Substrate treating apparatus

a technology of substrate and treating apparatus, which is applied in the direction of electrical equipment, basic electric elements, semiconductor/solid-state device manufacturing, etc., can solve the problems of affecting the uniformity of etching over the affecting the uniformity of etching treatment between a plurality of semiconductor wafers, and hardly available degree of freedom for the back surface of the semiconductor wafer, so as to prevent the increase of the temperature of the multiple valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

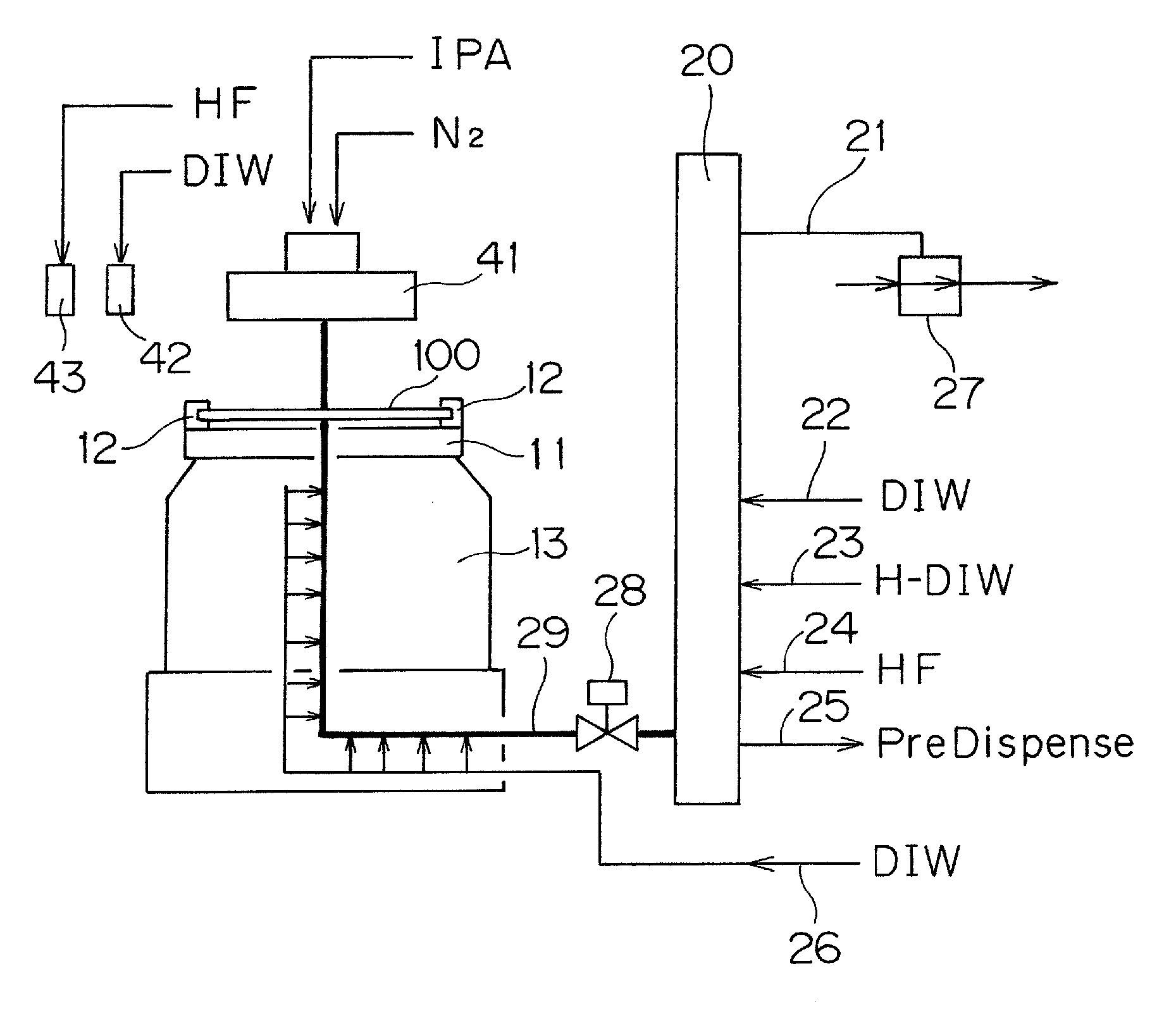

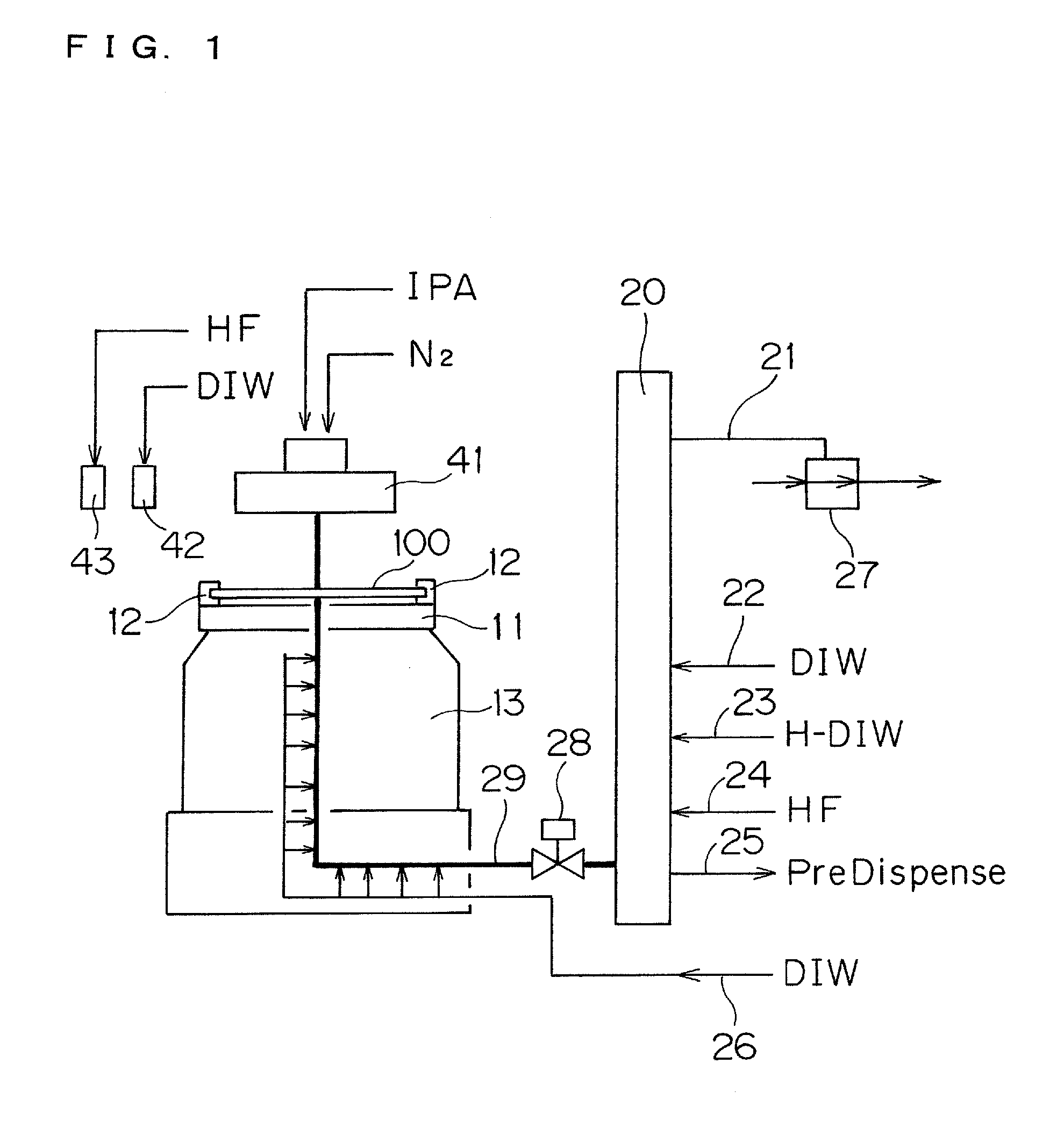

[0027]An embodiment of this invention will be described hereinafter with reference to the drawings. FIG. 1 is a schematic view of a substrate treating apparatus according to this invention.

