Fluid Regulating Valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

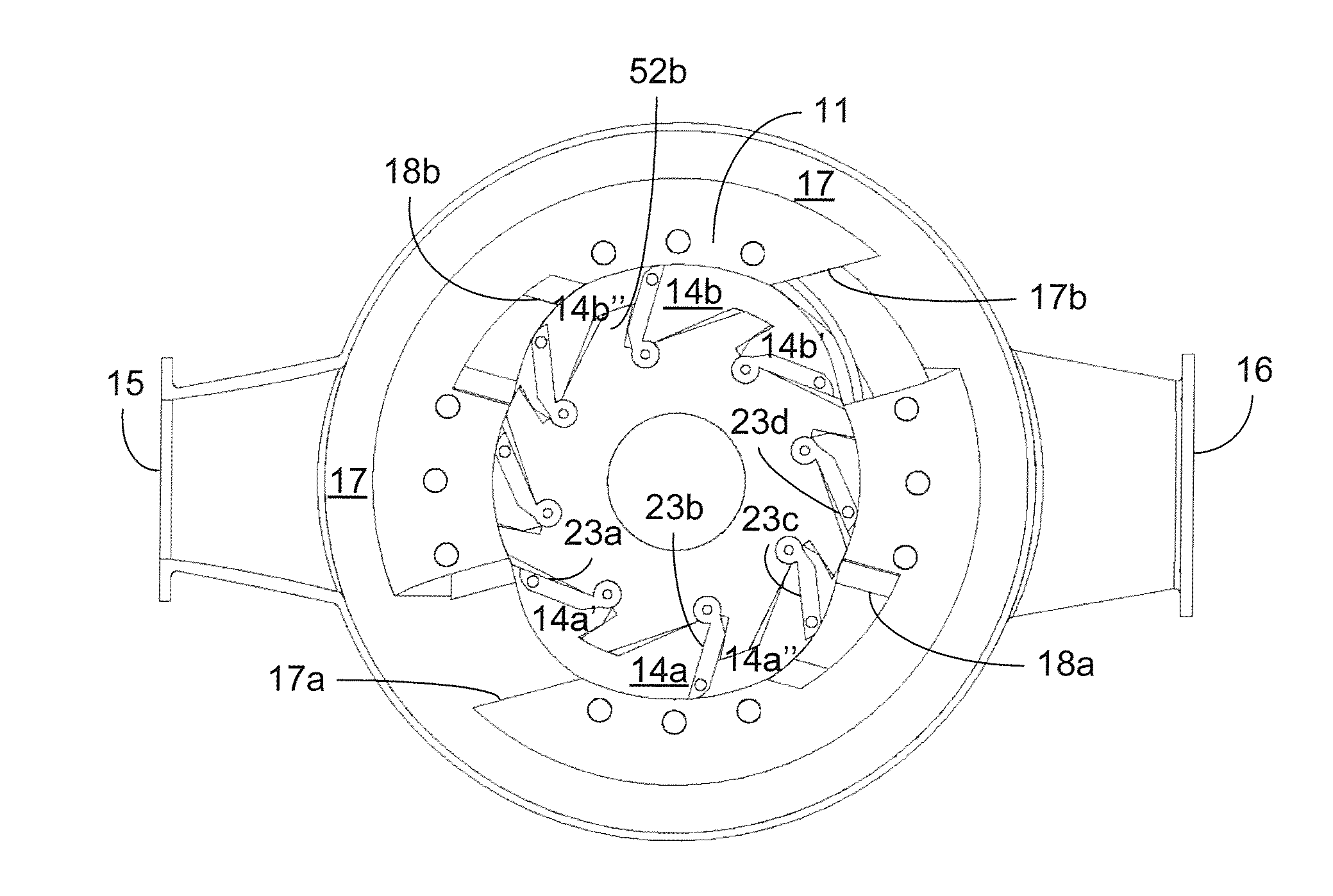

[0071]Comparative calculations of the efficiency at a previously known valve and a valve according to the present invention has been carried out. Except the differences in balancing of the rotor both valves are essentially equal and comprises a rotor with an active rotor length of approx. 300 mm.

[0072]At the previously know valve, a clearance of 2 mm between the rotor and the stator is needed for compensating for the deflection of the unbalanced rotor. This clearance results in a leakage opening of approx. 300 mm×2 mm=600 mm2 between the high pressure side and low pressure side at each vane.

[0073]Calculations have been carried out for such a known valve when driven at a differential pressure of 5 bar, where the fluid pressure upstream of the device is 6 bar and downstream 1 bar. These calculations show that if the valve is driven with an input water flow of 80 litres per second, then the internal leakage from the high pressure side to the low pressure side of the rotor is approximat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com