Infusion packets and a process for their manufacture

a technology of infusion packets and manufacturing processes, applied in the field of infusion packets, can solve the problems of thin materials prone to tear under the stress applied, materials conventionally used to manufacture infusion packets are often not suitable for thermoforming,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]In a first aspect, the present invention relates to a process for the manufacture of infusion packets.

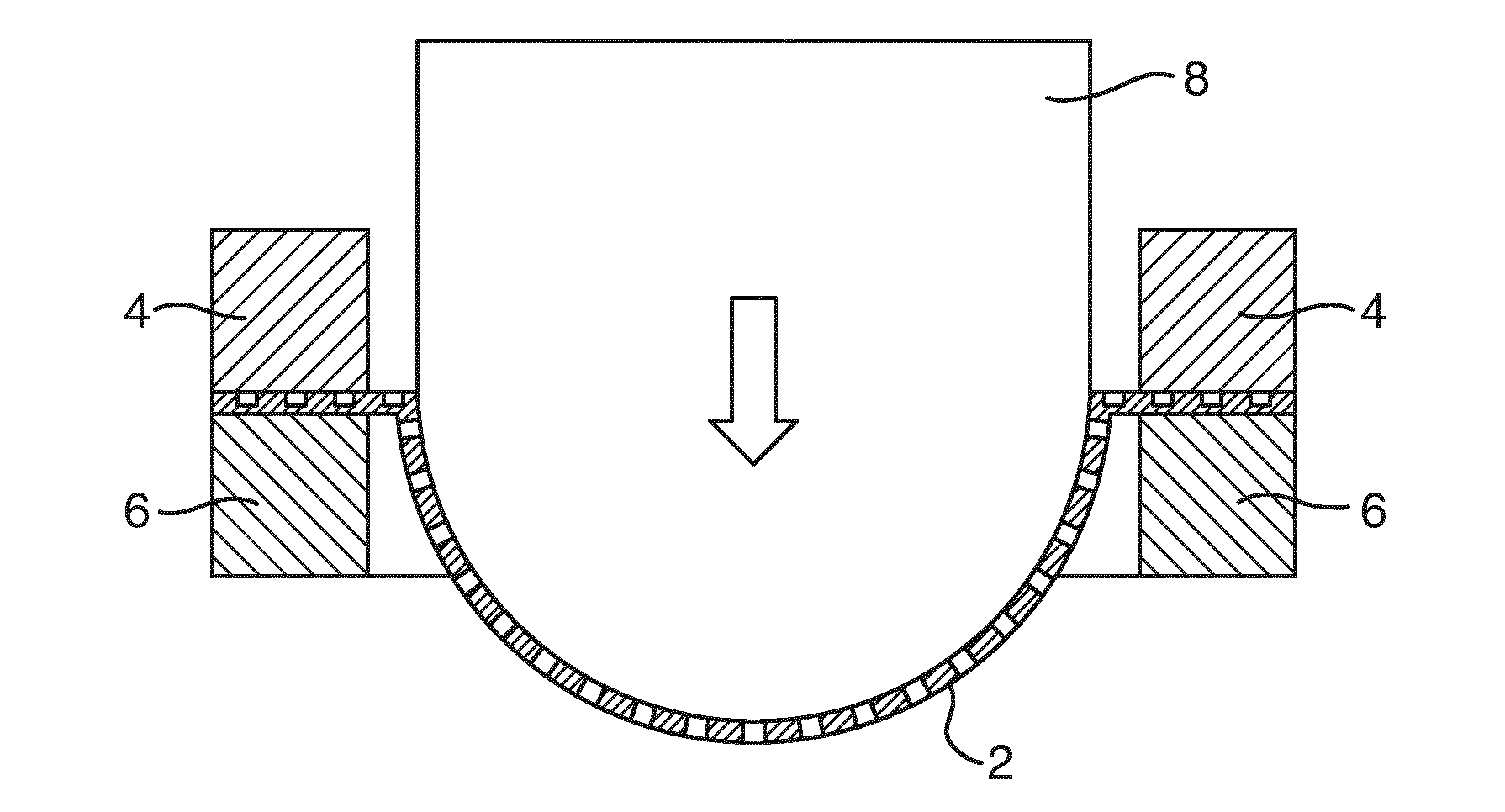

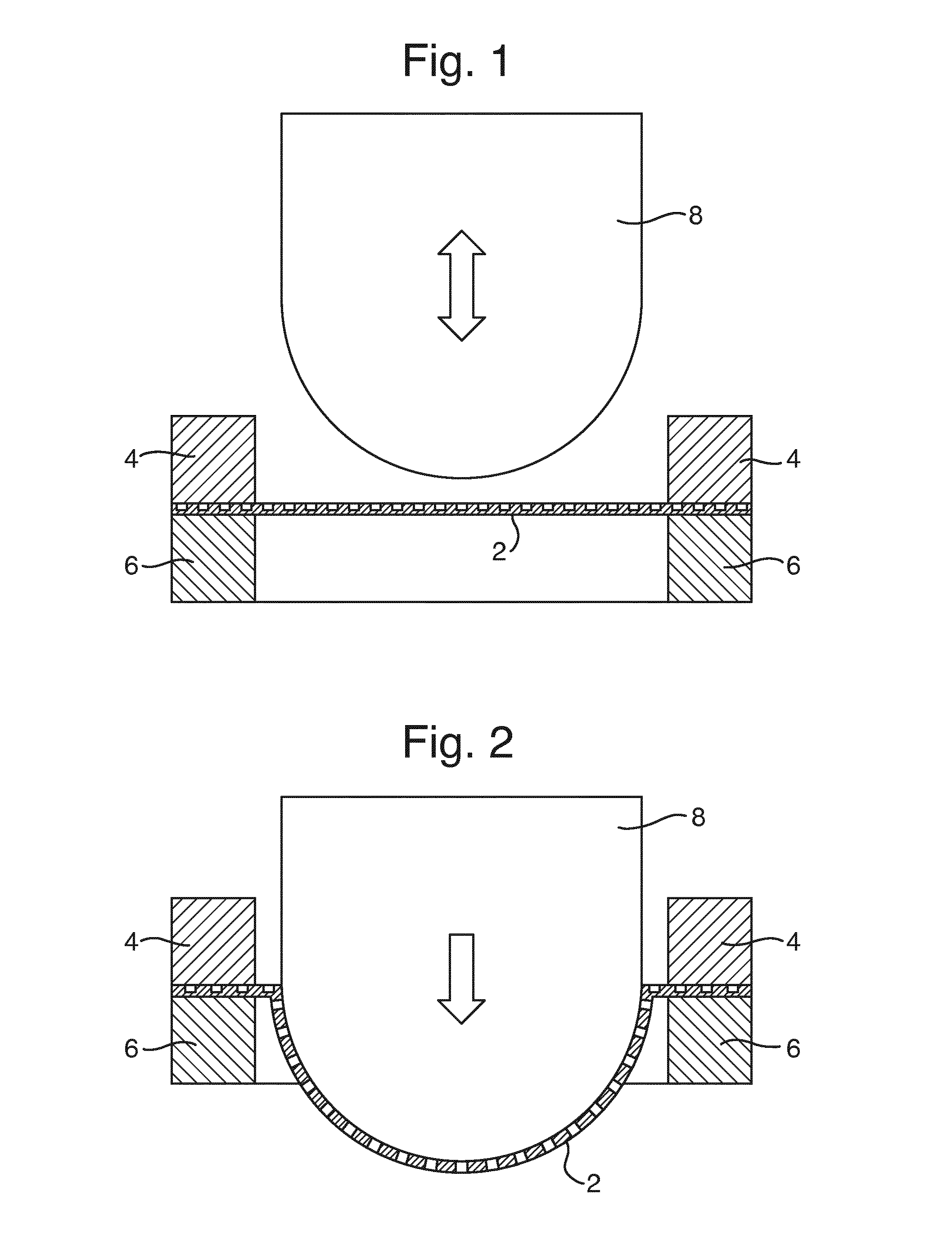

[0021]This process involves a first step in which a first sheet of thermoplastic material is provided. The first sheet of thermoplastic material may or may not be porous. In a second step, portions of this sheet are thermoformed into a predetermined three-dimensional shape (i.e. a shape having length, breadth and depth). The thermoformed portions of the first sheet are porous (i.e. permeable to aqueous liquids).

[0022]A variety of three-dimensional shapes are possible. For example, tetrahedral or hemispherical shapes and the like are possible. Hemispherical shapes are particularly preferred.

[0023]The first sheet of thermoplastic material is a polymer film with at least one embossed surface. In certain embodiments the embossed film may be embossed on both surfaces. This first sheet need not be porous prior to being thermoformed. During thermoforming, portions of the first sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com