Patents

Literature

66 results about "Sigma ligands" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sigma ligands for neuronal regeneration and functional recovery

InactiveUS20050020483A1Improve functional recoveryEnhance neuronal regenerationBiocideNervous disorderHuntingtons choreaNeuro-degenerative disease

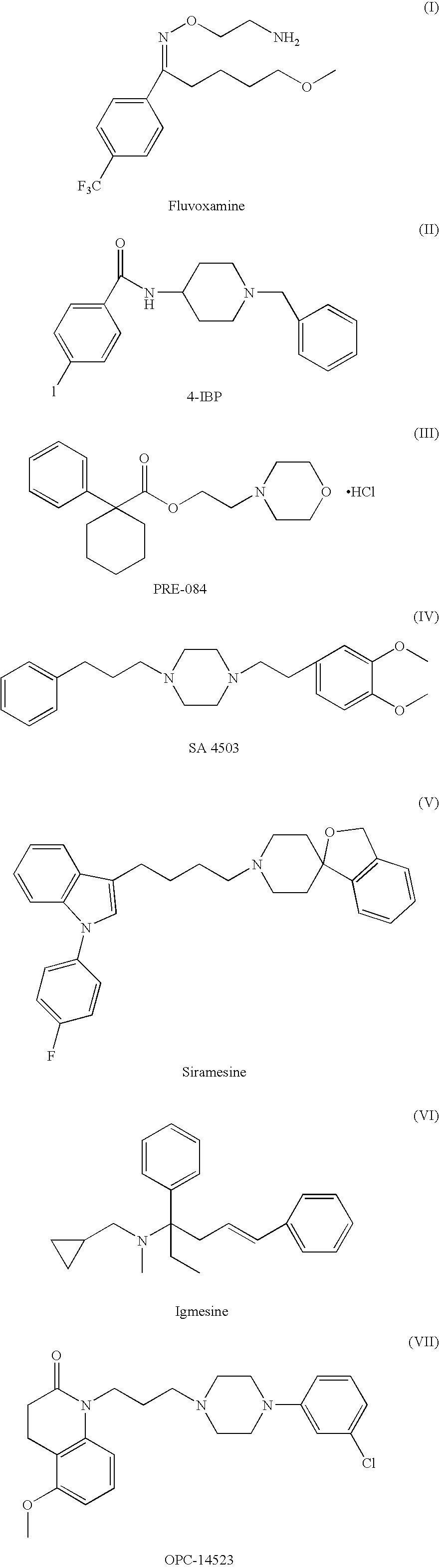

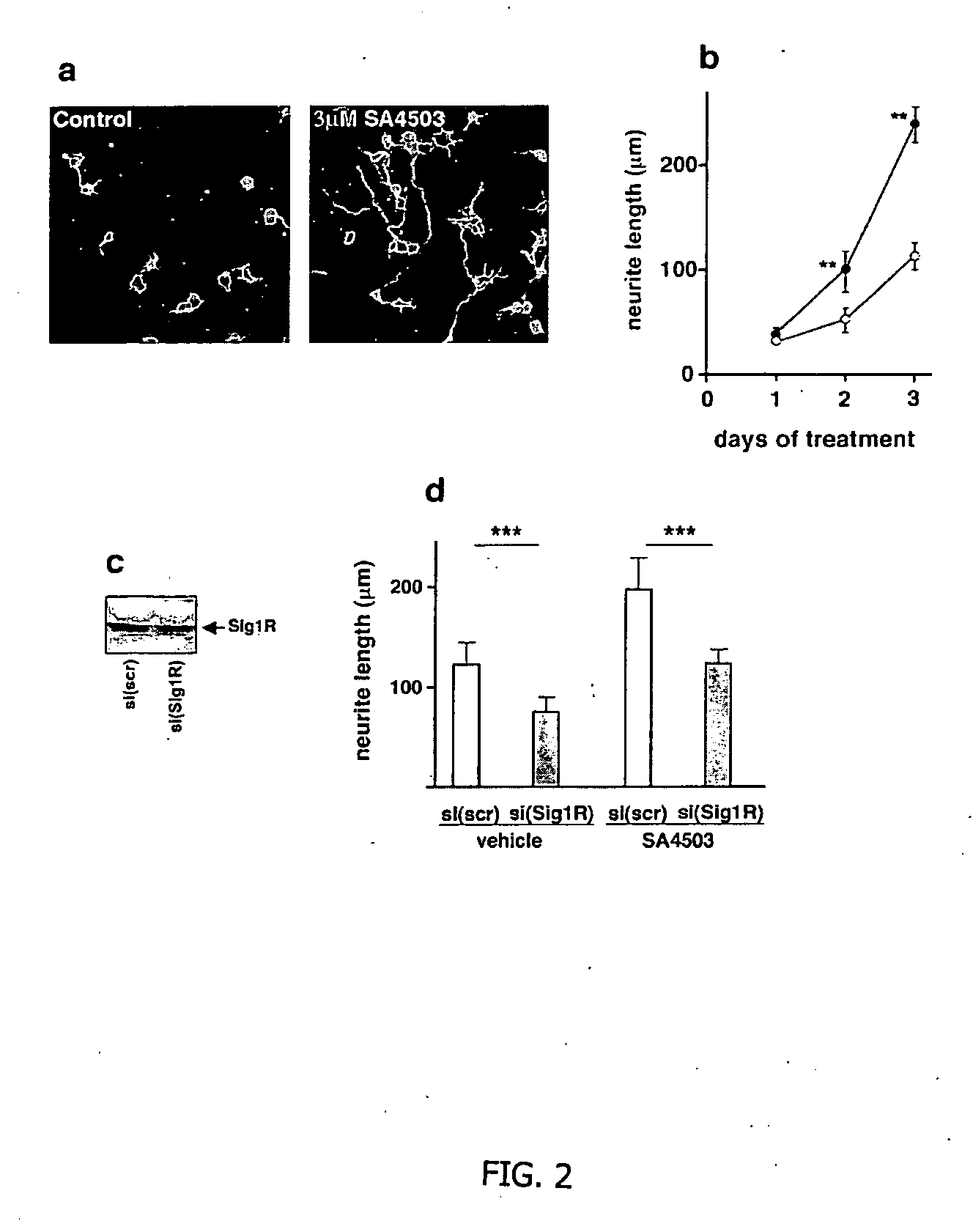

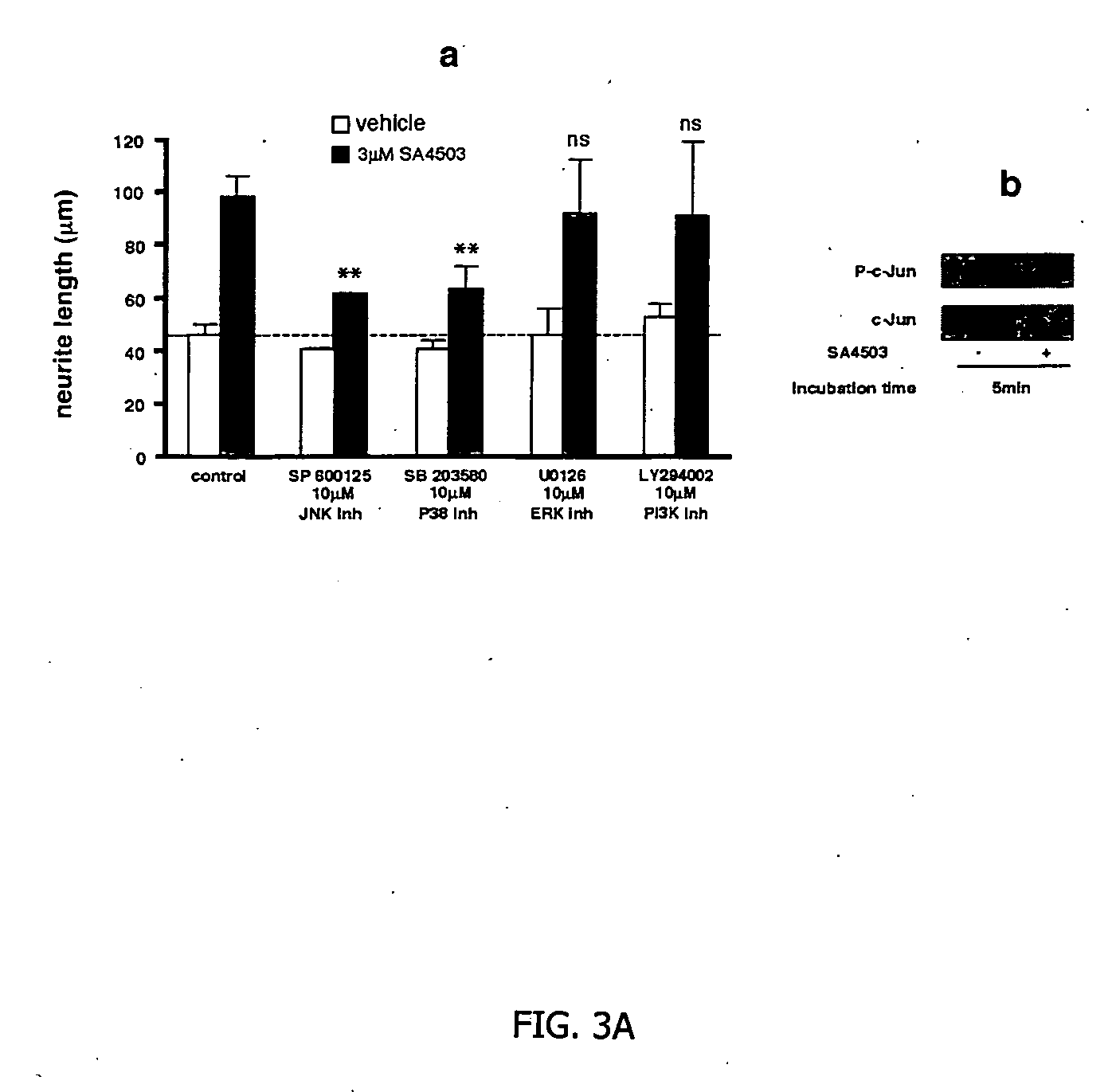

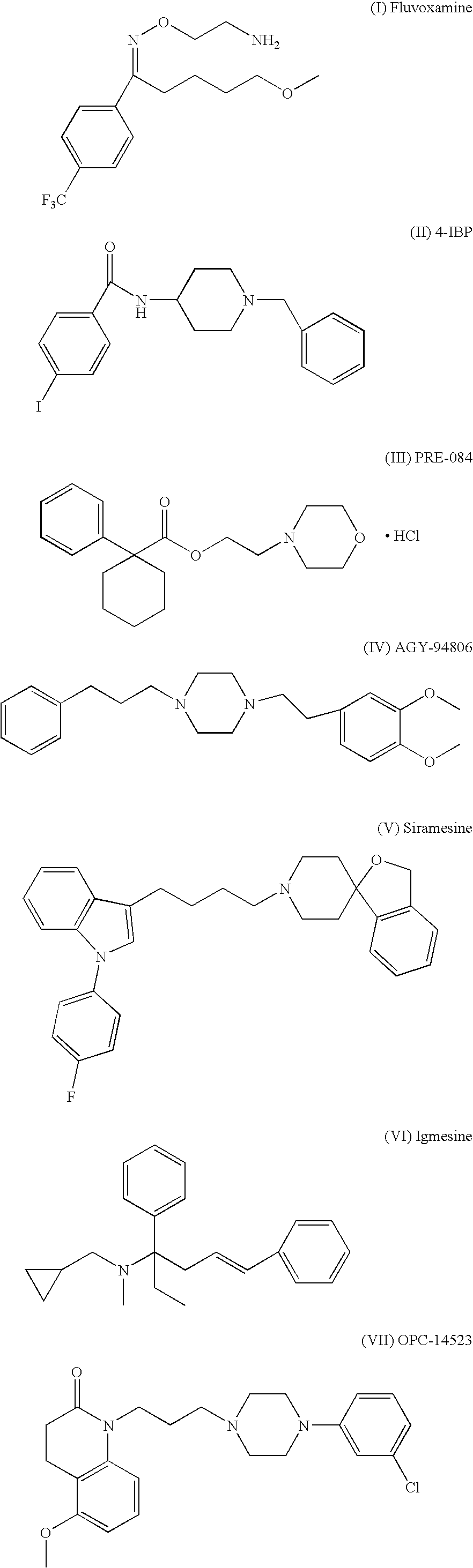

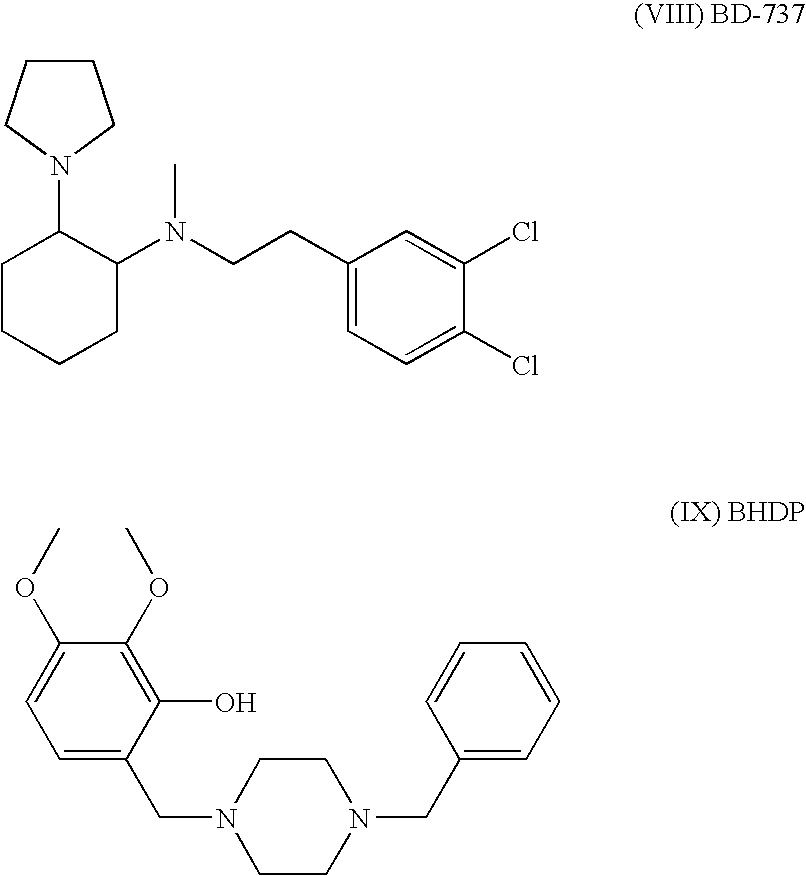

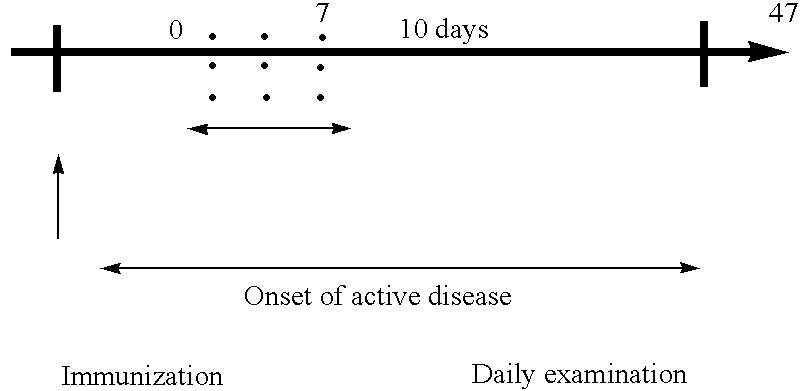

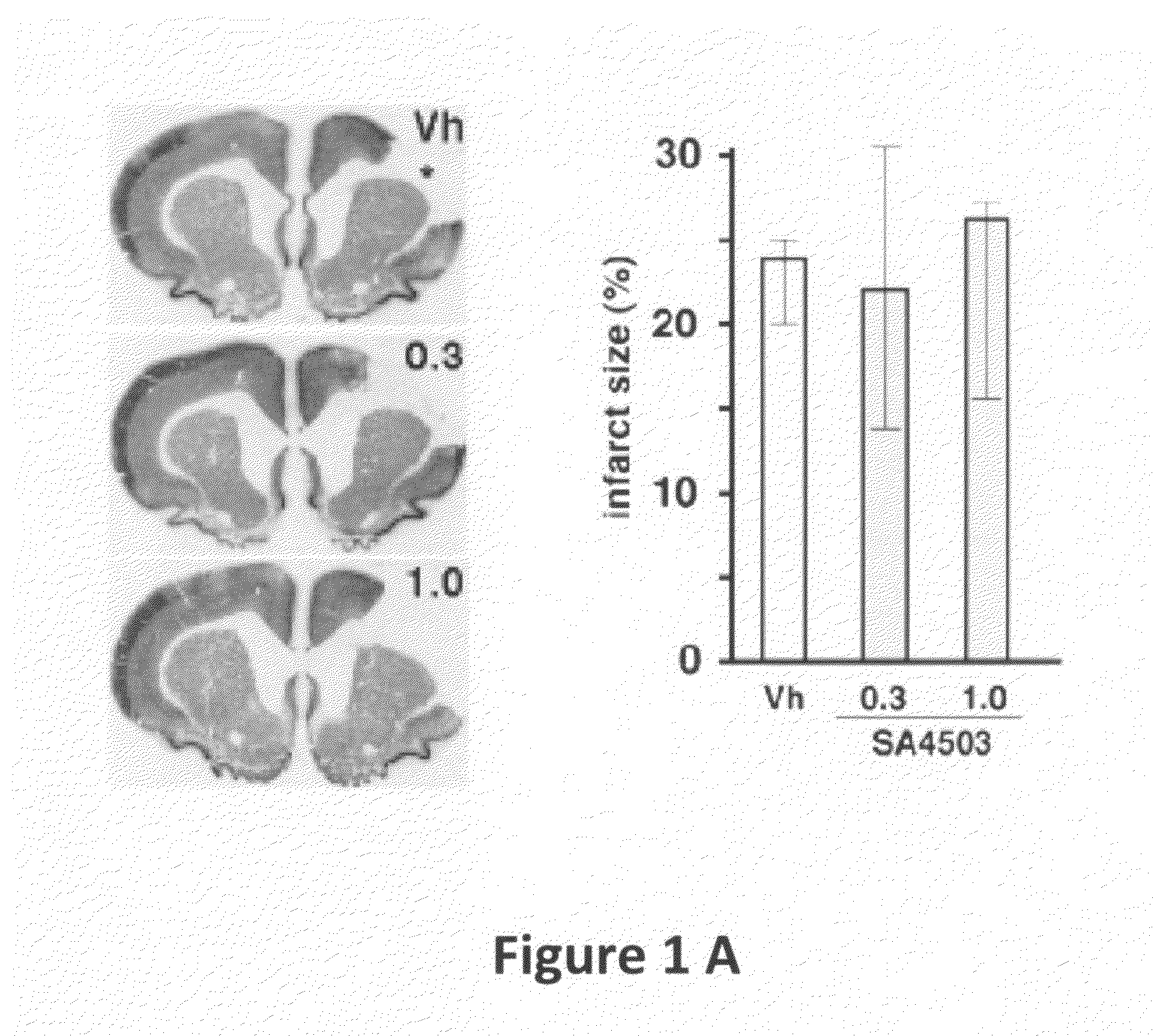

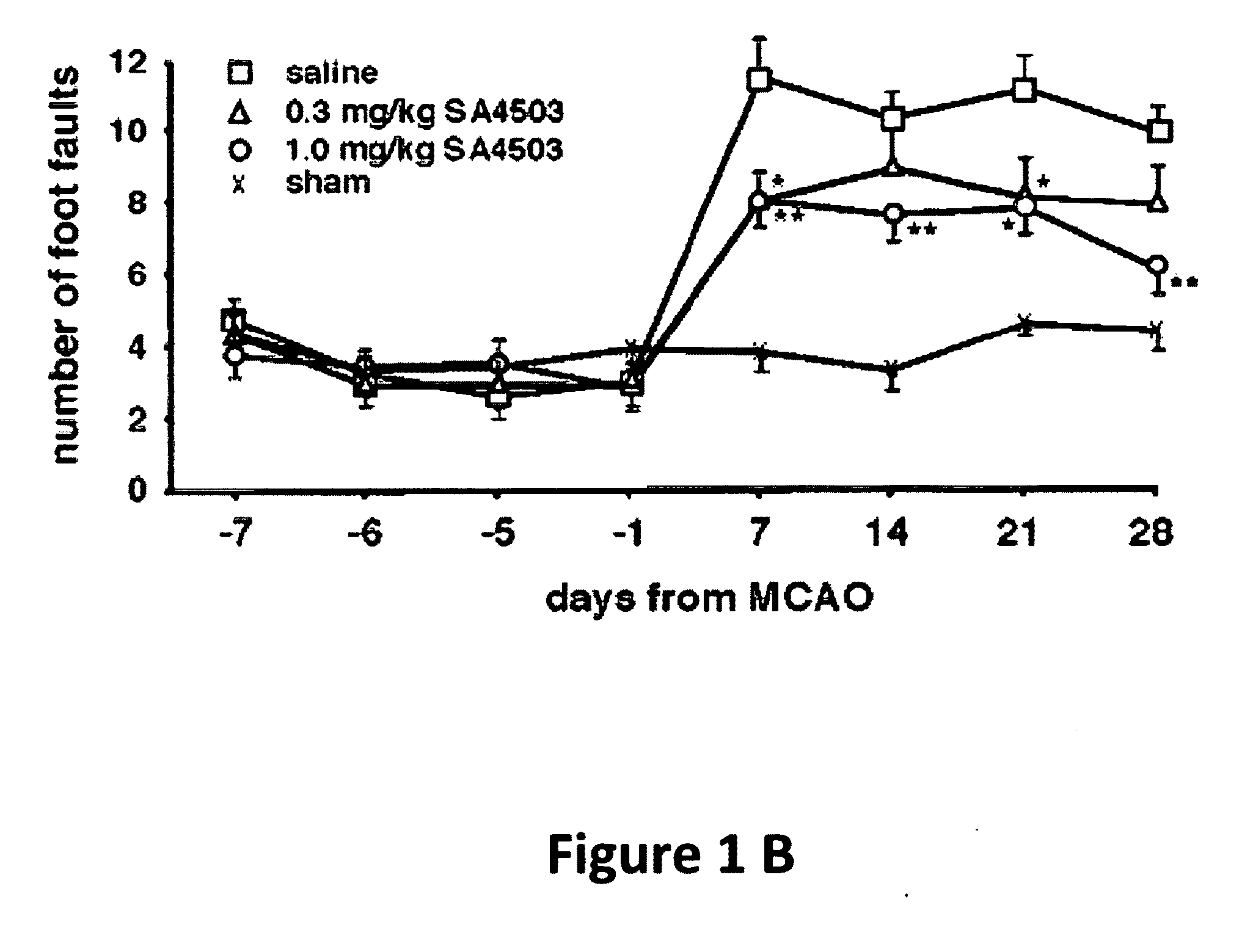

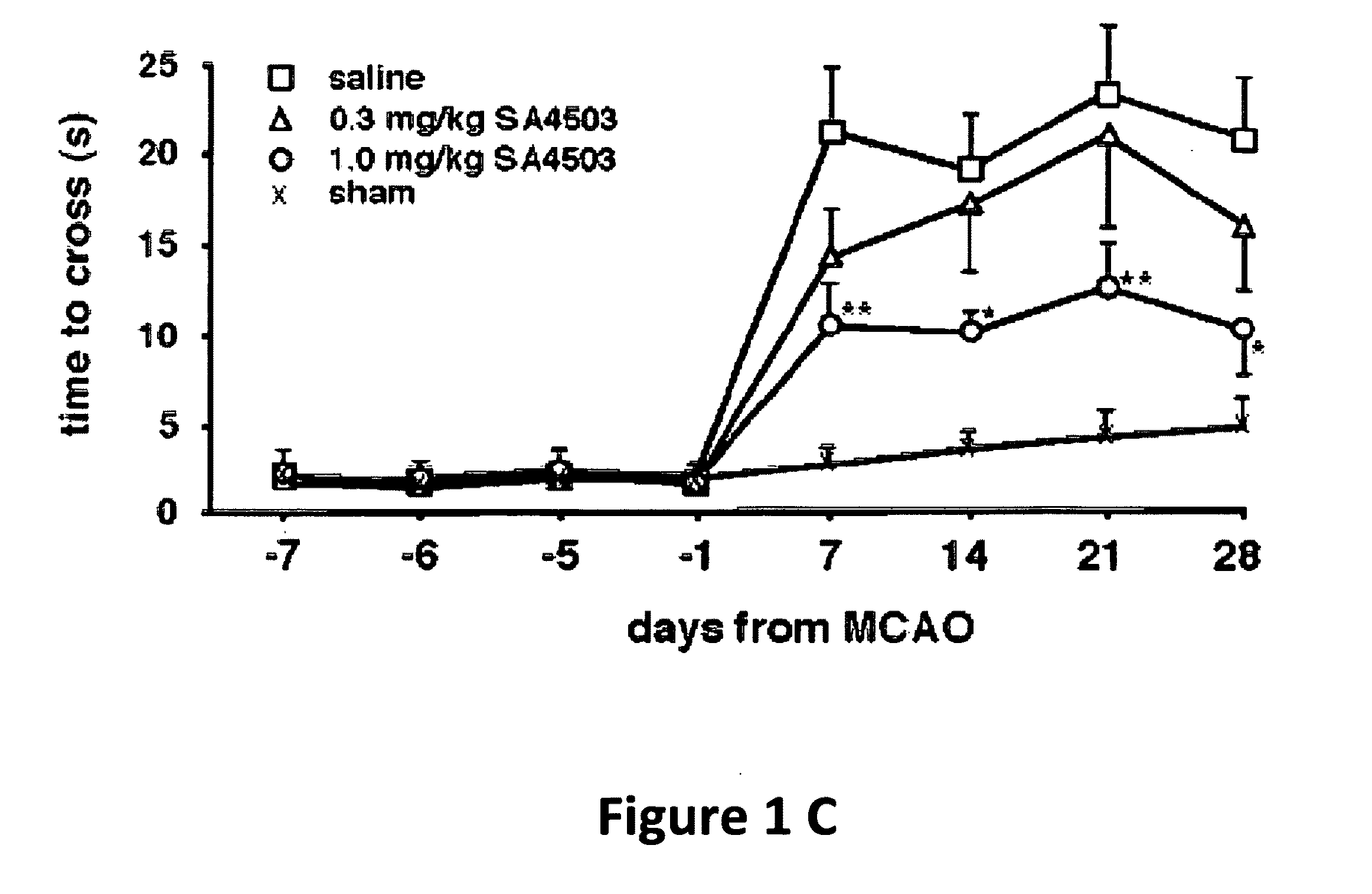

The invention discloses methods and compositions useful for facilitating neuronal regeneration and functional recovery in neurodegenerative diseases. The methods and compositions utilize ligands for the sigma receptors. These molecules can be delivered alone or in combination with agents which treat or prevent neurodegenerative diseases such as those caused by ischemic stroke, diabetic peripheral neuropathy, cancer therapy induced neuropathy, multiple sclerosis, amyotrophic lateral sclerosis, traumatic brain injury, spinal cord injury, Huntington's disease or Parkinson's disease. In other methods, the sigma receptor ligands are administered after stroke to facilitate functional recovery. The administration of the sigma receptor ligands effects faster functional recovery.

