Bullet or Projectile With Spiral Grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

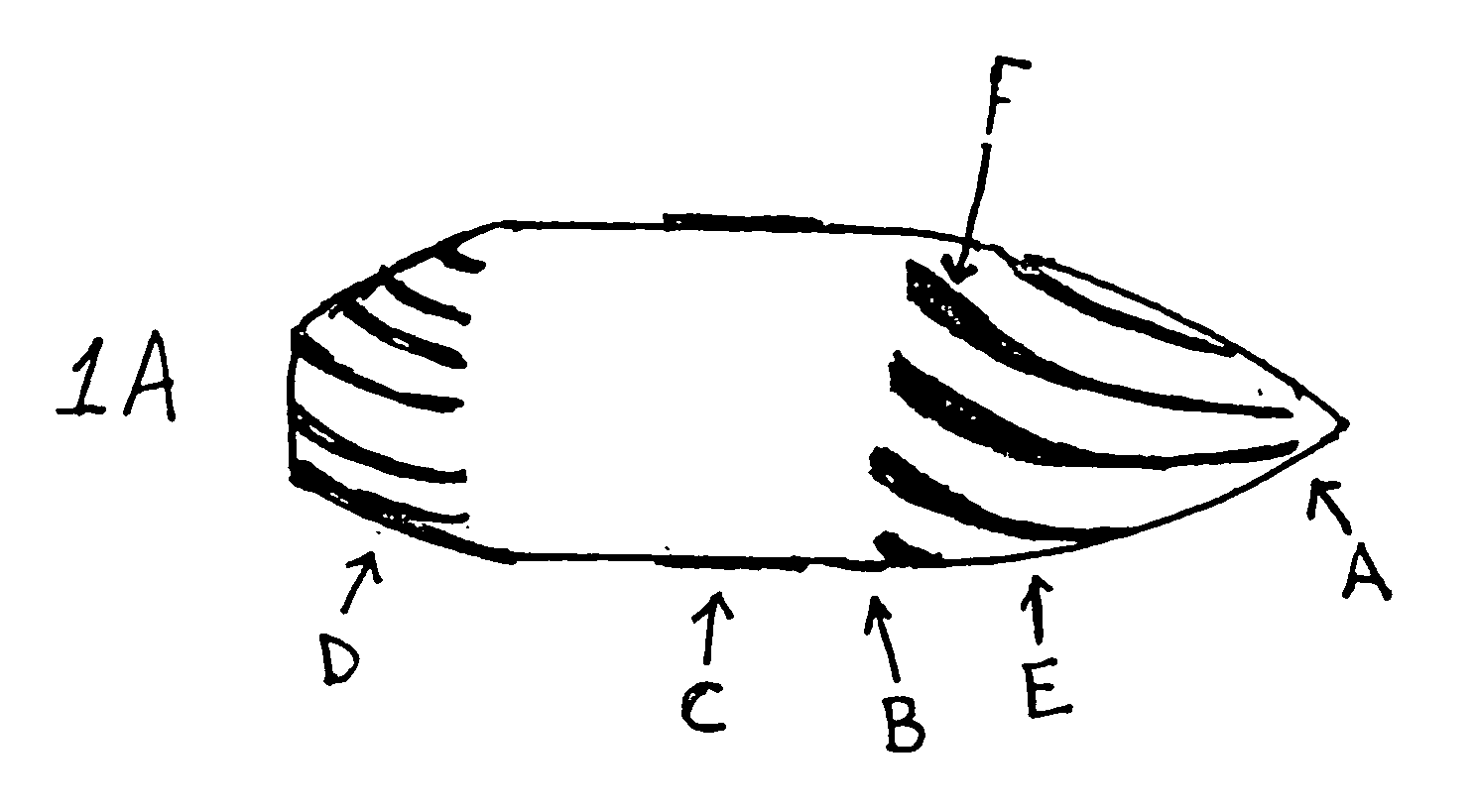

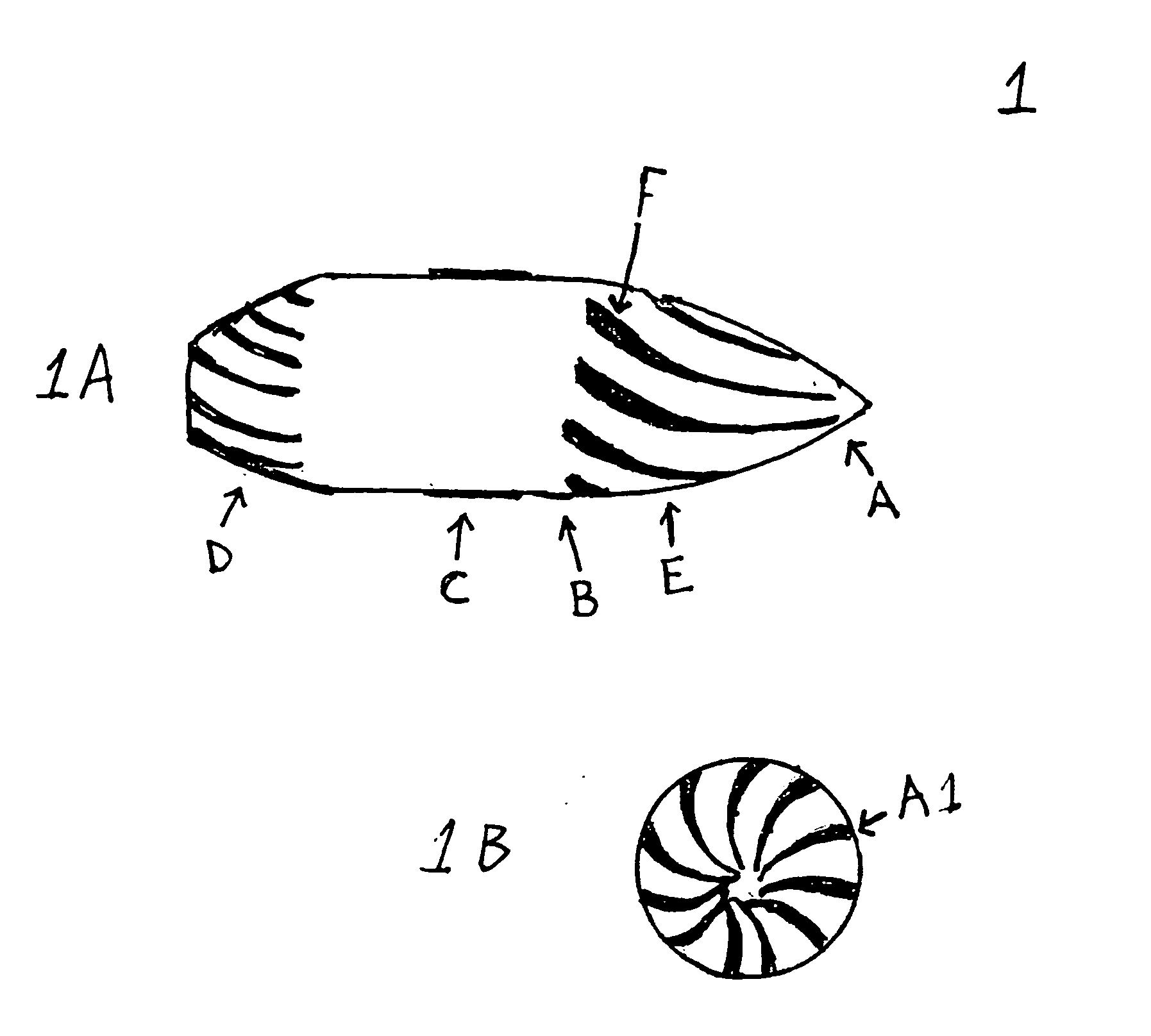

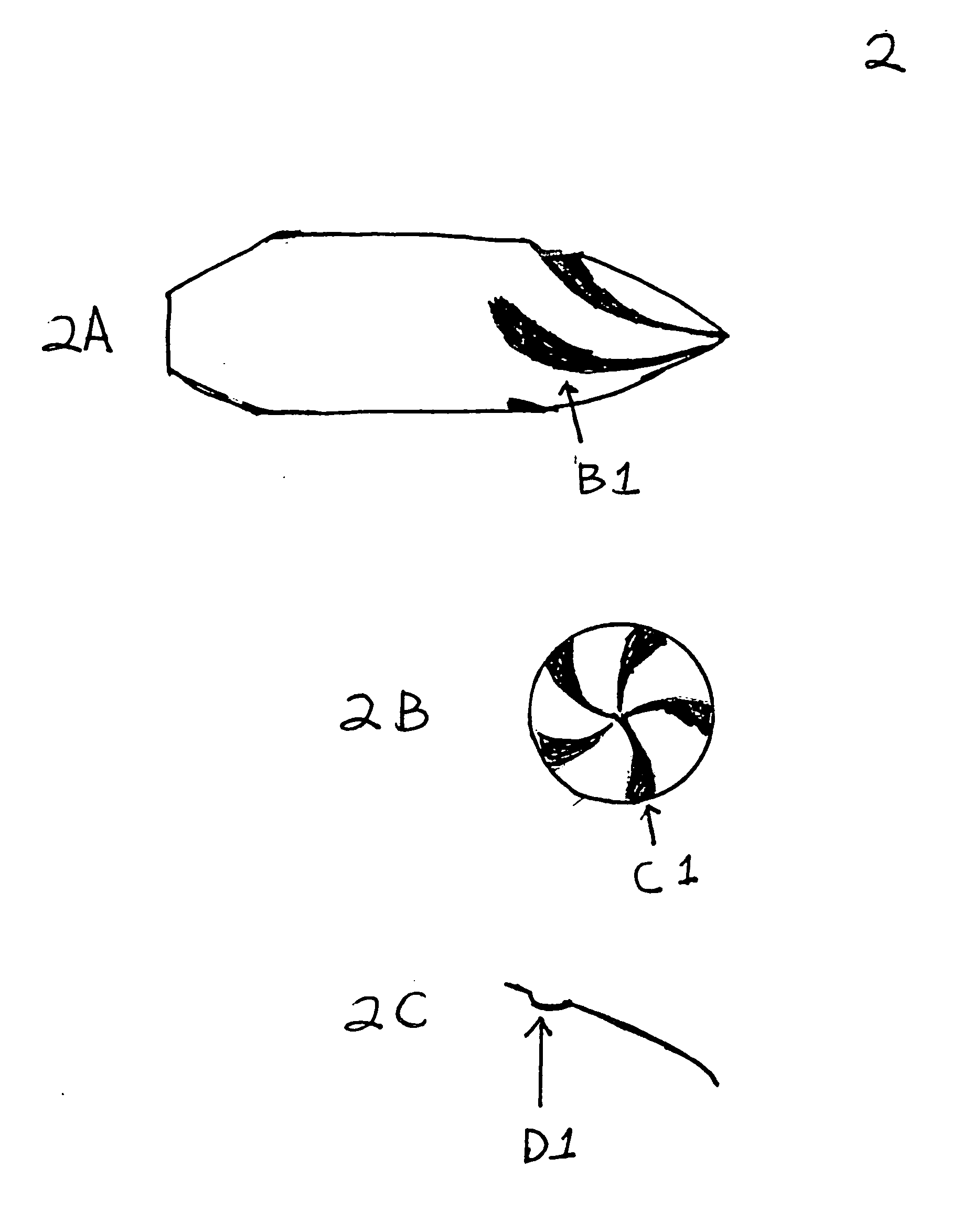

[0015]A bullet is generally designed with a nose A, ogive E, bore rider B, driving band C and boat tail D, but some designs may not include all of the features or may include additional features. The groove depth, width, and angle can vary depending on the bullet caliber, load, and desired performance. The groove depth and width may also very along the surface of the bullet. For example, the start of the ogive at the nose may have a very minimal groove depth, but as the spiral groove moves along the ogive the groove could get deeper, wider and the angle of the groove could change.

[0016]The grooves could be machined efficiently in an existing bullet with a CNC milling machine or a CNC lathe while utilizing the appropriate tooling to cut the groove. The bullets could also be cast in a mold which contains the grooves, so upon ejection from the mold the bullet is a finished product. The grooves could also be imparted during the forming process of a FMJ bullet or in a injection molding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com