catalyst

a technology of bisindenyl and catalyst, which is applied in the field of new bisindenyl catalysts, can solve the problems of low melting of homopolymer, polypropylene manufacturing, and polypropylene manufacturing limitations,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

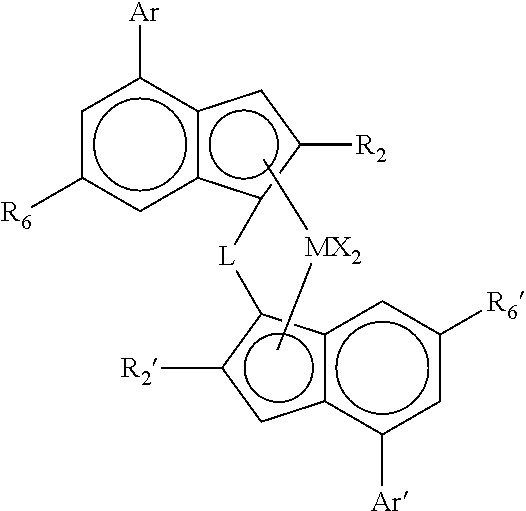

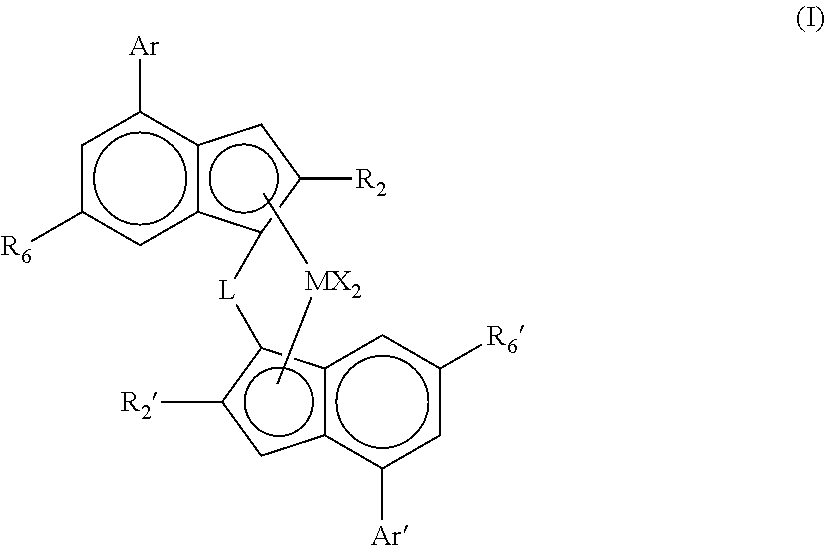

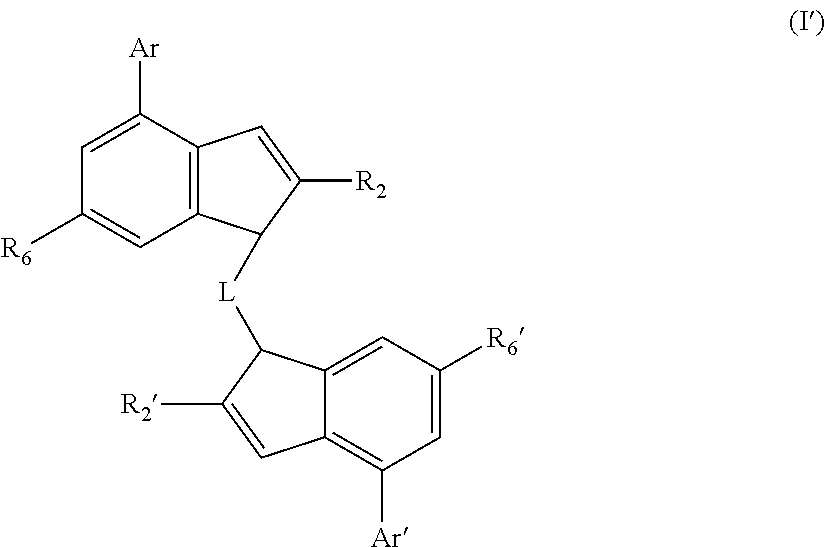

[0063]The catalysts of the invention preferably comprise a complex of formula (I)″

[0064]wherein

[0065]M is zirconium or hafnium;

[0066]each X is a sigma ligand;

[0067]L is a divalent bridge selected from —R′2C—, —R′2C—CR′2—, —R′2Si—, —R′2Si—SiR′2—, —R′2Ge—, wherein each R′ is independently a hydrogen atom, C1-20-alkyl, tri(C1-20-alkyl)silyl, C6-20-aryl, C7-20-arylalkyl or C7-20-alkylaryl;

[0068]R2 is a C1-20-hydrocarbyl radical;

[0069]R2′ is a C1-20-hydrocarbyl radical;

[0070]R6 is a linear or branched aliphatic C1-20-hydrocarbyl group, SR9 or OR9;

[0071]R6′ is a linear or branched aliphatic C1-20-hydrocarbyl group, SR9′ or OR9′;

[0072]with the proviso that neither R6 or R6′ represents a group having a quaternary carbon atom attached directly to the indenyl ring;

[0073]R9 is a C1-20-hydrocarbyl group;

[0074]R9′ is a C1-20-hydrocarbyl group;

[0075]Ar is a C6-12-aryl or C5-12-heteroaryl group optionally carrying one or more substituents R8;

[0076]Ar′ is a C6-12-aryl or C5-12-heteroaryl group opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com