Pump device

a pump and guide tube technology, applied in the direction of pump installation, non-positive displacement fluid engine, liquid fuel engine components, etc., can solve the problems of large pump electrical energy consumption, large electrical energy loss, and inability to customize the diameter of the guide tube closely, so as to achieve the effect of energy loss due to turbulence in the outlet flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

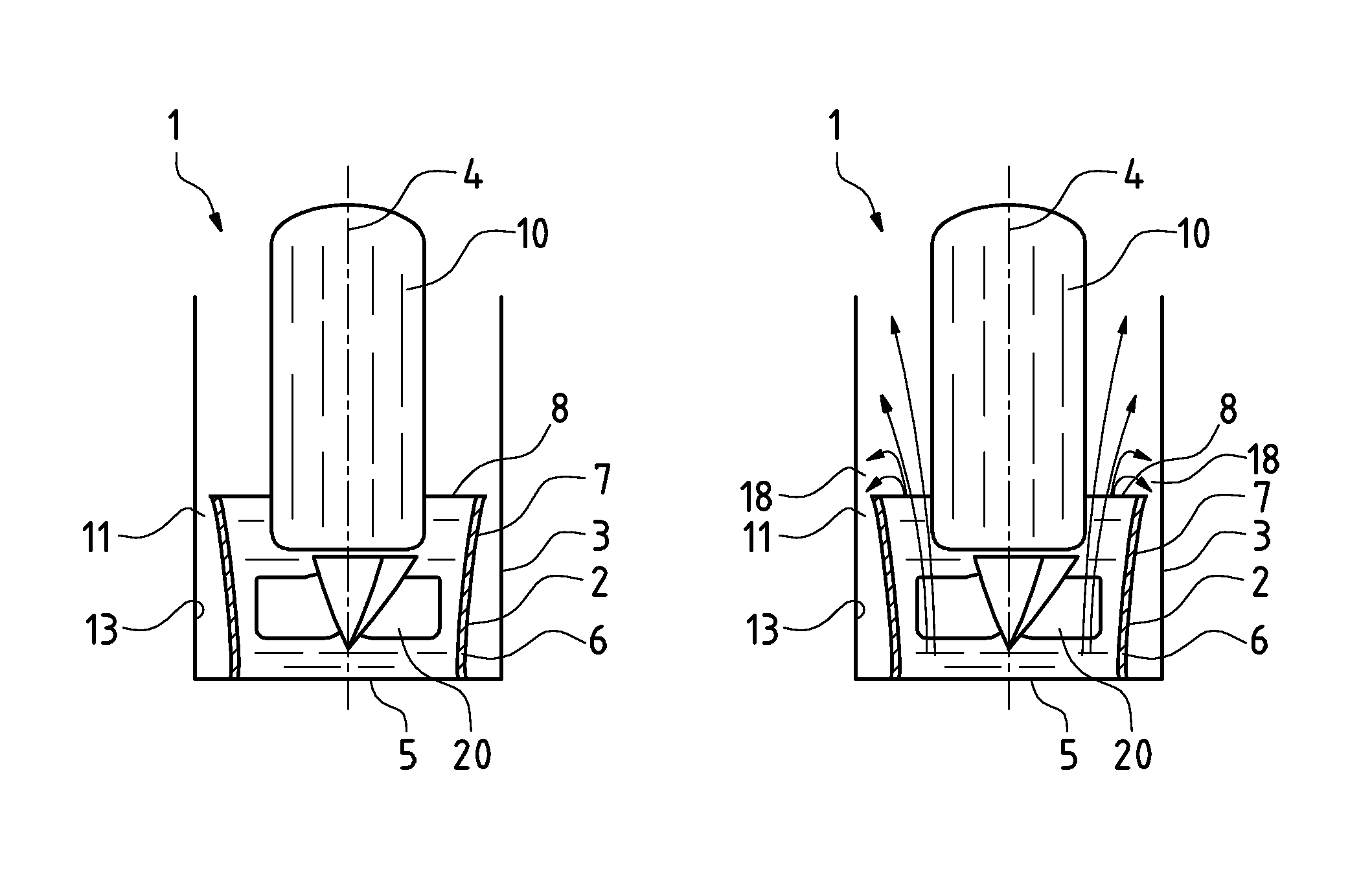

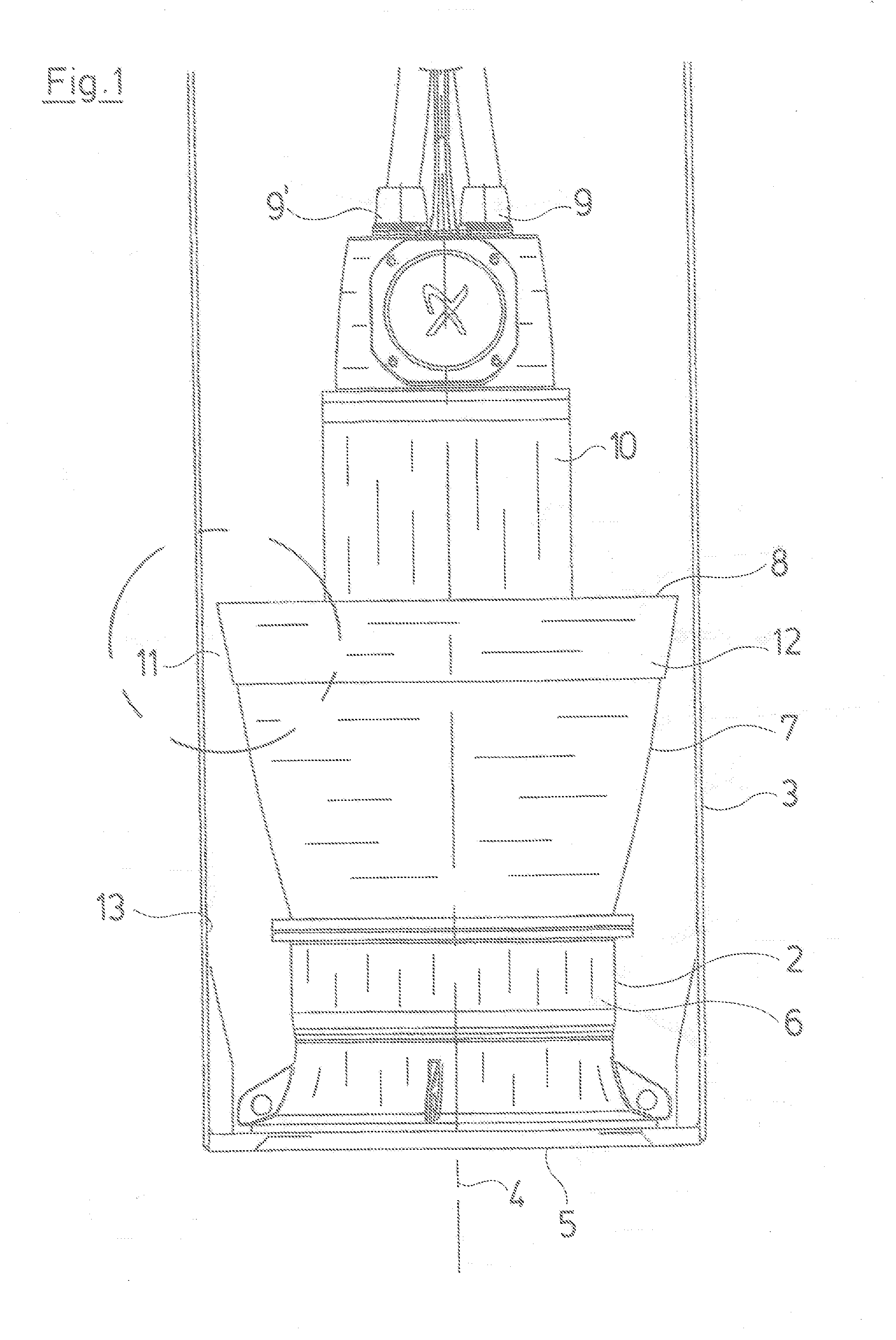