Owner:MS SCI CORP

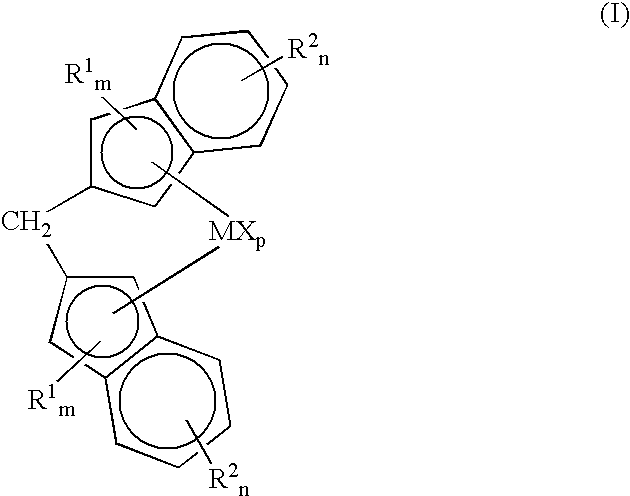

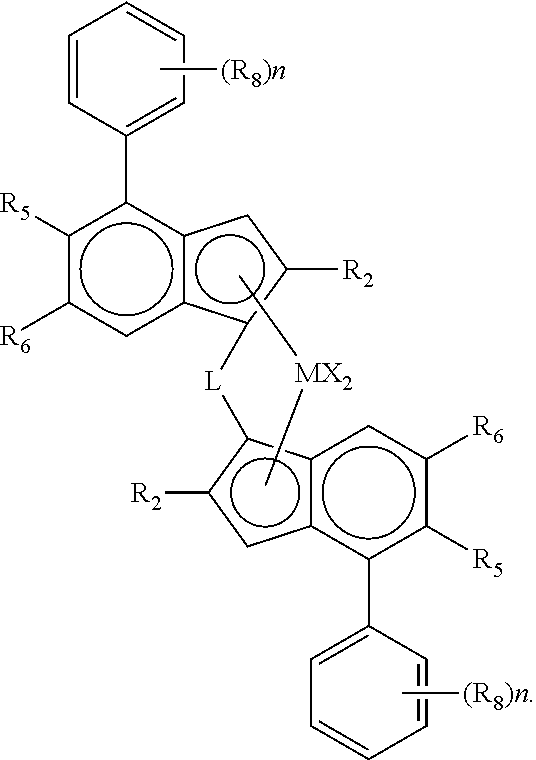

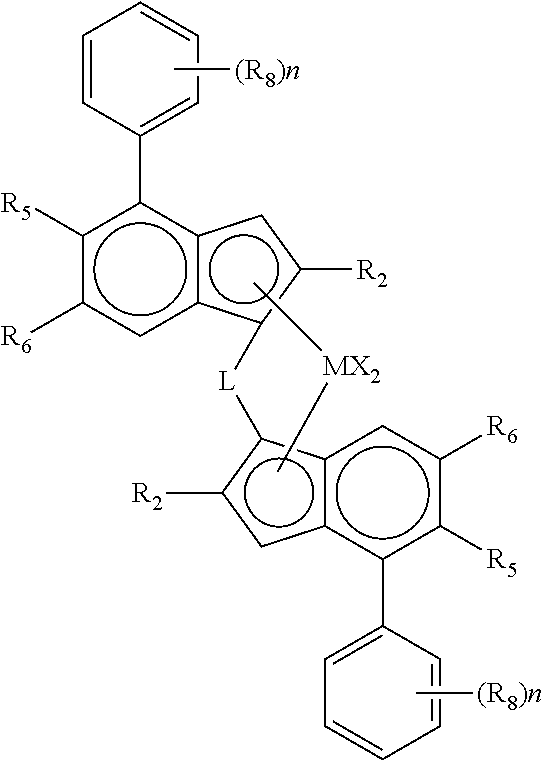

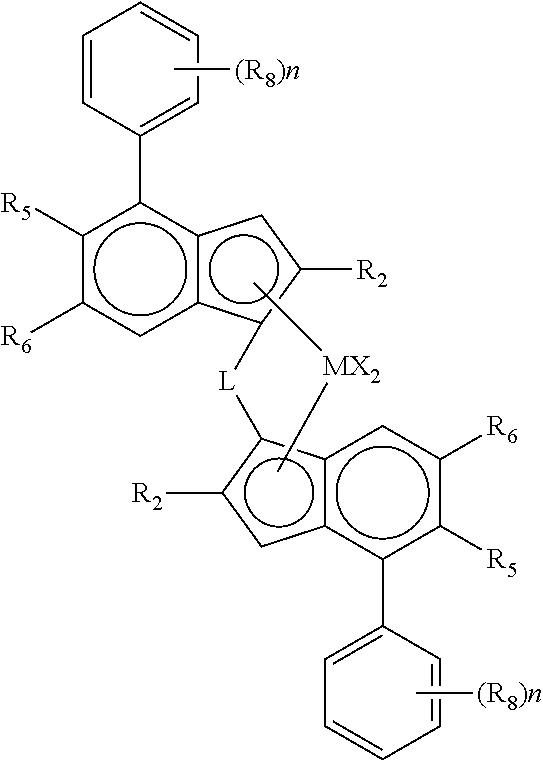

Bis(tetrahydro-indenyl) metallocenes as olefin-polymerization-catalyst

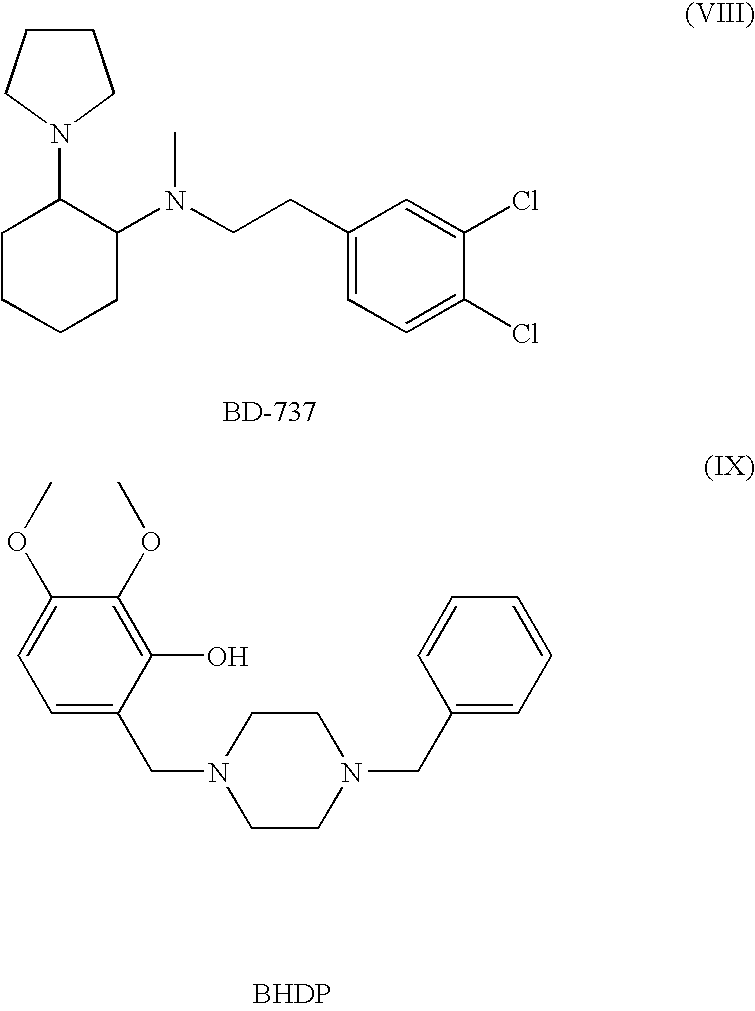

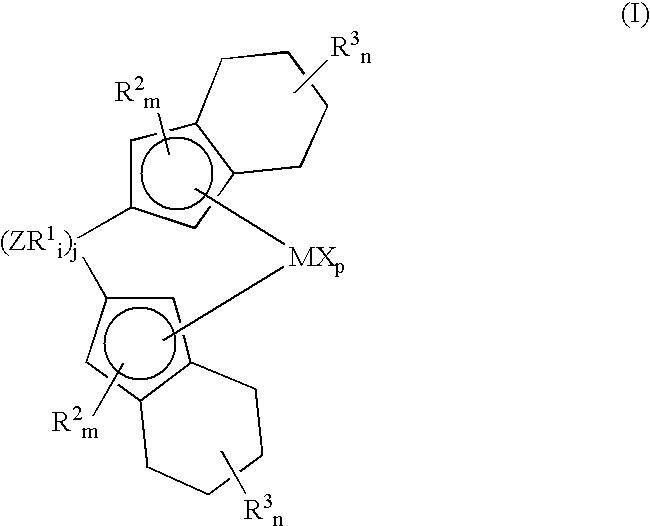

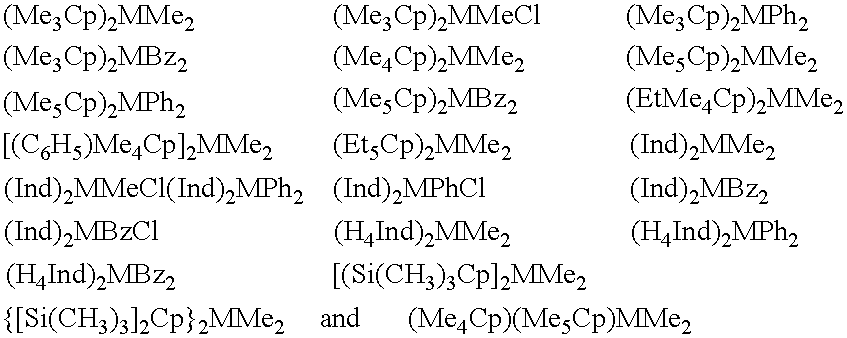

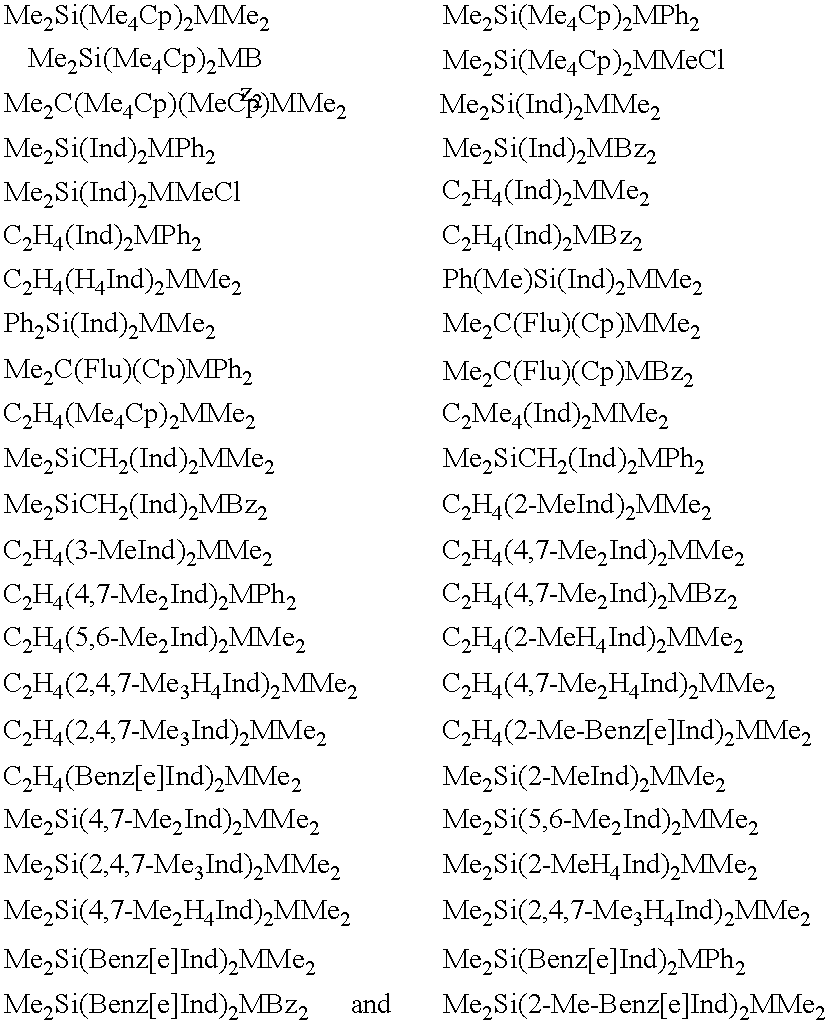

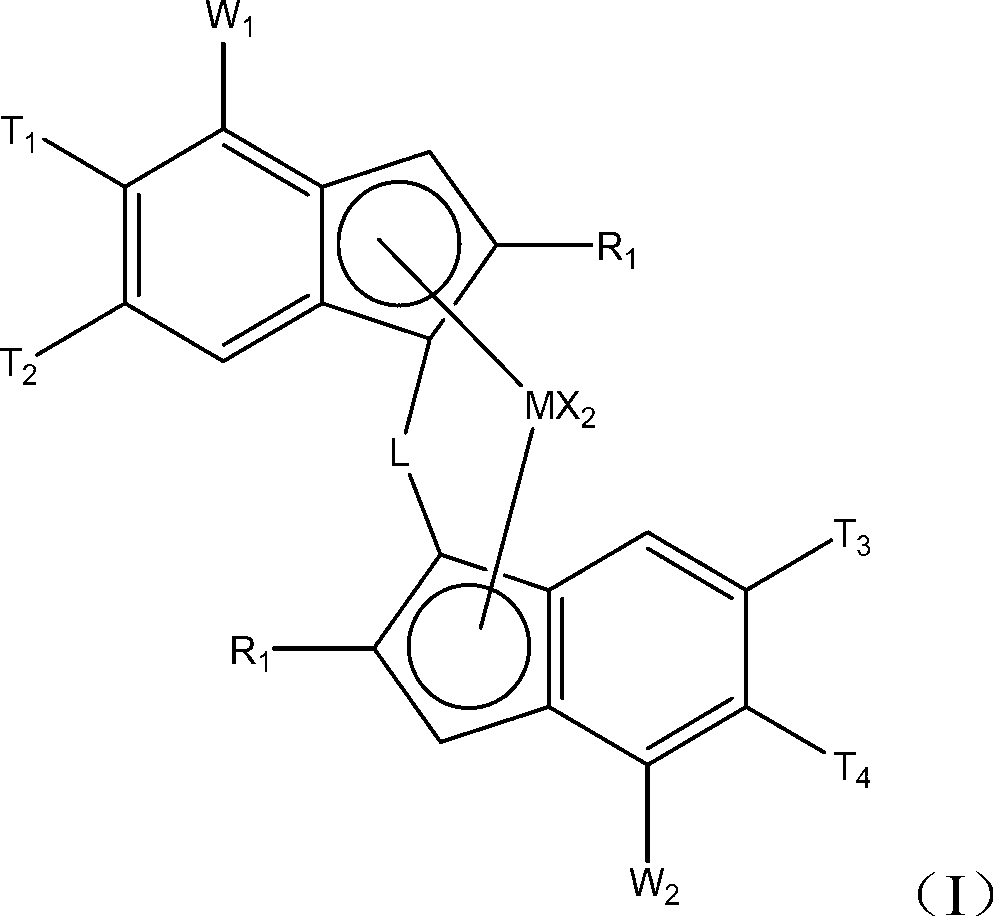

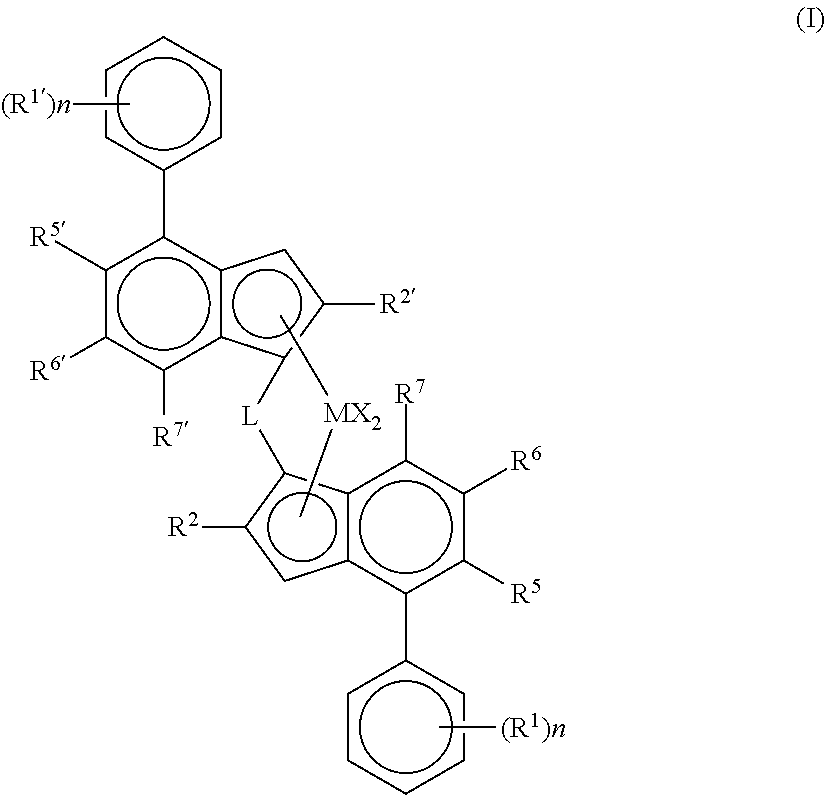

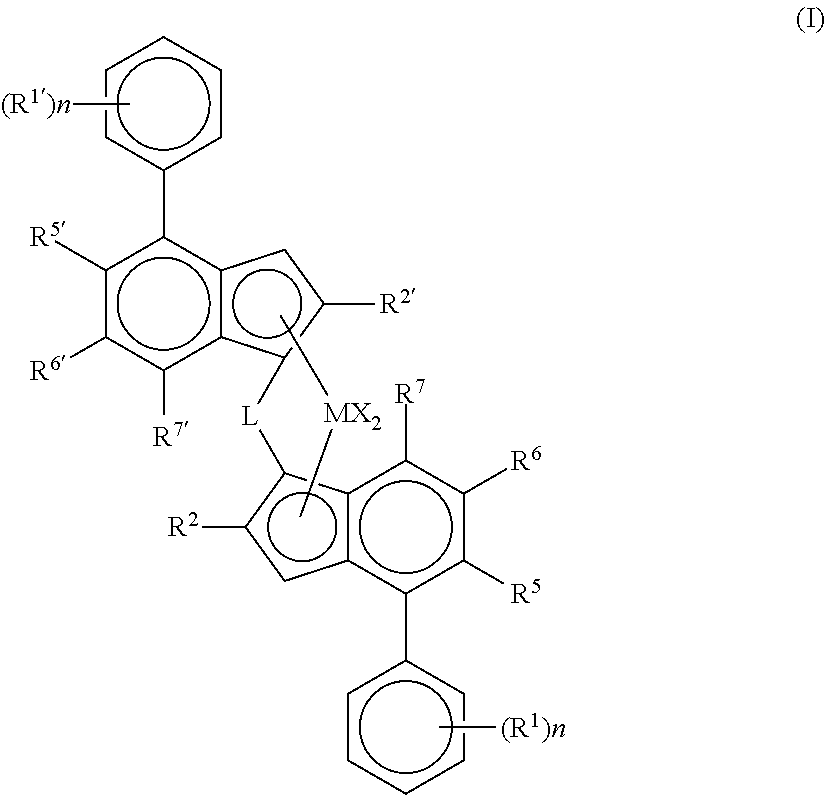

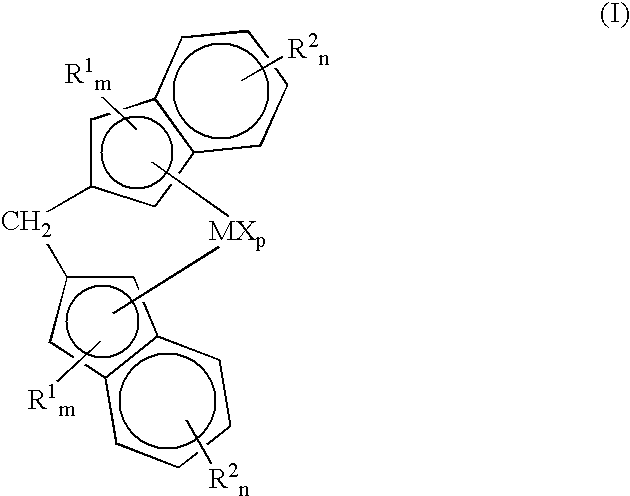

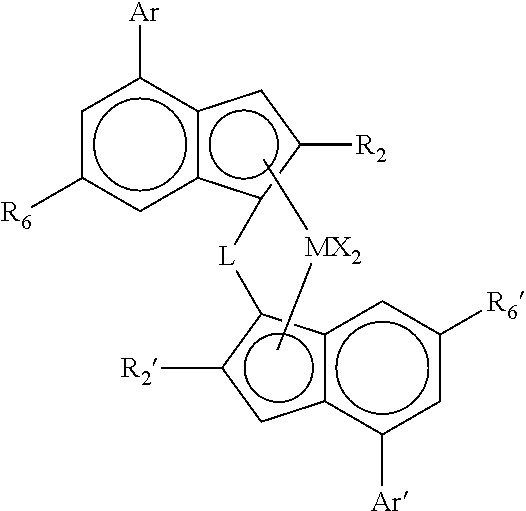

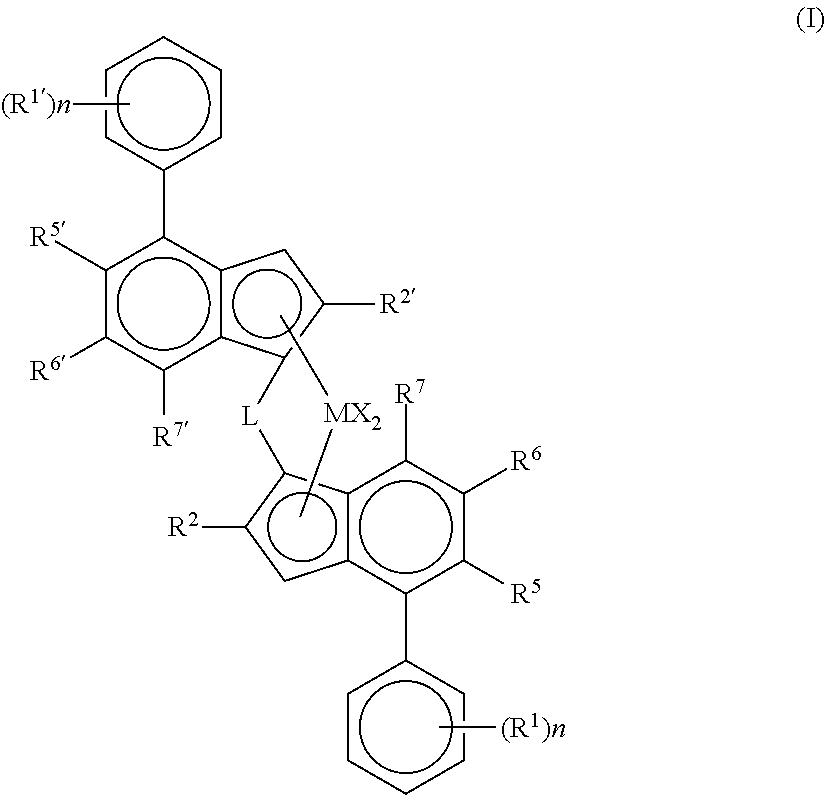

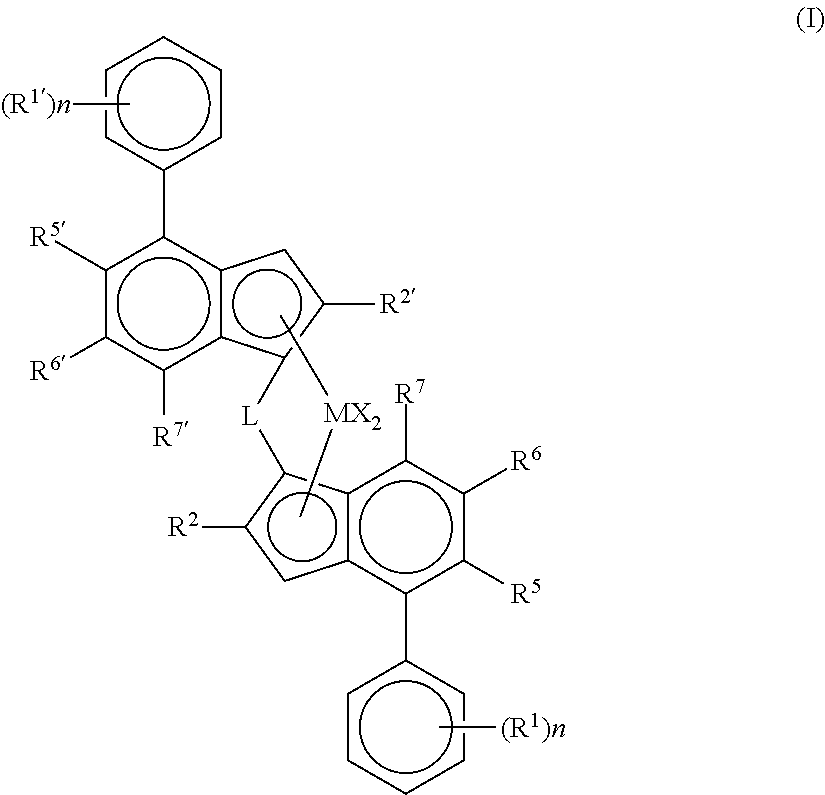

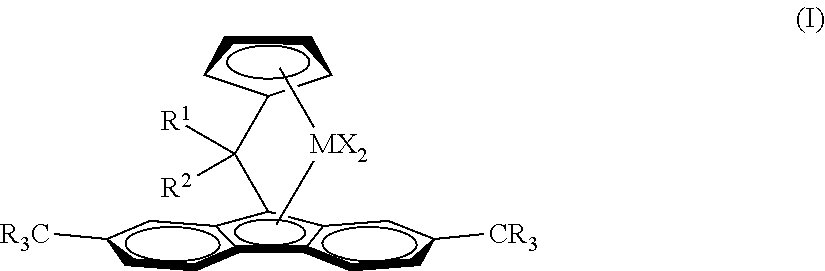

A new class of bridged bis(tetrahydro-indenyl)metallocenes of formula (I),wherein M is Zr or Hf; X are monoanionic sigma ligands; (ZR1i)j is a divalent group bridging the two tetrahydro-indenyl residues; R2 and R3 are halogen, alkyl, cycloalkyl, aryl, alklyaryl or arylalkyl radicals; p is 0-3; i is 1 or 2; j is 1-4; m is 1-2; and n is 0-8. Furthermore, catalysts systems for olefin polymerization containing them are described.

Owner:BASELL POLYOLEFINE GMBH

Process for the preparation of metallocene compounds

InactiveUS6191294B1Silicon organic compoundsGroup 8/9/10/18 element organic compoundsLeaving groupAlkaline earth metal

A new process is disclosed, particularly simple, convenient and practical, for the direct synthesis of metallocenes of formula (I): (CP)(ZR1m)n(A)rMLpL'q wherein (ZR1m)n is a divalent group bridging Cp and A; Cp is a substituted or unsubstituted cyclopentadieryl group; A is -O-, -S-, -N(R2)-, wherein R2 is hydrogen, alkyl, cycloalkyl aryl, alkylaryl or arylalkyl, or A has the same meaning of Cp; M is a transition metal belonging to group 3, 4, 5, 6 or to the lanthanide or actinide groups; L is a monoanionic sigma ligand, such as alkyl, cycloalkyl, aryl, alkylaryl or arylalkyl, optionally containing Si or Ge; L' is halogen or -OR5, R5 being a hydrocarbon radical; m is 1 or 2; n is 0-4; r is 0 or 1; p is 1-3; q is 0-2. Said process comprises reacting the ligand (Y-Cp)(ZR1m)n(A-Y)r, wherein Y is a suitable leaving group, with at least 1 molar equivalent of ML's in the presence of at least (1+r+p) molar equivalents of LjB or LMgL', wherein B is an alkaline or alkaline-earth metal, s ranges from 3 to 6, and j is 1 or 2.

Owner:MONTELL TECH CO BV

Sigma ligands for neuronal regeneration and functional recovery

InactiveUS20050059689A1Promote recoveryPromote regenerationBiocideNervous disorderHuntingtons choreaNeuro-degenerative disease

The invention discloses methods and compositions useful for facilitating neuronal regeneration and functional recovery in neurodegenerative diseases. The methods and compositions utilize ligands for the sigma receptor, wherein the ligand is preferably SA-4503, or salts, or solvates thereof These molecules can be delivered alone or in combination with agents which treat or prevent neurodegenerative diseases such as those caused by ischemic stroke, diabetic peripheral neuropathy, cancer therapy induced neuropathy, multiple sclerosis, amyotrophic lateral sclerosis, traumatic brain injury, spinal cord injury, Huntington's disease or Parkinson's disease. In other methods, the sigma receptor ligands are administered after stroke to facilitate functional recovery. The administration of the sigma receptor ligands effects faster functional recovery.

