Aluminum plating apparatus and method for producing aluminum film using same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

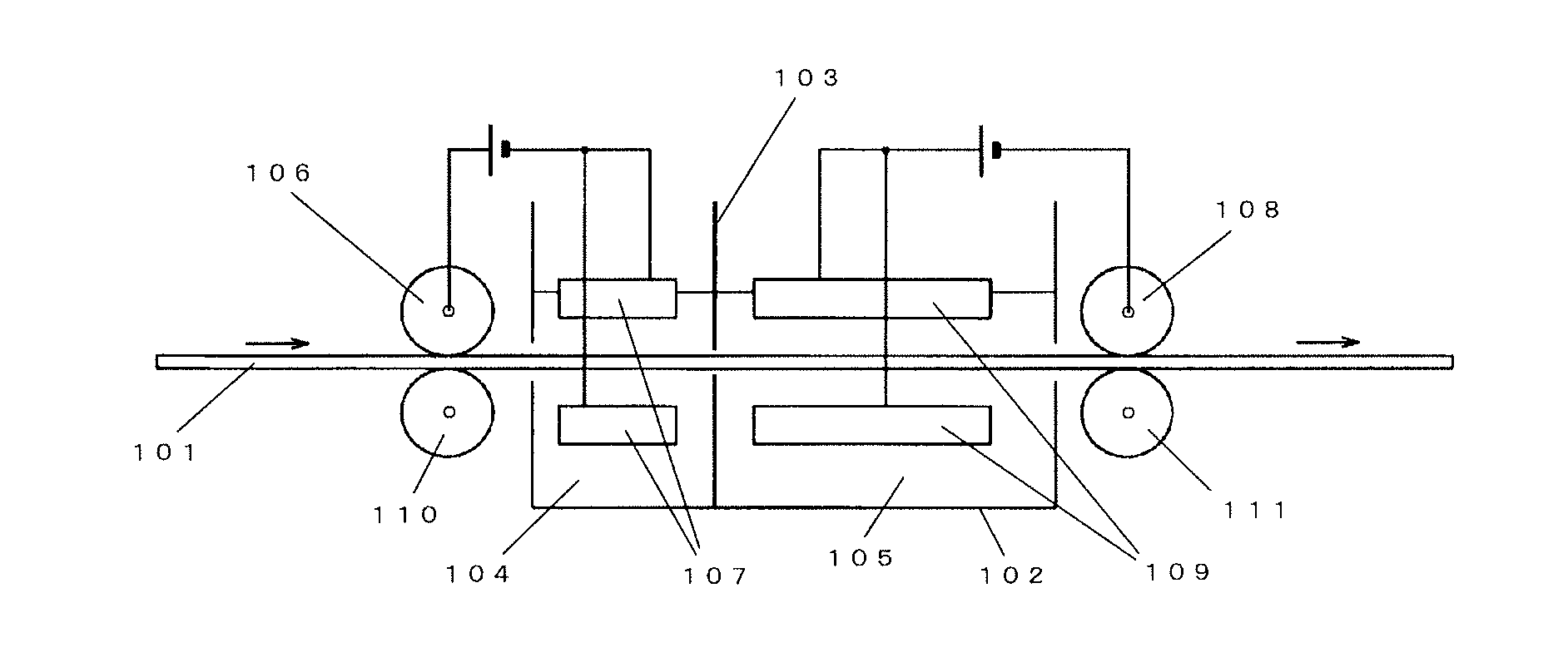

[0079]Ten aluminum apparatuses of the present invention shown in FIG. 1 were placed in series to form a film of aluminum plating on a base body.

Base Body

[0080]As the base body, a resin formed body was used that had a three-dimensional network structure having a surface on which an aluminum film was formed by the sputtering process.

[0081]As the resin formed body having a three-dimensional network structure, a foamed-urethane resin formed body having a porosity of 95%, the number of pores (the number of cells) per inch of about 50, a pore diameter of about 550 μm, a width of 500 mm, and a thickness of 1 mm was used. Conductive treatment was performed by forming an aluminum film having a coating weight of 10 g / m2 on the foamed-urethane resin formed body by the sputtering process.

[0082]It was confirmed that an aluminum oxide film of 30 nm was formed in the aluminum film on the surface of the resin formed body.

