Fastener for dismountably assembling laminar elements

a technology for assembling laminar or planar elements and fasteners, which is applied in the direction of rod connections, containers, couplings, etc., can solve the problems of not being able to support and resist the weight of the lower boxes, and up an essentially planar space,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

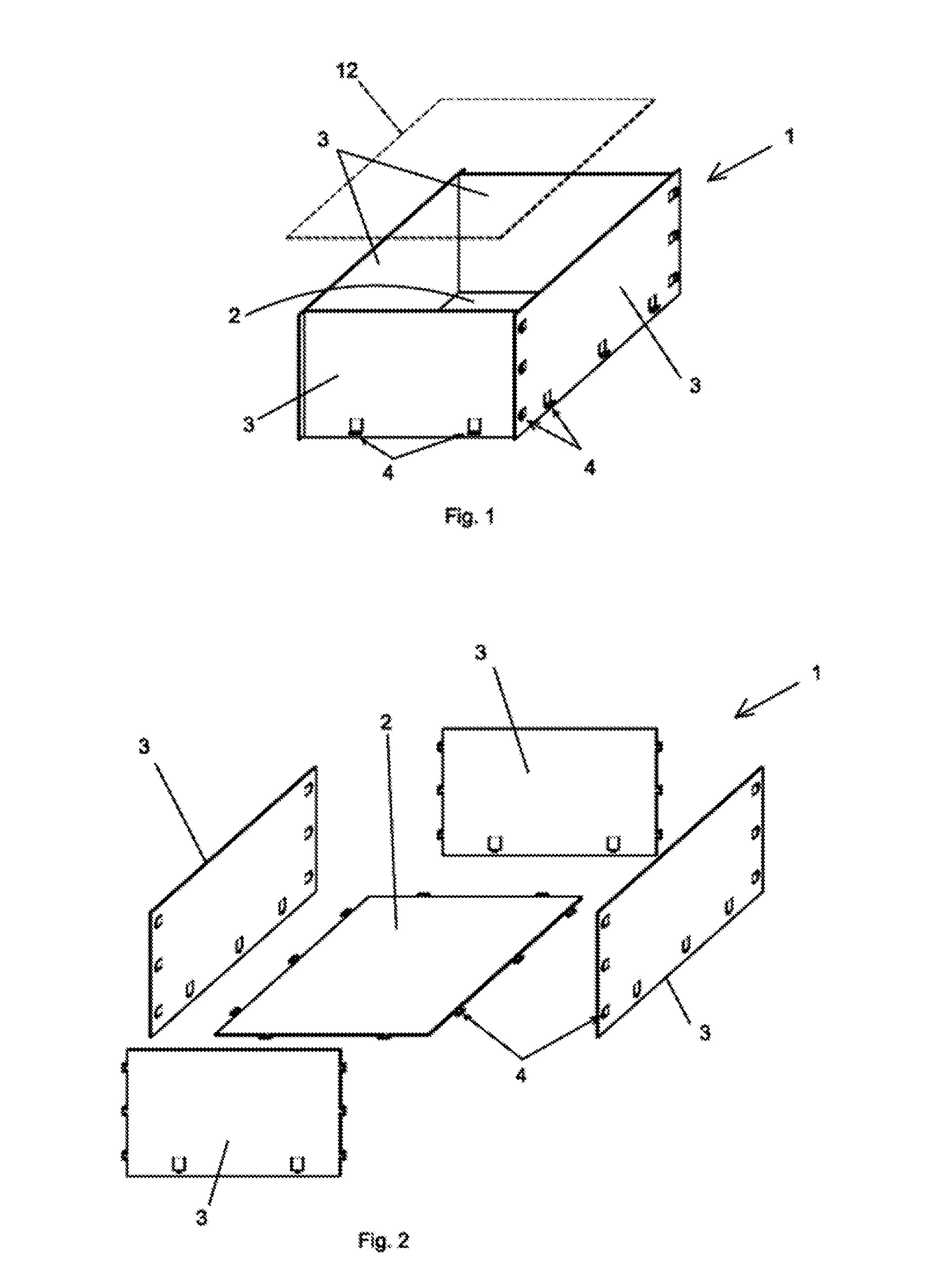

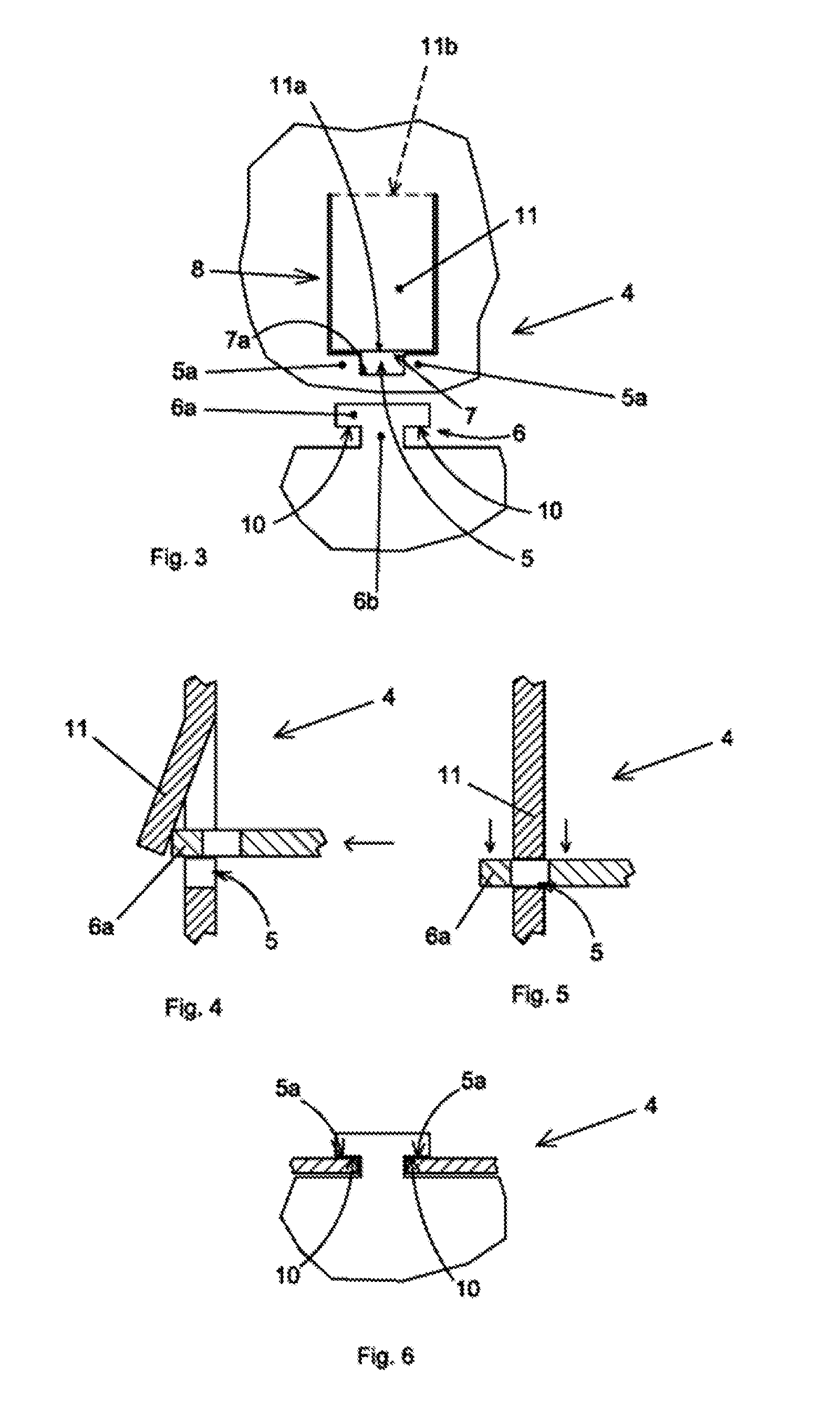

[0028]The fastener arrangement or fastener (4) (FIG. 1) of the invention may be used for dismountably assembling laminar or planar elements, such as the bottom (2) and lateral (3) walls of the box (1) shown in the figures, which may also have a lid (12) which supports or provides a mount for the stacking of boxes, etc.

