Artificial lawn

a technology of artificial turf and piles, applied in the field of artificial turf, can solve the problems of affecting playability, splitting and fracture, and the tip of the pile to be fibrillated (to form fibrils), and achieve the effects of improving flexibility of piles, preventing the progression of fibrillation, and stable durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

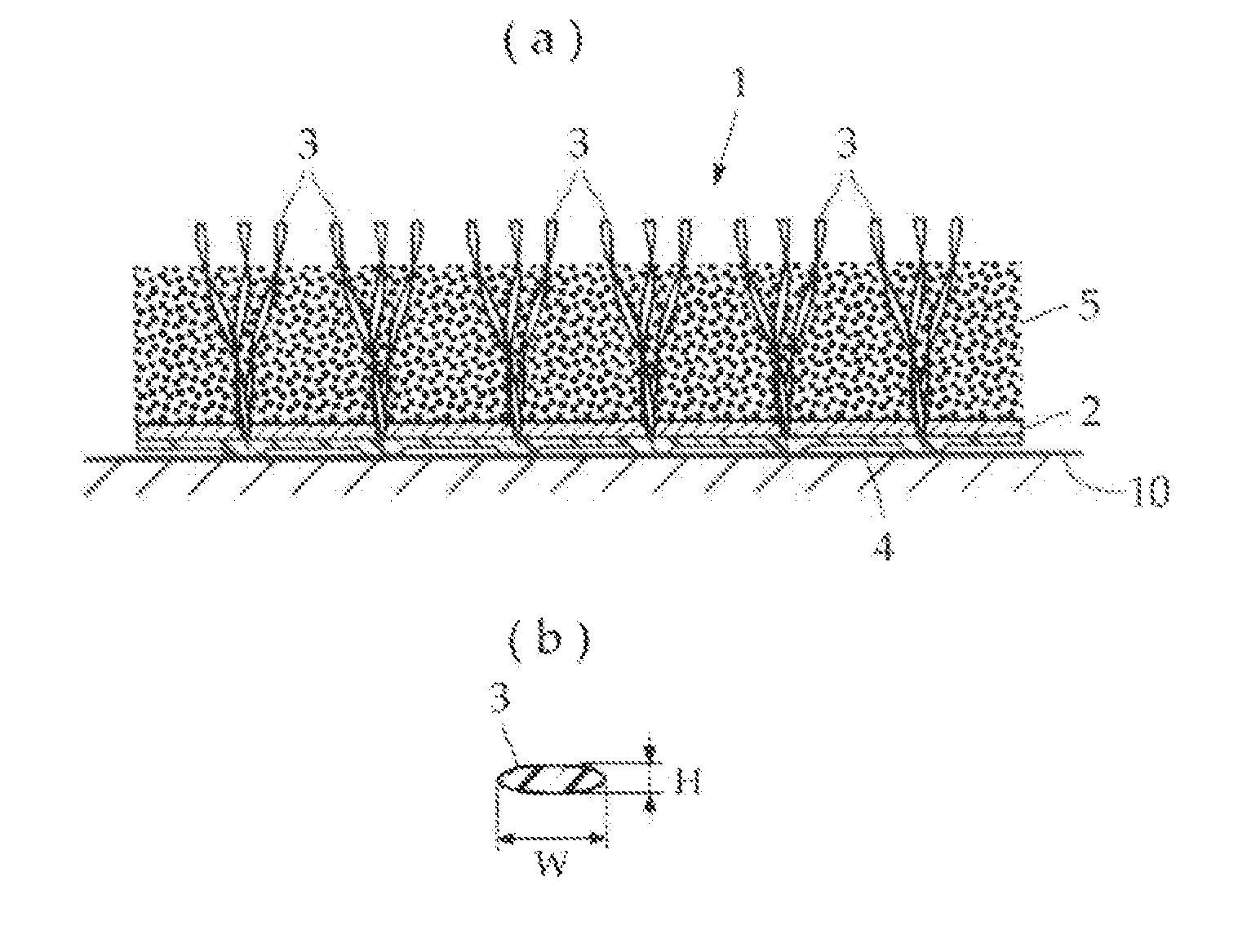

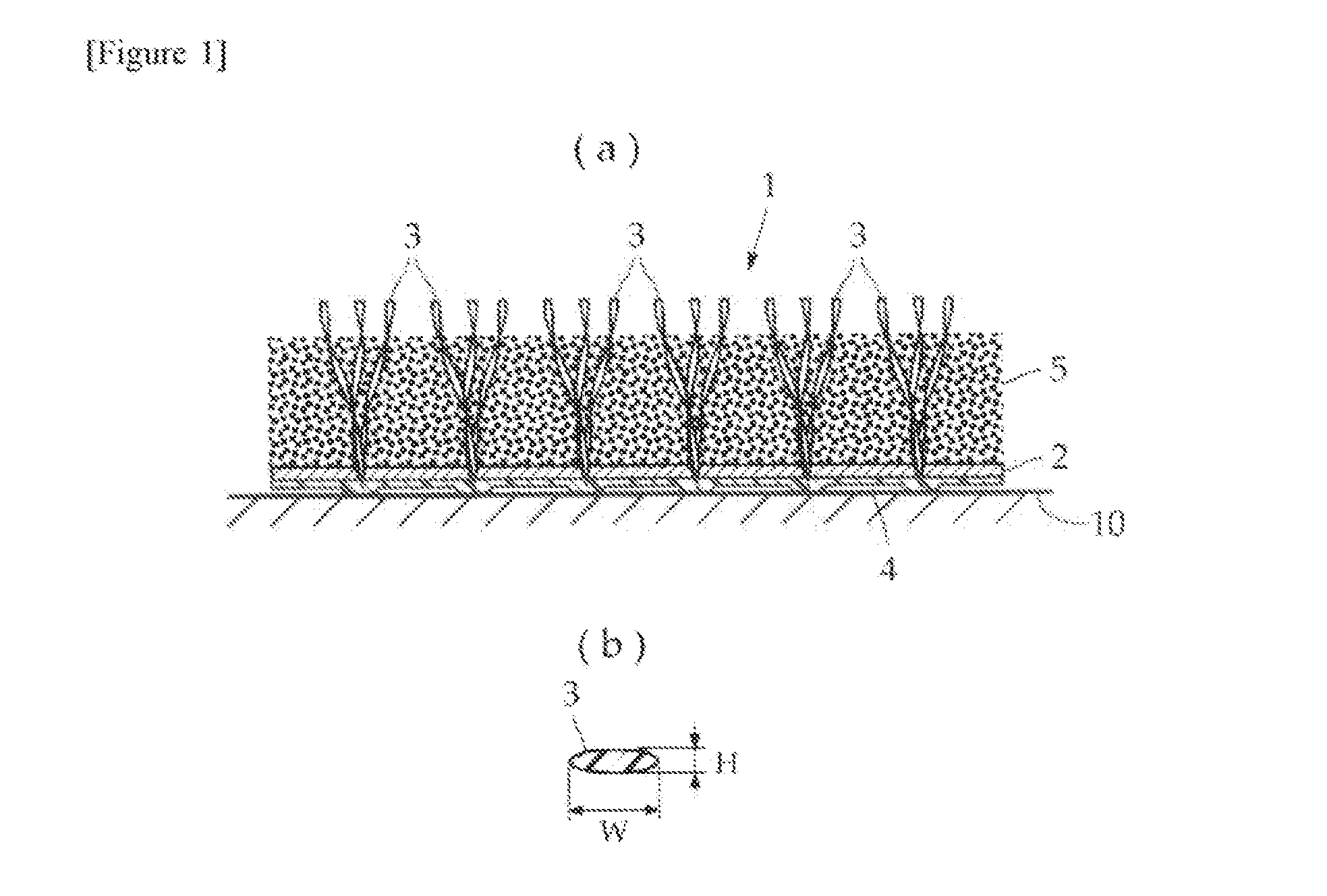

[0049][Degree of crystal orientation] 0.81

[Minor axis length H] 0.235 mm

[Major axis length W] 1.16 mm

[Flattening ratio W / H] 4.936

[Tensile modulus of elasticity] 190 N / mm2

[Durability]⊚

[Processability]◯

[Appearance]◯

[0050][Overall evaluation]◯

example 2

[0051][Degree of crystal orientation] 0.75

[Minor axis length H] 0.196 mm

[Major axis length W] 1.37 mm

[Flattening ratio W / H] 6.990

[Tensile modulus of elasticity] 206 N / mm2

[Durability]⊚

[Processability]◯

[Appearance]◯

[0052][Overall evaluation]◯

example 3

[0053][Degree of crystal orientation] 0.90

[Minor axis length H] 0.243 mm

[Major axis length W] 1.12 mm

[Flattening ratio W / H] 4.609

[Tensile modulus of elasticity] 273 N / mm2

[Durability]⊚

[Processability]◯

[Appearance]◯

[0054][Overall evaluation]◯

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com