Apparauts for fluid pumping

a technology of apparatuses and fluids, applied in the direction of pump control, positive displacement liquid engines, pumping, etc., can solve the problems of increasing the lifting requirement of reducing the lifting requirement, and not having enough reservoir pressure to push fluid to the surface, etc., to achieve the effect of small footprint, minimal maintenance requirements, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

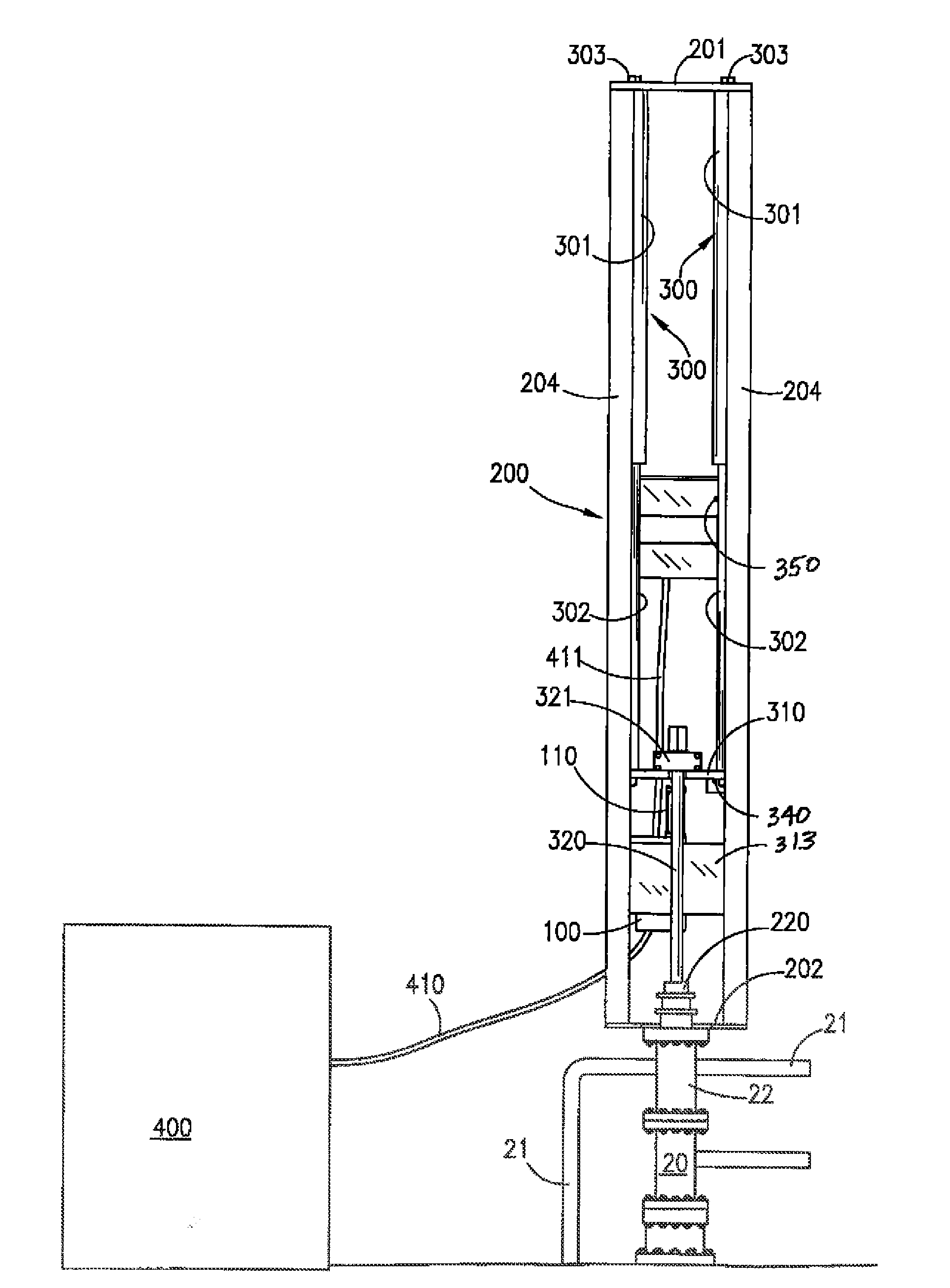

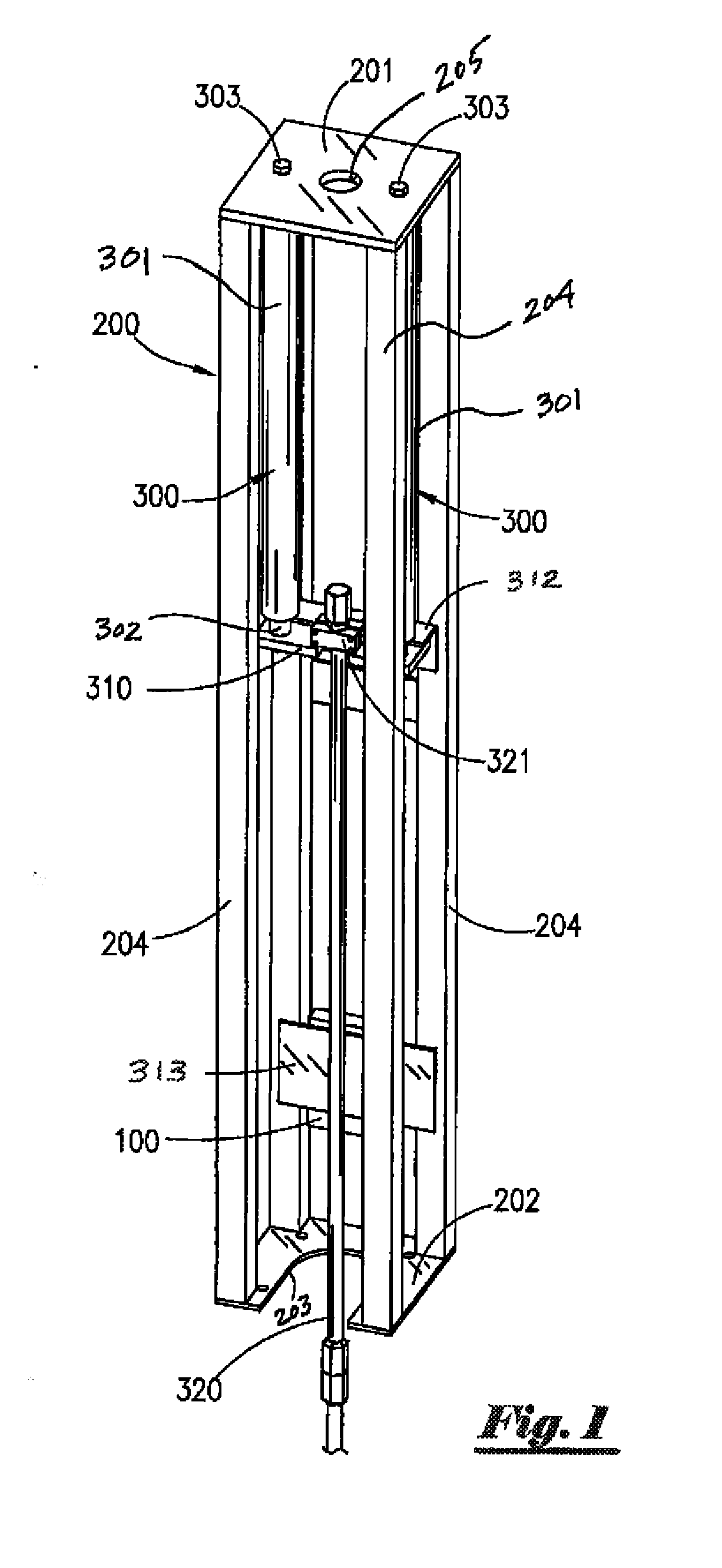