Owner:MS SCI CORP

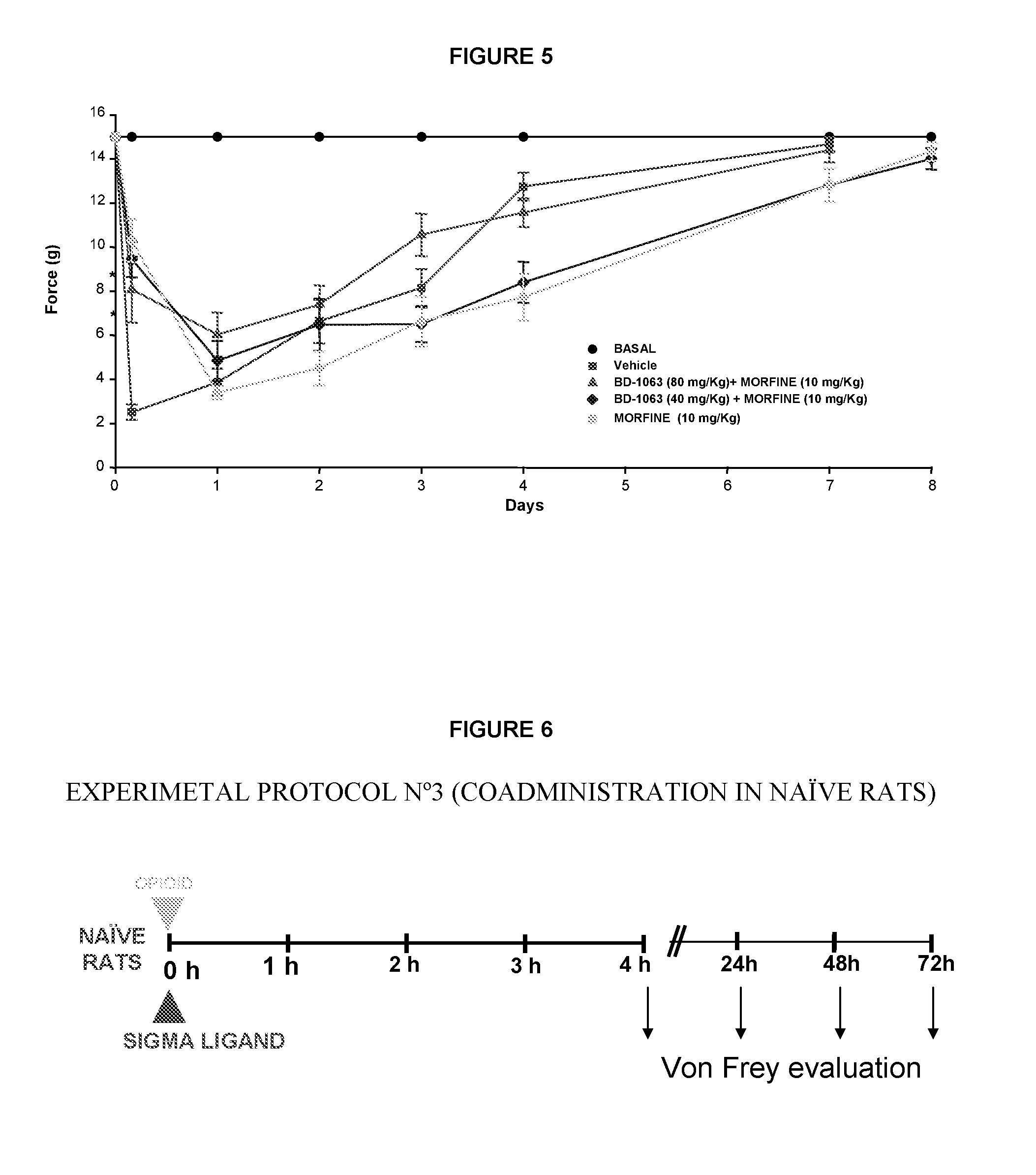

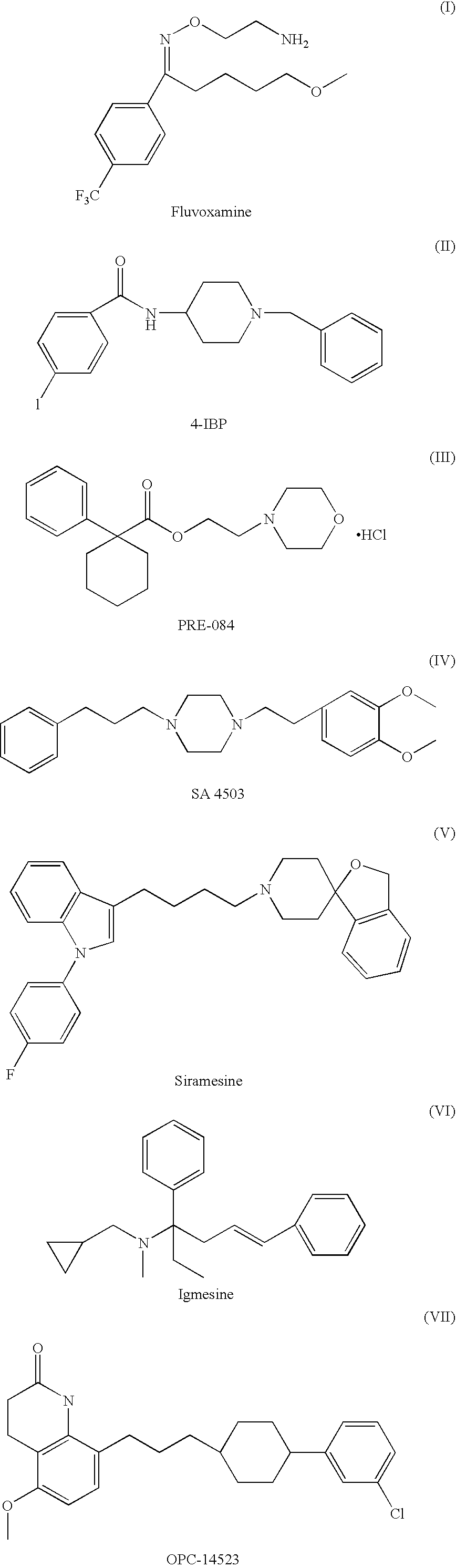

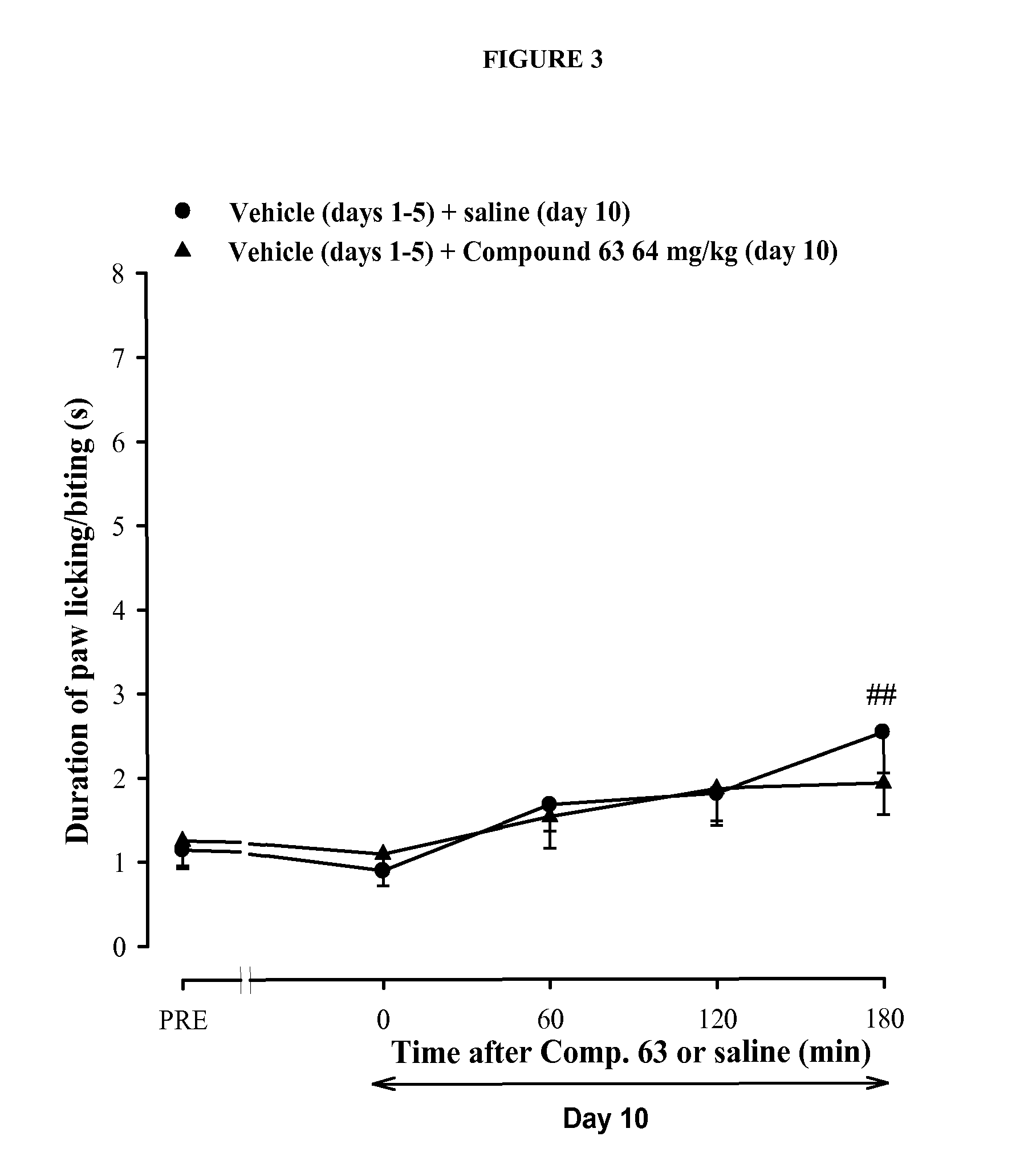

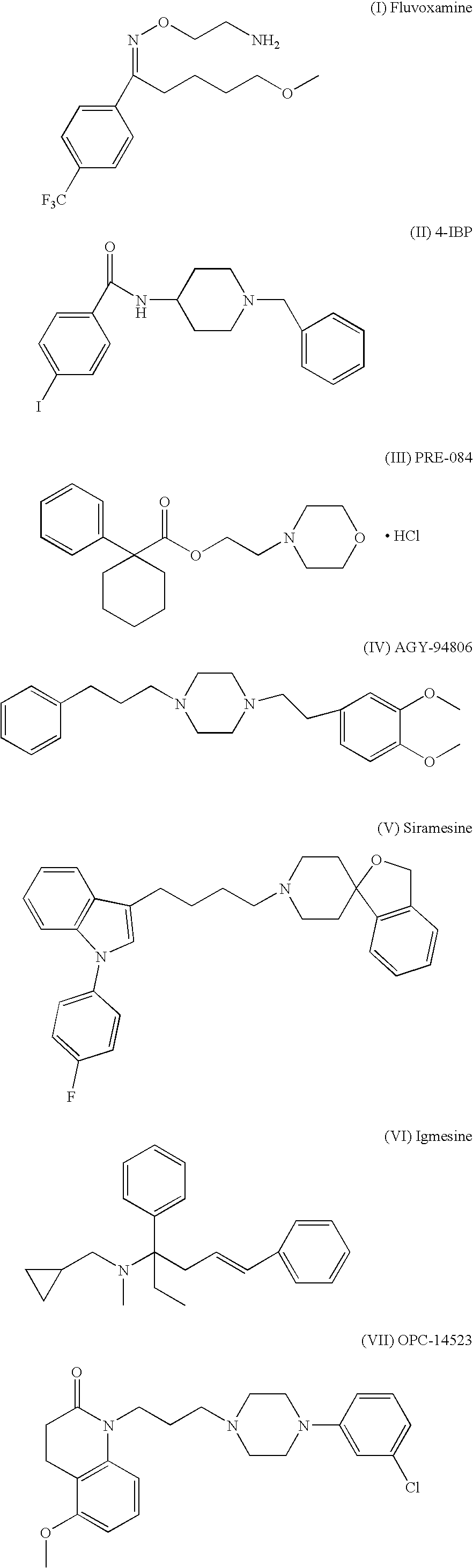

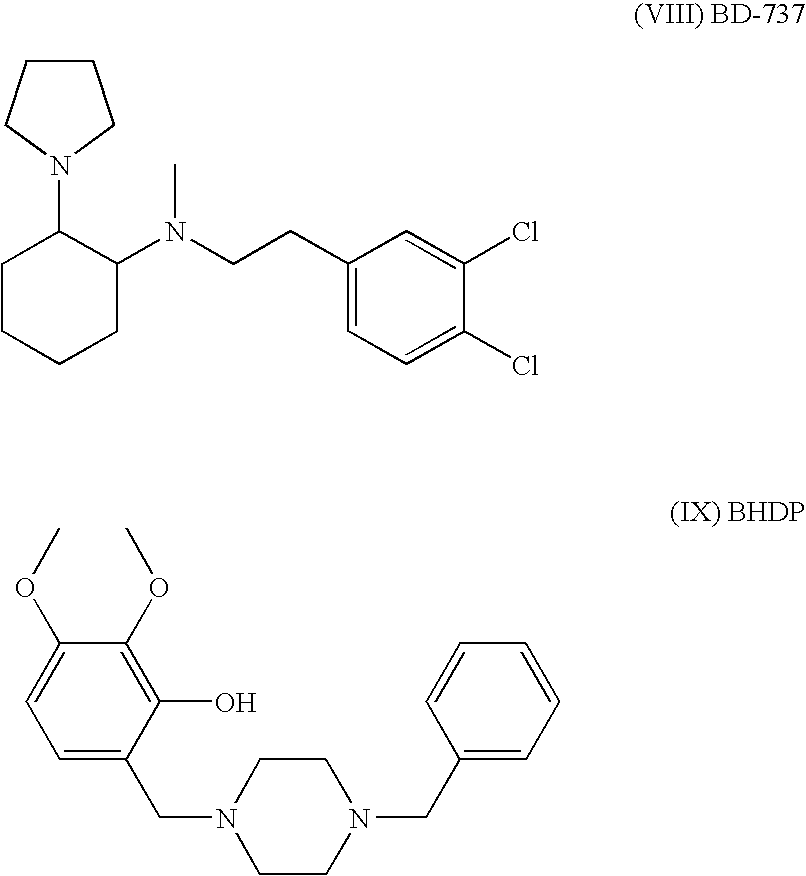

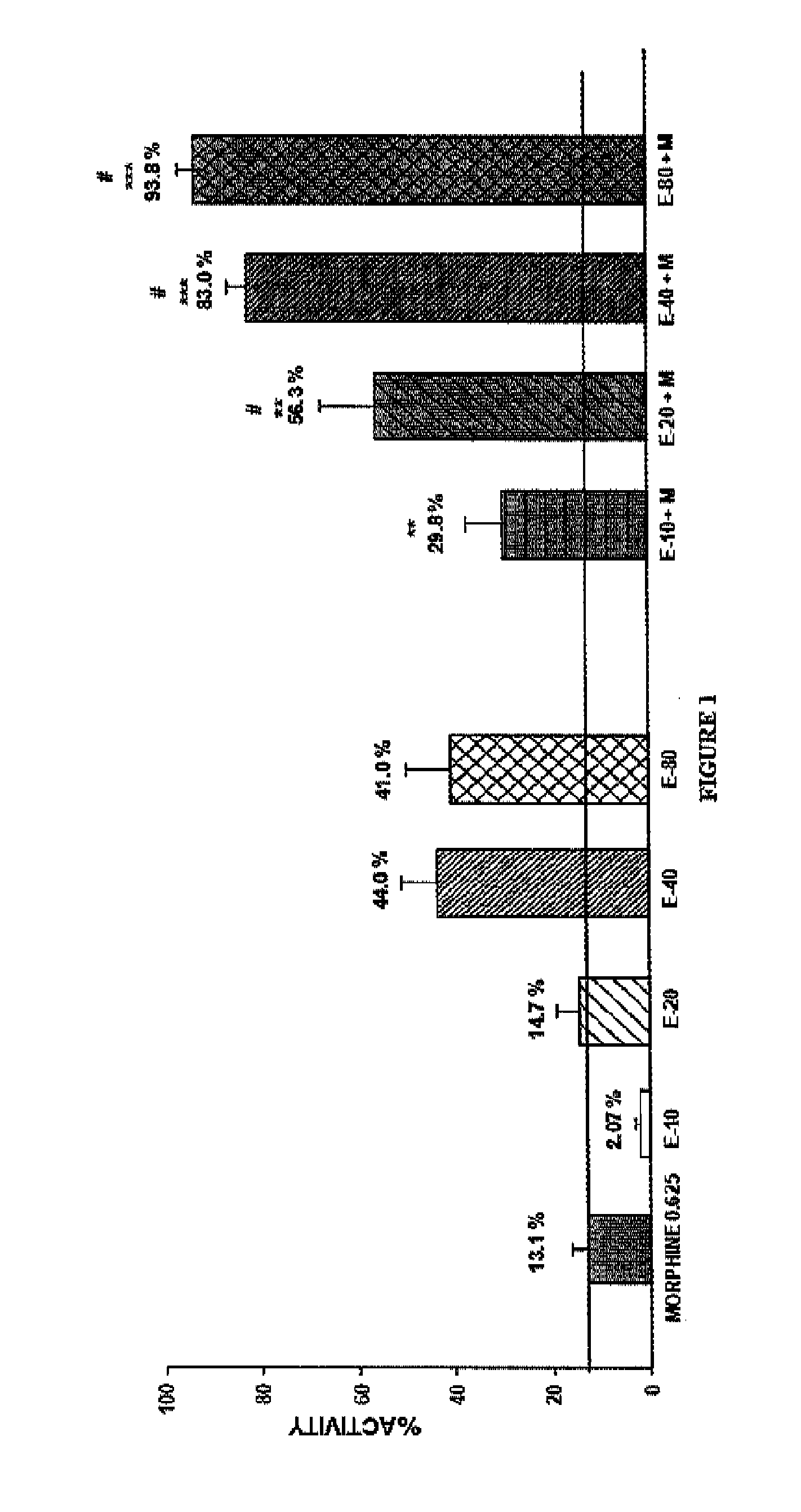

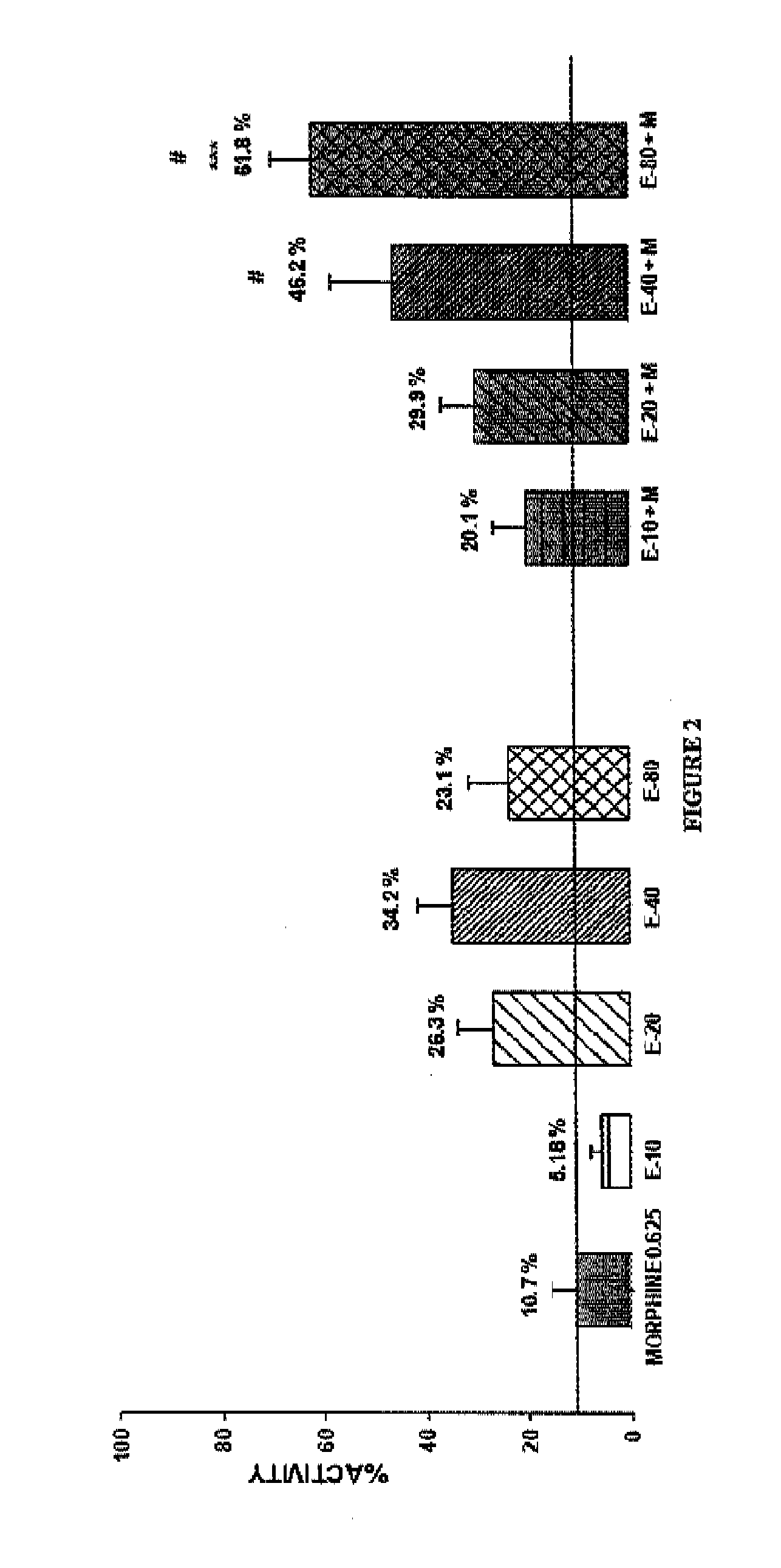

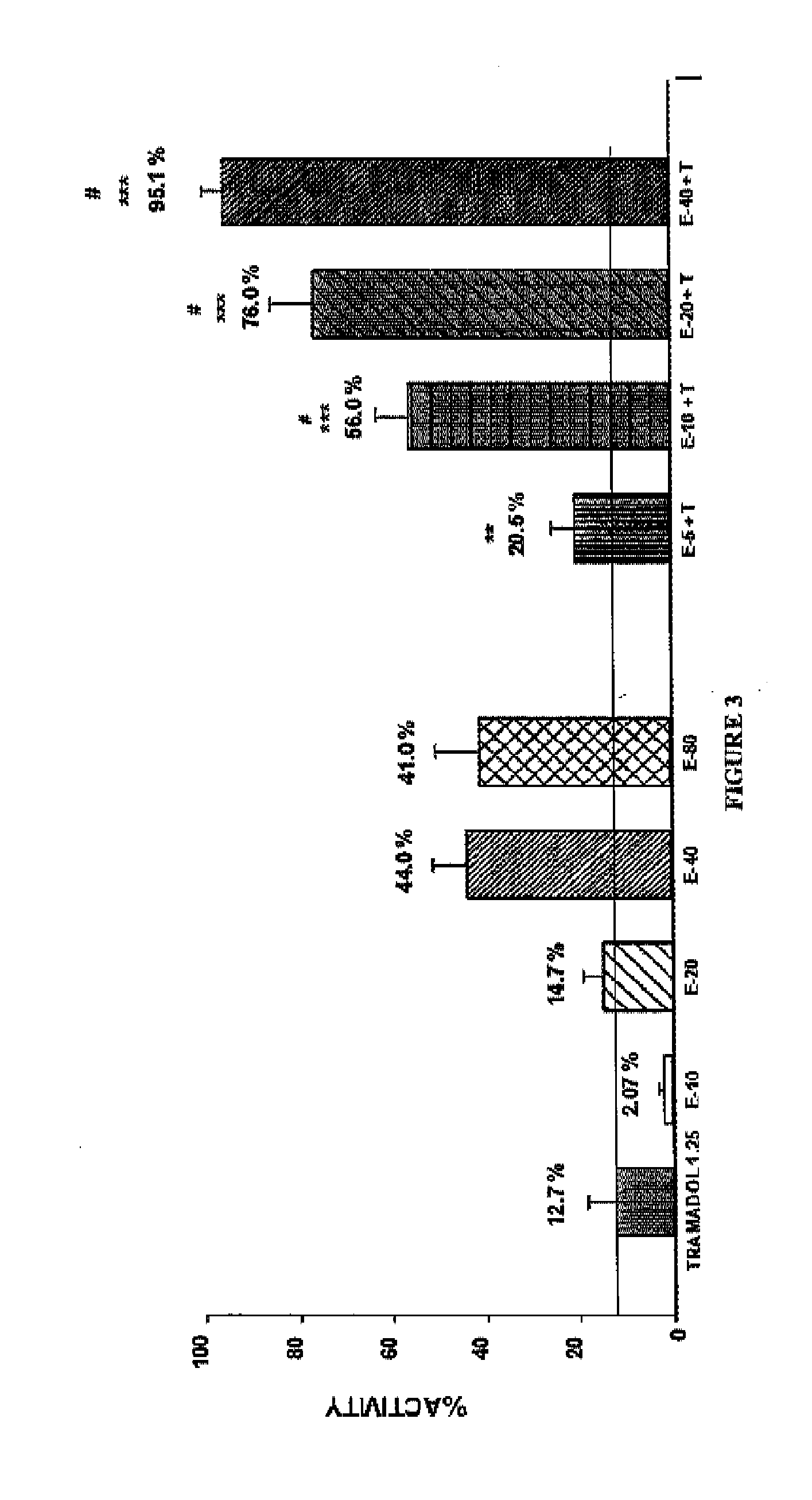

Use of sigma ligands in opioid-induced hyperalgesia

InactiveUS20130158033A1Organic active ingredientsNervous disorderMedicineOpioid-induced hyperalgesia