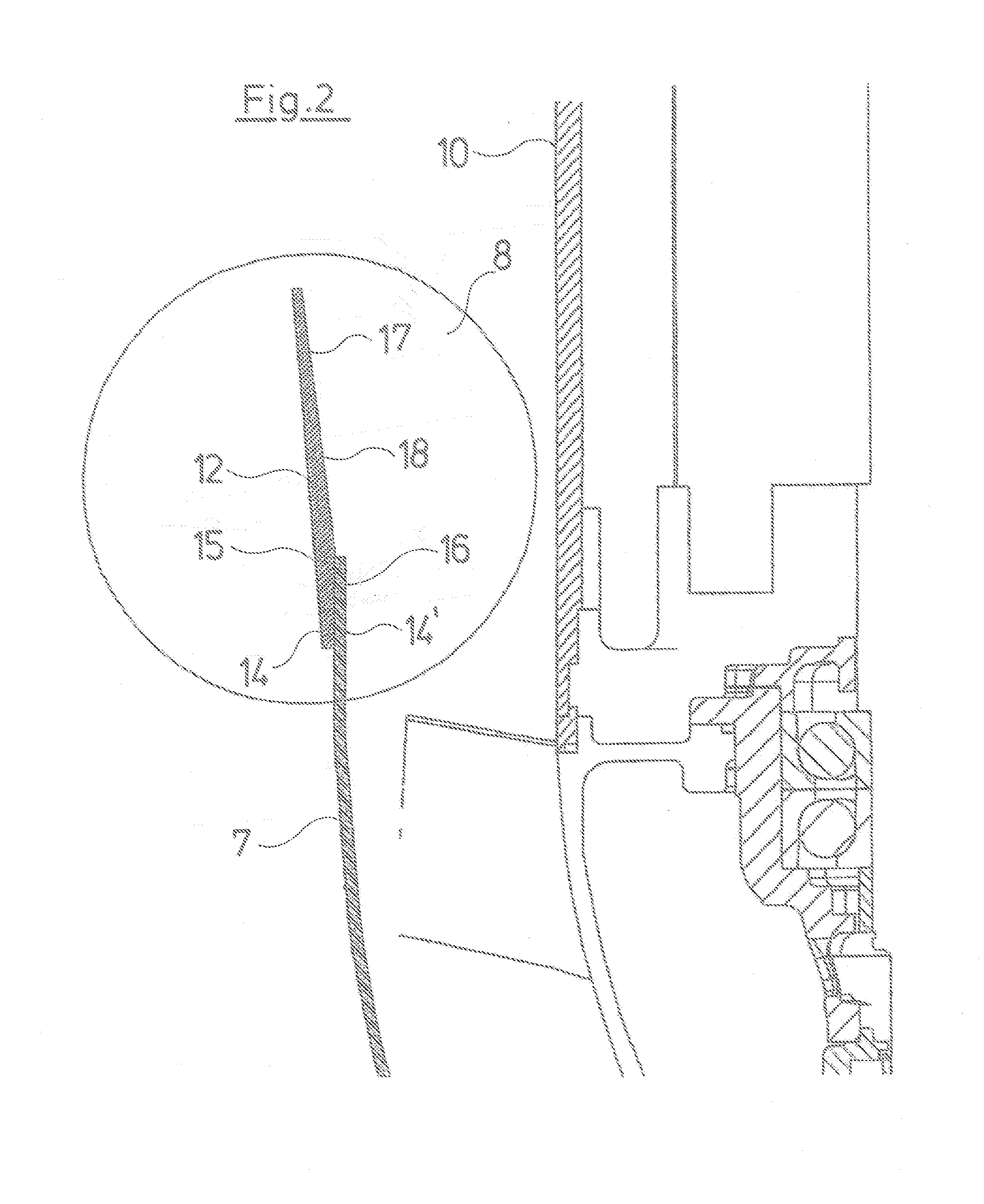

[0030]The pump system 1 comprises a pump device 2, which in this case is a submersible axial flow pump which is arranged in the center of a pipe in form of a column pipe 3. Specifically, the longitudinal axis 4 of the pump device 2 is arranged coaxially to the longitudinal axis of the pipe, in this case the column pipe 3. An axial flow pump in the meaning of the invention is a pump which propeller produces an axial flow. The invention may also be carried out with a mixed flow pump which uses an impeller which at least partly produces a radial flow which is deflected in axial direction by the surrounding volute or guide channel or guide tube, respectively. Thus, the mixed flow pump is a combination or compromise between a radial and an axial flow pump. The pump device 2 comprises an inlet portion 5 at its first axial end, in this case the lower end at which water enters the pump. Inside the pump housing 6 a propeller portion with diffuser vanes and an axial propeller is arranged. Als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com