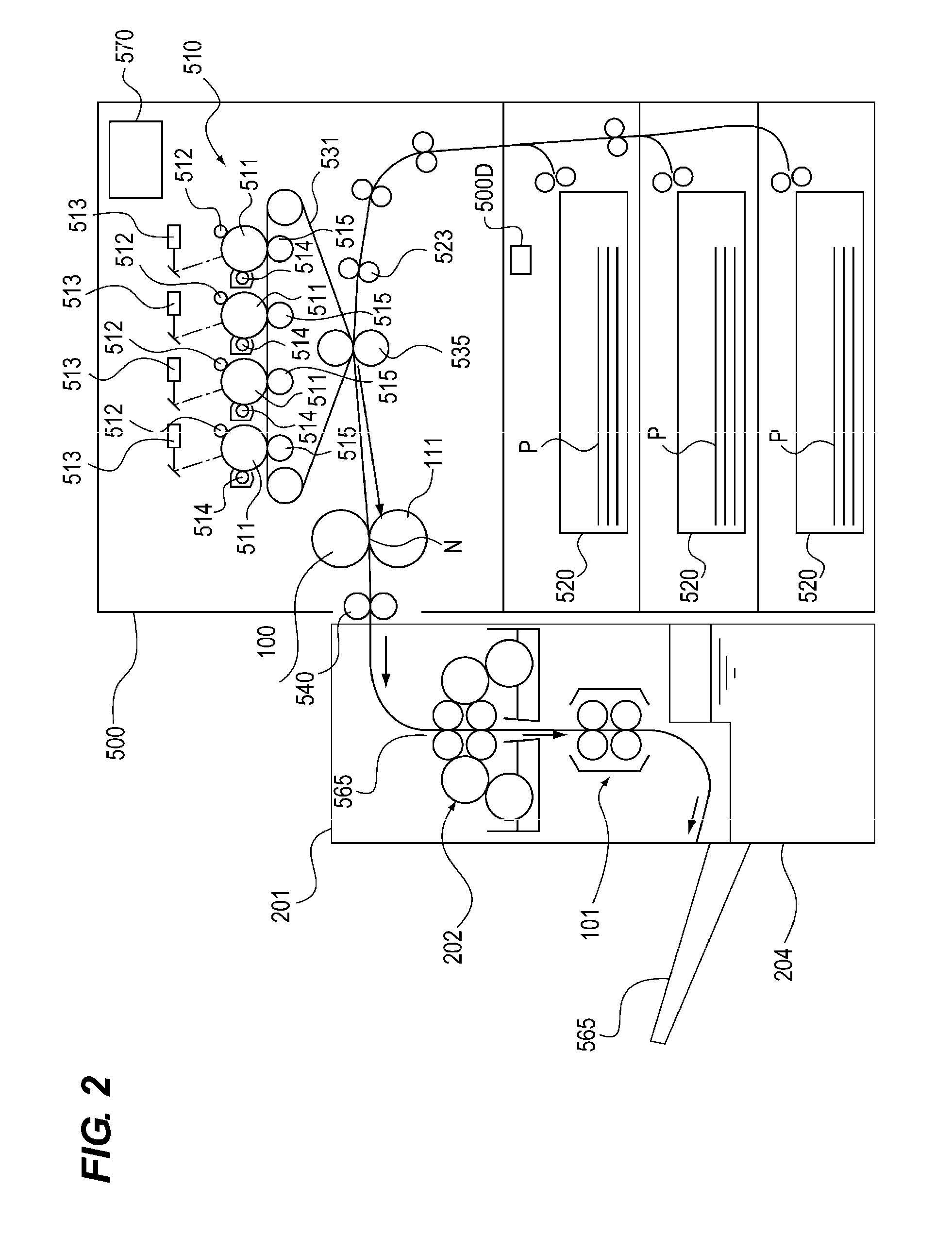

[0052]FIG. 2 is a cross-sectional view schematically illustrating a color electrophotographic printer 500 as an example of the image forming apparatus which is taken along a conveying direction of a sheet. Herein, the color electrophotographic printer will be simply referred to as a “printer”.

[0053]The sheet is used to form a toner image thereon. Specific examples of the sheet include plain paper, a resin sheet-like medium as a substitute for the plain paper, thick paper, a medium used for an overhead projector, and the like.

[0054]The printer illustrated in FIG. 2 includes an image forming portion 510 of each color of Y (yellow), M (magenta), C (cyan), and Bk (black). The image forming portion 510 of each color is used to form a toner image of each color on the sheet. The image forming portion 510 of each color includes process portions as follows; an electrophotographic photoconducto...

second embodiment

[0141]The configuration of the sheet pulling and conveying apparatus according to the embodiment will be described using FIGS. 17 to 19. FIG. 17 is a top view illustrating the sheet pulling and conveying apparatus 101 used in the embodiment. The embodiment is different from the first embodiment only in the sheet pulling and conveying apparatus 101, and thus the configurations overlapped with the first embodiment will not be repeated.

[0142]In the above-mentioned embodiment, as the load portion, the electromagnetic hysteresis brake (the electromagnetic brake) is exemplified in which the brake torque can be changed as the exciting current is changed. In this regard, as the load portion, the embodiment describes a configuration in which a plurality of torque limiters TL1 to TL3 is connected to the driving gear 104G2 of the first roller A104 through clutches CL2 to CL4. Then, the load controller performs control such that the clutches CL2 to CL4 are selectively connected or disconnected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inner diameter | aaaaa | aaaaa |

| inner diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com