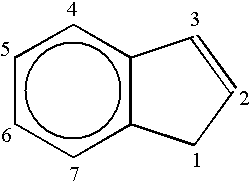

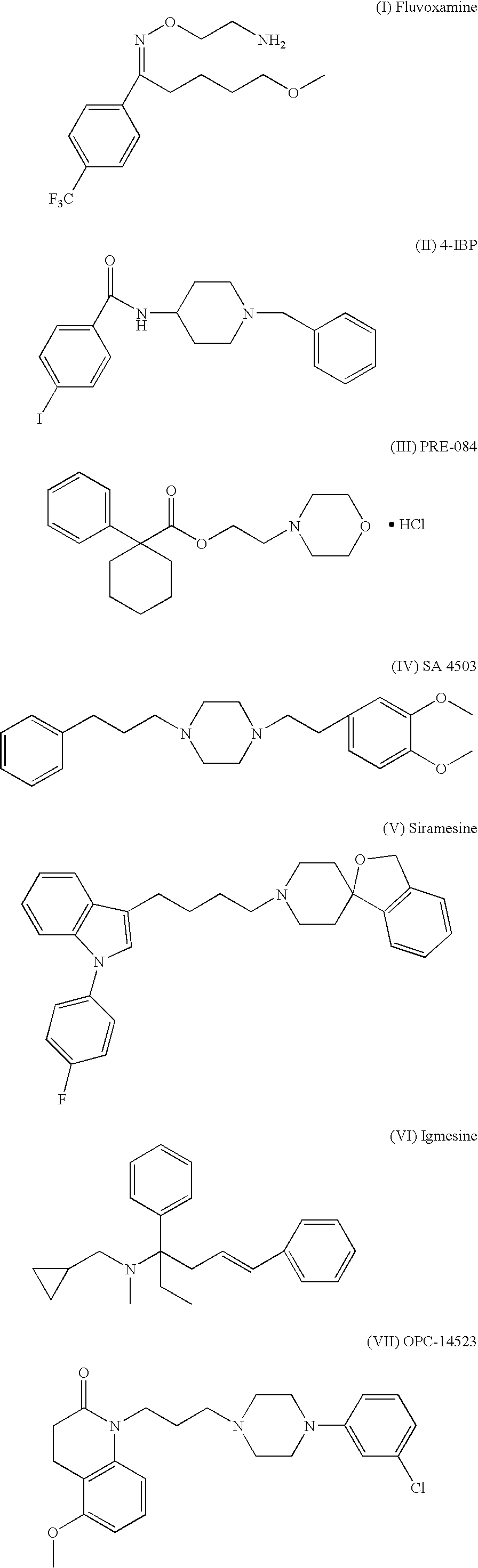

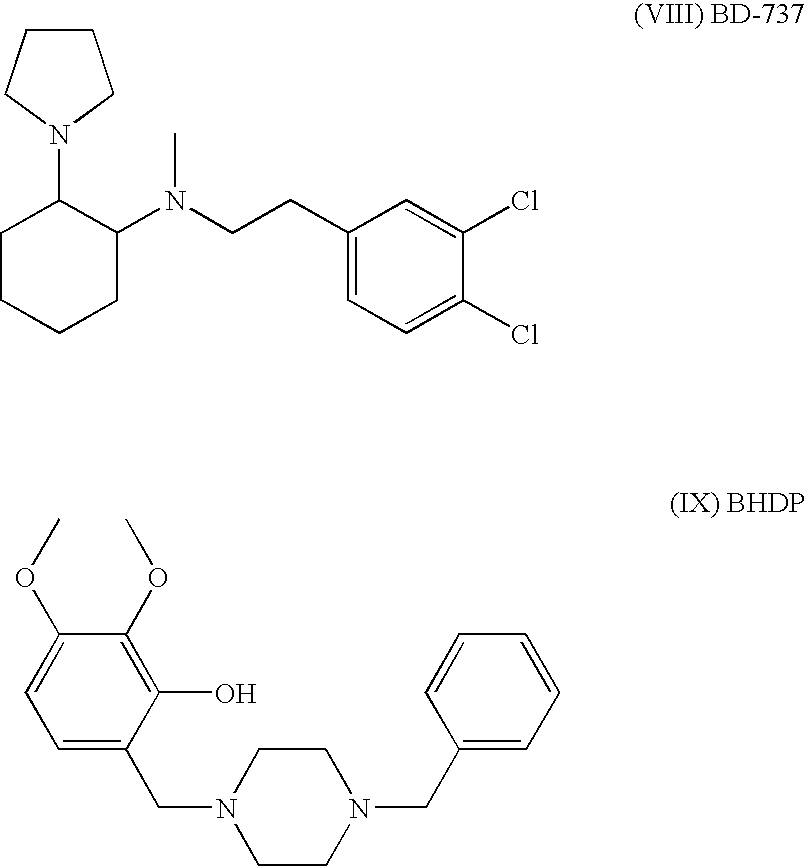

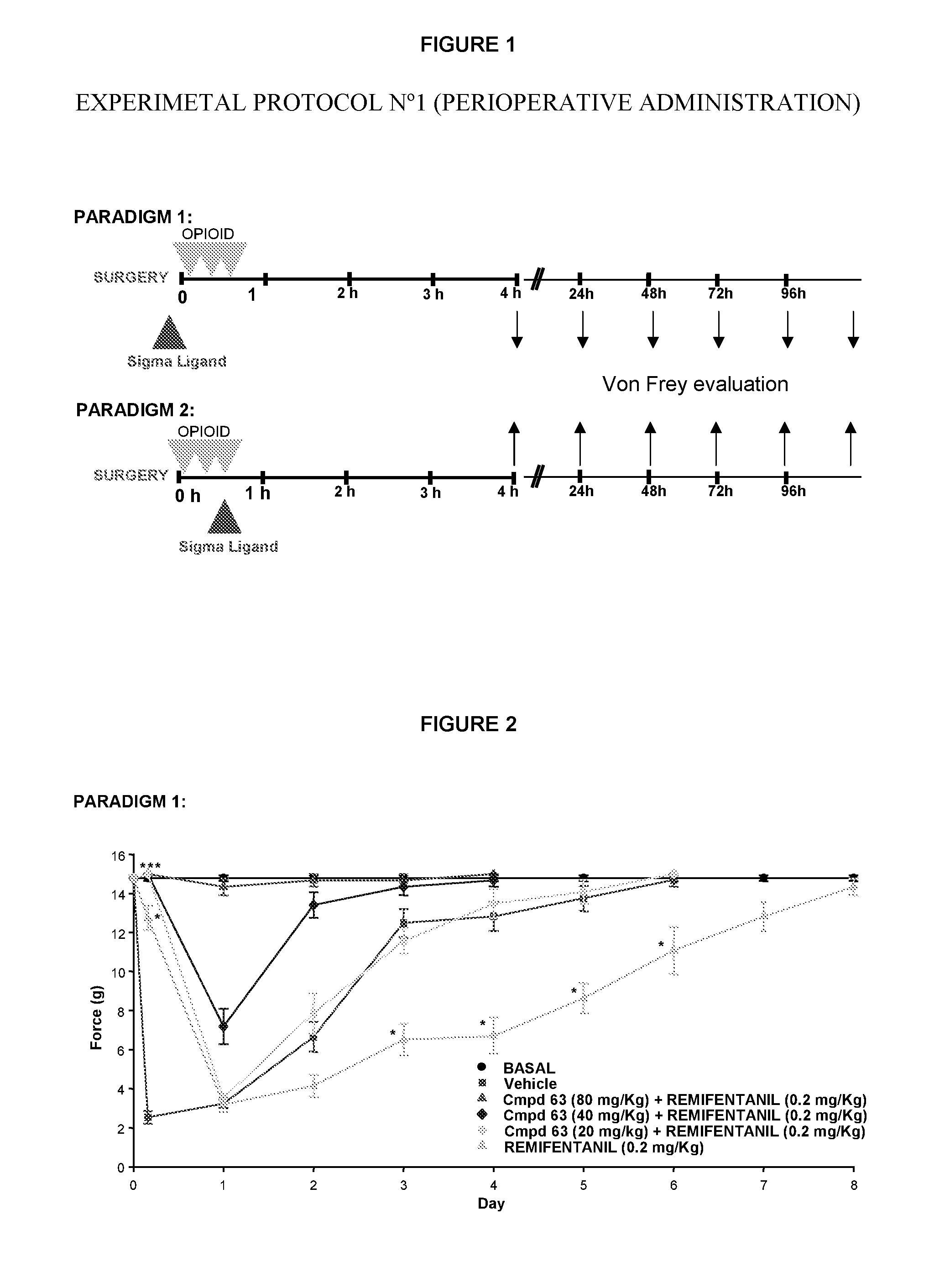

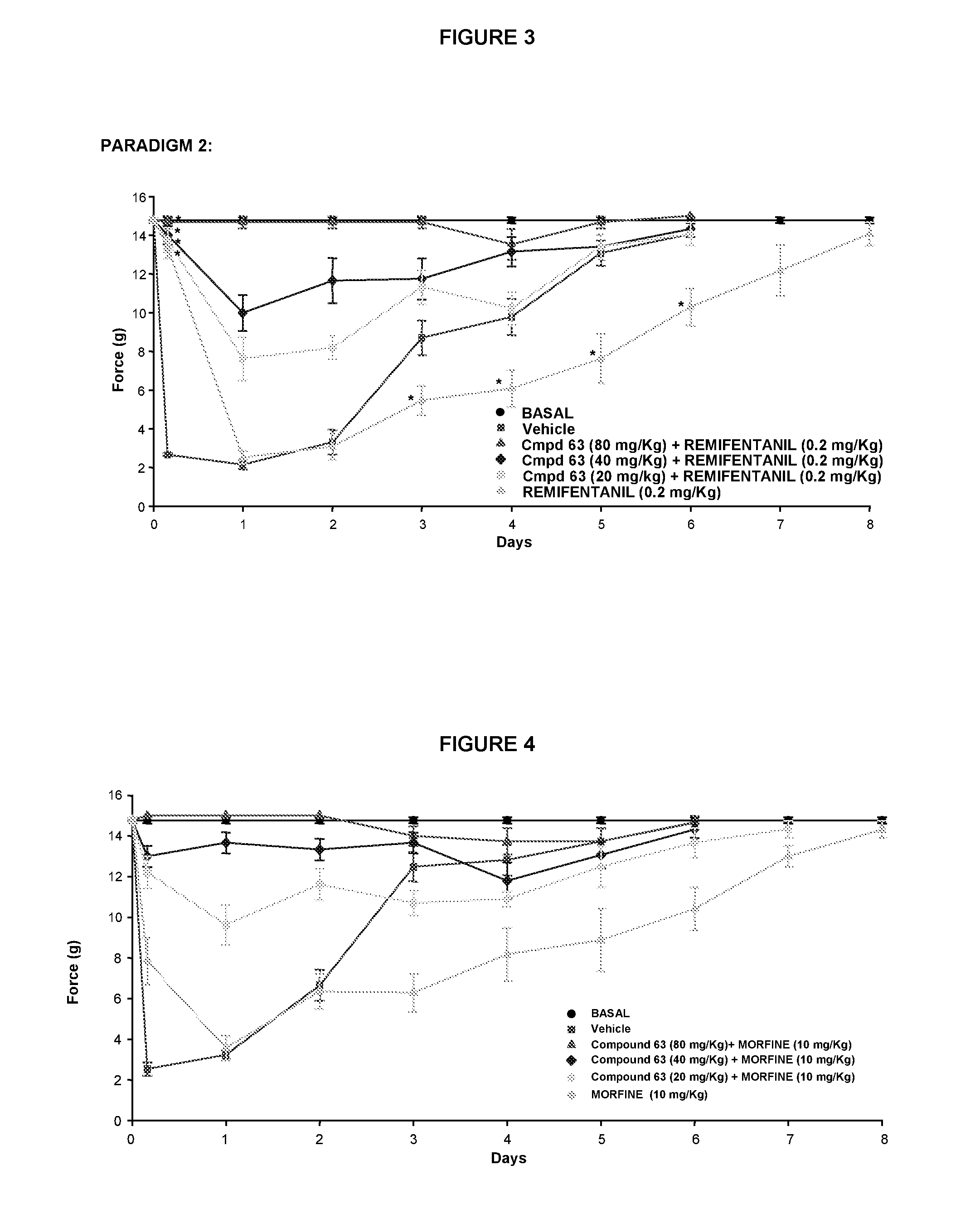

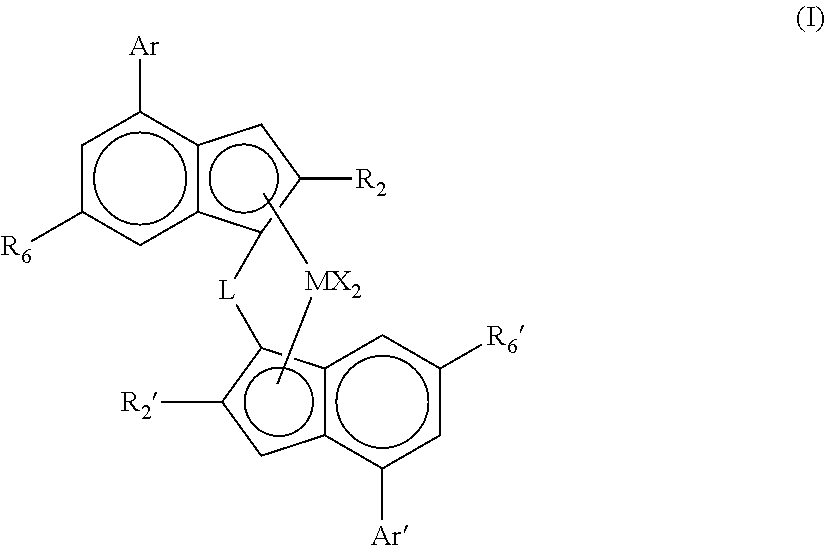

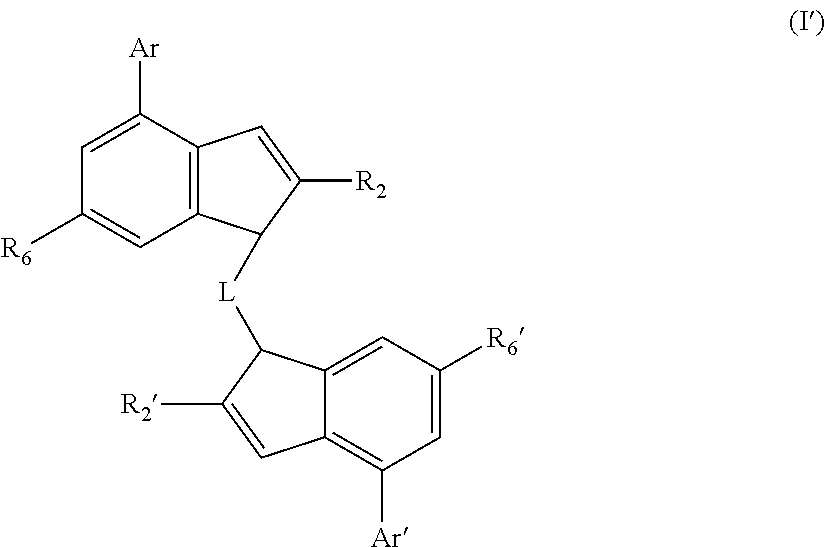

The invention refers to the use of a sigma ligand, particularly a sigma ligand of formula (I) to prevent and / or treat opioid-induced hyperalgesia (OIH) associated to opioid therapy.