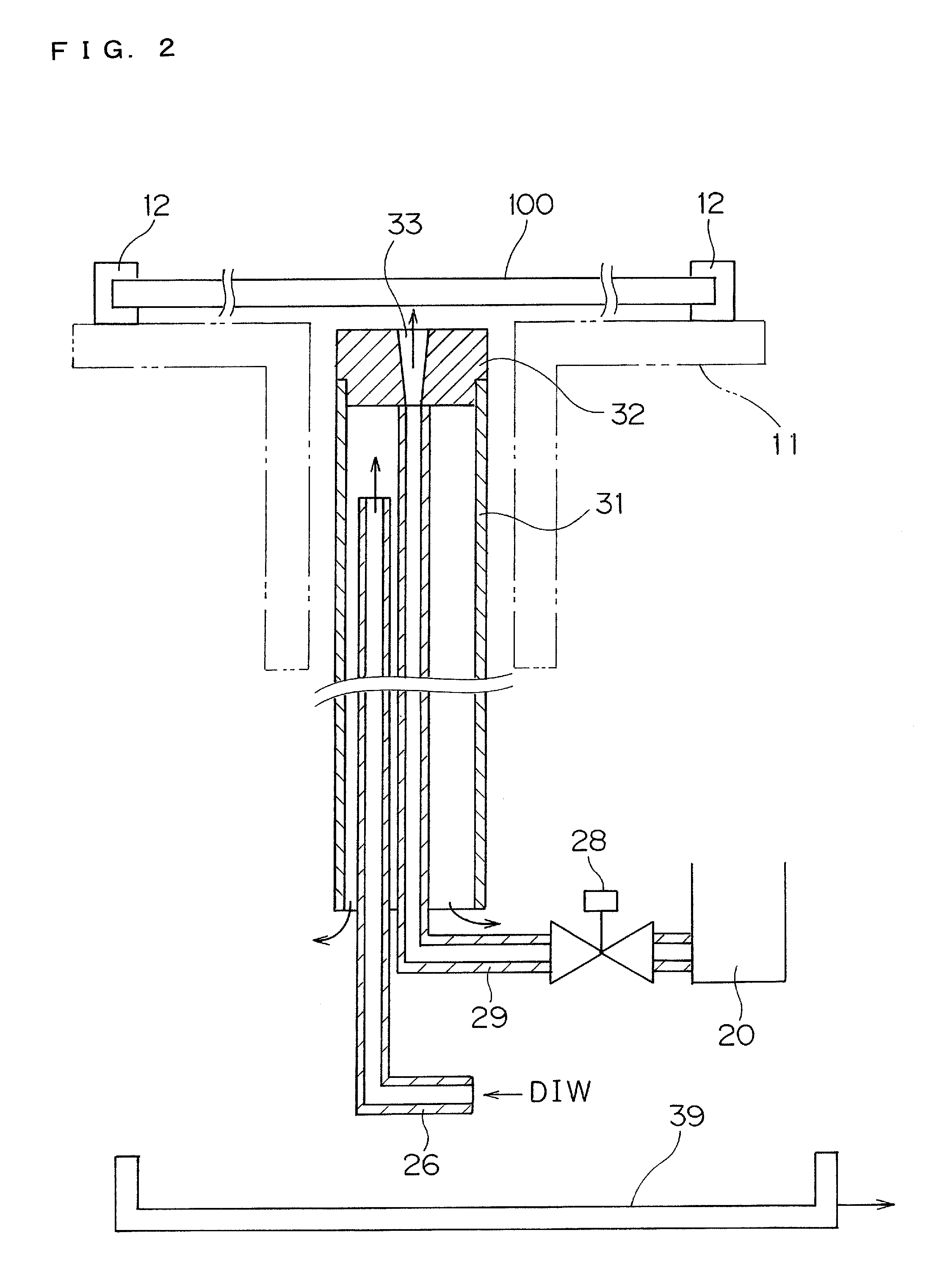

[0028]This substrate treating apparatus is used to perform etching treatment with hydrofluoric acid of a semiconductor wafer 100 as a substrate, and includes a spin chuck 11 for rotatably holding the semiconductor wafer 100. The spin chuck 11 has a plurality of chuck members 12 arranged on an upper surface thereof for holding edges of the semiconductor wafer 100. The spin chuck 11 is driven by a motor mounted inside a base 13 to spin about a central axis extending vertically. The spin chuck 11 is surrounded by a cup member, not shown, for capturing liquids scattering from the semiconductor wafer 100 in a spin.

[0029]This substrate treating apparatus includes a compound nozzle 41 for supplying isopropyl alcohol as an organic solvent and nitrogen gas as an inert gas to the front surface of the semico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com