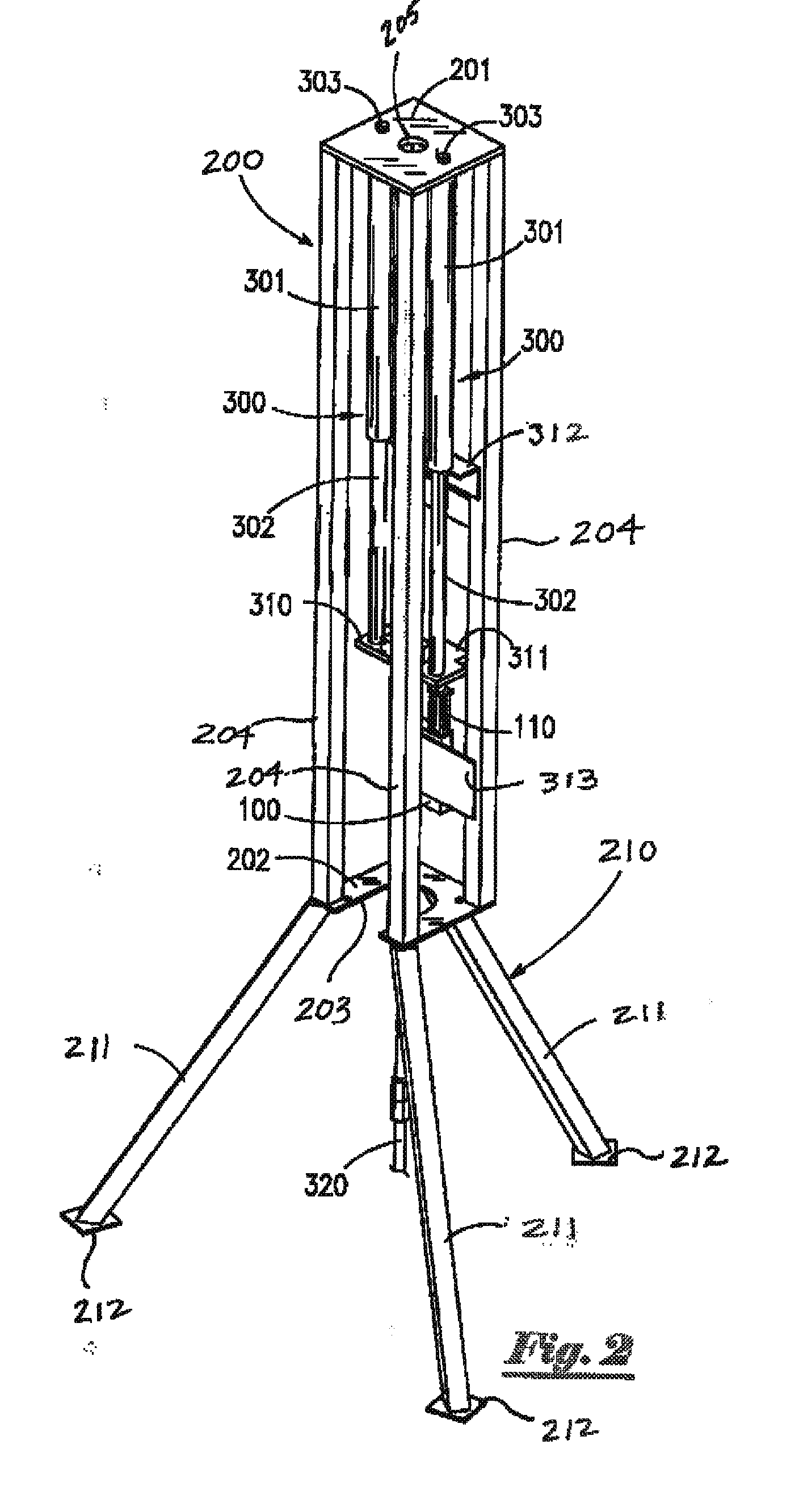

[0039]Referring to the drawings, FIG. 1 depicts a front perspective view of support tower assembly 200 of a hydraulic pumping apparatus 10 of the present invention. Elongate support tower assembly 200 is capable of being mounted to the upper end of a well that extends into the earth's crust. Said tower assembly 200 has substantially planar upper plate member 201 having optional central aperture 205, lower substantially planar plate member 202 having cut-out section 203 and elongate column support members 204 extending between said upper and lower plate members. Support tower assembly 200 provides a rigid support frame for supporting at least one hydraulic cylinder assembly 300. In the preferred embodiment, said elongate tower assembly 200 (and said at least one hydraulic cylinder assembly 300 supported therein) are mounted in substantially axial alignment over a well.

[0040]As depicted in FIG. 1, tandem cylinder assemblies 300 are mounted within support tower assembly 200. Each of sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com