Owner:LAB DEL DR ESTEVE SA

Sigma ligands for neuronal regeneration and functional recovery

InactiveUS20050032827A1Promote recoveryPromote regenerationBiocideNervous disorderHuntingtons choreaNeuro-degenerative disease

The invention discloses methods and compositions useful for facilitating neuronal regeneration and functional recovery in neurodegenerative diseases. The methods and compositions utilize ligands for the sigma receptor, wherein the ligand is preferably siramesine, or salts, or solvates thereof. These molecules can be delivered alone or in combination with agents which treat or prevent neurodegenerative diseases such as those caused by ischemic stroke, diabetic peripheral neuropathy, cancer therapy induced neuropathy, multiple sclerosis, amyotrophic lateral sclerosis, traumatic brain injury, spinal cord injury, Huntington's disease or Parkinson's disease. In other methods, the sigma receptor ligands are administered after stroke to facilitate functional recovery. The administration of the sigma receptor ligands effects faster functional recovery.

Owner:MS SCI CORP

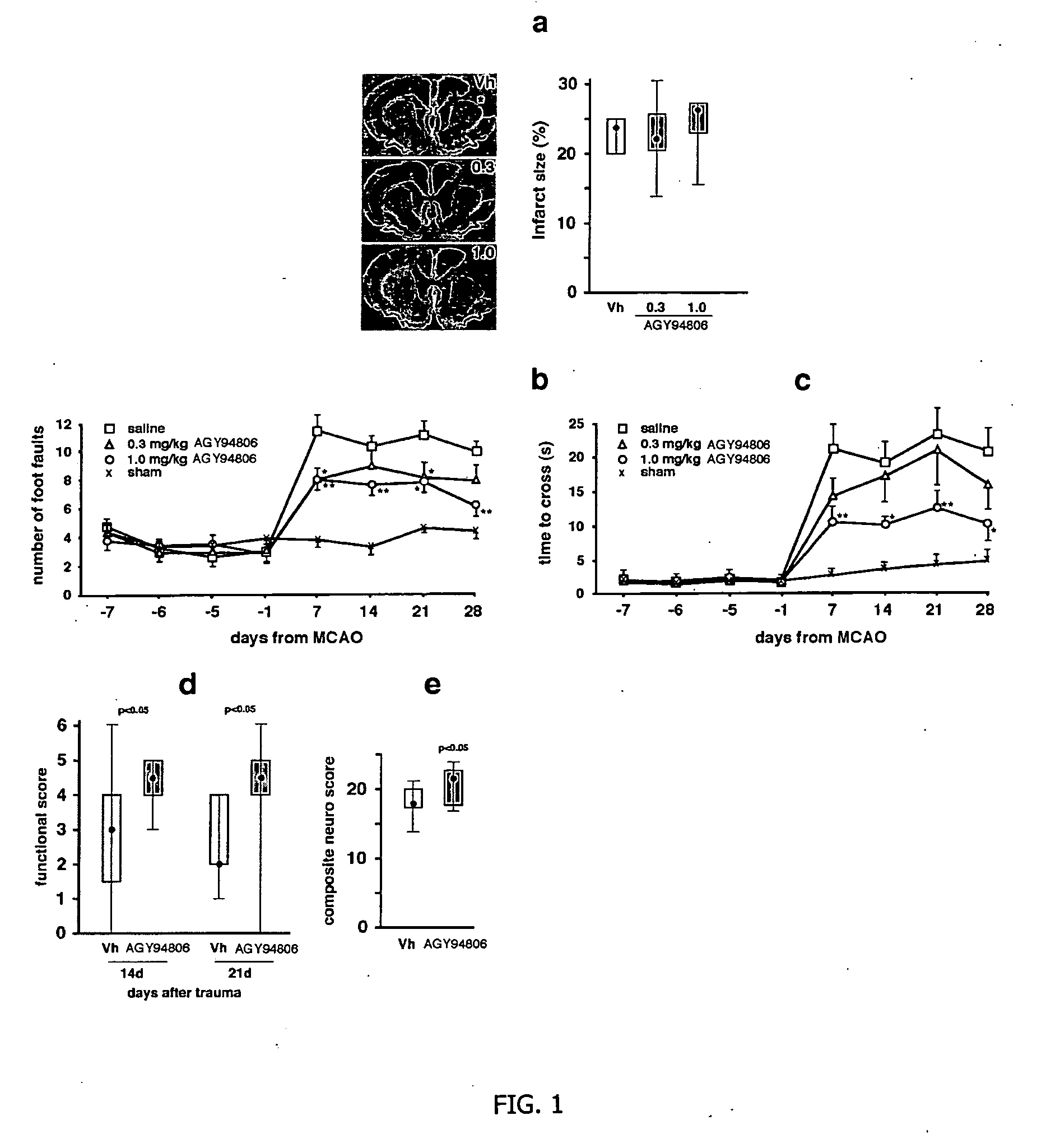

Sigma ligands for neuronal regeneration and functional recovery

InactiveUS20060052386A1Promote recoveryPromote regenerationOrganic active ingredientsNervous disorderHuntingtons choreaRisk stroke

The invention discloses methods and compositions useful for facilitating neuronal regeneration and functional recovery in neurodegenerative diseases. The methods and compositions utilize ligands for the sigma receptor, wherein the ligand is preferably AGY-94806, or salts, or solvates thereof. These molecules can be delivered alone or in combination with agents which treat or prevent neurodegenerative diseases such as those caused by ischemic stroke, diabetic peripheral neuropathy, cancer therapy induced neuropathy, multiple sclerosis, amyotrophic lateral sclerosis, traumatic brain injury, spinal cord injury, Huntington's disease or Parkinson's disease. In other methods, the sigma receptor ligands are administered after stroke to facilitate functional recovery. The administration of the sigma receptor ligands effects faster functional recovery.

Owner:MS SCI CORP

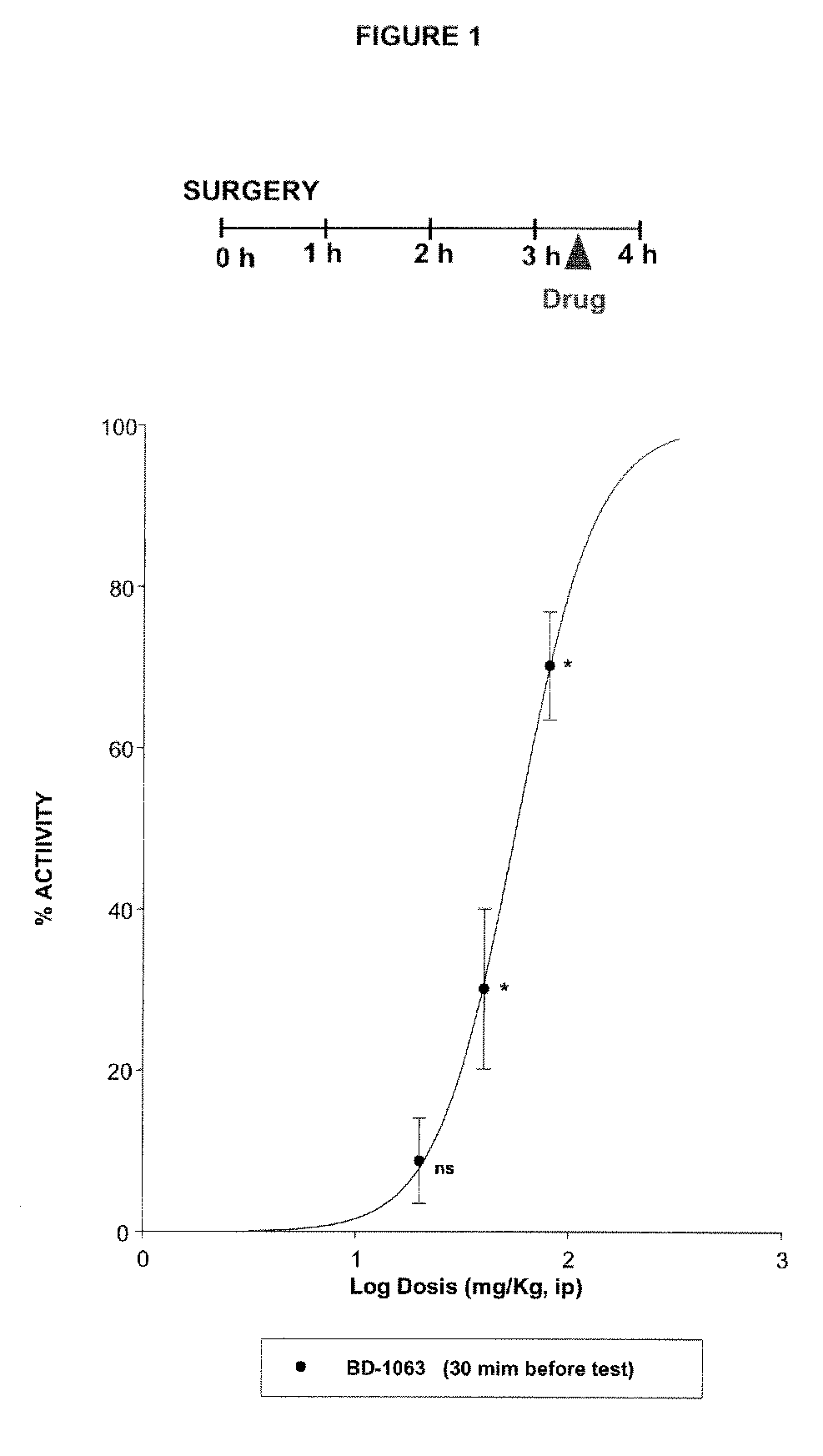

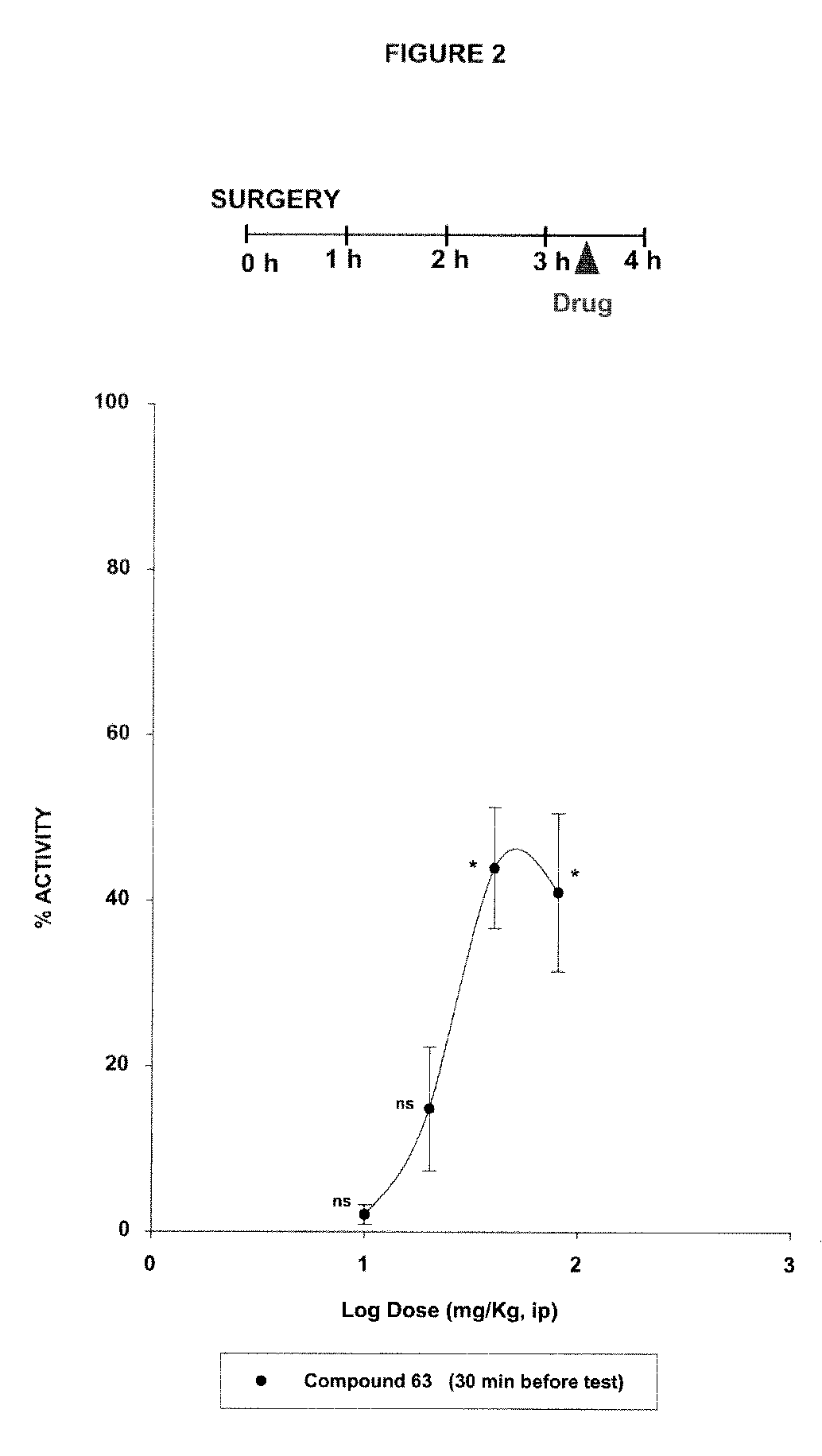

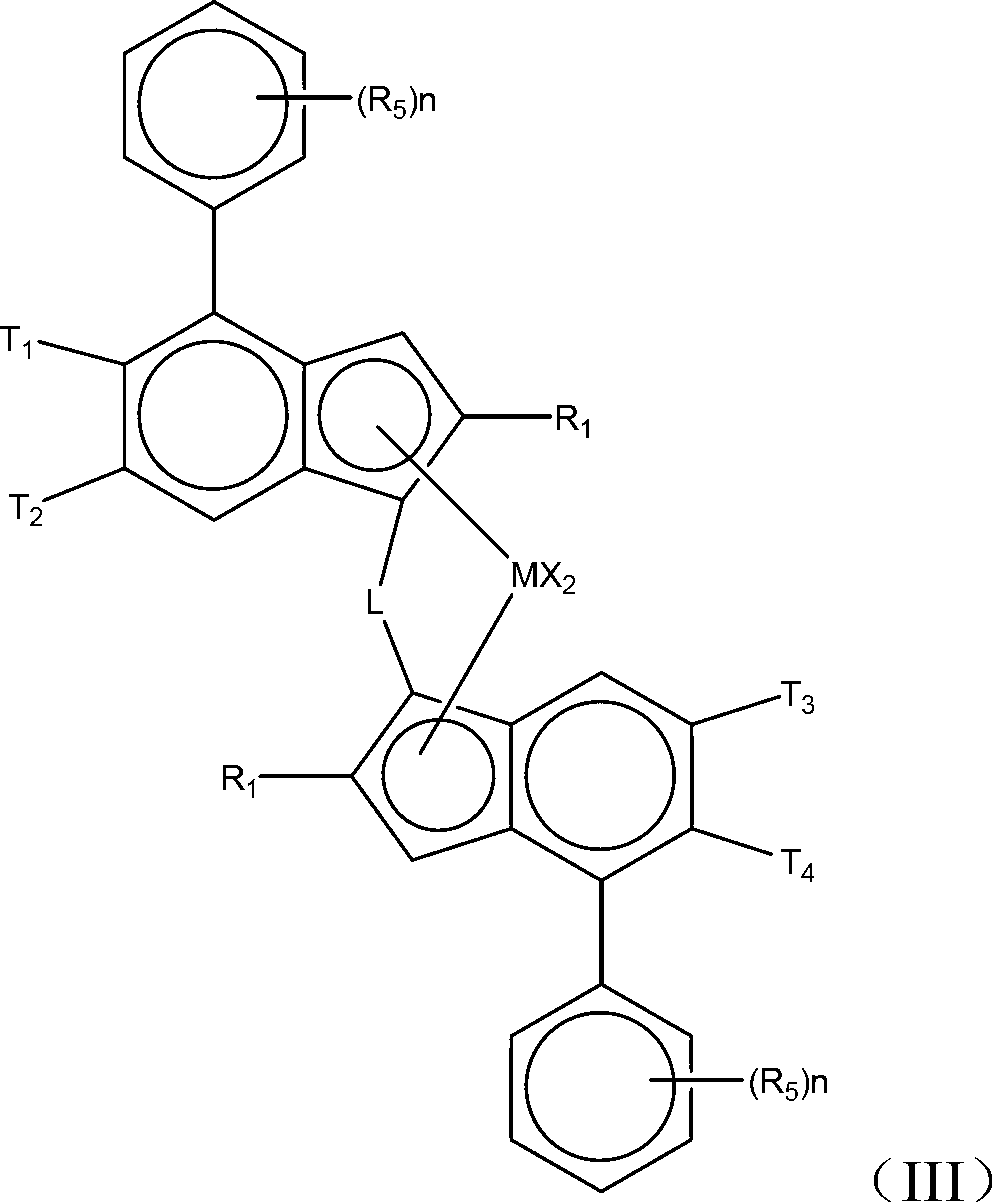

Sigma ligands for use in the prevention and/or treatment of post-operative pain

The invention refers to the use of a sigma ligand, particularly a sigma ligand of formulae (I), (II) or (III) to prevent and / or treat acute and chronic pain developed as a consequence of surgery, especially superficial and / or deep pain secondary to surgical tissue injury, and peripheral neuropathic pain, neuralgia, allodynia, causalgia, hyperalgesia, hyperesthesia, hyperpathia, neuritis or neuropathy secondary to surgical procedure.

Owner:LAB DEL DR ESTEVE SA

Use of sigma ligands in bone cancer pain

The invention refers to the use of a sigma ligand, particularly a sigma ligand of formula (I) to prevent and / or treat pain associated to bone cancer.

Owner:LAB DEL DR ESTEVE SA

Sigma ligands for neuronal regeneration and functional recovery

InactiveUS20060014753A1Improve functional recoveryEnhance neuronal regenerationBiocideNervous disorderNeuro-degenerative diseaseNeuron

The invention discloses methods and compositions useful for facilitating neuronal regeneration and functional recovery in neurodegenerative diseases. The methods and compositions utilize ligands for the sigma receptor, wherein the ligand is preferably AGY-94806, or salts, or solvates thereof. These molecules can be delivered alone or in combination with agents which treat or prevent neurodegenerative diseases such as those caused by multiple sclerosis. In other methods, the sigma receptor ligands are administered after MS to facilitate functional recovery. The administration of the sigma receptor ligands causes faster functional recovery.

Owner:MS SCI CORP

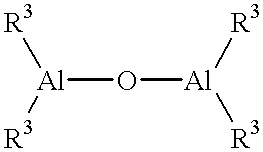

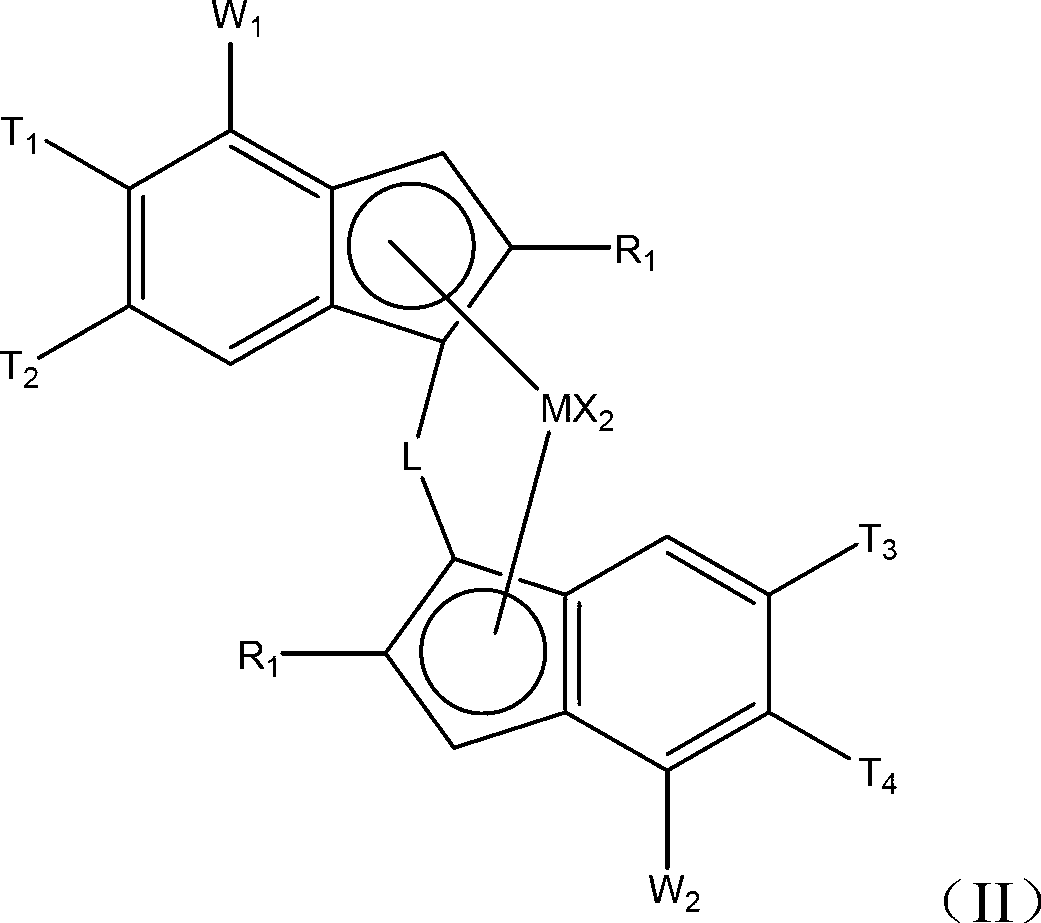

Solid particulate catalysts comprising bridged metallocenes

A solid, particulate catalyst comprising: (i) a complex of Formula (I), wherein M is zirconium or hafnium; each X is a sigma ligand; L is a divalent bridge selected from -R'2C-, -R'2C-CR'2-, -R'2Si-, -R'2Si-SiR'2-, -R'2Ge-, wherein each R' is independently a hydrogen atom, C1-C20-alkyl, tri(C1-C20-alkyl)silyl, C6-C20-aryl, C7-C20-arylalkyl or C7-C20-alkylaryl; each R1 independently is a linear or branched C1-C20 hydrocarbyl radical optionally containing one or more heteroatoms from groups 14-16; T1 and T4, which can be the same or different, are an OR<2>, a SR<2>, CH(R<18>)2, CH2R<18>, aryl or heteroaryl group; each R<2>, which can be the same or different, is a C1-C20 hydrocarbyl radical; each R<18>, which can be the same or different, is a C1-C20 hydrocarbyl radical or two R<18> groups together with the carbon atom to which they are attached may form a cyclic C4-C20 hydrocarbyl group; T2 and T3, which may be the same or different, are a C(R<18>)3 group; W1 and W2, which may be the same or different, are a 5 or 6 membered aryl or heteroaryl ring wherein each atom of said ring is optionally substituted with an R<5> group; each R<5>, which can be the same or different, is a C1-C20 hydrocarbyl radical optionally containing one or more heteroatoms belonging to groups 14-16; and optionally two adjacent R<5> groups taken together can form a further mono or multicyclic ring condensed to W1 or W2, optionally substituted by one or two groups R5; and (ii) a cocatalyst.

