Low cost burner

a burner and low-cost technology, applied in the field of low-cost burners, can solve the problems of difficult conception and implementation, and difficulty in achieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Definitions

[0027]The use of the term “approximately” provides an additional determined range. The term is defined in the following manner: the additional range set by the term is approximately ±10%. By way of example, but not in a limitative way, if the term reads “approximately 8 cm”, the exact range lies within 7.2 to 8.8 millimeters.

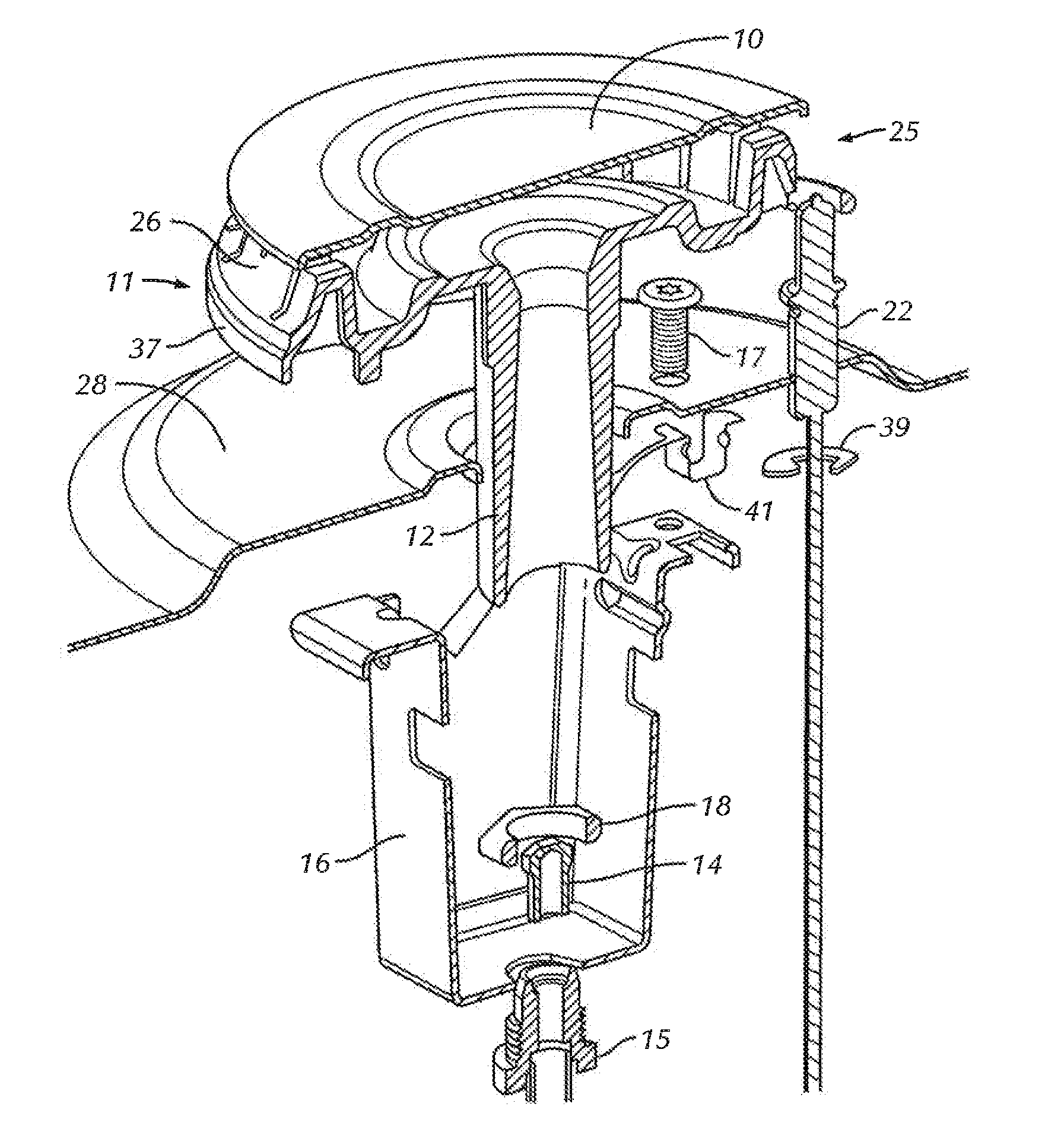

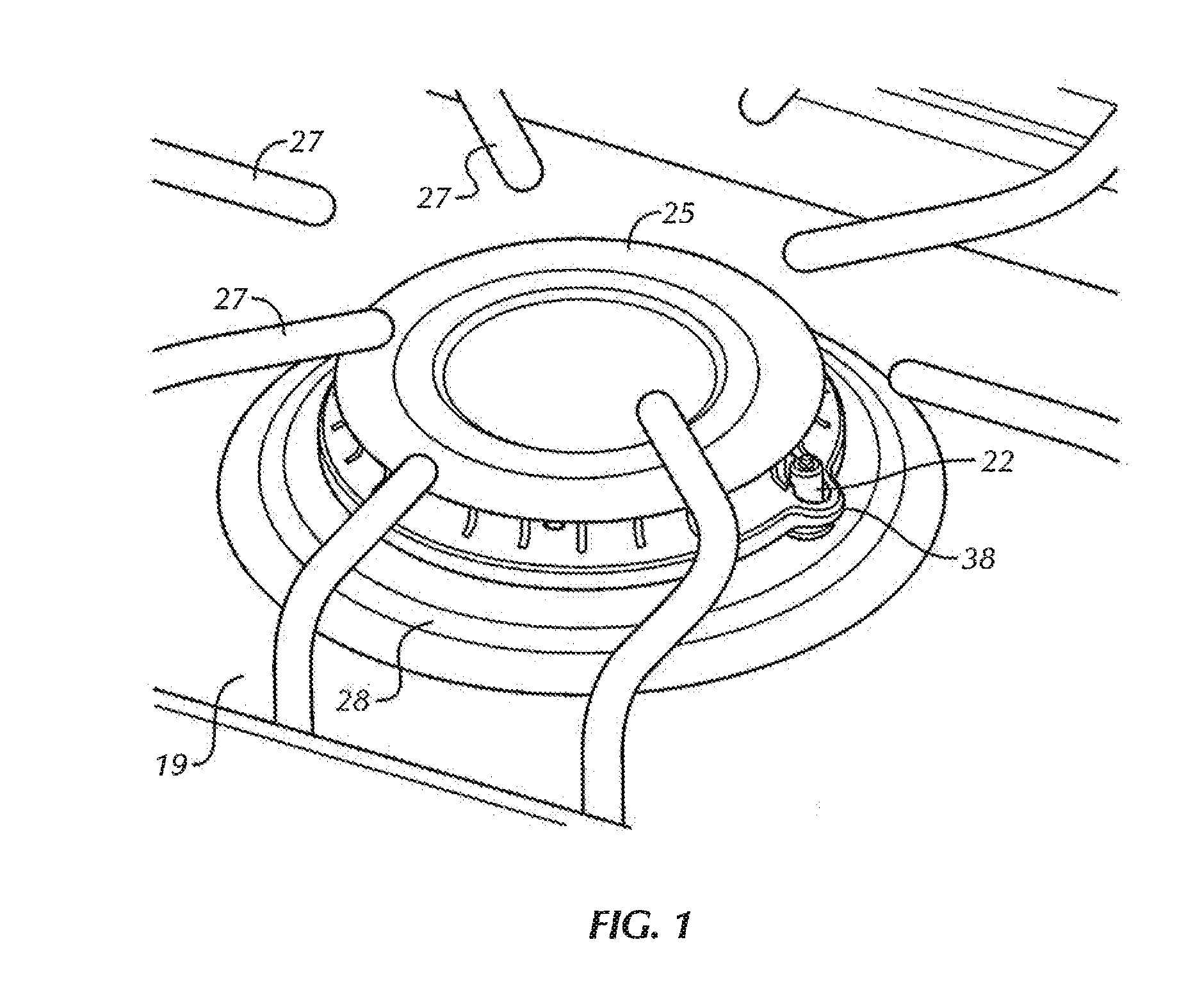

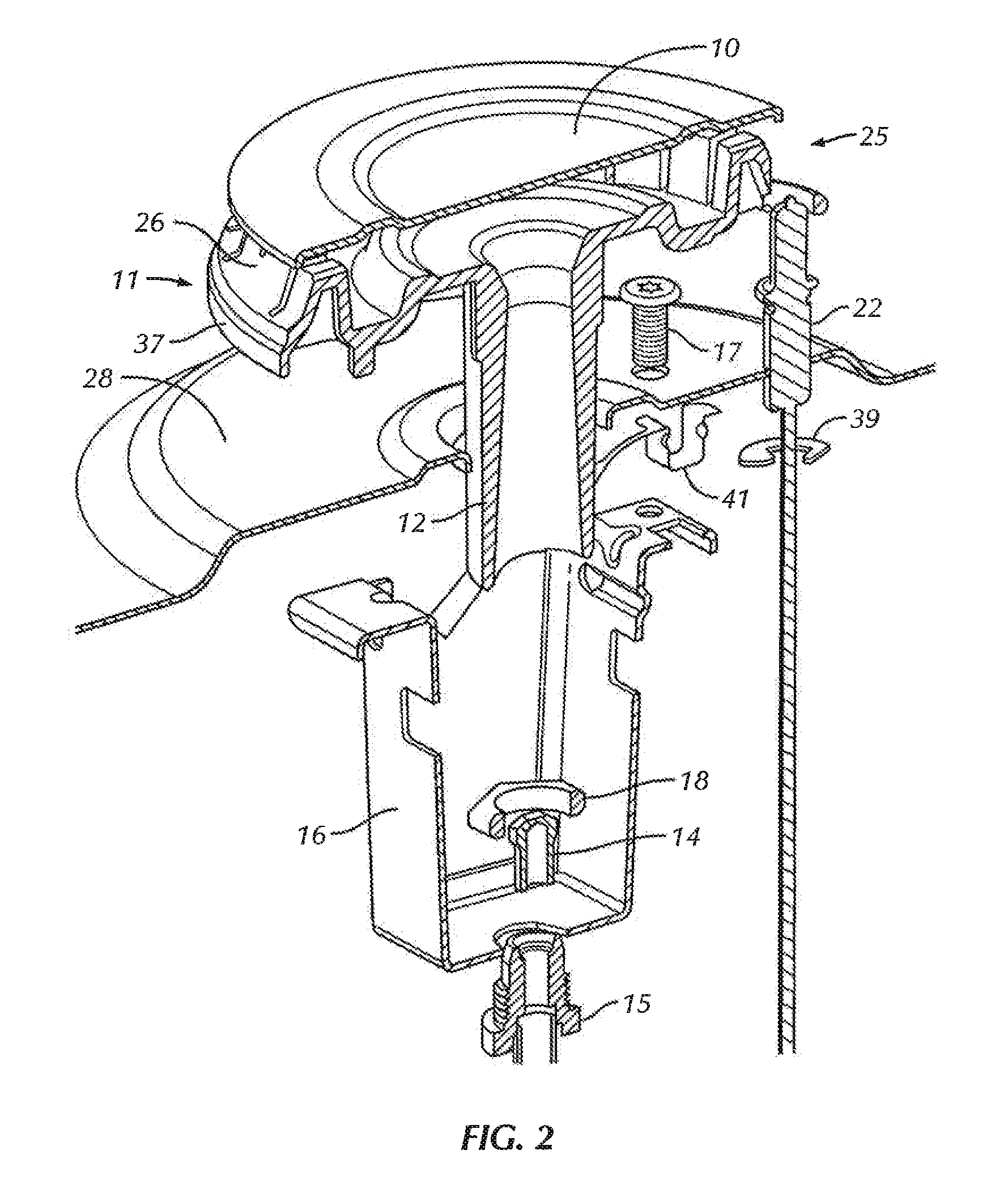

[0028]FIG. 1 illustrates the burner 25 object of present invention, set over a surface or cover 19, the referred to cover 19 preferably comprises a volcano 28 which is understood as a truncated cone protuberance in a volcano manner over which the burner 25 is placed, in an alternative embodiment of present invention, the cover 19 can be completely smooth, or lacking volcanoes; given this the burner 25 is placed flush in regards to the cover 19; in another alternative embodiment the cover 19 can have crammed recesses in truncated conical shape which can house the burner 25. In either case, over the burner assembly 25 (with or without volcano 28) a gril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com