Method for regenerating an Otto particulate filter of a combustion engine of a vehicle

A combustion engine and particle filter technology, applied in the direction of combustion engine, internal combustion piston engine, engine components, etc., can solve the problems of increased material consumption, poor operation mode, low efficiency, etc., and achieve the effect of reducing regeneration time and improving regeneration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

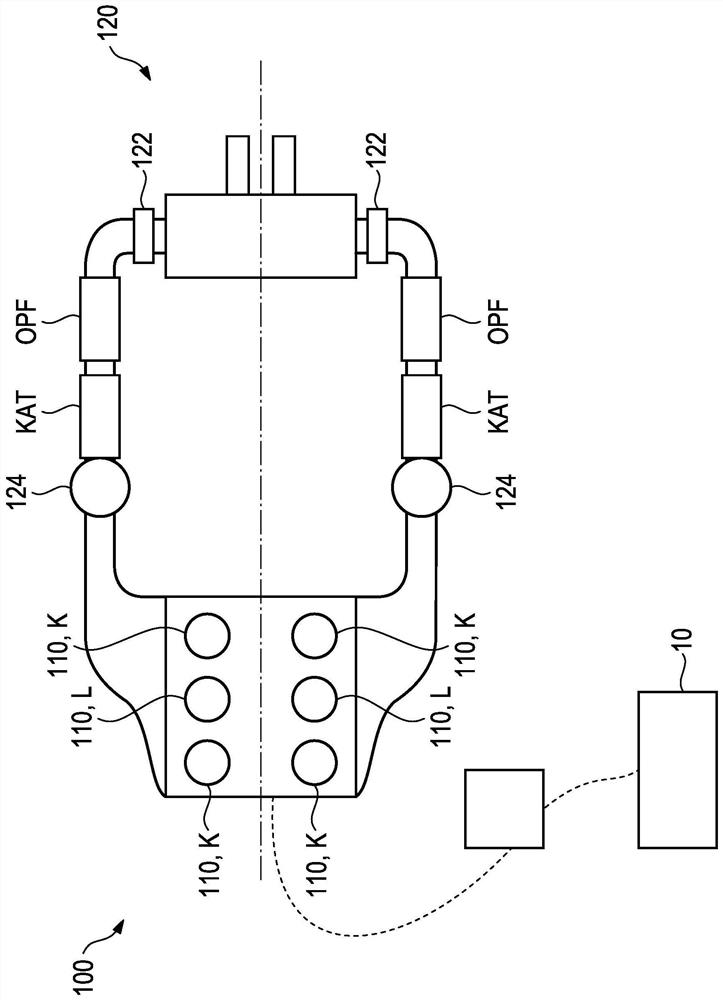

[0042] exist figure 1 A combustion engine 100 with six cylinders 110 is shown schematically in FIG. Separate branches of the exhaust system 120 are provided for each of three of the cylinders 110 of the combustion engine 100 . In order to be able to ensure aftertreatment of the exhaust gas of the individual cylinders 110 , a catalytic converter KAT and an Otto particle filter OPF are provided in the exhaust system 120 for each exhaust branch.

[0043] Now, regeneration of the Otto particulate filter OPF is performed as follows. In a first step, the load level of the Otto particulate filter OPF and especially the correlation when exceeding the regeneration threshold can be identified. Therefore, if regeneration has to be performed due to excessive load levels of the Otto particulate filter OPF, the vehicle is advantageously at a standstill, in particular on a vehicle stand in a workshop.