Owner:BOREALIS AG

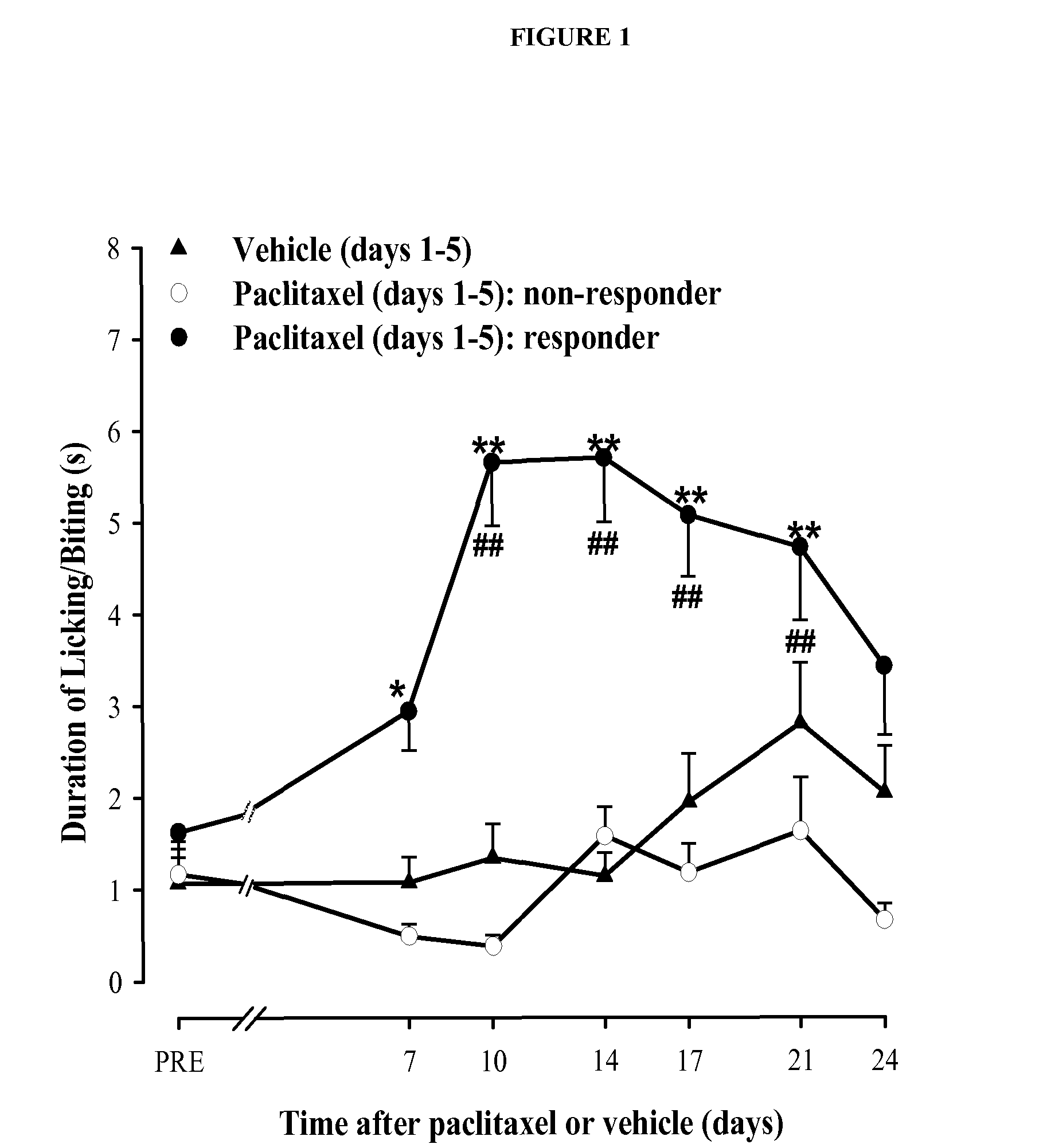

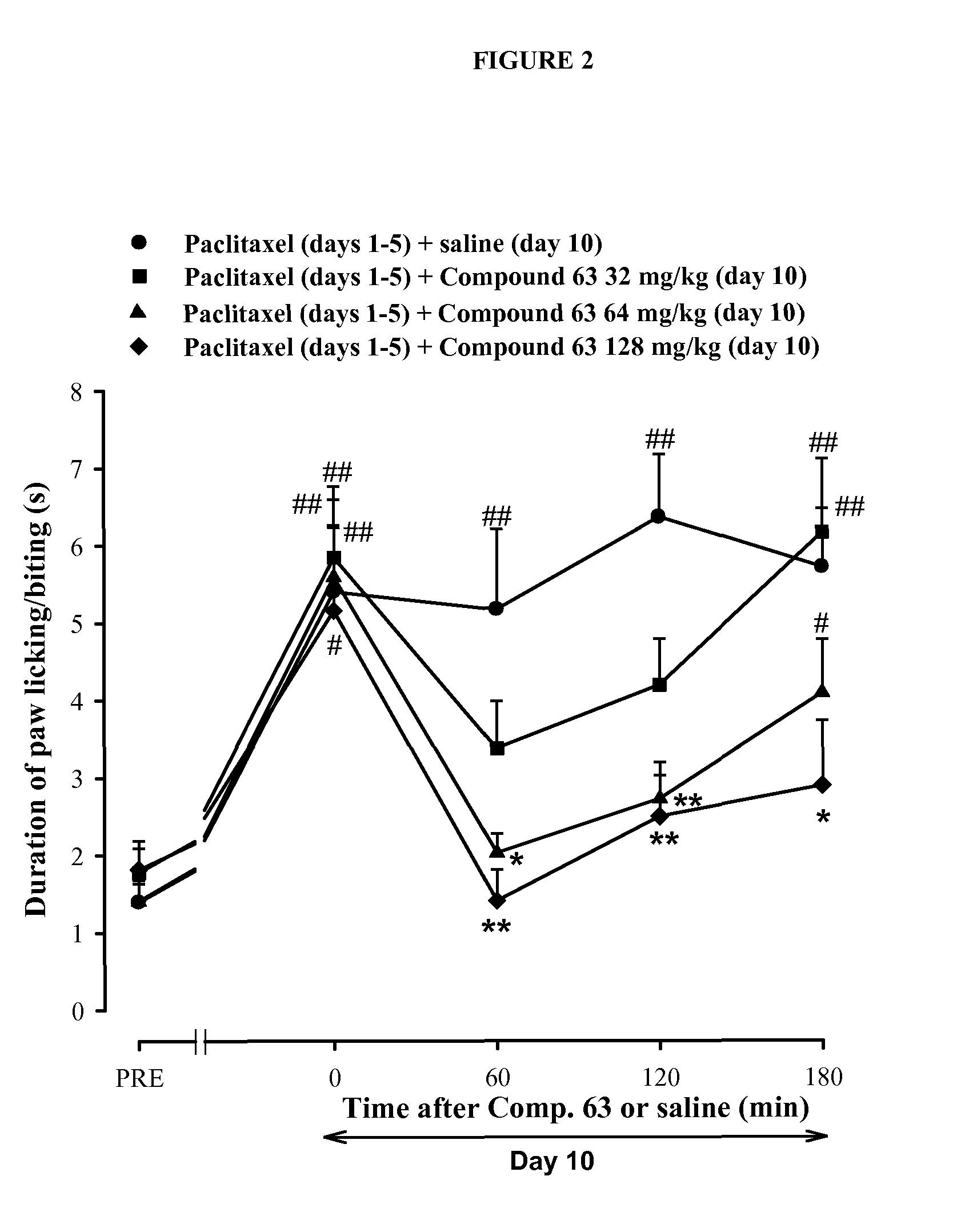

Sigma ligands for the prevention or treatment of pain induced by chemotherapy

InactiveUS20120141606A1Avoid developmentEffective treatmentBiocideHeavy metal active ingredientsPlatinumMedicine

The invention refers to the use of a sigma ligand of formula (I) to prevent or treat pain induced by a chemotherapeutic agent, especially pain induced by taxanes, vinca alkaloids or platinum-containing chemotherapeutic drugs.

Owner:LAB DEL DR ESTEVE SA

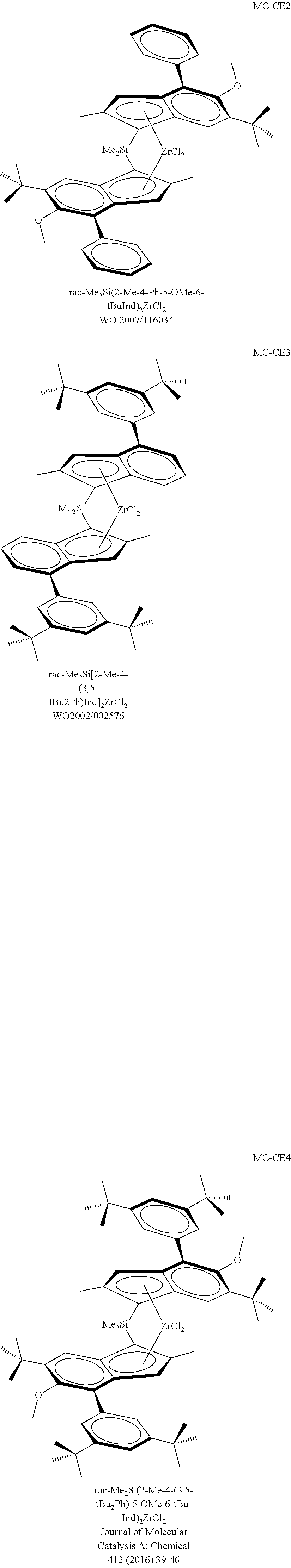

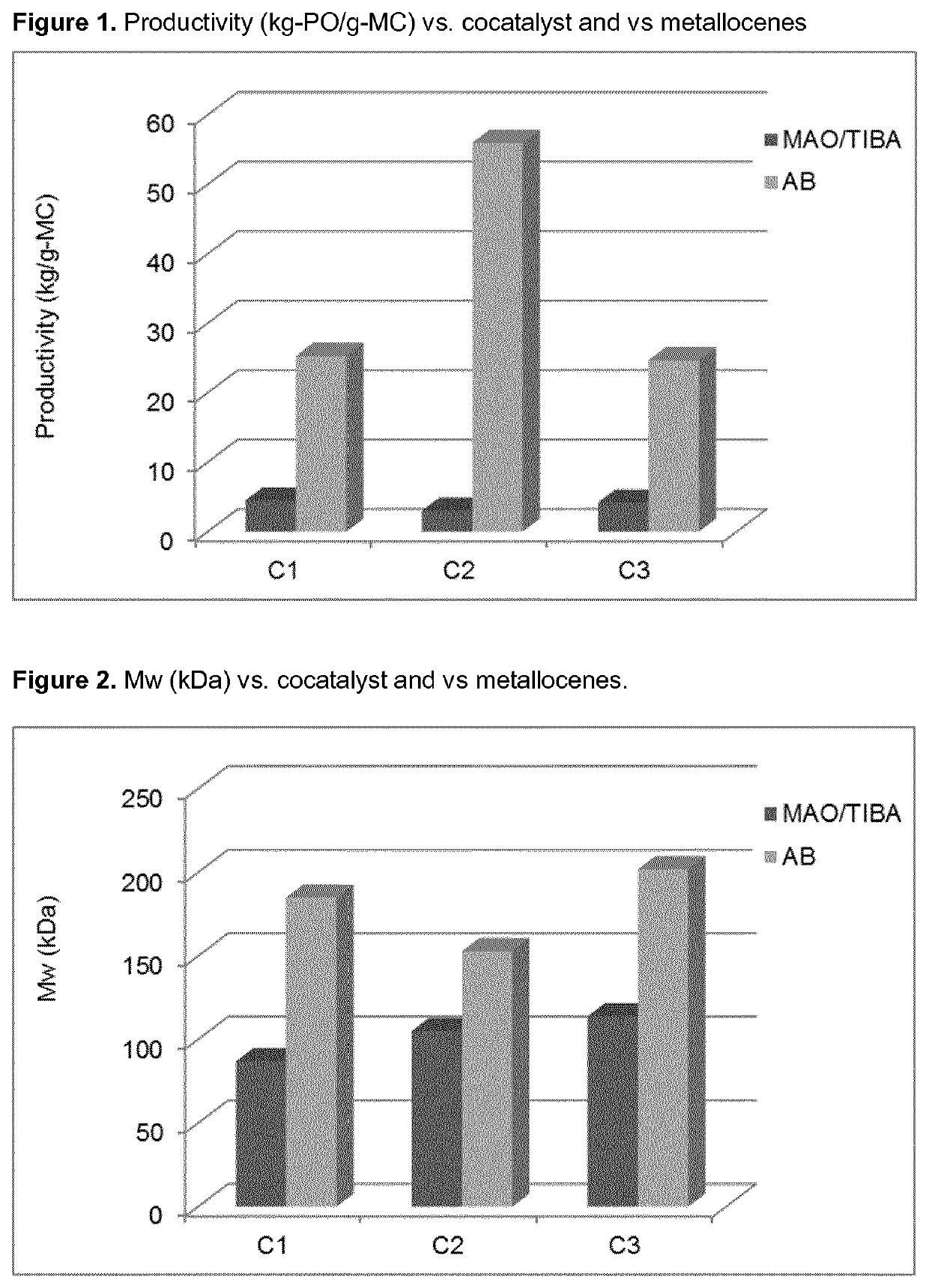

Improved catalyst system for producing polyethylene copolymers in a high temperature solution polymerization process

ActiveUS20170037165A1High activityIncrease productivityMetallocenesBoron containingSolution polymerization

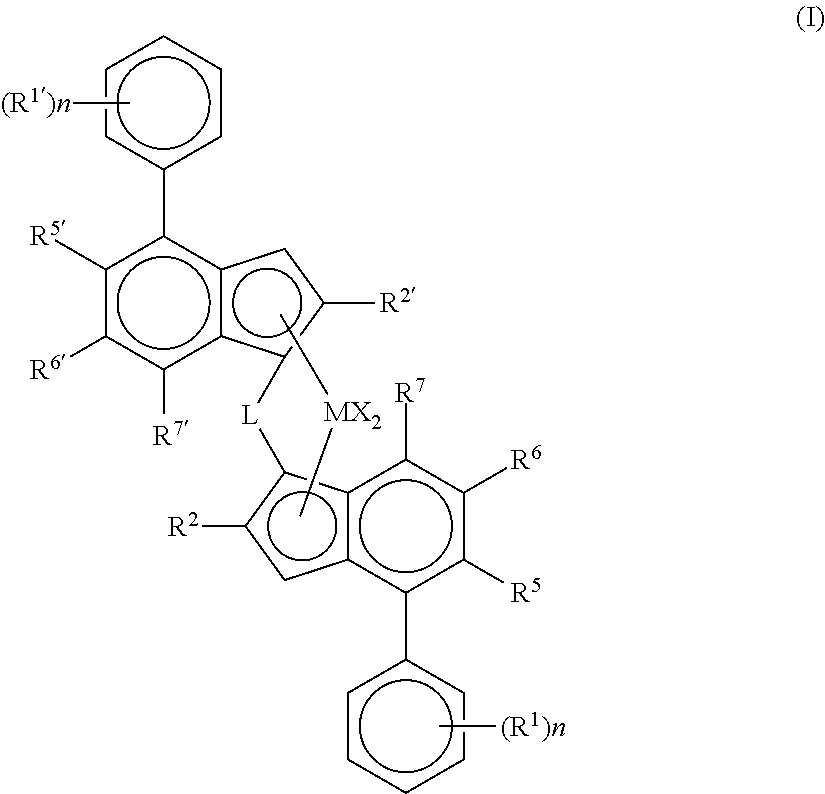

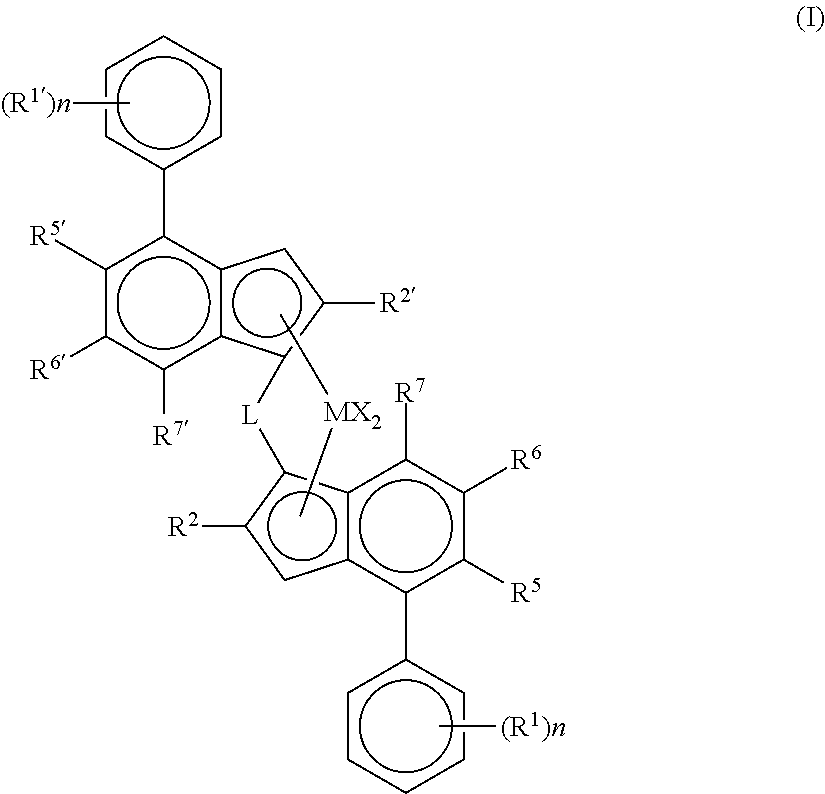

Catalyst system for producing ethylene copolymers in a high temperature solution process, the catalyst system comprising (i) a metallocene complex of formula (I) wherein M is Hf or Zr X is a sigma ligand, L is a bridge of the formula —SiR82—, wherein each R8 is independently a C1-C20-hydrocarbyl, tri(C1-C20-alkyl)silyl, C6-C20-aryl, C7-C20-arylalkyl or C7-C20-alkylaryl n is 0, 1 or 2 R1 and R1′ are the same or can be different and can be a linear or branched C1-C6-alkyl group, R2 and R2′ are the same or are different and are a CH2—R9 group, with R9 being H or linear or branched C1-C6-alkyl group R5 and R5′ are the same or are different and can be H or a linear or branched C1-C6-alkyl group or a OR group, wherein R is a C1-C6-alkyl group R6 and R6′ are the same or are different and can be H or a C(R10)3 group, with R10 being the same or different and R10 can be H or a linear or branched C1-C6-alkyl group or R5 and R6 and / or R5′ and R6′ taken together form an unsubstituted 4-7 membered ring condensed to the benzene ring of the indenyl moiety, with the proviso that if R5 and R6 as well as R5′ and R6′ taken together form an unsubstituted 5 membered ring condensed to the benzene ring of the indenyl moiety then R2 and R2′ are not a C1-alkyl group; and R7 and R7′ can be the same or are different and can be H or a linear or branched C1-C6-alkyl group (ii) an aluminoxane cocatalyst and (iii) optionally a boron containing cocatalyst

Owner:BOREALIS AG

Sigma ligands for neuronal regeneration and functional recovery

InactiveUS20110152284A1Promote recoveryPromote regenerationBiocideNervous disorderHuntingtons choreaSigma-1 receptor

The invention discloses methods and compositions useful for facilitating neuronal regeneration and functional recovery in neurodegenerative diseases. The methods and compositions utilize ligands for the sigma receptor, wherein the ligand is preferable AGY-94806, or salts or solvates thereof. These molecules can be delivered alone or in combination with agents which treat or prevent neurodegenerative diseases such as those caused by ischemic stroke, multiple sclerosis, amyotrophic lateral sclerosis, traumatic brain injury, Huntington's disease, or Parkinson's disease. In other methods, the sigma receptor ligands are administered after stroke to facilitate functional recovery. The administration of the sigma receptor ligands effects functional recovery.

Owner:WIELOCH TADEUSZ +2

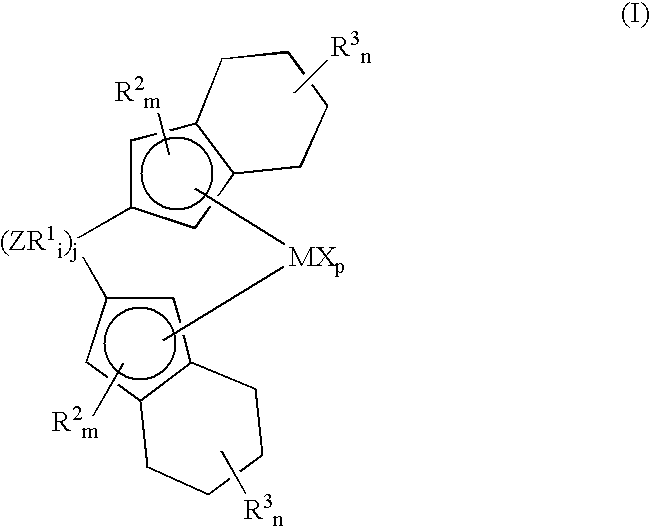

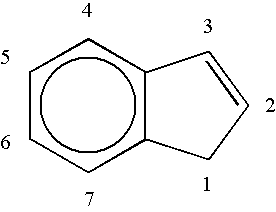

Transition metal compound, polymerization catalyst using same and process for producing styrenic polymer using said polymerization catalyst

InactiveUSRE36563E1Efficient productionHigh degree of syndiotactic configurationOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePtru catalyst

There are disclosed a transition metal compound of the general formula RMXa-1Lb (R is a pi ligand, a fused polycyclic cyclopentadienyl group in which at least one of many-membered rings to which cyclopentadienyl groups are fusedly bonded is a saturated ring, M is a transition metal, X is a sigma ligand, L is a Lewis base, a is the valency of M, and b is 0, 1 or 2); a polymerization catalyst for styrene, etc. comprising the above transition metal, preferably further comprising an oxygen atom containing compound ionic compound or organoboron compound and optionally a Lewis base; and a process for producing a polymer of a compound containing an ethylenically unsaturated double bond or an acetylenic polymer, especially a syndiotactic polystyrene by using the above polymerization catalyst. The catalyst is particularly effective for producing highly syndiotactic polystyrene minimized in residual metals amounts at a low cost in enhanced efficiency.