Aluminum-Plating Apparatus

[0083]Ten aluminum apparatuses of the present invent...

example 2

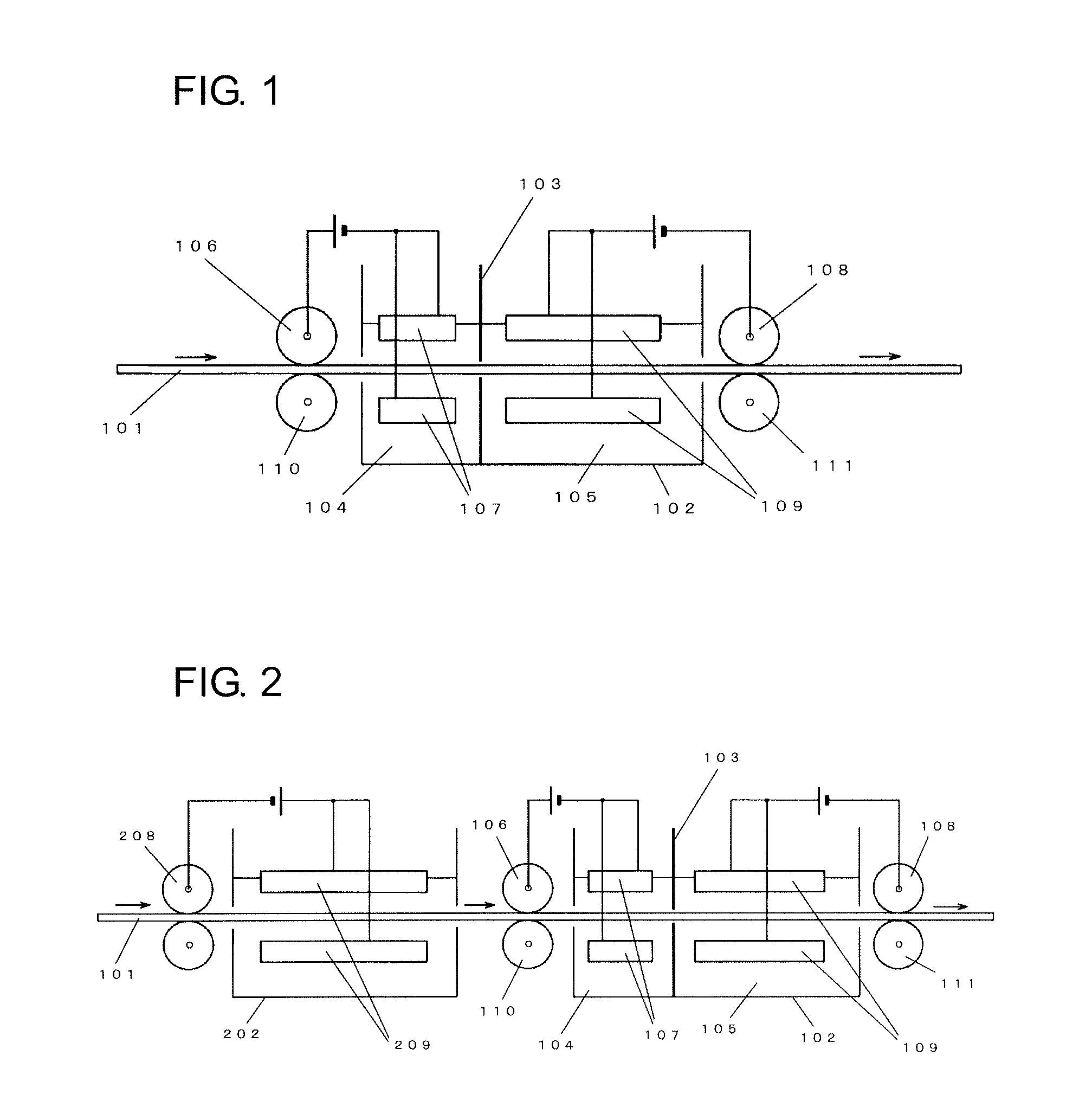

[0095]As shown in FIG. 2, a conventional aluminum-plating apparatus was placed at the most upstream side in the conveying direction for the base body. Nine aluminum apparatuses of the present invention used in Example 1 were placed in series at the downstream side of the above-described conventional aluminum-plating apparatus to form a film of aluminum plating on a base body.

Base Body

[0096]A resin formed body having the same three-dimensional network structure as that employed in Example 1 was used.

[0097]Conductive treatment of the resin formed body was carried out by coating a carbon paint as a conductive paint on the surface of a resinous porous body. The carbon paint contained 25% carbon particles, a resin binder, an introfier, and an antifoaming agent. The carbon black had a particle diameter of 0.5 μm.

Aluminum-Plating Apparatus

[0098]The conventional aluminum-plating apparatus placed at the most upstream side in the conveying direction for the base body had the same structure as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com