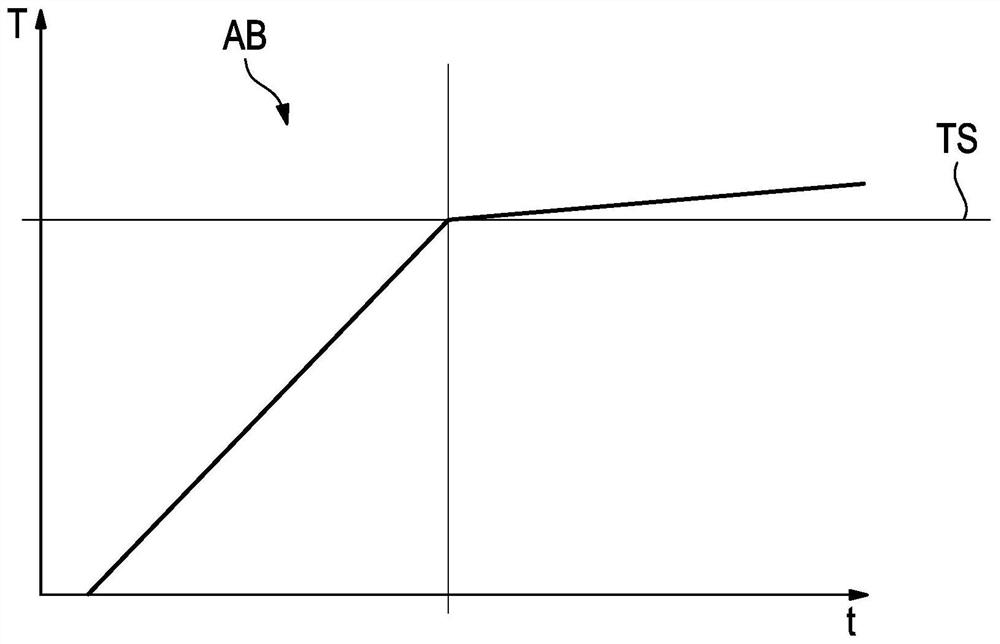

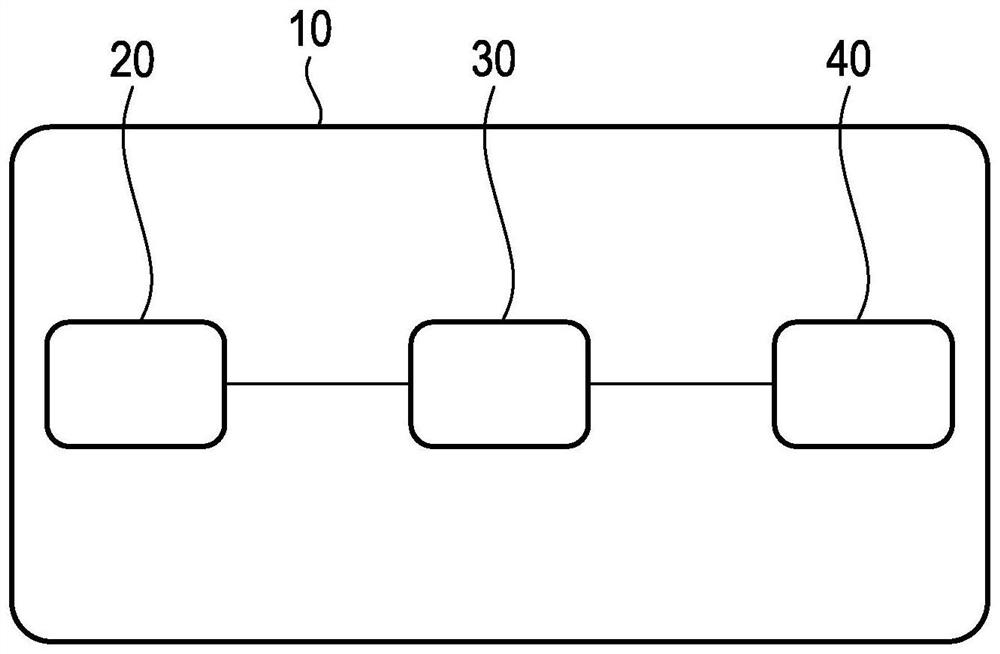

[0044] Now, by means of the control device 10 (such as its image 3 shown schematical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com