Owner:IDEMITSU KOSAN CO LTD

Methylene bridged metallocenes as olefin-polymerization-catalyst components

A new class of methylene-bridged metallocenes of formula (I), wherein M is a transition metal of group 3, 4, 5, 6, lanthanide or actinide; X is a monoanionic sigma ligand; R<1 >can be alkyl, cycloalkyl, aryl, alkylaryl or arylalkyl radicals; R<2 >can be halogen, alkyl, cycloalkyl, aryl, alkylaryl or arylalkyl radical; p is 0-3; m is 0-2; and n is 0-4. Furthermore, the corresponding ligands, a new process for their preparation and catalysts systems containing said methylene-bridged metallocenes are described.

Owner:BASELL POLYOLEFINE GMBH

Sigma ligands for neuronal regeneration and functional recovery

Owner:MS SCI CORP

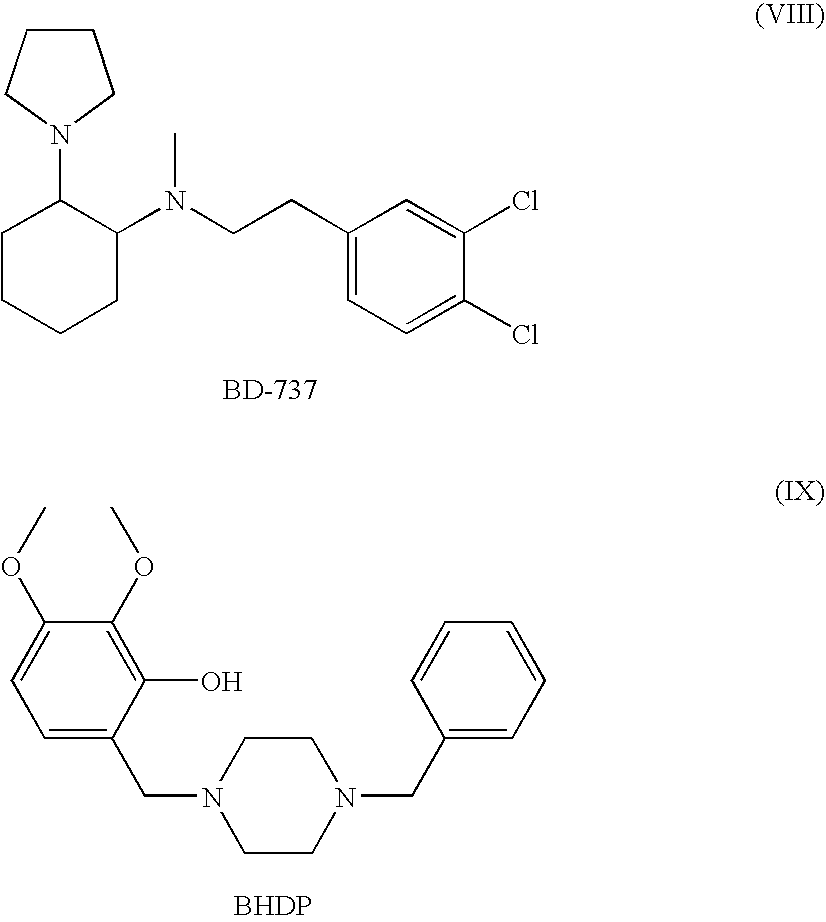

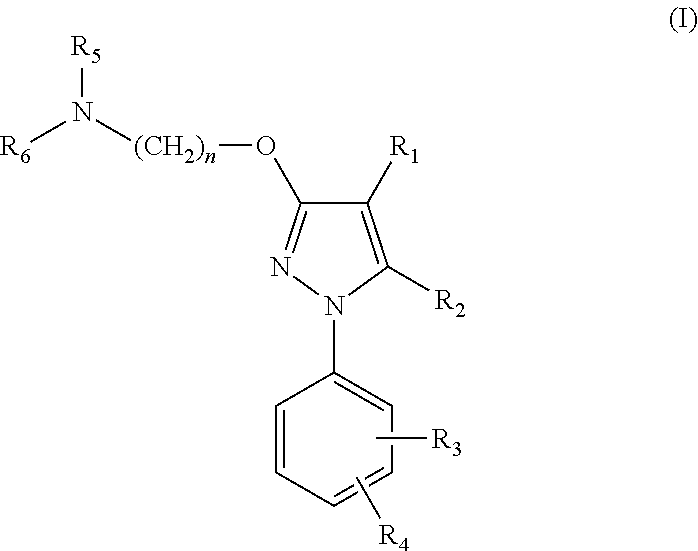

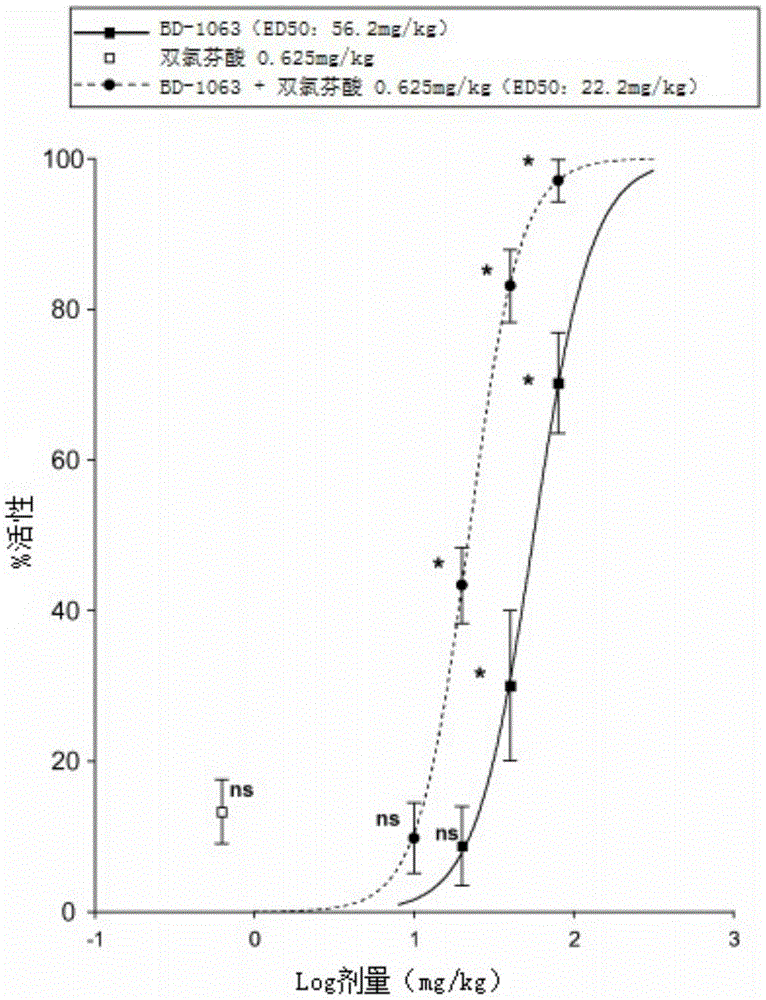

1-aryl-3-aminoalkoxy pyrazoles as sigma ligands enhancing analgesic effect of opioids and attenuating the dependency thereof

The invention relates to the use of a group of sigma receptor ligands of formula (I)for the potentiation of the analgesic effect of opioids and opiates and at the same time for decreasing the dependency induced by them.

Owner:LAB DEL DR ESTEVE SA

catalyst

InactiveUS20150329653A1Group 4/14 element organic compoundsOrganic compound preparationParticulatesSolid particle

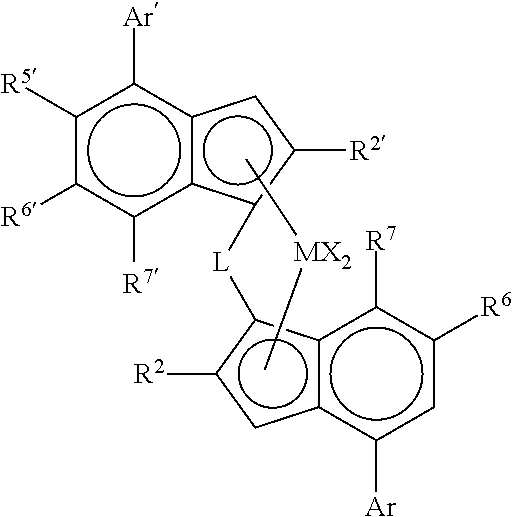

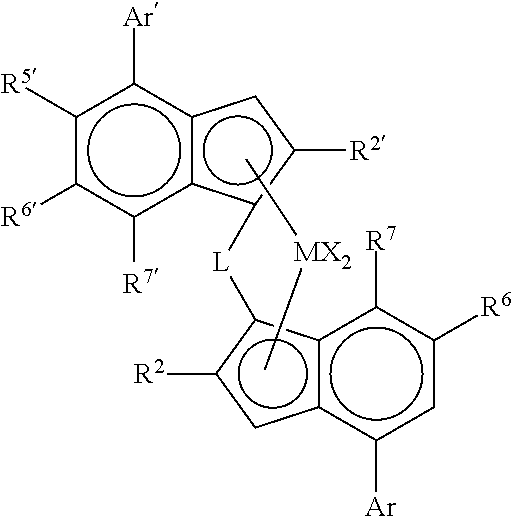

A catalyst in solid particulate form free from an external carrier material comprising(i) a complex of formula (I)whereinM is zirconium or hafnium;each X is a sigma ligand;L is a divalent bridge selected from —R′2C—, —R′2C—CR′2—, —R′2Si—, —R′2Si—SiR′2—, —R′2Ge—, wherein each R′ is independently a hydrogen atom, C1-20-alkyl, tri(C1-20-alkyl)silyl, C6-20-aryl, C7-20-arylalkyl or C7-20-alkylaryl;R2 is a C1-20-hydrocarbyl radical;R2′ is a C1-20-hydrocarbyl radical;R6 is a linear or branched aliphatic C1-20-hydrocarbyl group, SR9 or OR9;R6′ is a linear or branched aliphatic C1-20-hydrocarbyl group, SR9′ or OR9′;with the proviso that neither R6 or R6′ represents a group having a quaternary carbon atom directly attached to the indenyl ring;R9 is a C1-20-hydrocarbyl group;R9′ is a C1-20-hydrocarbyl group;Ar is a C6-12-aryl or C5-12-heteroaryl group optionally carrying one or more substituents R8;Ar′ is a C6-12-aryl or C5-12-heteroaryl group optionally carrying one or more substituents R8′;each R8 is a C1-20-hydrocarbyl group;each R8′ is a C1-20-hydrocarbyl group; andwherein at least two of R2 and R2′; R6 and R6′; or Ar and Ar′ are the same;and (ii) a cocatalyst comprising a compound of a group 13 metal, e.g. Al or boron.

Owner:BOREALIS AG

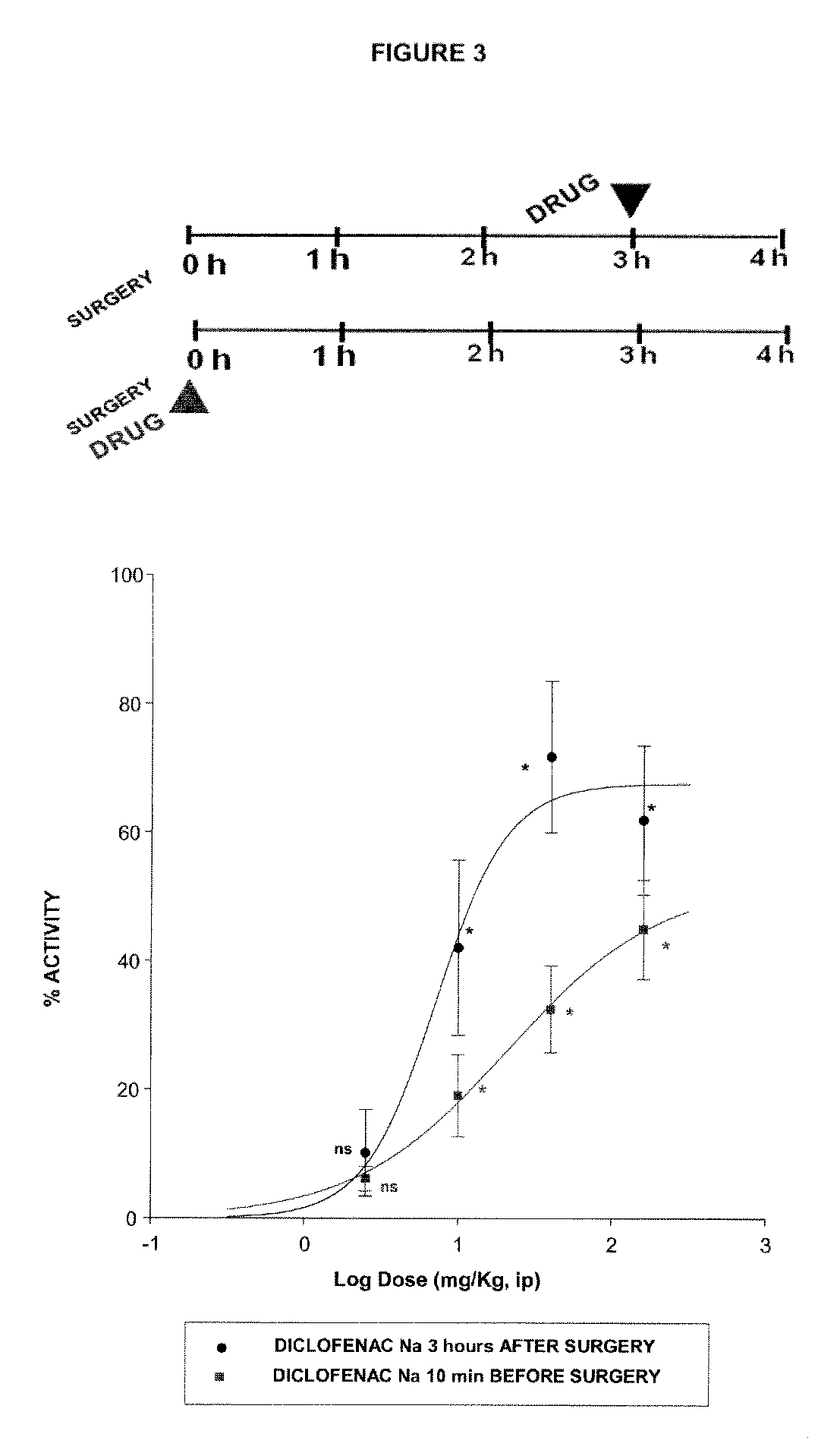

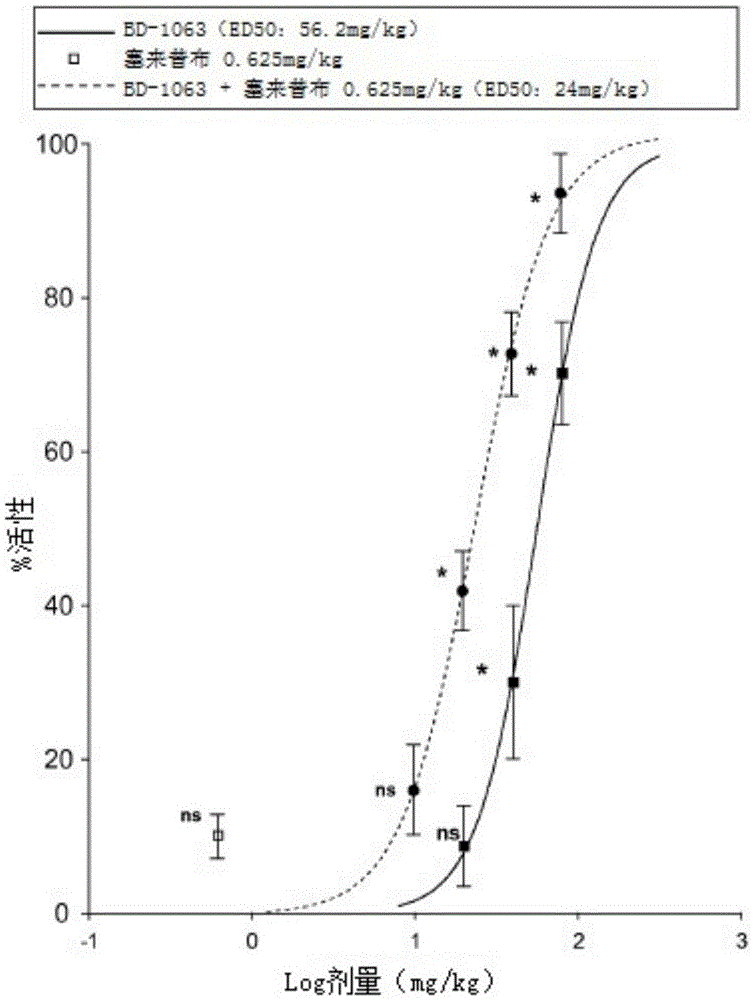

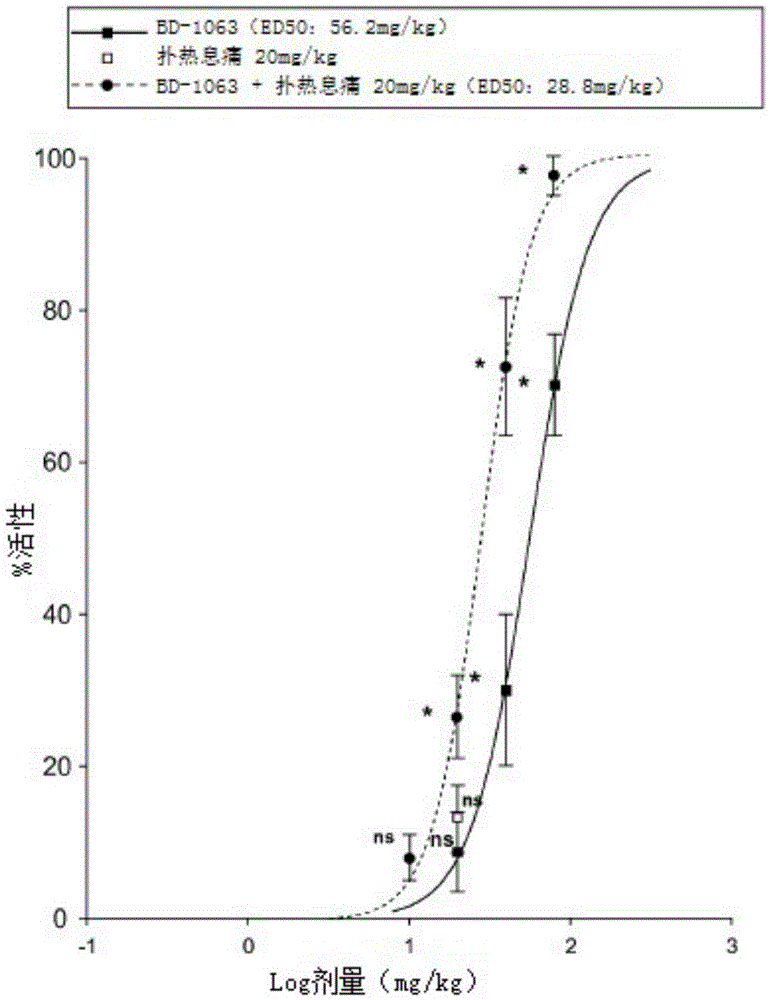

NSAID and sigma receptor ligand combinations

The invention refers to a synergistic combination comprising a sigma ligand, particularly a Sigma ligand of general formula (I), and NSAID compound, a medicament comprising said active substance combination, and the use of said active substance combination for the manufacture of a medicament, particularly for the prophylaxis and / or treatment of pain.