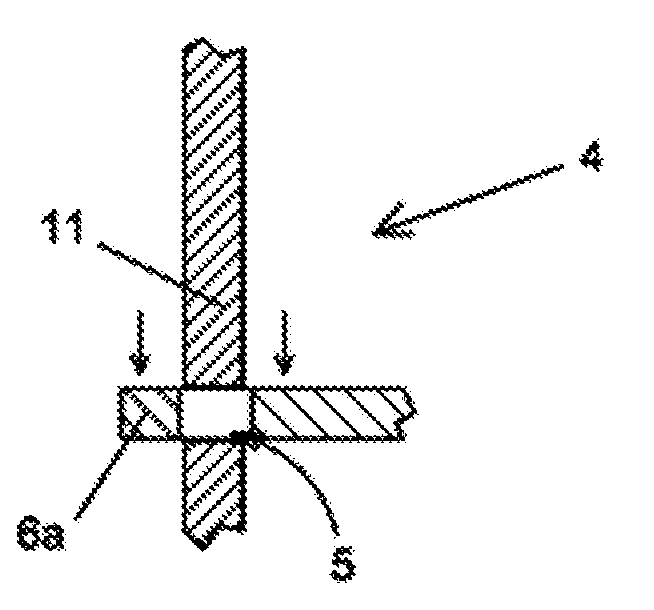

[0029]According to one embodiment of the invention, the fastener comprises a tongue (6) (FIG. 3) having a widened head (6a) and a neck (6b). Tongue (6) may be included in one of the elements to be assembled, and a through-slot or groove (5) may be included in the other element to be assembled. Groove (5) may be designed, sized and configured for receiving said neck (6b). Groove (5) may have a width larger than the width of the neck (6b) and smaller than the width of the widened head (6a). Groove (5) may have an open side (7) where a resiliently displaceable retainer (8) is located. Groove (5) may include a closed side (7a) opposite to the open side (7), as shown in FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com