Owner:LAB DEL DR ESTEVE SA

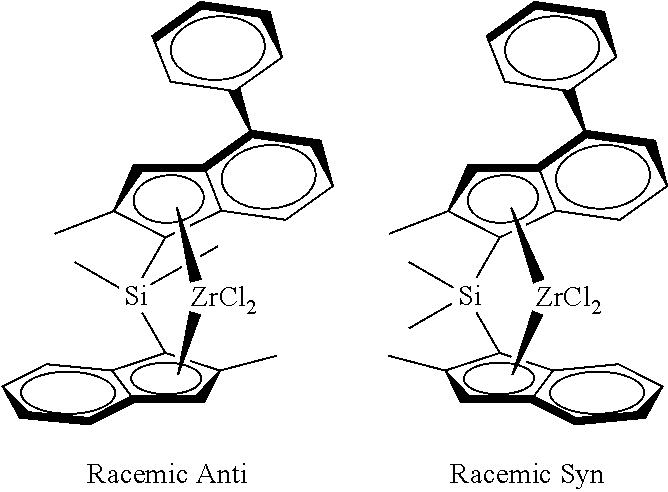

Catalysts

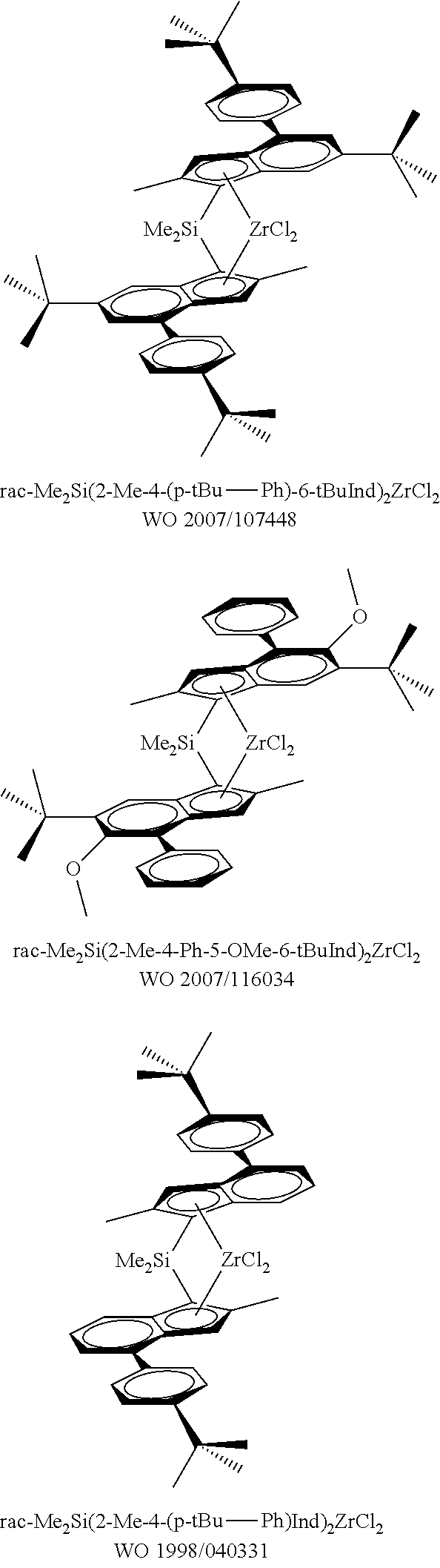

ActiveUS20140221584A1Increase productivityImprove performanceSilicon organic compoundsOrganic compound preparationArylPtru catalyst

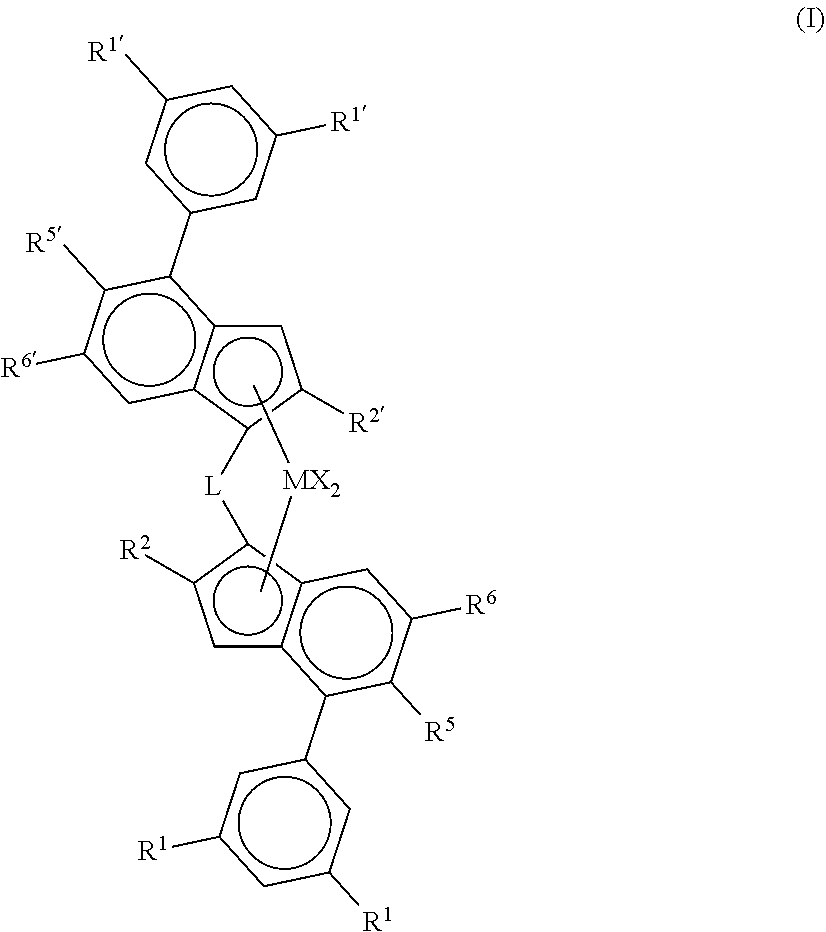

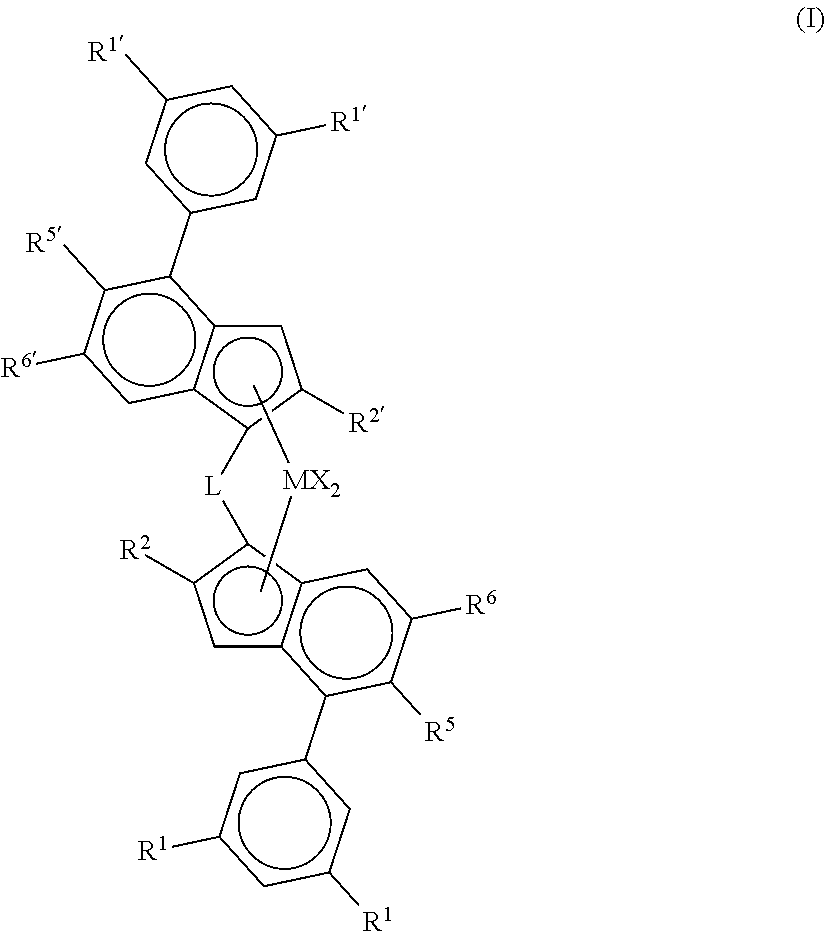

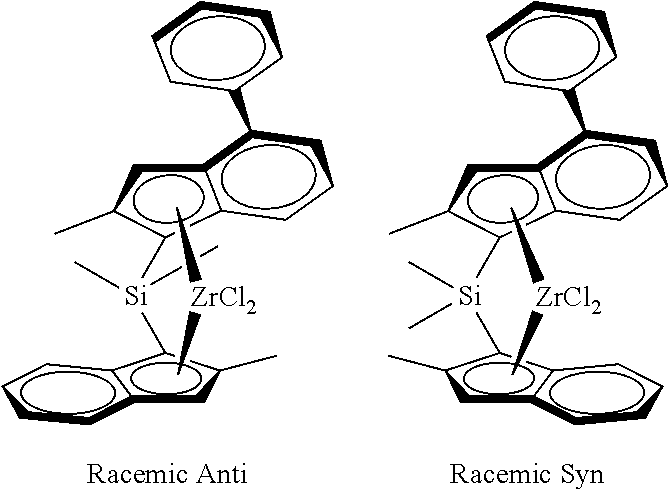

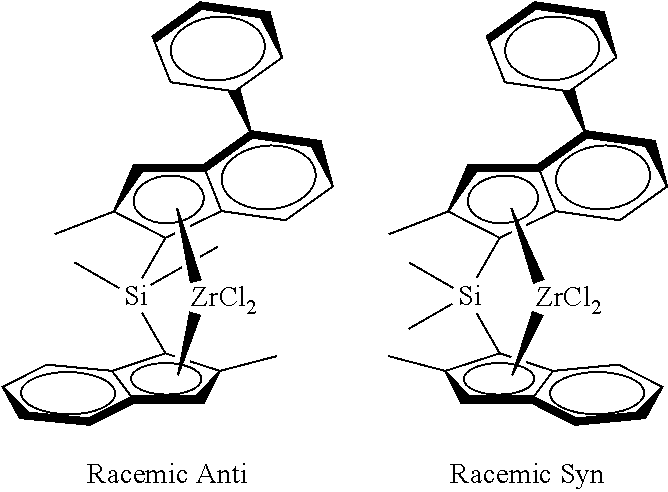

A racemic complex of formula (I), wherein M is zirconium or hafnium; each X is a sigma ligand; L is a divalent bridge selected from —R′2C—, —R′2C—CR′2, —R′2Si—, —R′2Si—SiR′2—, —R′2Ge—, wherein each R′ is independently a hydrogen atom, C1-20-hydrocarbyl, tri(C1-20-alkyl)silyl, C6-20-aryl, C7-20-arylalkyl or C7-20-alkylaryl; R2 and R2′ are each independently a C1-20 hydrocarbyl radical optionally containing one or more heteroatoms from groups 14-16; R5′ is a C1-20 hydrocarbyl group optionally containing one or more heteroatoms from groups 14-16 and optionally substituted by one or more halo atoms.

Owner:BOREALIS AG

Catalysts

ActiveUS20190308995A1Easy and cheapPromote polymerizationSilicon organic compoundsOrganic compound preparationHydrogen atomHydrogen

A complex of formula (I) wherein M is zirconium or hafnium; each X independently is a sigma ligand; L is a divalent bridge selected from —R′2C—, —R′2C—CR′2—, —R′2Si—, —R′2Si—SiR′2—, —R′2Ge—, wherein each R′ is independently a hydrogen atom or a C1-C20-hydrocarbyl group optionally containing one or more silicon atoms or heteroatoms of Group 14-16 of the periodic table or fluorine atoms, and optionally two R′ groups taken together can form a ring; R2 and R2′ are each independently a C1-C20 hydrocarbyl group, —OC1-hydrocarbyl group or —SC1-20 hydrocarbyl group; R5 is a —OC1-20 hydrocarbyl group or —SC1-20 hydrocarbyl group, said R5 group being optionally substituted by one or more halo groups; R5′ is hydrogen or a C1-20 hydrocarbyl group; —OC1-20 hydrocarbyl group or —SC1-20 hydrocarbyl group; said C1-20 hydrocarbyl group being optionally substituted by one or more halo groups; R6 and R6′ are each independently a C1-20 hydrocarbyl group; —C1-20 hydrocarbyl group or —SC1-20 hydrocarbyl group; each R1 and R1′ are independently —CH2Rx wherein Rx are each independently H, or a C1-20 hydrocarbyl group, optionally containing heteroatoms.

Owner:BOREALIS AG

Method for preparing metallocene compounds

A new process is disclosed, particularly simple, convenient and practical, for the direct synthesis of metallocenes of formula (I): (CP)(ZR1m)n(A)rMLpL'q wherein (ZR1m)n is a divalent group bridging Cp and A; Cp is a substituted or unsubstituted cyclopentadieryl group; A is -O-, -S-, -N(R2)-, wherein R2 is hydrogen, alkyl, cycloalkyl aryl, alkylaryl or arylalkyl, or A has the same meaning of Cp; M is a transition metal belonging to group 3, 4, 5, 6 or to the lanthanide or actinide groups; L is a monoanionic sigma ligand, such as alkyl, cycloalkyl, aryl, alkylaryl or arylalkyl, optionally containing Si or Ge; L' is halogen or -OR5, R5 being a hydrocarbon radical; m is 1 or 2; n is 0-4; r is 0 or 1; p is 1-3; q is 0-2. Said process comprises reacting the ligand (Y-Cp)(ZR1m)n(A-Y)r, wherein Y is a suitable leaving group, with at least 1 molar equivalent of ML's in the presence of at least (1+r+p) molar equivalents of LjB or LMgL', wherein B is an alkaline or alkaline-earth metal, s ranges from 3 to 6, and j is 1 or 2.

Owner:MONTELL TECH CO BV

catalyst

ActiveUS20150344595A1Group 4/14 element organic compoundsOrganic compound preparationArylPtru catalyst

A catalyst in solid particulate form free from an external carrier material comprising(I) a complex of formula (I)whereinM is zirconium or hafnium;each X is a sigma ligand;L is a divalent bridge selected from —R′2C—, —R′2C—CR′2—, —R′2Si—, —R′2Si—SiR′2—, —R′2Ge—, wherein each R′ is independently a hydrogen atom, C1-C20-alkyl, tri(C1-C20-alkyl)silyl, C6-C20-aryl, C7-C20-arylalkyl or C7-C20-alkylaryl;each R2 is independently hydrogen or a C1-C20 hydrocarbyl radical provided that at least one R2 is not hydrogen;each R5 is independently hydrogen or a C1-20 hydrocarbyl group optionally containing one or more heteroatoms from groups 14-16;each R6 is independently hydrogen or a C1-20 hydrocarbyl group optionally containing one or more heteroatoms from groups 14-16;each n is independently 1, 2 or 3; andeach R8 is a C1-20 hydrocarbyl group;and (ii) a cocatalyst comprising a compound of a group 13 metal, e.g. Al or boron.

Owner:BOREALIS AG

Process for the preparation of a solid metallocene catalyst system and its use in polymerisation of olefins

InactiveCN102884090ASimplified curing stepsOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsAluminoxaneHafnium

Owner:北欧化工公司

Catalyst system for producing polyethylene copolymers in a high temperature solution polymerization process

Owner:BOREALIS AG

Catalyst system for producing polyethylene copolymers in a high temperature solution polymerization process

InactiveUS10301411B2Improve stabilityIncreased comonomer incorporationSilicon organic compoundsCatalystsAluminum alkylBoron containing

Catalyst system for producing ethylene copolymers in a high temperature solution process, the catalyst system comprising (i) a metallocene complex of formula (I) wherein M is Hf X is a sigma ligand, L is a bridge of the formula —SiR82—, wherein each R8 is independently a C1-C20-hydrocarbyl, tri(C1-C20-alkyl)silyl, C6-C20-aryl, C7-C20-arylalkyl or C7-C20-alkylaryl n is 0, 1 or 2 R1 and R1′ are the same or can be different and can be a linear or branched C1-C6-alkyl group, R2 and R2′ are the same or are different and are a CH2—R9 group, with R9 being H or linear or branched C1-C6-alkyl group R5 and R5′ are the same or are different and can be H or a linear or branched C1-C6-alkyl group or a OR group, wherein R is a C1-C6-alkyl group R6 and R6′ are the same or are different and can be H or a C(R10)3 group, with R10 being the same or different and R10 can be H or a linear or branched C1-C6-alkyl group or R5 and R6 and / or R5′ and R6′ taken together form an unsubstituted 4-7 membered ring condensed to the benzene ring of the indenyl moiety, and R7 and R7′ can be the same or are different and can be H or a linear or branched C1-C6-alkyl group (ii) an aluminoxane cocatalyst and / or (iii) a boron containing cocatalyst and (iv) optionally an aluminum alkyl compound.

Owner:BOREALIS AG

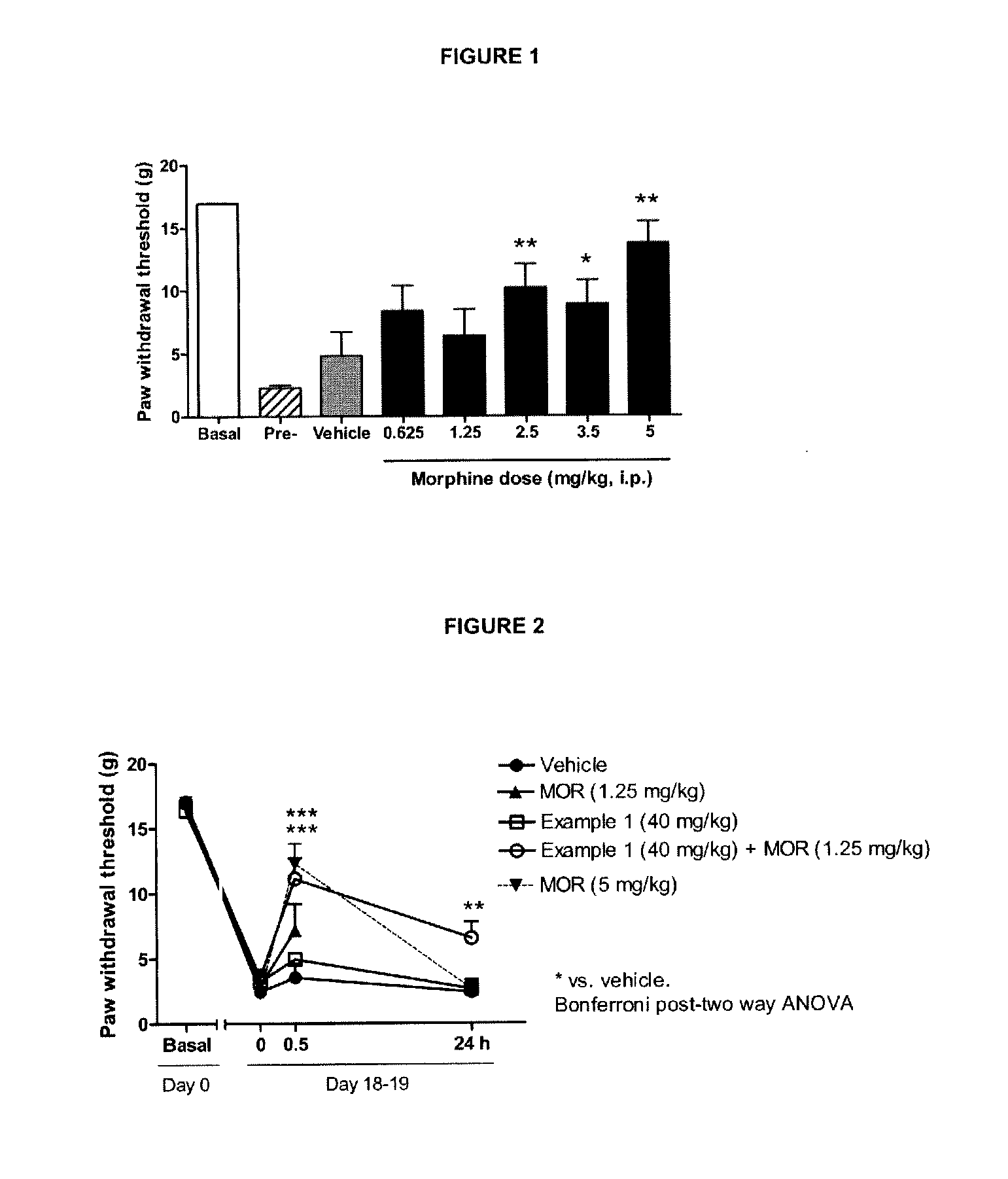

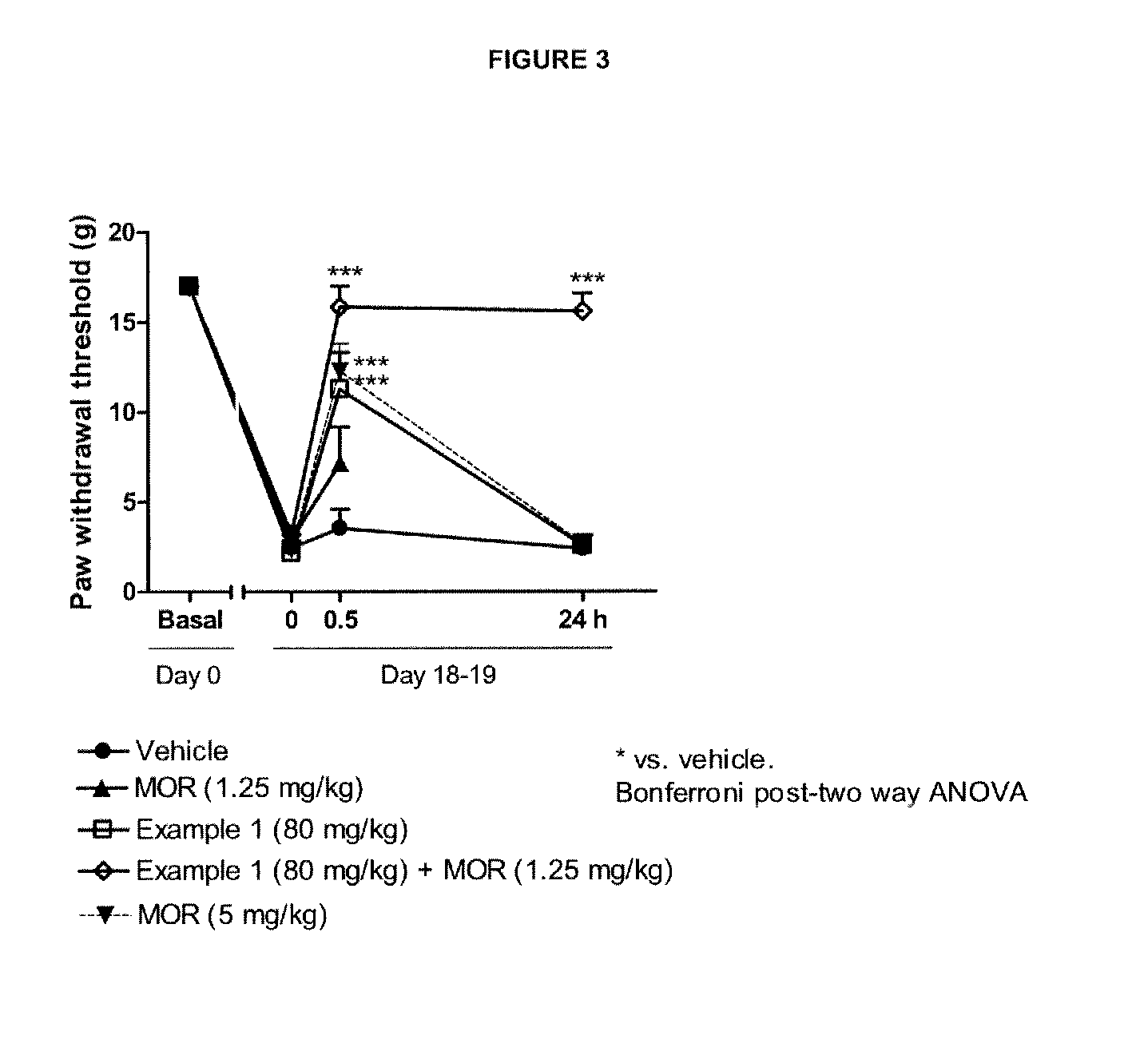

Sigma ligands for potentiating the analgesic effect of opioids and opiates in post-operative pain and attenuating the dependency thereof

The invention refers to a combination comprising a sigma ligand of formula (I) and an opioid or opiate for use in the prevention and / or treatment of pain developed as a consequence of surgery, especially peripheral neuropathic pain, allodynia, causalgia, hyperalgesia, hyperesthesia, hyperpathia, neuralgia, neuritis or neuropathy. The invention also refers to the sigma ligands of formula (I) for use in potentiating the analgesic effect of an opioid or opiate and / or for decreasing the dependency induced thereby when said opioid or opiate is used in the prevention and / or treatment of pain developed as a consequence of surgery.

Owner:LAB DEL DR ESTEVE SA

Sigma ligands for neuronal regeneration and functional recovery

InactiveCN1802168AOrganic active ingredientsPeptide/protein ingredientsHuntingtons choreaRisk stroke

The invention discloses methods and compositions useful for facilitating neuronal regeneration and functional recovery in neurodegenerative diseases. The methods and compositions utilize ligands for the sigma receptor, wherein the ligand is preferably SA-4503, or salts, or solvates thereof These molecules can be delivered alone or in combination with agents which treat or prevent neurodegenerative diseases such as those caused by ischemic stroke, diabetic peripheral neuropathy, cancer therapy induced neuropathy, multiple sclerosis, amyotrophic lateral sclerosis, traumatic brain injury, spinal cord injury, Huntington's disease or Parkinson's disease. In other methods, the sigma receptor ligands are administered after stroke to facilitate functional recovery. The administration of the sigma receptor ligands effects faster functional recovery.

Owner:MS SCI CORP

New catalyst system for producing polyethylene copolymers in a high temperature solution polymerization process

Catalyst system for producing ethylene copolymers in a high temperature solution process, the catalyst system comprising (i) a metallocene complex of formula (I), M is Hf or a mixture with Zr, provided that more than 50% by moles of the complex of Formula I has M=Hf, X is a sigma ligand, R are the same or different from each other and can be saturated linear or branched C1-C10 alkyl, C5-C10 aryl, C6-C20 alkylaryl or C6-C20 arylalkyl groups, which can optionally contain up to 2 heteroatoms or silicon atoms, R1 is a C6-C20-aryl, which can be unsubstituted or substituted by one or up to 5 linear or branched C1-C10 alkyl group(s), R2 is a saturated linear or cyclic C3-C20 alkyl group or a branched CR3R4R5 group, wherein R3 is hydrogen or an C1-C20 alkyl group and R4 and R5 are the same or are different and can be an C1-C20 alkyl group and (ii) a boron containing cocatalyst

Owner:BOREALIS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com